Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2525results about How to "Achieving tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

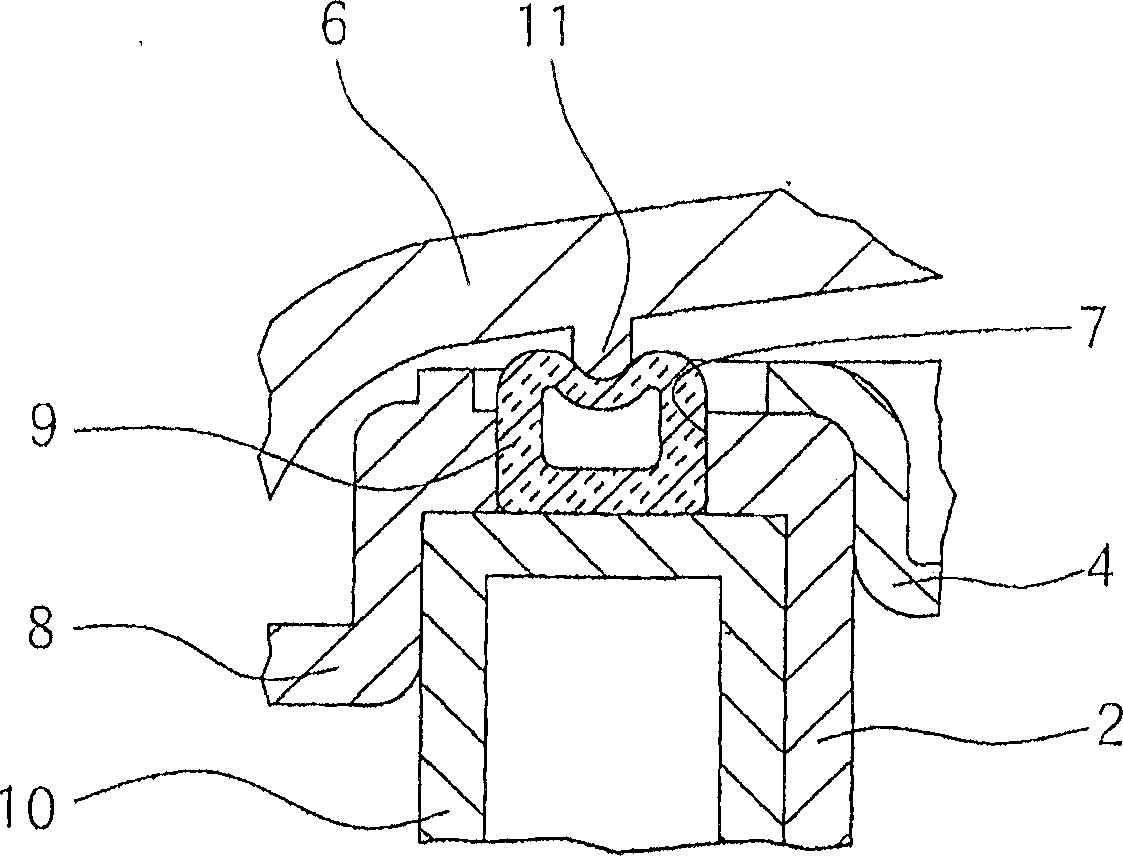

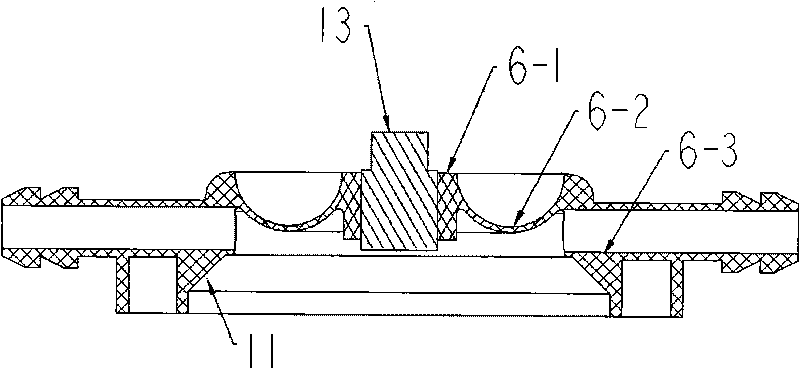

Tank-type general purpose type radial seal ring for puncture outfit and puncture outfit

InactiveCN101480354AReduce thicknessLow movement resistanceCannulasSurgical needlesSurgical ManipulationGeneral purpose

The invention relates to a common groove radical gasket for a puncture outfit and the puncture outfit. Because the radial gasket is provided with a lithe groove, supporting zones with guide function and a through hole, the supporting zones are connected by the lithe groove, the thickness of the lithe groove is far less than the average thickness of the supporting zones, when a surgical instrument is inserted along tapered guide grooves of the supporting zones, the lithe groove is firstly distorted for holding the surgical instrument so as to achieve the sealing effect because the wall is very thin. When the surgical instrument is shaken, the supporting zones divided by the lithe groove are shaken together, and a sealing ring formed by the lithe groove always holds the surgical instrument to keep the sealing state always, thereby the best dynamic sealing effect is achieved. Especially, the lithe groove is thin, the dynamic sealing effect is good, and the kinetic resistance of the surgical instrument is little. The puncture outfit realizes the free replacement among surgical instruments with 12 mm, 10 mm, and 5 mm in diameter and is convenient for operation.

Owner:周星 +1

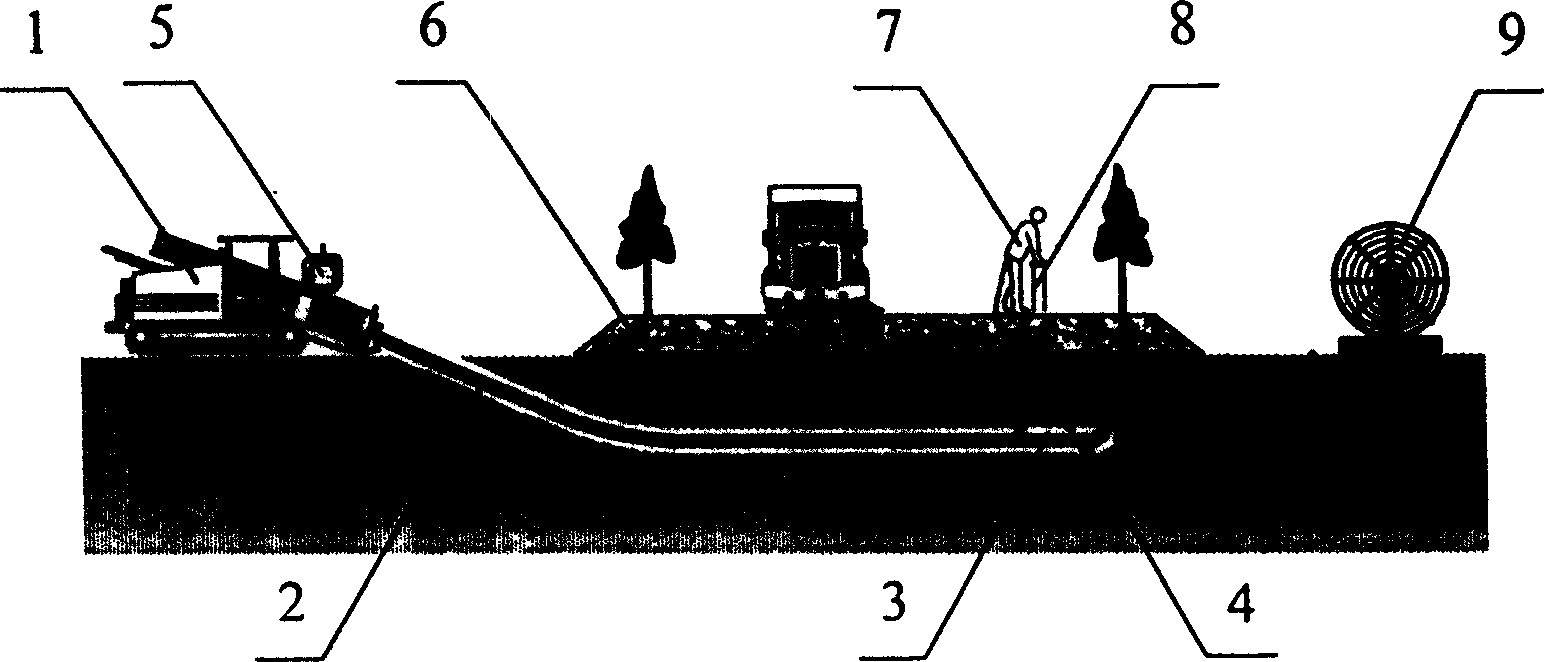

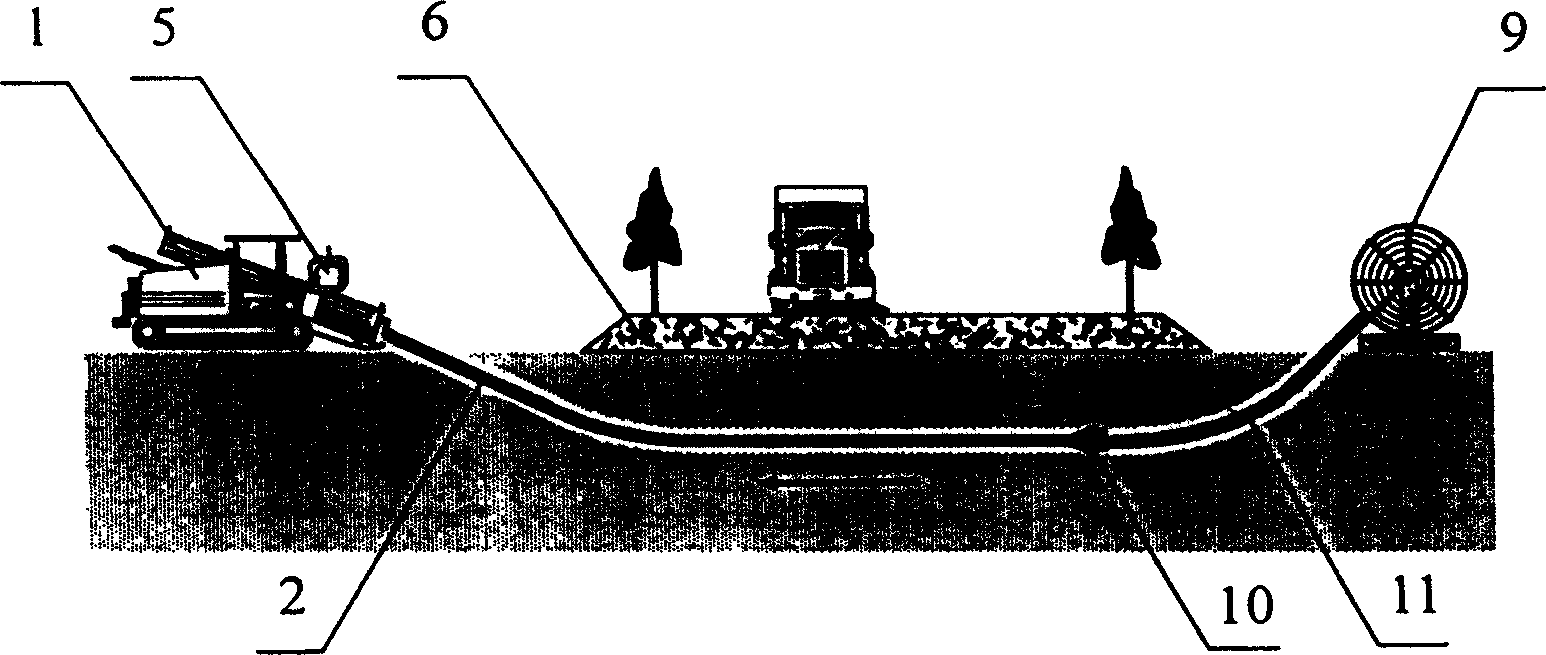

Real time measuring method and apparatus for horizontal directional drilling

InactiveCN1603576AReduce volumeAchieve modularitySurveyDirectional drillingMeasurement deviceUnit operation

One kind of horizontal direction detection sneaks in along with drills the measuring technique and the equipment, uses in the horizontal direction detection sneaks in when the fact to survey underground drilling tool inclining, parameter and so on rotation and temperature, and the measurement result will transmit the ground through the transmitting coil by the radio magnetic wave way. The method use underground drilling tool interior along with drills in the metering equipment the inclination angle, the appearance angle and the temperature sensor surveys the corresponding parameter, after signal processing and transmission unit operation, use wireless launch unit to ground receiver real-time transmission. Its metering equipment has two sections of metals shells and center the compartment insulation shell seal becomes. In an end shell is loaded with the power source; The wireless radiating element installs in the insulator shell; Is loaded with electric circuit of board the signal processing and the transfer element, the inclination angle sensor, the appearance angle sensor and the temperature sensor sets in another end shell. The invention volume small, structure simple, cost inexpensive, the antijamming ability is strong, works reliably under the adverse circumstance, can suit the majority direction detection to sneak in the equipment request.

Owner:ZOOMLION HEAVY IND CO LTD

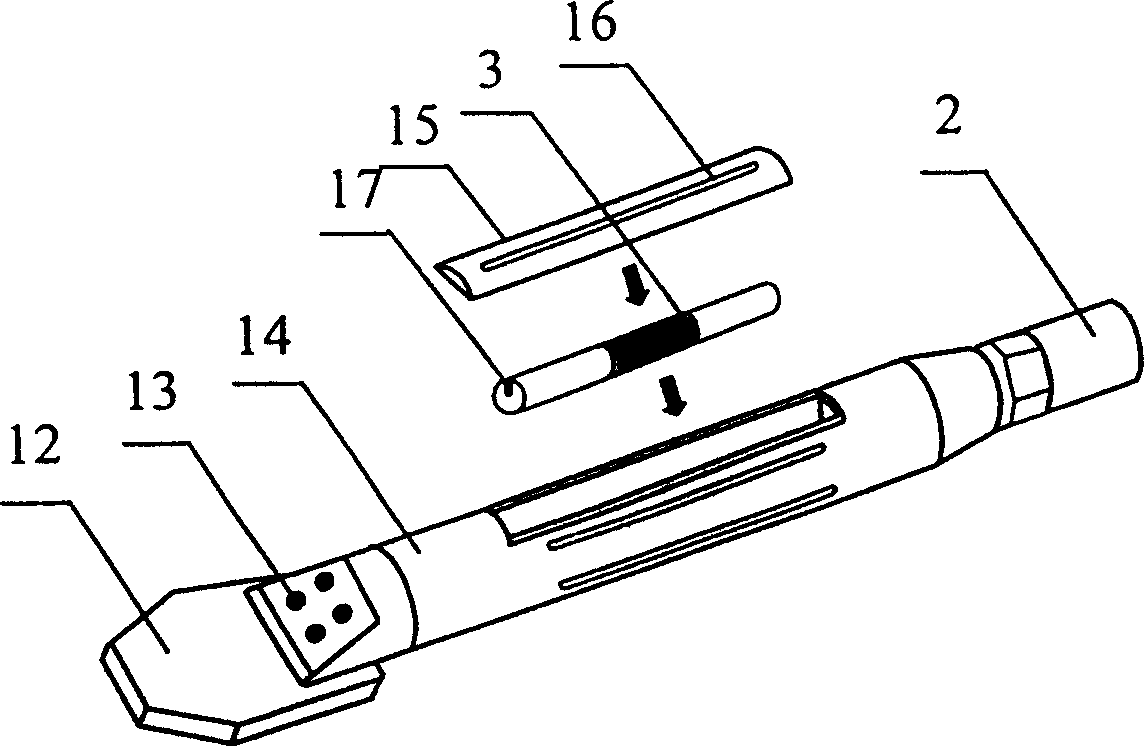

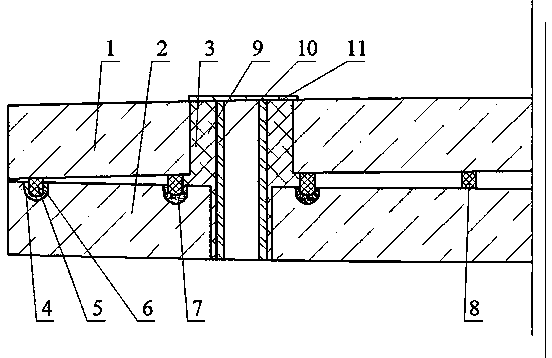

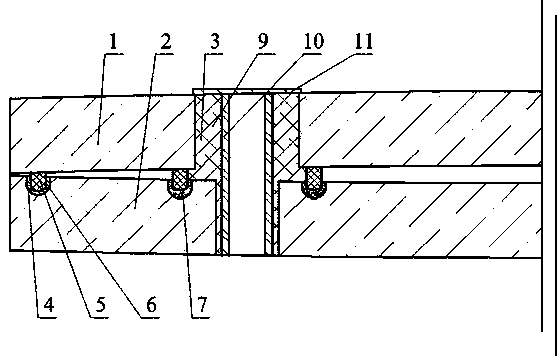

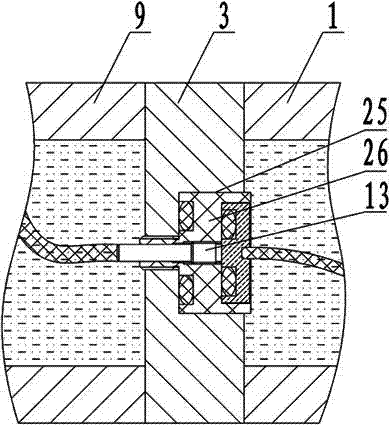

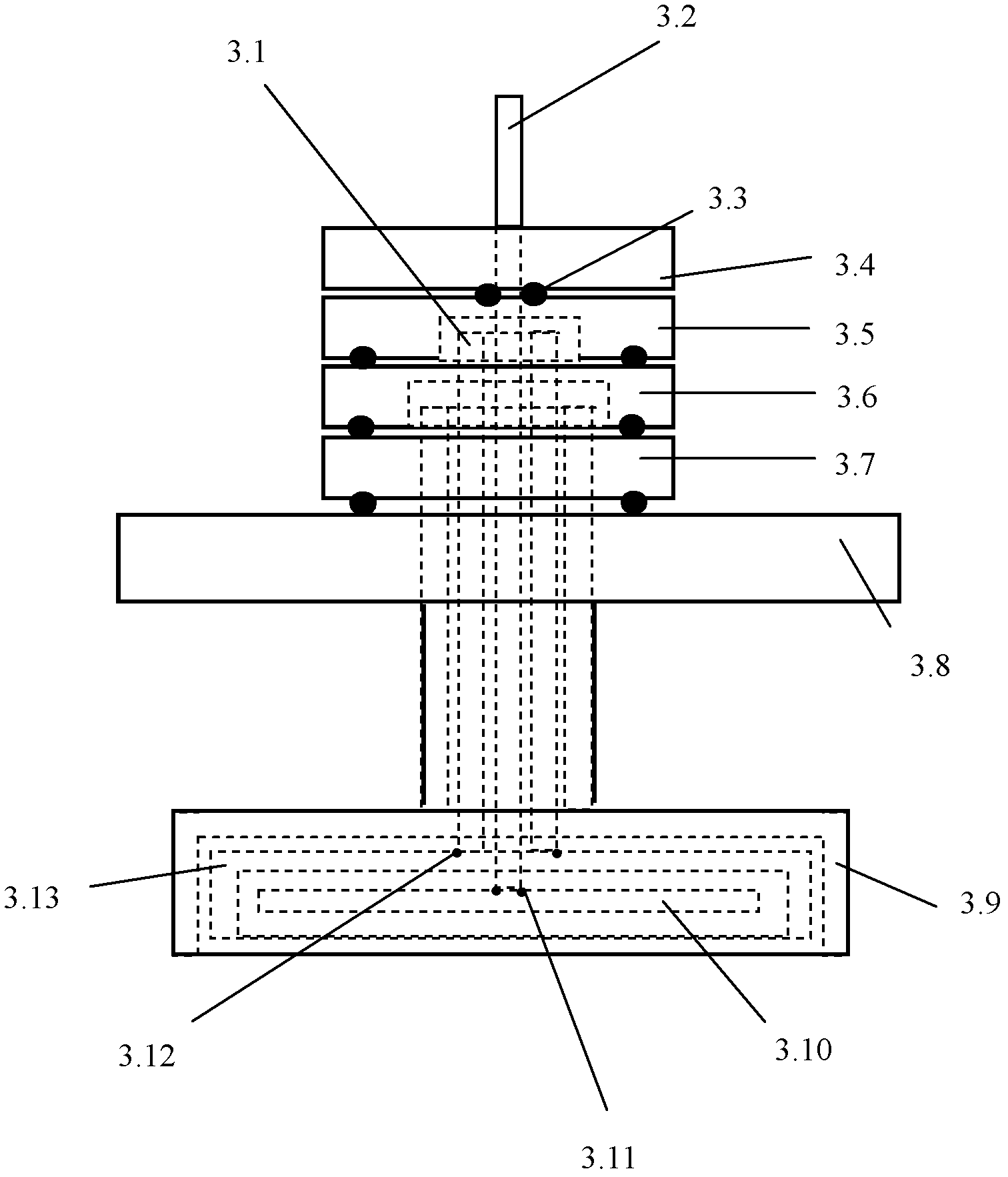

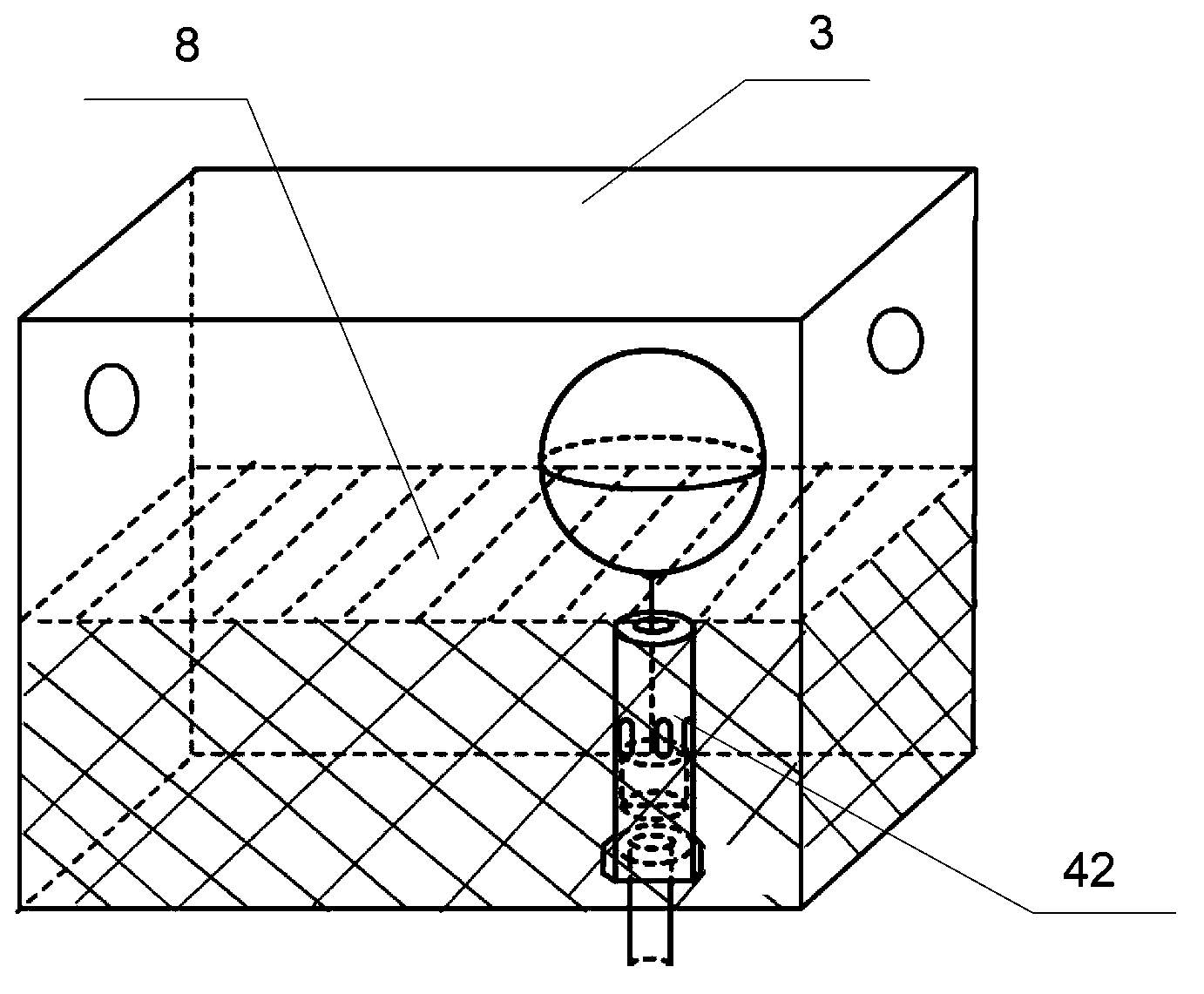

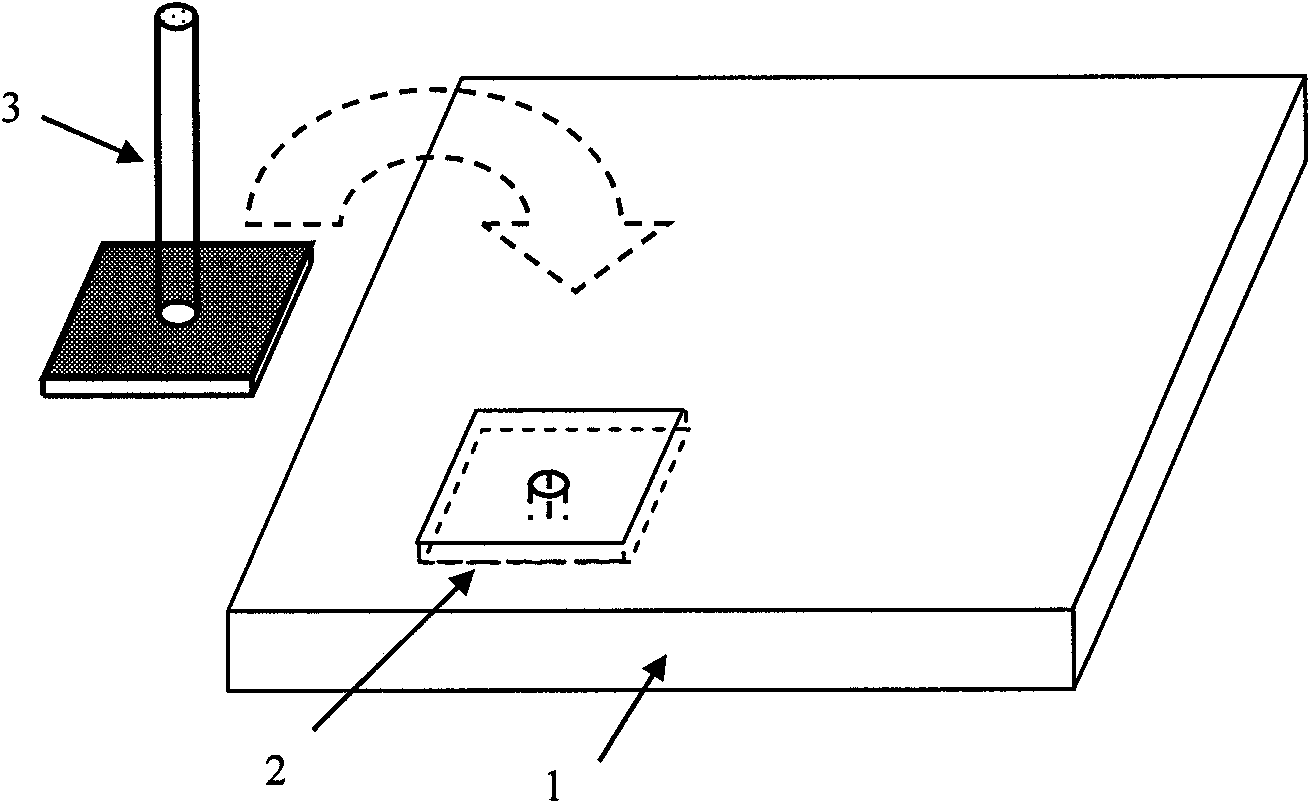

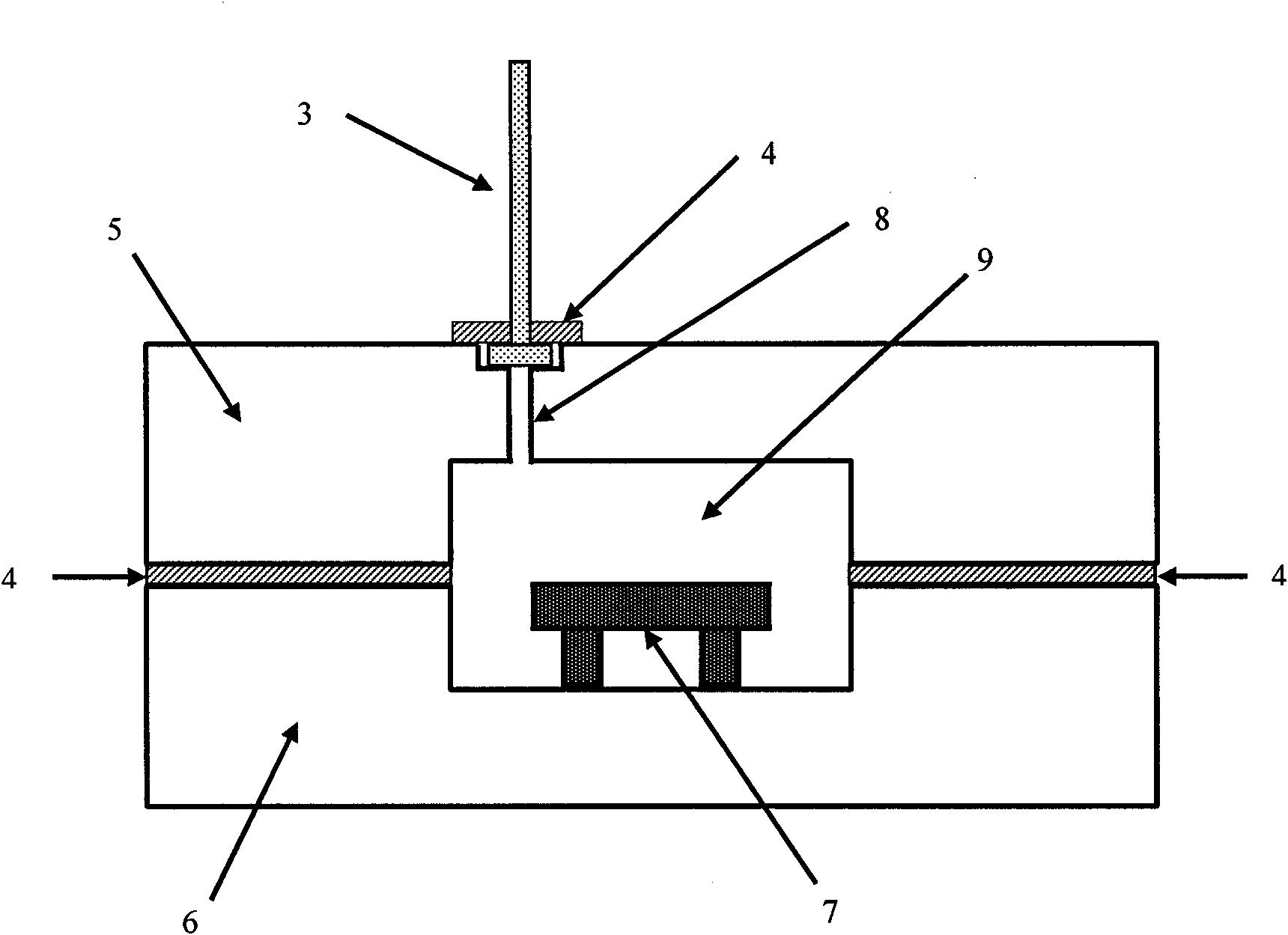

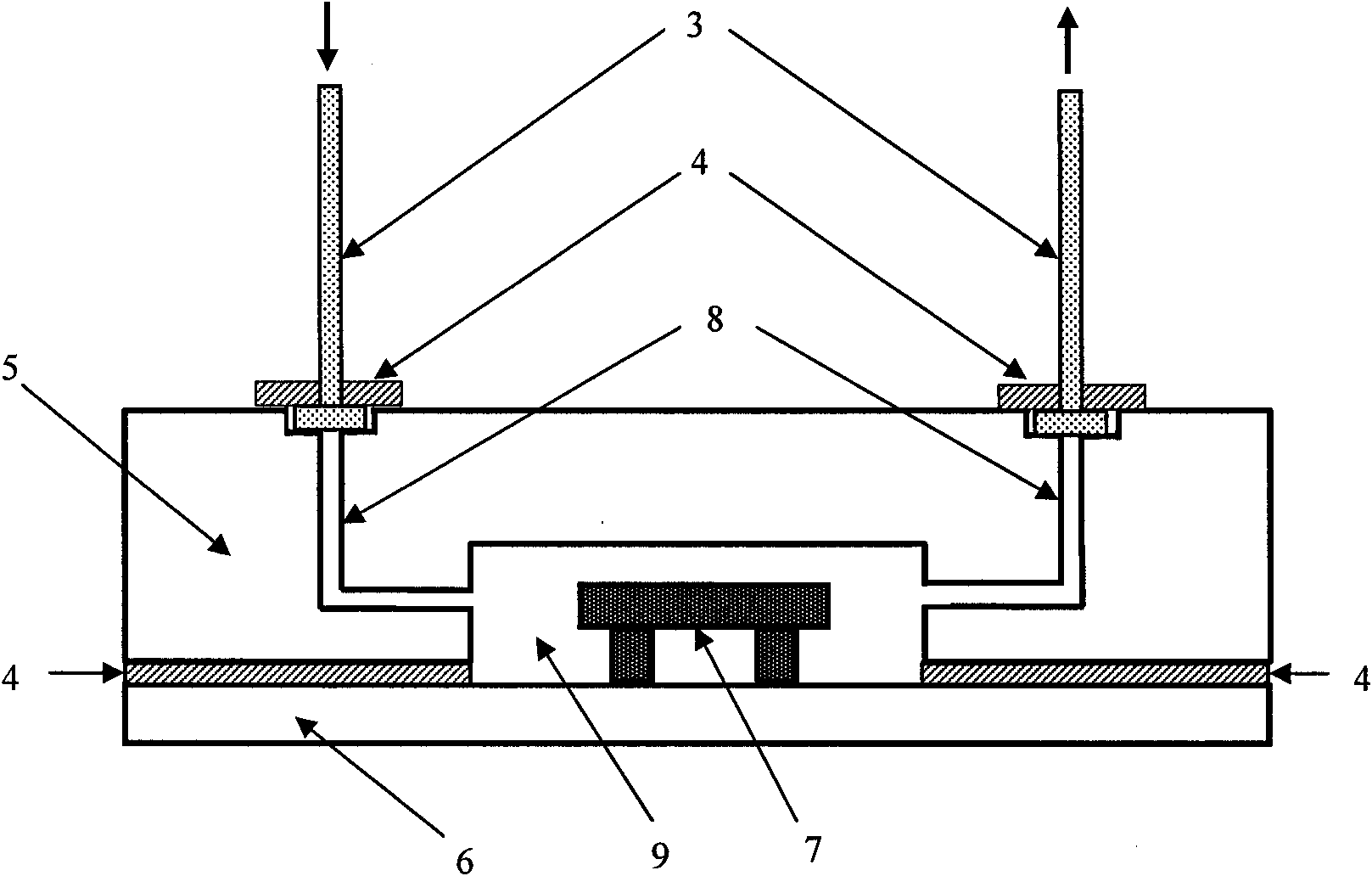

Direct shear-seepage test device and test method for single fracture rock specimen under hydrostatic pressure condition

ActiveCN107782628ARealize integrationAchieving tightnessMaterial strength using tensile/compressive forcesData acquisitionInstability

The invention belongs to the field of rocks and rock mass mechanics and discloses a direct shear-seepage test device and test method for a single fracture rock specimen under a hydrostatic pressure condition. The device is characterized by comprising a loading system, an acoustic emission monitoring system, a seal system, a data acquisition system and a rock specimen pre-treatment system. By the direct shear-seepage test device and the test method, hydrostatic pressure packaging and direct shear-seepage testing of the single fracture rock specimen under high shear displacement and high seepagepressure conditions can be realized, friction fracture changes of a fracture face in a shearing process can be monitored in real time through the acoustic emission monitoring system, fracture face changes of the single fracture rock specimen before and after direct shear-seepage testing can be analyzed through a fracture face data processing system, deeply analyzing a direct shear-seepage mechanism and exploring main factors having effects on direct shear-seepage characteristics of single fracture rock can be realized, and a theoretical foundation and a test basis are provided for a shear-seepage instability mechanism of mining-induced fracture rock under the action of underground water.

Owner:TAIYUAN UNIV OF TECH

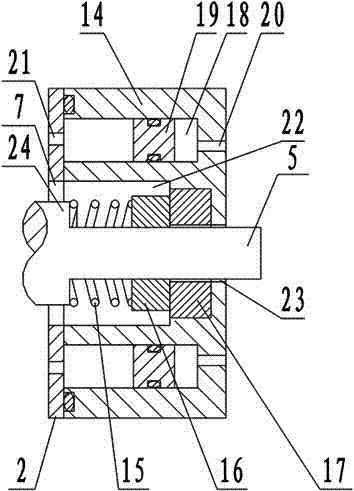

Floating blind-mating flow connector

ActiveCN103557392AImprove sealingExtended service lifeJoints with fluid cut-off meansEngineeringMechanical engineering

The invention discloses a floating blind-mating flow connector which comprises a socket and a plug matched with the socket, wherein a first flow guide hole is formed in the plug; a first snap ring, a valve bush, a first spring and a first valve core are arranged in the first flow guide hole; the valve bush is provided with a first bumping shoulder matched with the first snap ring; a first spring is arranged between the valve bush and the first valve core; a third flow guide hole is formed in the socket; a second snap ring groove is formed in the lateral wall at the front end of the third flow guide hole; a second snap ring, a flow guide post, a second ring and a second valve core are arranged in the third flow guide hole; the second snap ring is placed in the second snap ring groove; a third bumping shoulder matched with the second snap ring is arranged a the front part of the flow guide post; a fifth flow guide hole is formed in the third bumping shoulder; the second spring is arranged between the third bumping shoulder and the second valve core. According to the invention, both the socket and the plug can be used singly; the sealing effect is excellent and jamming is avoided when the socket and the plug are used together, so that, the fluid in the socket and the plug is enabled to run off quickly and the service life of the socket and the socket is prolonged.

Owner:中国电子科技集团公司第四十研究所

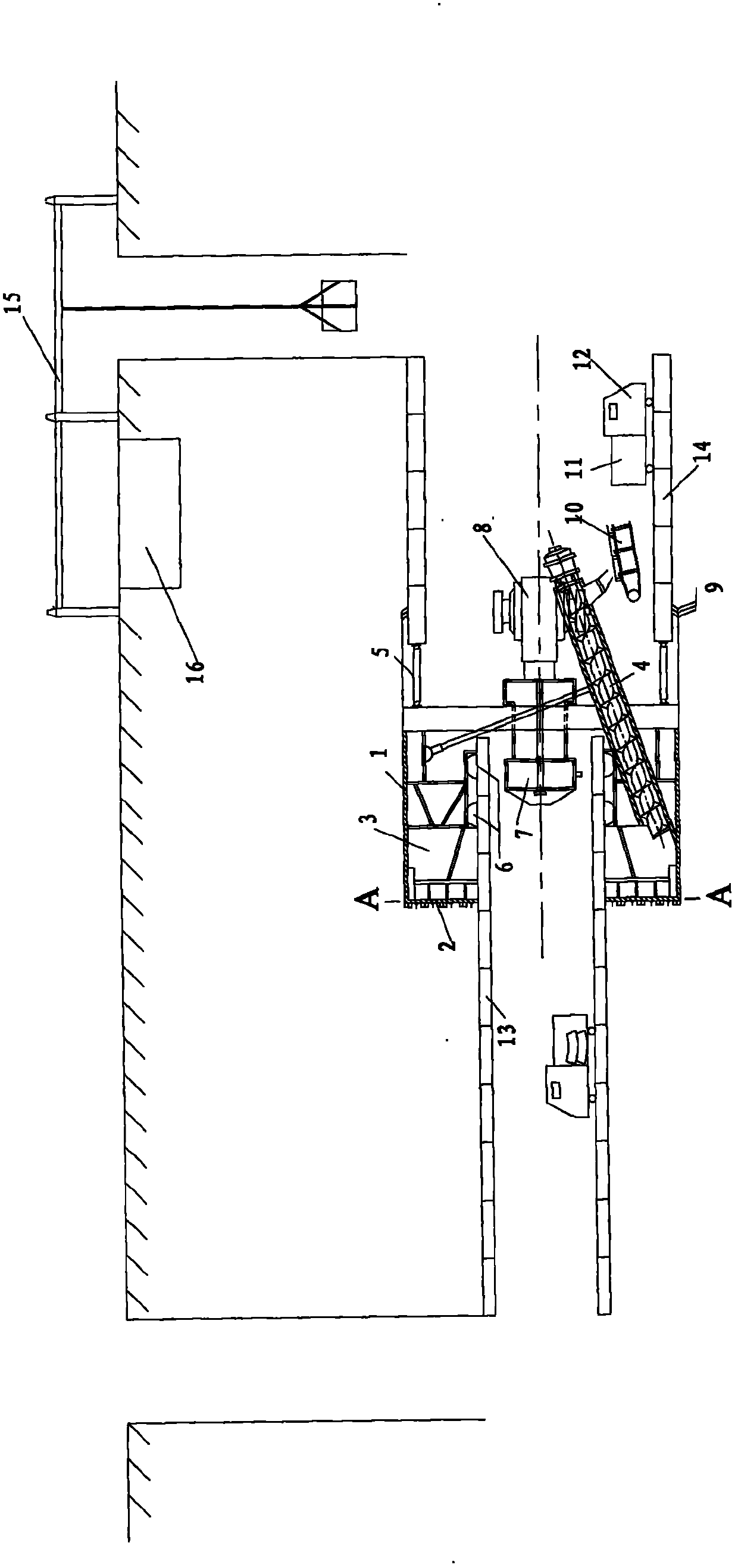

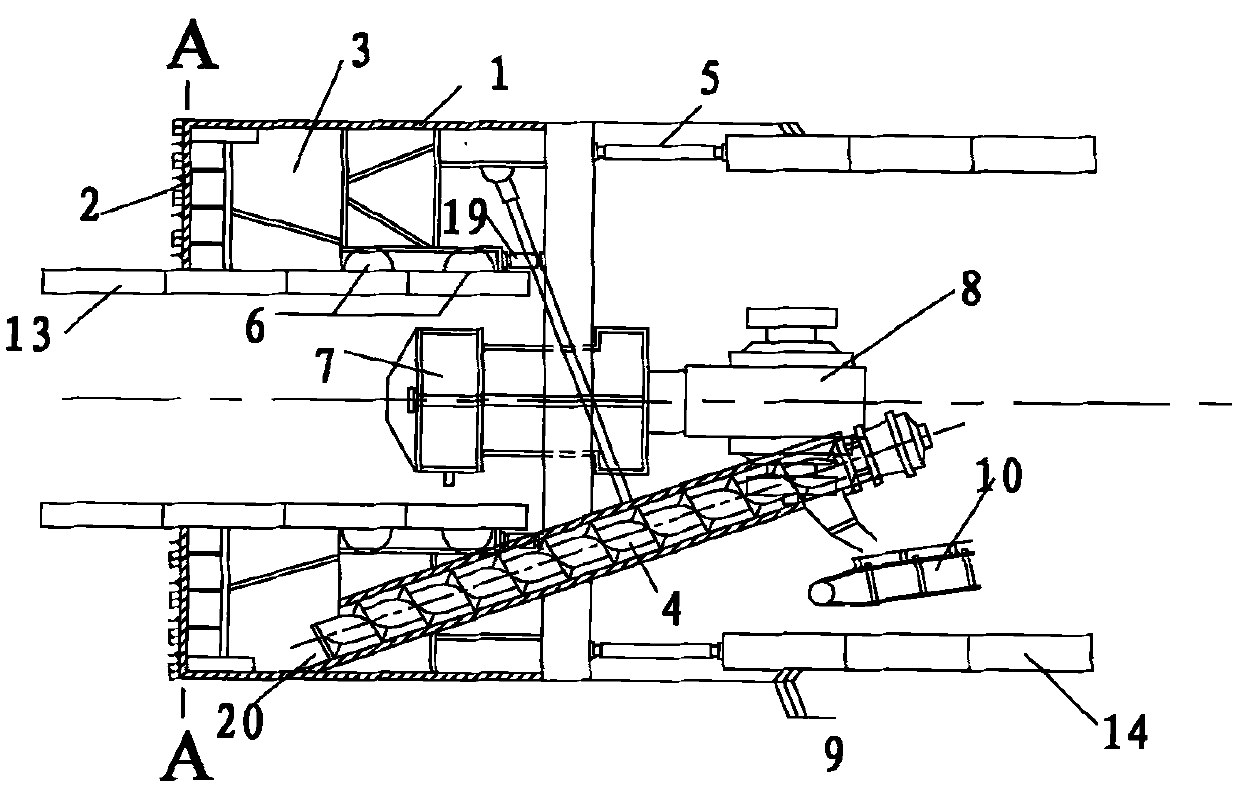

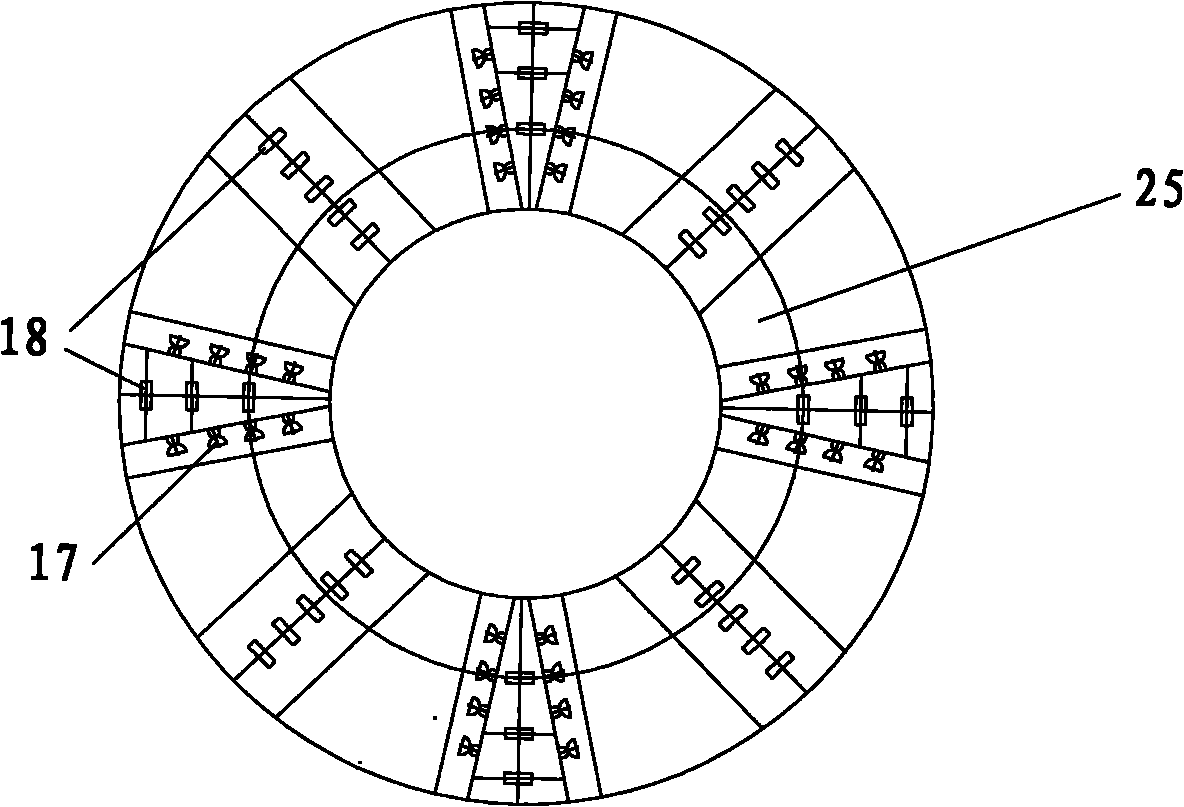

Earth pressure balance type annular shield machine

InactiveCN102200014AAchieve transformationIncrease the range of applicable soil layersTunnelsNitrile rubberEarth pressure balance

The invention relates to an earth pressure balance type annular shield machine. The shield machine comprises a shield machine shell, an annular knife disc, an earth pressure cabin, a screw conveyer, thrust cylinders, a gasket, a pipe piece disassembling machine, a pipe piece assembling machine and a sealing brush, wherein the annular knife disc is arranged at the front part of the shield machine shell, and the earth pressure cabin is arranged at the rear part of the annular knife disc; the screw conveyer is arranged at the lower part of the shield machine shell, and the thrust cylinders are uniformly distributed around the shield machine shell; the gasket is a nitrile rubber corrugated pipe inflatable gasket, and the side part of the gasket is provided with a gasket jack; the pipe piece disassembling machine is arranged at the front end of the upper part of the screw conveyer; the pipe piece assembling machine is arranged behind the pipe piece disassembling machine; and the gasket brush is arranged at the tail part of the shield machine. Compared with the prior art, the earth pressure balance type annular shield machine can be used for excavating tunnels with different diameters as required, the range of applicable soil layers is wide, the earth pressure in the earth cabin is maintained through the expansion and contraction of compressed air, and the functions of sealing and water stopping are realized.

Owner:TONGJI UNIV

Double-vacuum layer convex glass with sealing strips and mounting holes through metal welding

A piece of double-vacuum layer convex glass with sealing strips and mounting holes through metal welding comprises an upper piece of glass, a lower piece of glass and a middle piece of glass, and is characterized in that the mounting holes are comprised; the upper and the lower piece of glass are convex glass; at least one is respectively arranged at the peripheries of the lower surfaces of the upper glass and the middle glass and of the mounting hole; at least two sealing strips are respectively arranged at the peripheries of the upper surfaces of the lower glass and the middle glass and of the mounting hole; the peripheries of the three pieces of glass are automatically welded together in a vacuum furnace through metal solder; the mounting hole is also automatically sealed through the metal solder. The vacuum glass and the manufacturing method thereof are simple in process. According to the vacuum glass and the toughened vacuum glass prepared, not only are mounting and using convenient, but also the airtightness of the vacuum glass is ensured, and the strength, and heat insulation and acoustic insulation performance are also increased.

Owner:戴长虹

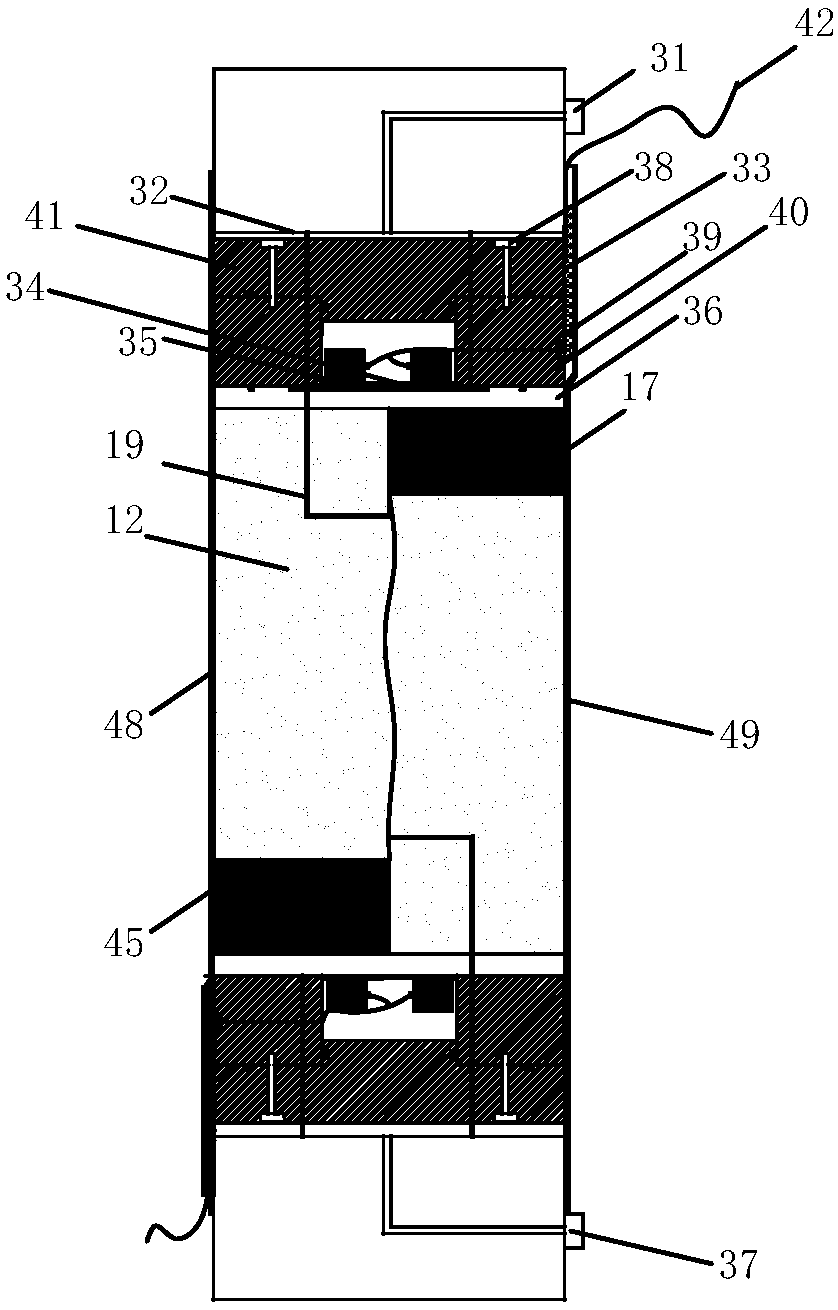

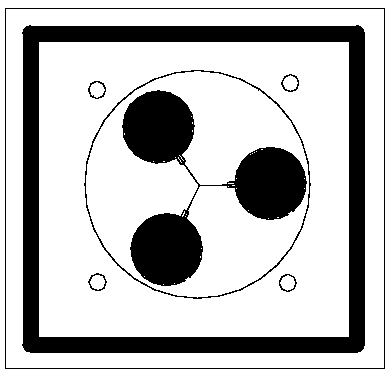

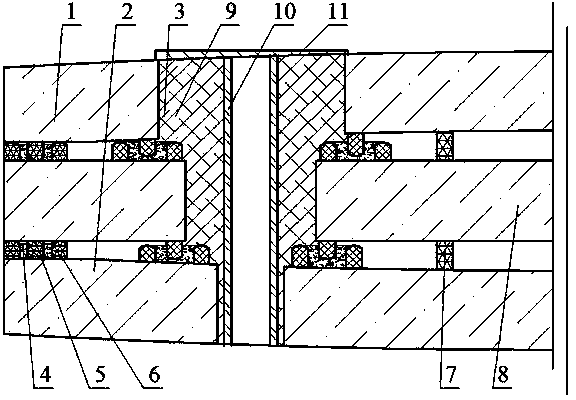

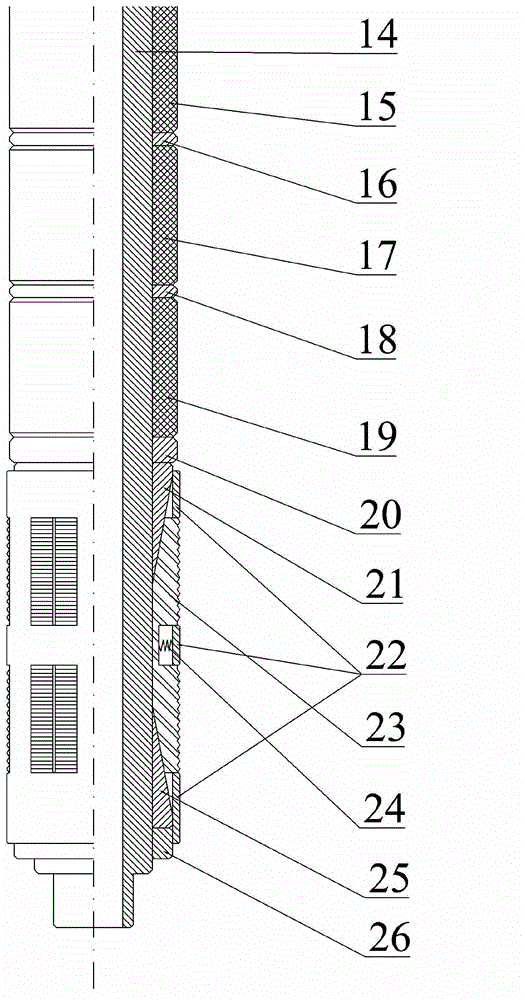

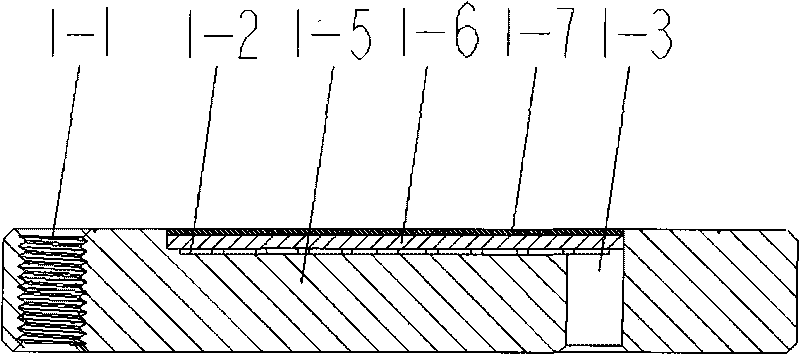

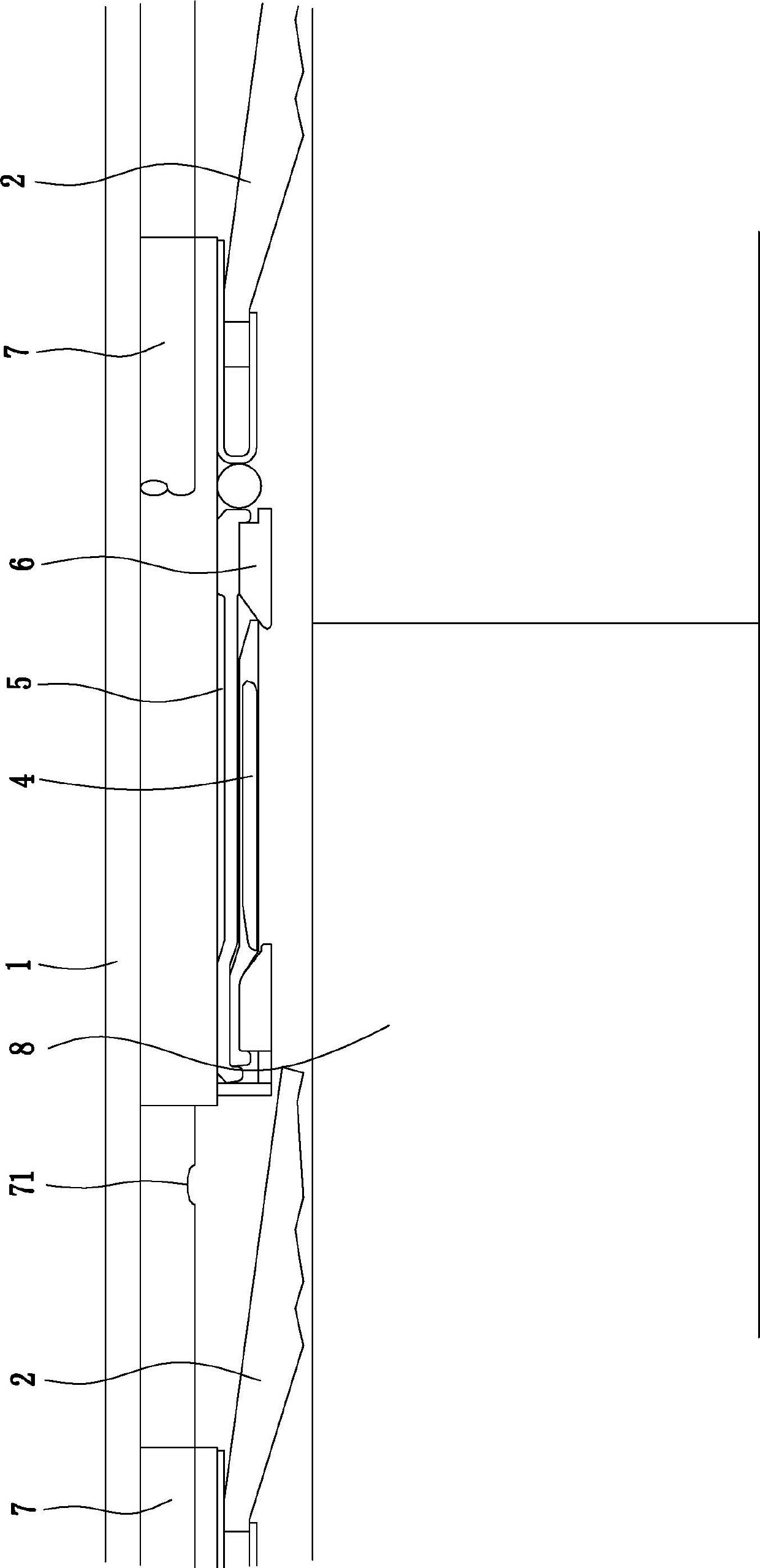

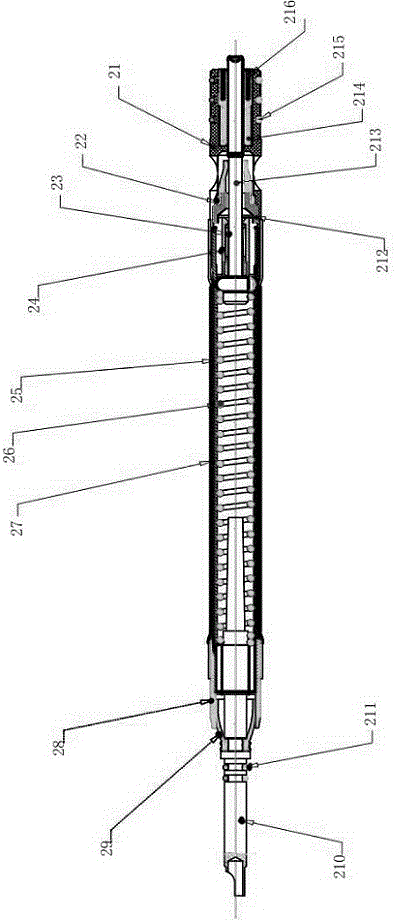

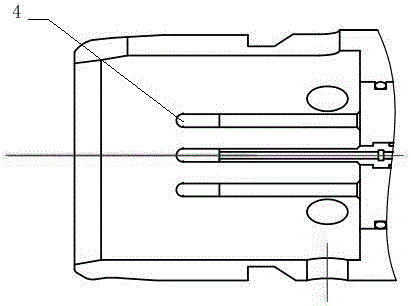

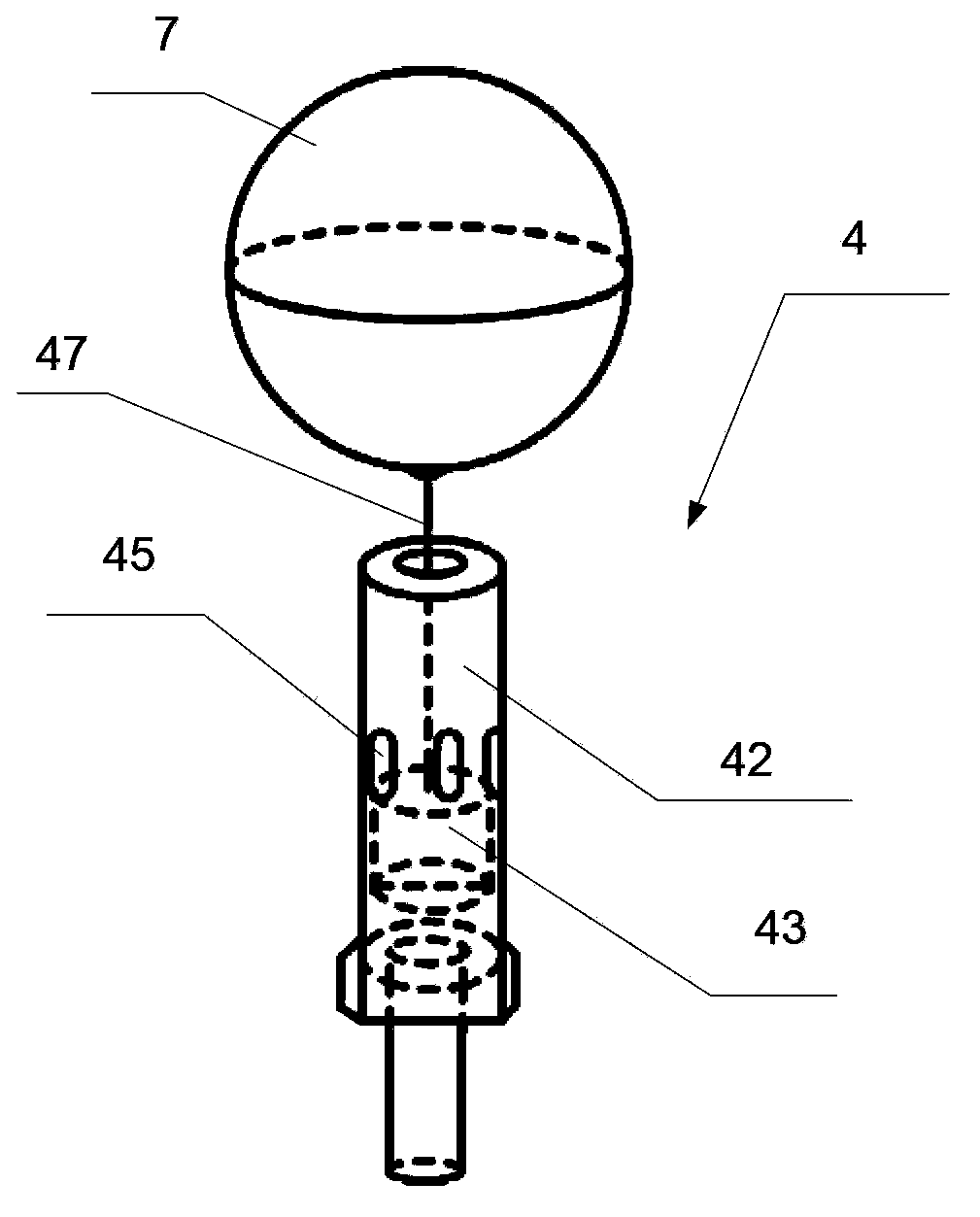

Downhole electric control compression type packer

ActiveCN102979477AAchieving tightnessAccurate data feedbackSealing/packingThreaded pipeElectric machine

The invention provides a downhole electric control compression type packer, which comprises a base pipe, a motor, a speed reduction device, a transmission device and a packing device, wherein the motor, the speed reduction device, the transmission device and the packing device are sheathed on the base pipe, the motor comprises a circular motor output shaft, the circular motor output shaft is rotatably sheathed on the base pipe, the speed reduction device comprises a circular NN-shaped planetary gear speed reducer with small teeth difference (5), the circular NN-shaped planetary gear speed reducer with small teeth difference (5) comprises a circular input shaft and a circular output shaft, the input shaft of the circular NN-shaped planetary gear speed reducer with small teeth difference (5) is connected with the circular motor output shaft, and the transmission device comprises a thread pipe (6), a transmission nut sleeve (9) and a lower sleeve (10).

Owner:PETROCHINA CO LTD

Vacuum convex glass welded with seal grooves and mounting holes

InactiveCN103420587AGuaranteed tightnessHigh strengthGlass reforming apparatusGlass productionEngineeringUltimate tensile strength

A piece of vacuum convex glass welded with seal grooves and mounting holes includes a piece of upper glass and a piece of lower glass, and is characterized in that the mounting holes and extraction openings are integrated; the upper glass and the lower glass are convex glass; seal strips are arranged on the peripheries of the upper glass and the extraction openings; the seal grooves are formed in the peripheries of the lower glass and the extraction openings; the peripheries of the upper glass and the lower glass are welded in an ordinary pressure lower edge sealing furnace through low temperature glass solder; the extraction openings are automatically sealed in a vacuum furnace through metal solder; a sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and the manufacture method, provided by the invention, have the advantages that the technology is simple, the manufactured vacuum glass and the toughened vacuum glass facilitate mounting and use, the airtightness of the vacuum glass is guaranteed, and intensity as well as heat and sound insulation performance of the glass can be improved.

Owner:戴长虹

Plane double-vacuum-layer glass with sealing strips and grooves and mounting holes through metal welding

The invention provides plane double-vacuum-layer glass provided with sealing strips and grooves and mounting holes through metal welding. The plane vacuum glass comprises upper glass, lower glass and middle glass, and is characterized in that the plane double-vacuum-layer glass is provided with mounting holes; sealing strips are arranged at the peripheries of lower surfaces of the upper glass and the middle glass, and the mounting holes; sealing strips and sealing grooves are formed in the peripheries of the upper surfaces of the middle glass and the lower glass, and the mounting holes; the peripheries of three blocks of glass are automatically welded together through metal welding material in a vacuum furnace; the mounting holes are sealed automatically by adopting metal welding material; two closed vacuum layers are formed among three blocks of glass; supporting materials arranged in a dot matrix manner are arranged in the vacuum layers. The manufacturing method and technology of the vacuum glass provided by the invention are simple, the vacuum glass and tempered vacuum glass manufactured through the manufacturing method and technology has the advantages that the mounting and use are convenient, the air tightness of the vacuum glass can be guaranteed, and the strength, heat insulation performance and sound insulation performance of the vacuum glass are increased.

Owner:戴长虹

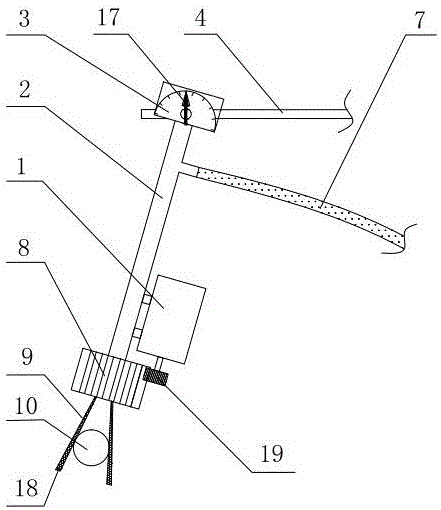

Device for stable, high-speed and variable-angle water entry experiment of rotating body

ActiveCN106353066AHigh water entry speedReduce frictionHydrodynamic testingWater tanksPositive pressure

The invention belongs to the model facility of hydraulics experiment, and specifically relates to a device for stable, high-speed and variable-angle water entry experiment of rotating body, comprising a transparent water tank, a data acquisition system which the connection is controlled by the industrial personal computer as well as a release device of water entry objects arranged above the transparent water tank, the release device of water entry objects comprises an entry angle protractor and a gas guide rod under flexible connection with a horizontal bracing piece, the bottom sleeve connection of the gas guide rod is arranged with the rotary gear and rotating head motor under coordination with the rotary gear, the motor operation drivers the rotation of the water entry objects. The gas guide rod is under sealed connection with a gas supply device via the high-pressure windpipe, the gas supply device comprises a high-pressure gas cylinder with the electro-magnetic switch valve and a air compressor connecting to the high-pressure gas cylinder, negative or positive pressure is formed in the high-pressure gas cylinder by controlling the operation of the air compressor, so as to control absorption and high-speed release of the water entry objects. The device for stable, high-speed and variable-angle water entry experiment of rotating body can stably release different forms of water entry objects under high-speed rotation at high speed, and can accurately control the object entry angle.

Owner:ZHEJIANG UNIV

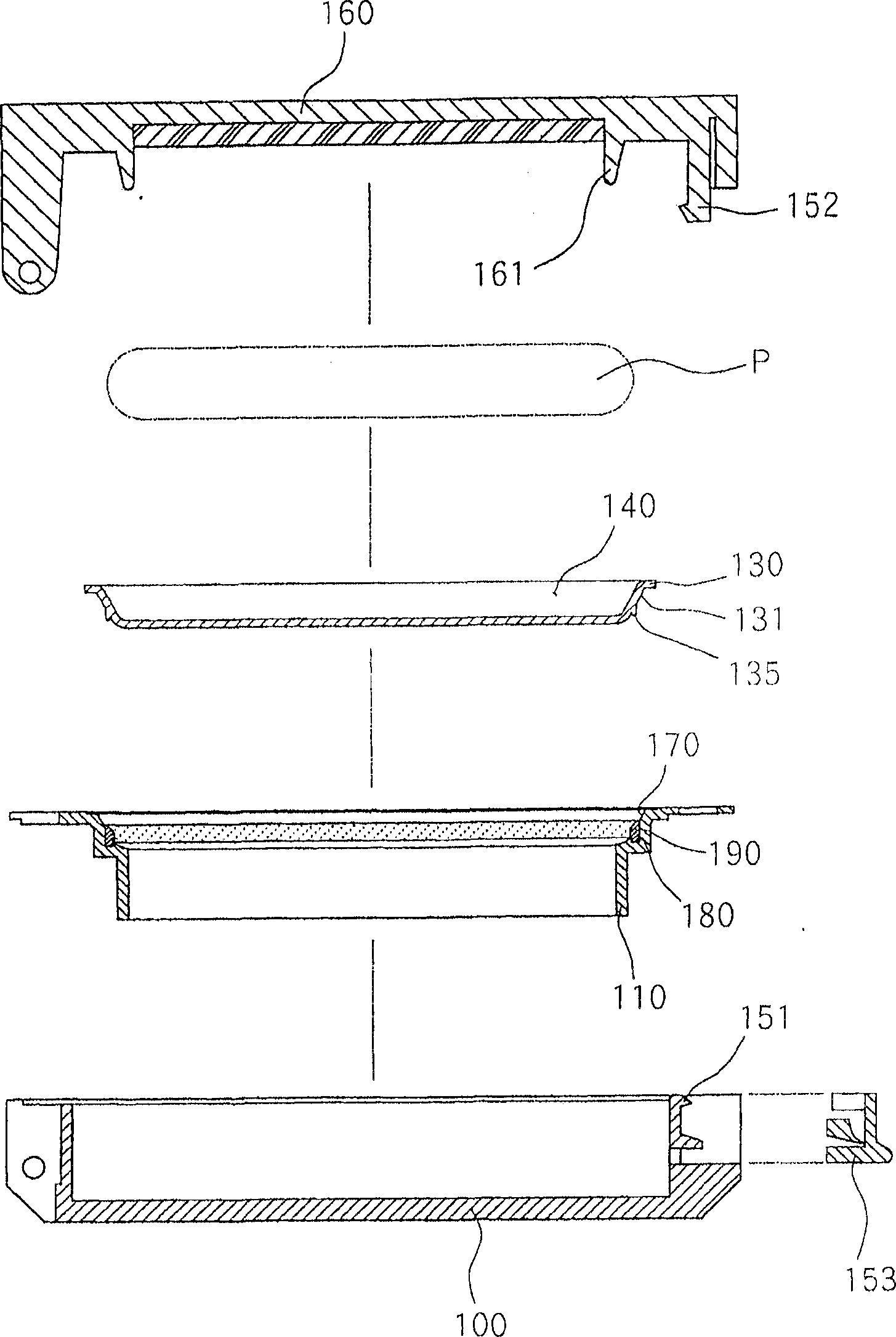

Compact cosmetic case with airtight sealed structure

InactiveCN1819785ASimple structureImprove sealingPackaging toiletriesPackaging cosmeticsProduction rateHermetic seal

A compact cosmetic box with airtight sealed structure has simple structure and enhanced airtight sealed effect to prevent leakage of powdery cosmetics, thus improving the quality, improving the production efficiency and lowering the production cost. The compact cosmetic box comprises a main body (100), an inner housing for accommodating the powder (110), an inner cover hinged on the inner housing (110) and provided with a powder puff base (140), and an outer cover hinged on the main body (100) with a locking portion (150). A groove (180) is formed surrounding the upper surface of the inner housing (110), and the groove is filled with liquid rubber to form a rubber seal (190). A locking hole is formed on the inner housing (110), and a locking rod (138) with locking bump (136) is formed on the inner cover (130) to be locked on the locking hole (116).

Owner:株式会社甫炅TL

Separator and separation method thereof

ActiveCN102225383AAvoid cloggingAvoid accumulationReversed direction vortexEngineeringSeparation method

The invention discloses a separator and a separation method thereof. The separator comprises a cyclone separator and an auger stripper, wherein an inlet is positioned at one side of the upper part of a separating circular cylinder and is tangent to and communicated with a cylindrical part of the separating circular cylinder; a separating conical cylinder is arranged at the lower part of the separating circular cylinder; the auger stripper is communicated with the lower part of the separating conical cylinder; the upper part of an overflow pipe of an overflow part extends out of the separating circular cylinder and is coaxially fixedly connected with the separating circular cylinder; the lower part of the overflow pipe is inserted into the separating circular cylinder; the lower port of the overflow pipe extends downwards to form an overflow port; a limiting ring is arranged between the separating circular cylinder and the overflow pipe; the upper edge of the limiting ring is aligned to the upper edge of the inlet; a bottom flow port is arranged at the lower end of the separating conical cylinder; the bottom flow port is communicated with the upper part of the auger stripper; or the quantity of the inlets is two or more than two, the inlets are symmetrically arranged relative to the axis of the cyclone separator, and the auger stripper is connected with the overflow port and spirally inserts into the overflow pipe. The separator can be used for separating solid, semisolid or sticky materials, preventing solid or sticky materials from accumulating and preventing a discharging port from being blocked.

Owner:溧阳常大技术转移中心有限公司

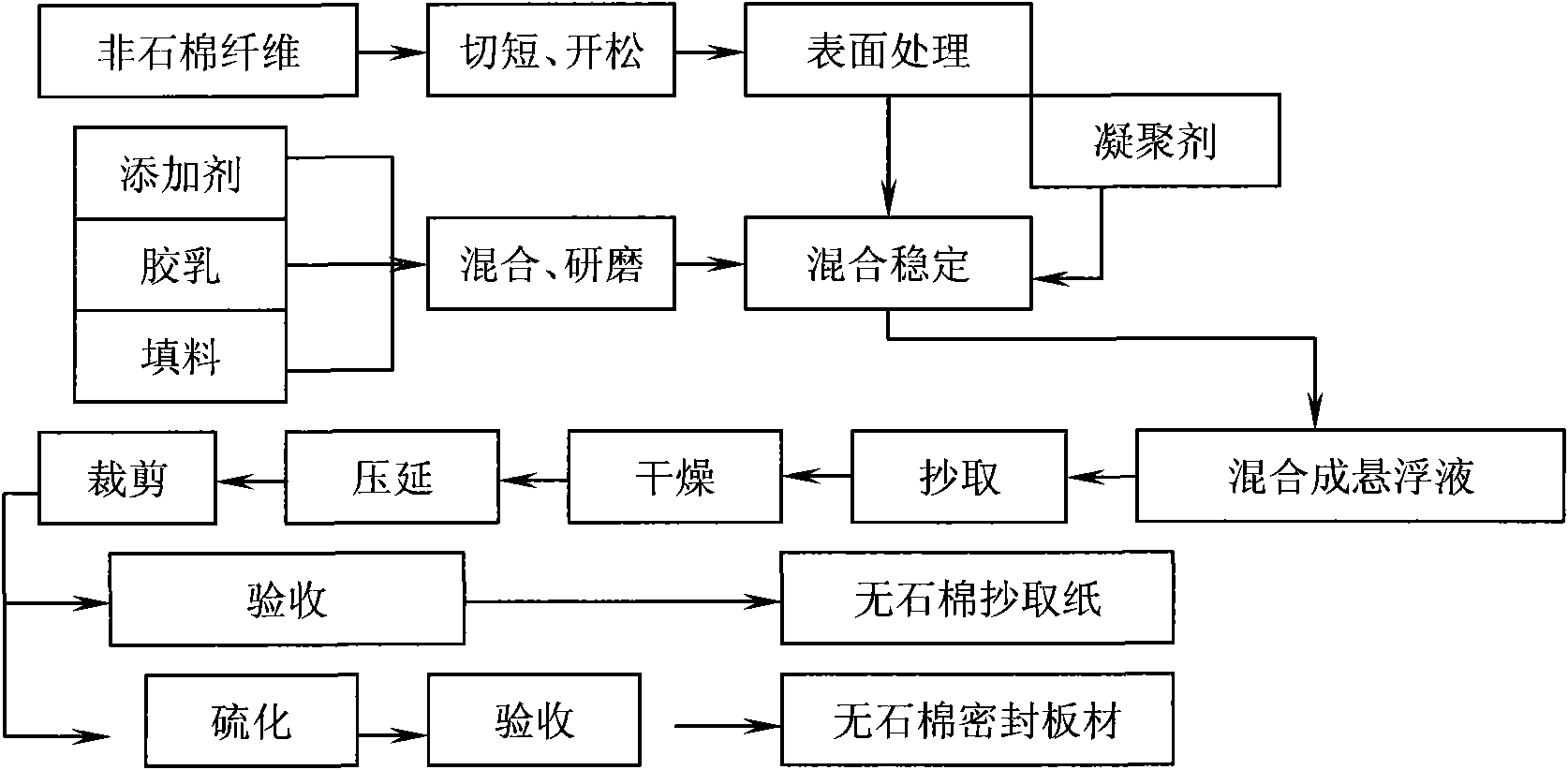

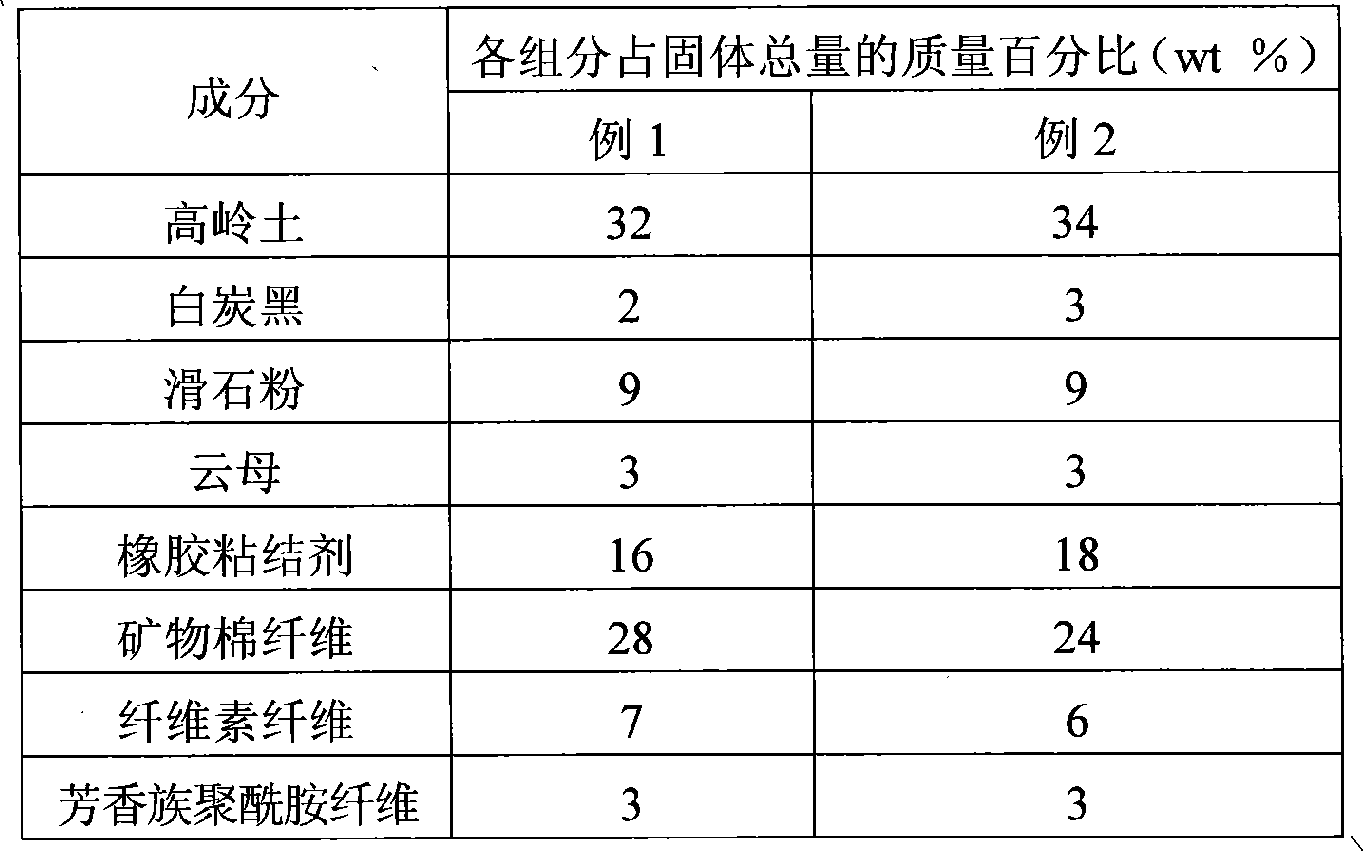

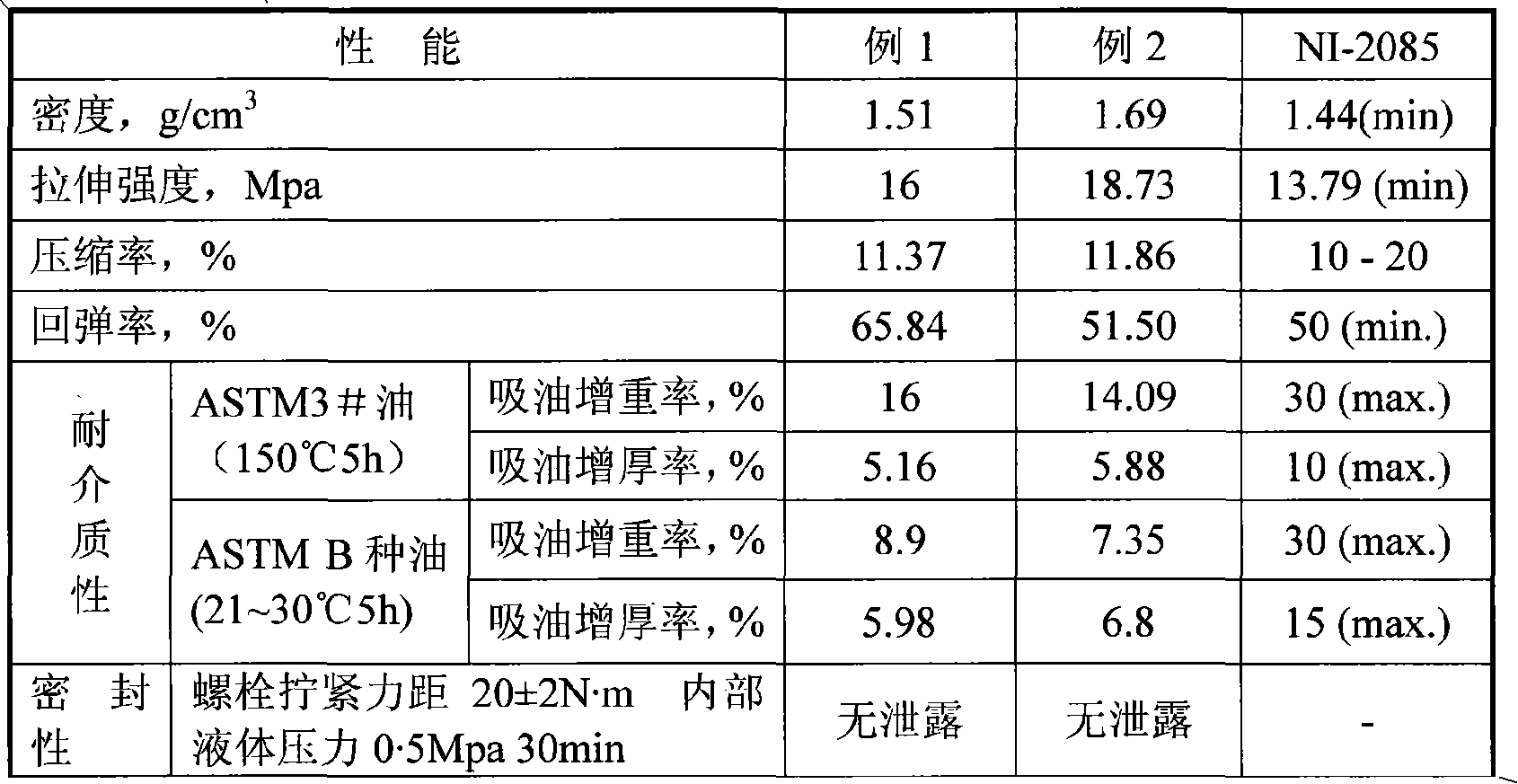

Method for preparing copy sheet used for sealing gasket

InactiveCN101575829AReasonable choiceNo pollution in the processFibreboardInorganic fibres/flakesAsbestos sheetVulcanization

The invention relates to a method for manufacturing a sealing gasket, in particular to a method for preparing a copy sheet used for a sealing gasket which does not contain asbestos fiber, belonging to the field of sealing materials. The copy sheet contains the main components of mineral cotton fiber, cellulose fiber, aromatic polyamide fiber, rubber cement and kaoline; the components are mixed to a dispersed system containing water, then a paper-making technique is adopted to dehydrate gradually and form a layer, and a finished product of the copy sheet is manufactured by compression, drying and vulcanization. The sealing gasket manufactured by the sheet has tensile strength, compression resilience performance, medium resistance and sealing performance and the like equivalent to that of the copying asbestos sealing gasket and can completely replace asbestos sheets for manufacturing the sealing materials of the gasket and the like.

Owner:KUNMING UNIV OF SCI & TECH +1

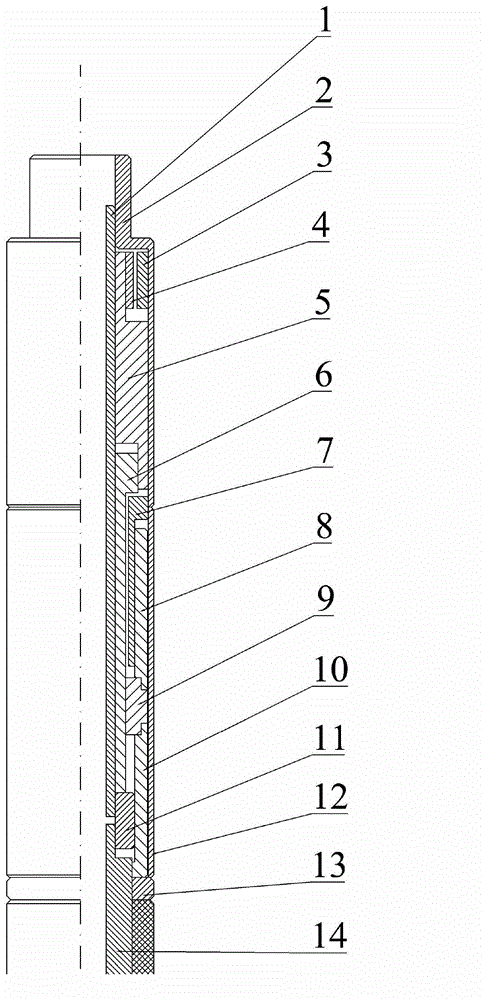

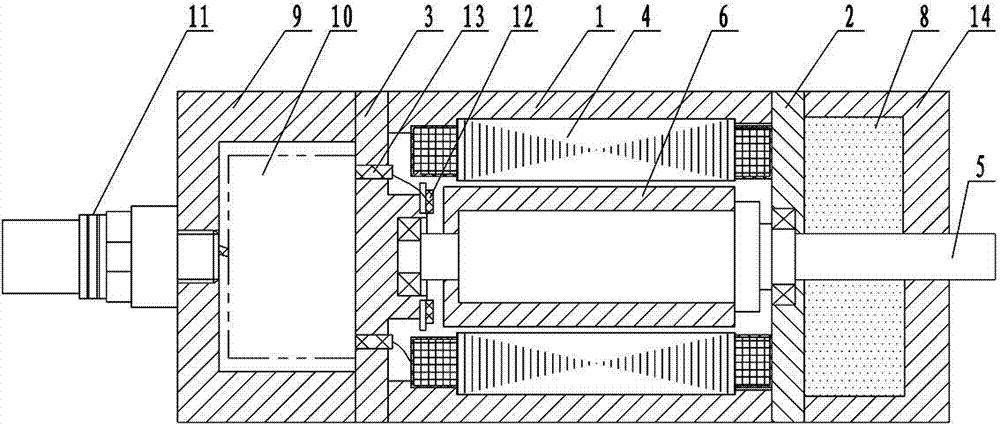

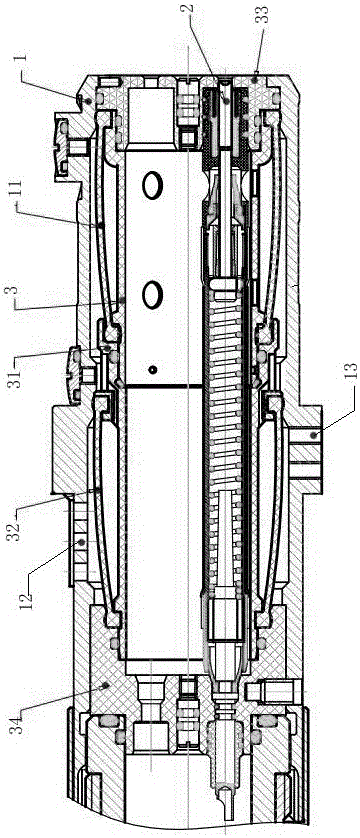

Controller integrated deep sea motor

ActiveCN102761204ASimple structureCompact structureAssociation with control/drive circuitsSupports/enclosures/casingsPressure balanceControl theory

The invention discloses a controller integrated deep sea motor. The controller integrated deep sea motor comprises a motor shell (1), a front end cover (2), a rear end cover (3), a stator (4), a motor shaft (5) and a rotor (6), wherein the outer side of the front end cover (2) is provided with a pressure balance and dynamic seal integrated mechanism (8); the outer side of the rear end cover (3) is provided with a controller hatchcover (9), and the controller hatchcover (9) is internally provided with a driving controller (10); the inner side of the rear end cover (3) is provided with a Hall integrated circuit (12); and the driving controller (10) is respectively connected with the Hall integrated circuit (12) and the stator (4) through an electric conduction screw (13) arranged on the rear end cover (3). The controller integrated deep sea motor provided by the invention has the beneficial effects that the balance of inner and outer pressure of the underwater motor is realized, and thus the motor is light enough; a balanced structure and a dynamic seal structure are integrated, and thus the structure of the underwater motor is compact; and the controller and the motor are integrated, so that the size of the motor is further recued, and the reliability of the motor is good.

Owner:CHENGDU OUXUN TECH CO LTD

Non-oxidation split charging device and non-oxidation split charging method for manufacturing alkali-metal high-temperature heat tubes

The invention relates to a non-oxidation split charging device and a non-oxidation split charging method for manufacturing alkali-metal high-temperature heat tubes, and belongs o the technical field of heat tubes. The device comprises high-temperature heat tubes, high-temperature storage tanks, operation boxes with gloves, ultrahigh vacuum molecular pump units, pipelines and valves, each operation box with gloves comprises exhaust manifolds, each pipeline comprises a main gas inlet pipe, a branched exhaust bypass, a gas inlet bypass and a gas outlet bypass, and the valves include ultrahigh vacuum seal valves, gas inlet valves and exhaust valves. An alkali-metal process is significantly improved, non-oxidation alkali-metal split charging is realized, alkali-metal split charging hours for the heat tubes are few, aftertreatment time for completing a technological process is short, quantitative split charging for the multiple heat tubes can be carried out at one step, so that work efficiency in a split charging process for a single heat tube or the multiple heat tubes is greatly improved, consumption of water, electricity, gas and the like is greatly reduced, and the non-oxidation alkali-metal split charging process is greatly improved.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Plane vacuum glass with sealing grooves and mounting holes through metal welding

InactiveCN103420586AEasy edge banding and sealingHigh bonding strengthGlass reforming apparatusGlass productionVacuum furnaceGlass manufacture

The invention provides plane vacuum glass provided with sealing grooves and mounting holes through metal welding. The plane vacuum glass comprises upper glass and lower glass, and is characterized in that the plane vacuum glass is provided with mounting holes; wherein the upper glass and the lower glass are plane glass; sealing strips are arranged at the peripheries of the upper glass and the mounting holes; sealing grooves are formed in the peripheries of the lower glass and the mounting holes; the peripheries of the upper glass and the lower glass are automatically welded together through metal welding material in a vacuum furnace; an extract opening is automatically sealed in the vacuum furnace by adopting metal welding material; a closed vacuum layer is formed between the upper glass and the lower glass; supporting materials arranged in a dot matrix manner are arranged in the vacuum layer. The manufacturing method and technology of the vacuum glass provided by the invention are simple, the vacuum glass and tempered vacuum glass manufactured through the manufacturing method and technology has the advantages that the mounting and use are convenient, the air tightness of the vacuum glass can be guaranteed, and the strength, heat insulation performance and sound insulation performance of the vacuum glass are increased.

Owner:戴长虹

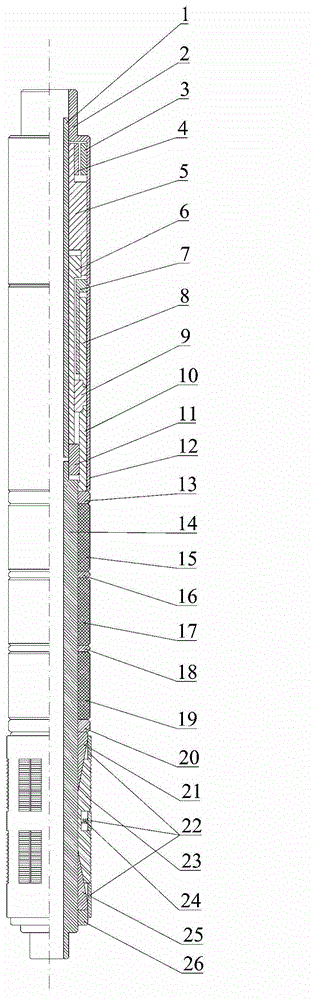

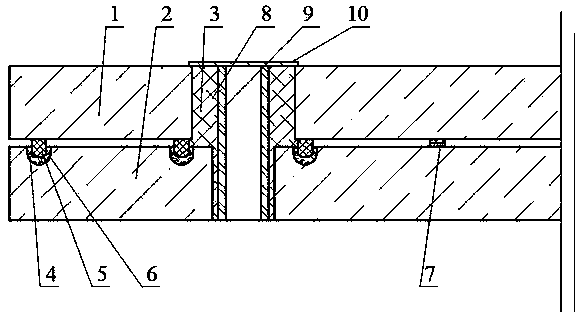

Shield tail sealing device for shield machine

ActiveCN102562081AAchieving tightnessUnderground chambersTunnel liningClassical mechanicsEngineering

The invention discloses a shield tail sealing device for a shield machine. The shield tail sealing device comprises a plurality of shield tail brushes arranged on a shield tail, a steel plate brush which is arranged on the shield tail and is positioned behind the shield tail brushes, and a sealing plate which is arranged on the shield tail and is positioned between two adjacent shield tail brushes at the last end; one end of the sealing plate is connected with the shield tail in a rotatable way, and the other end of the sealing plate is clamped on the shield tail in a detachable way; and an air bag which can be inflated, and pushes the sealing plate to ensure that the sealing plate is separated from the position where the shield tail is clamped with the sealing plate, and is pressed against a pipe piece tightly. Due to the adoption of the technical scheme, compared with the prior art, the shield tail sealing device for the shield machine has the advantages that the shield tail sealingdevice is provided with the shield tail brushes and the sealing plate, and the air bah can push the sealing plate out to be pressed against the pipe piece, so the sealing effect is achieved.

Owner:TIANHE MECHANICAL EQUIP MFG

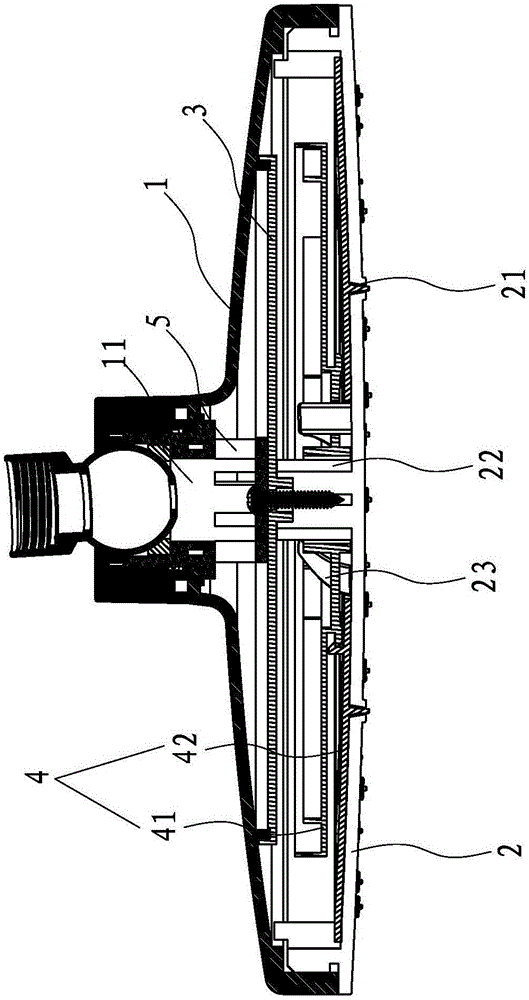

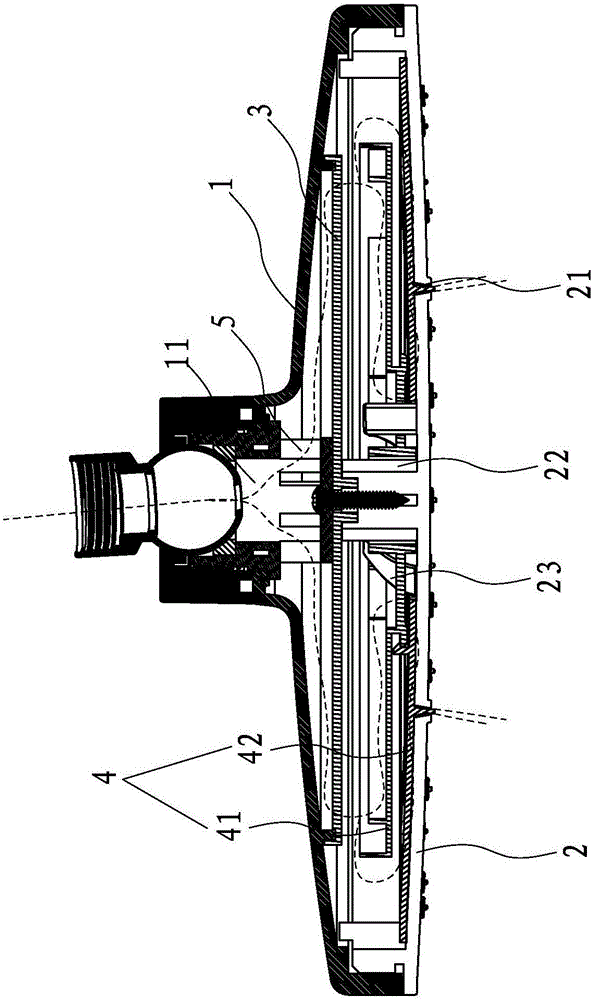

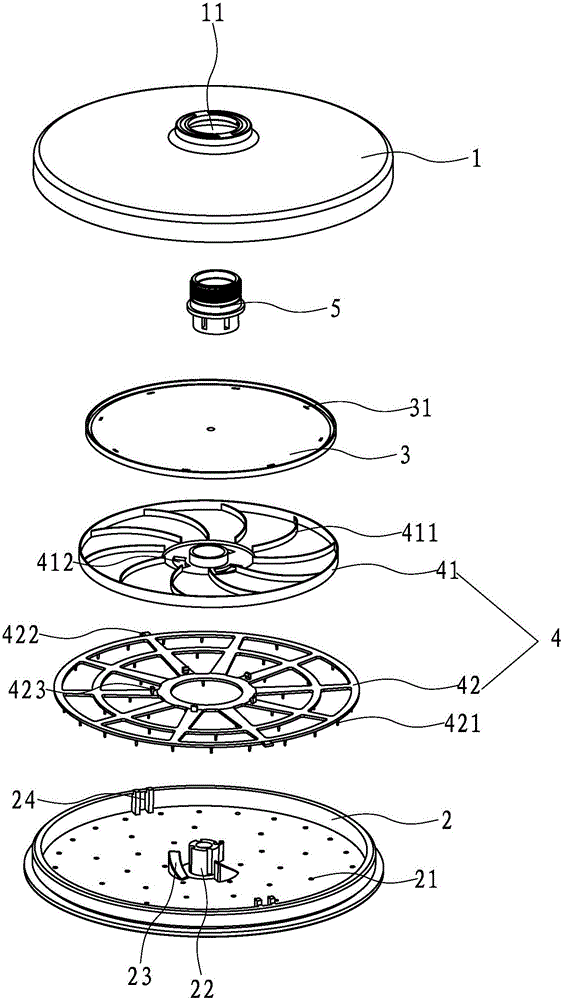

Self-cleaning top-spraying device

ActiveCN105149122AGuaranteed cleanlinessAvoid enteringSpray nozzlesCleaning needleBiochemical engineering

The invention relates to the technical field of top-spraying sprinklers, particularly to a self-cleaning top-spraying device. The device comprises a body, a water outlet panel and a cleaning needle disk, wherein the water outlet panel is arranged on the body; a water inlet is formed in the body; water outlet holes are formed in the water outlet panel; a rotating shaft is arranged on the water outlet panel; the cleaning needle disk comprises a rotating disk and a needle disk; the rotating shaft is sleeved with the rotating disk rotatably; the needle disk is clamped below the rotating shaft and can move relative to the rotating disk; cleaning needles corresponding to the water outlet holes are arranged on the needle disk; a fan blade structure which drives the rotating disk to rotate under current scour is arranged on the rotating disk; a spiral lifting platform which is used for increasing the horizontal height of the rotating disk when the rotating disk rotates is arranged on the water outlet panel; and a limiting device which limits the rotating of the needle disk and doesn't limit up-and-down motion of the needle disk is arranged on the water outlet panel. The self-cleaning top-spraying device solves the problem of the service life of an existing return spring and makes the whole structure simple; and lifting and dropping of the cleaning needles is realized through opening and closing of water currents, so that self-cleaning after a shower each time is realized.

Owner:XIAMEN SHUIDA SANITARY WARE

Vacuum plane glass provided with sealing strips and mounting hole through metal welding

A vacuum plane glass provided with sealing strips and a mounting hole through metal welding comprises an upper glass and a lower glass, and is characterized by further comprising the mounting hole, wherein both the upper and the lower glass are plane glasses; at least one sealing strip is respectively arranged at the peripheries of the mounting hole and the upper glass; at least two sealing strips are respectively arranged at the peripheries of the lower glass and the mounting hole; the sealing strips on the upper glass insert among the sealing strips on the lower glass; the peripheries of the lower and the upper glasses are automatically welded together in a vacuum furnace through metal solder; the mounting hole is also automatically sealed through the metal solder. The vacuum glass and the manufacturing method thereof are simple in process. According to the vacuum glass and the toughened vacuum glass prepared, not only are mounting and using convenient, but also the airtightness of the vacuum glass is ensured, and the strength, and heat insulation and acoustic insulation performance are also increased.

Owner:戴长虹

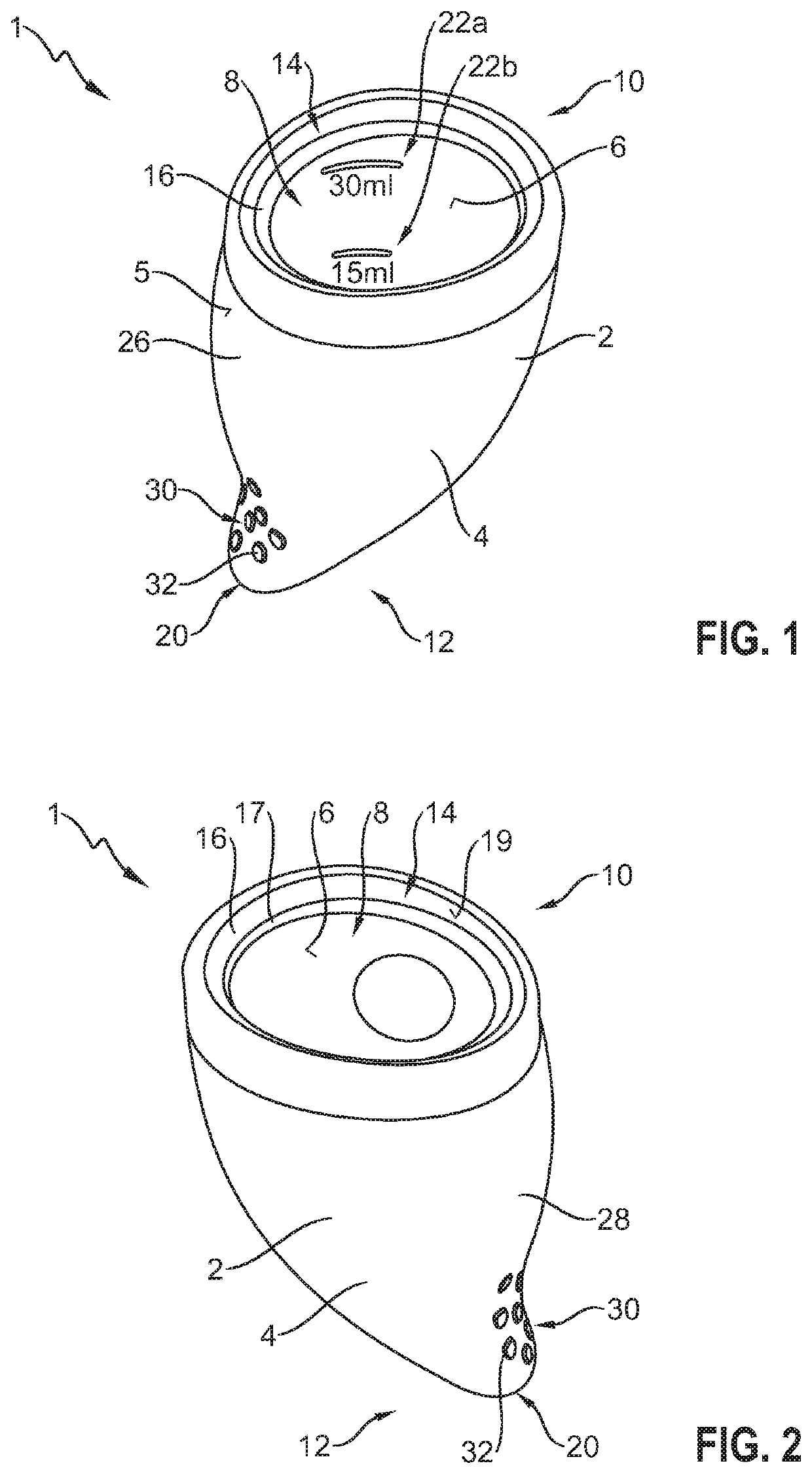

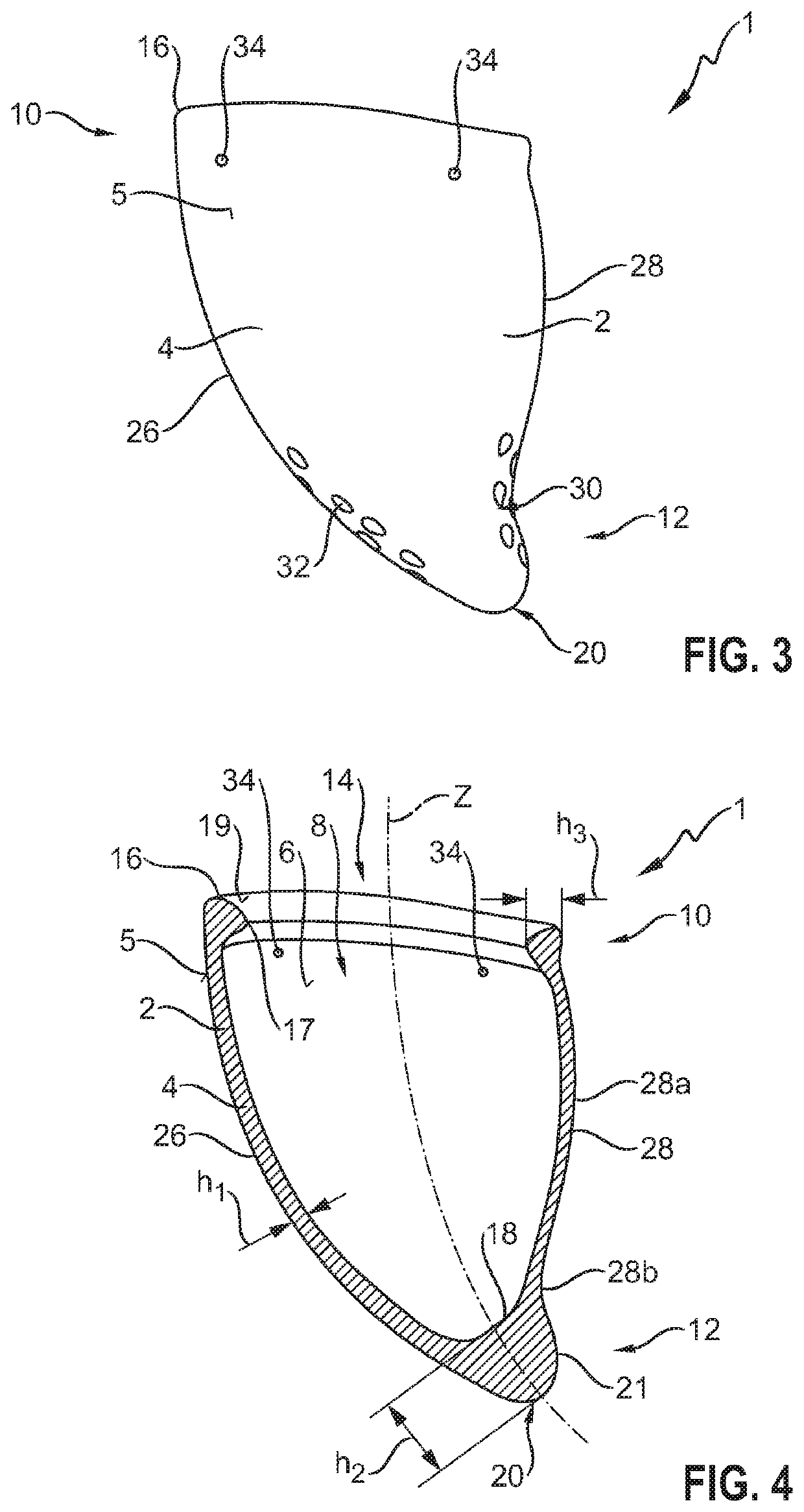

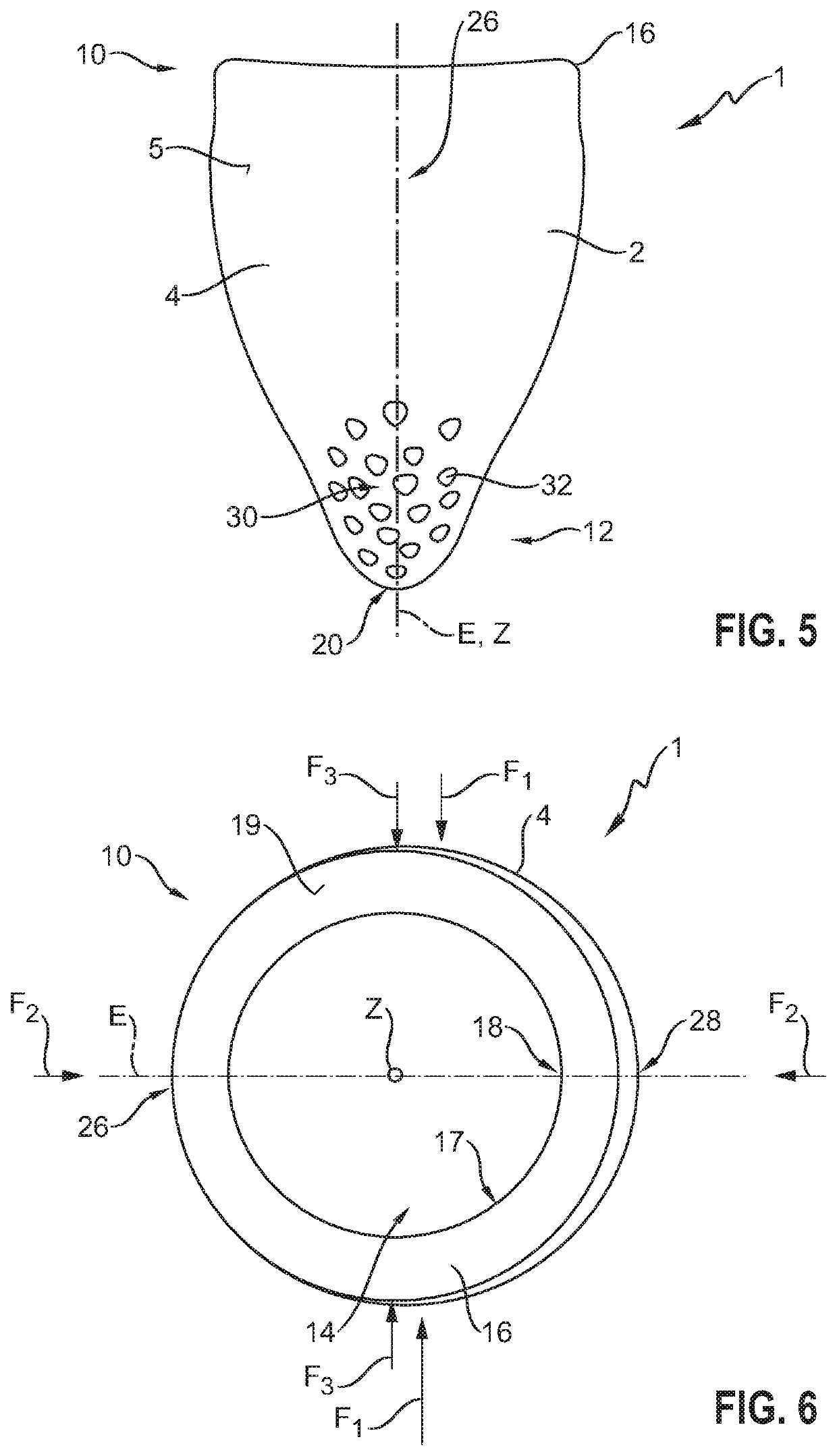

Hygiene product, in particular menstrual cup with an ergonomic shape

ActiveUS20190358077A1Improved fluid receptionImprove wearing comfortMedical devicesBodily discharge devicesBiomedical engineeringHygiene

The disclosure relates to a hygiene product, in particular a menstrual cup, having a cup body comprising a cup wall defining a receiving space using an inner surface, the cup body comprising on a first end an opening into the receiving space, the opening having an edge, and at a second end, a bottom opposite the opening, and the cup body comprising a generally conical shape, tapering towards the bottom and terminating in a tip. The hygiene product is characterized in that the cup body is rotationally asymmetric and a central axis of the cup body runs curved.

Owner:FUN FACTORY

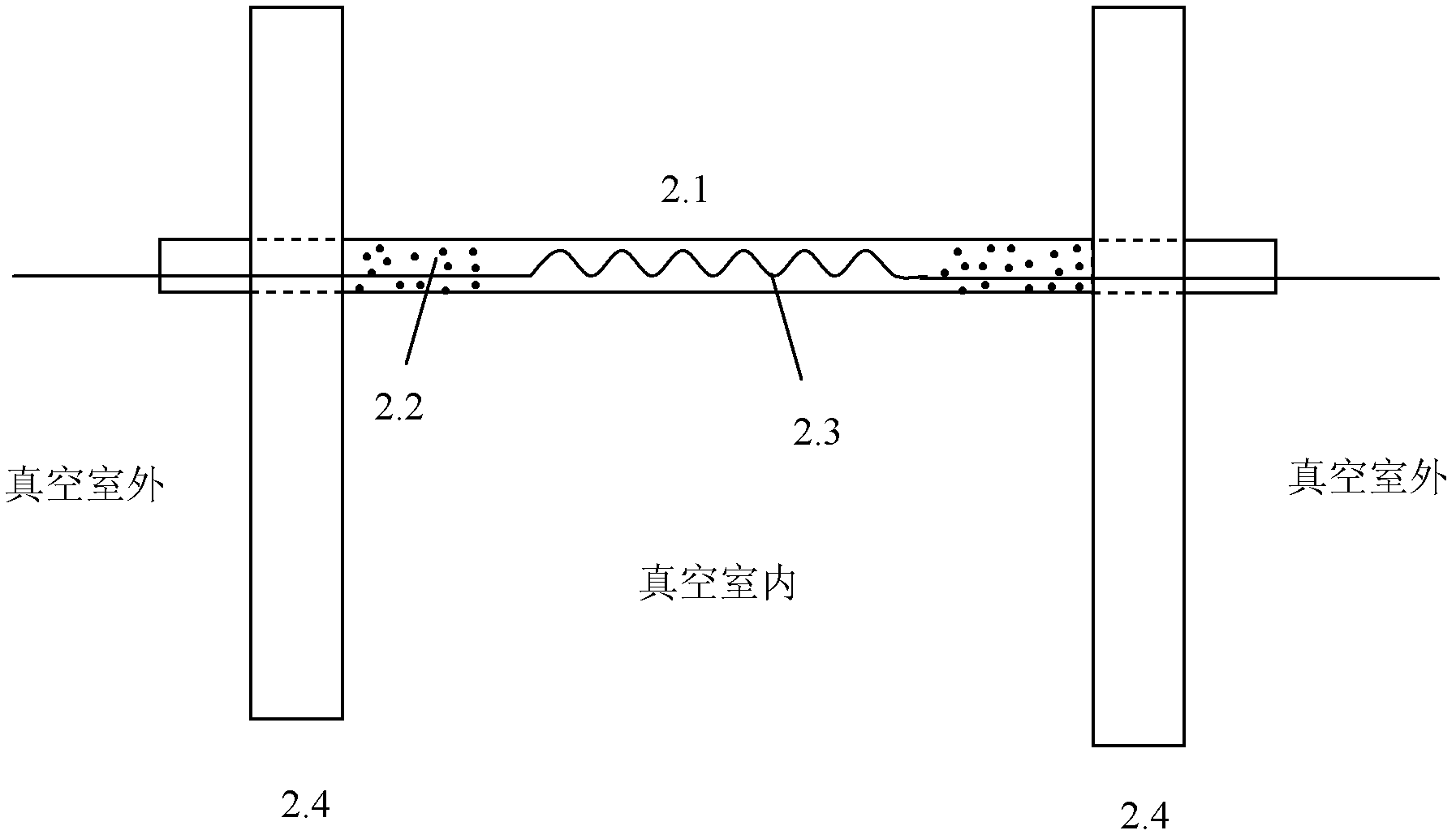

Plasma enhanced chemical vapor deposition vacuum equipment

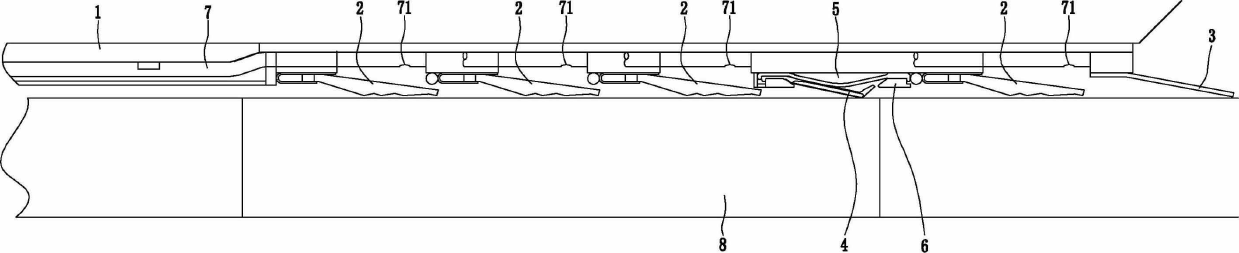

InactiveCN102534573AMonitor growth in real timePrecise control of optical constantsChemical vapor deposition coatingGas phaseEngineering

The invention discloses plasma enhanced chemical vapor deposition vacuum equipment, which has continuous structures with the same shape and constitution. Each structure consists of a left flange, a main vacuum chamber, a separator, a high vacuum seal valve device, an auxiliary vacuum chamber, a right flange and a large seal plate from left to right in turn; the left flange is connected with the main vacuum chamber through argon arc welding; the main vacuum chamber is connected with the separator through argon arc welding; the separator is connected with the auxiliary vacuum chamber through argon arc welding; a fluorine rubber gasket is sealed between the separator and the high vacuum seal valve device; the auxiliary vacuum chamber is connected with the right flange through argon arc welding; a fluorine rubber gasket is sealed between the high vacuum seal valve device and the right flange; the right flange and the large seal plate are connected in a sealing way through a fluorine rubber gasket; and multiple vacuum chambers are connected by repeating the sequence, so that the pollution-free multi-layer film preparation is carried out. The plasma enhanced chemical vapor deposition vacuum equipment has a wide application prospect in the technical field of vacuum coating equipment real-time monitoring.

Owner:BEIHANG UNIV

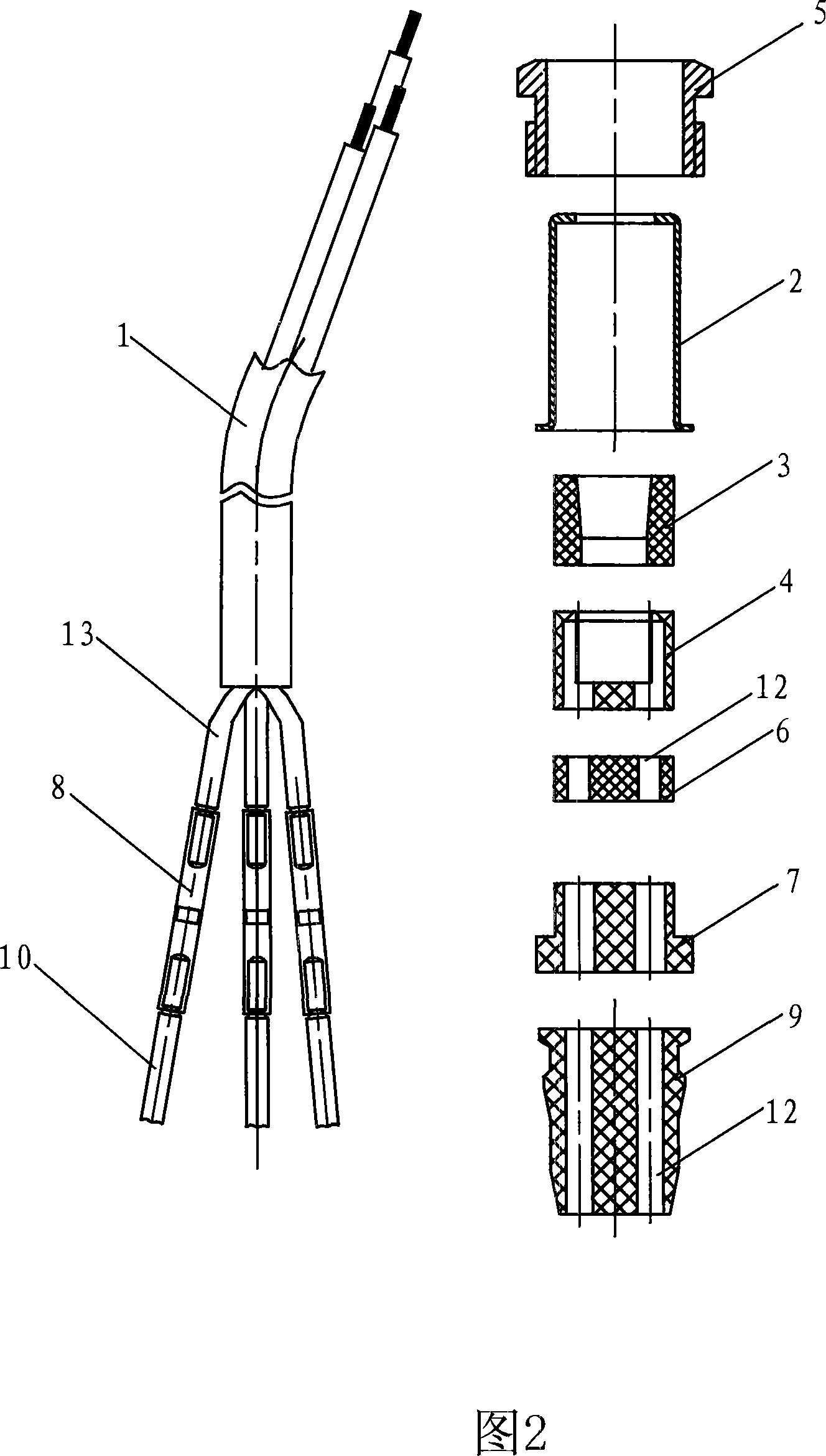

Leak-proof cable connection sealing device

ActiveCN101232217AAchieving tightnessTo achieve complete sealing requirementsCable inlet sealing meansSupports/enclosures/casingsEngineeringCopper

The invention discloses a leakproof sealing device for cable connection, which comprises a cable line and a terminal box cover. The invention is characterized in that the cable line has three synchronous sealing in different positions that are the sealing between a rubber insulation layer on the external surface of the cable line and a contacting piece, the clearance sealing between an inner core wire of the rubber insulation layer and a core wire, and the surface sealing of solid copper post head; compared with prior art, the leakproof sealing device for cable connection of the invention has the sealing principle in the three positions that a rubber sealing part which has elastic deformation is squeezed and therefore deformed under the exogenic action so as to enable the rubber sealing part to adhere closely with contacted objects, thus serving the sealing purpose.

Owner:ZHEJIANG DAYUAN PUMPS IND

Automatic packaging type intelligent dustbin

InactiveCN102826313ASimple structureThe packaging principle is simpleRefuse receptaclesWrapper twisting/gatheringEngineeringControl system

The invention discloses an automatic packaging type intelligent dustbin, which comprises a dustbin body, wherein a dustbin cover is arranged at the upper part of the dustbin body; a package bag sleeve corresponding to the dustbin cover is arranged in the dustbin body; a garbage bag is sleeved on the package bag sleeve and corresponds to a package mechanism arranged in the dustbin body; a storage chamber corresponding to the bottom of the box body is arranged at the lower part of the box body; a classification storage device is arranged in the storage chamber; and the package mechanism and the classification storage device are electrically connected with a control system. The automatic packaging type intelligent dustbin can be used for accommodating normal garbage and medical garbage and also can be used for sealing and sorting the medical garbage; by a motor and screw transmission structure and a simple connecting rod mechanism, the structure is simple; the package principle is simple; the package mechanism is simple; and the dustbin is easy to realize.

Owner:SHANDONG UNIV

Production technology for polycrystalline silicon

The invention discloses a production technology for polycrystalline silicon. The production technology includes the following steps: 1, a first coating, a second coating and a third coating are sequentially arranged on the surface of a crucible from inside to outside, and a crystalline silicone leftover material layer is laid; 2, a small quantity of raw polycrystalline silicon materials in the melted state is contained in the crucible, and the temperature of the crucible is controlled to be lower than the melting point of the crystalline silicone leftover material layer to enable the small quantity of melted raw polycrystalline silicon materials to form a crystallization protection layer; 3, in the vacuum environment, to-be-processed raw polycrystalline silicon materials are contained in the crucible, placed in a melting furnace with an electron beam generating device and processed through laser irradiation; 4, high-frequency induction heating is carried out in the vacuum environment, a slag forming constituent is added, plasma heating is carried out, steam-and-hydrogen-mixed argon is introduced, and directional solidification is carried out to obtain the polycrystalline silicon serving as the target product. By means of the production technology, the boron content, the phosphorous content and the metal impurity content can be effectively reduced, the complete polycrystalline silicon is prepared, long crystal dislocation is less, grain boundaries are proper, and the conversion rate of a polycrystalline silicon battery is increased.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

Tubular product hydraulic forming device capable of achieving inside and outside pressurization

The invention discloses a tubular product hydraulic forming device capable of achieving inside and outside pressurization and relates to a tubular product part forming device. The device solves the difficult problems that a traditional inner high-pressure forming die can achieve tubular product axial feeding but can not achieve tubular product outside pressure sealing, and a whole sealing container can be used for achieving the outside pressure sealing but not achieving the axial feeding. The tubular product hydraulic forming device comprises an upper die of a die, a lower die of the die, an upper template, a lower template, a left side punch and a right side punch, wherein a ring-shaped groove surrounding a cavity of the die is formed in the upper die, a ring-shaped protrusion is formed in the lower die, the groove is in clearance fit with the protrusion, a ring-shaped elastic sealing ring between the groove and the protrusion and a sealing ring among the left side punch, the right side punch and a boss of the lower die jointly ensure the tubular product outside pressure sealing, a die splitting mode that the groove is in clearance fit with the boss is adopted to ensure that no leakage of the tubular product outside pressure happens, under the joint effects of the inside pressure, the outside pressure and the axial feeding, plastic deformation occurs in the tubular product, and formability of the low-plastic tubular product is improved.

Owner:HARBIN INST OF TECH

Oil-charging jack capable of hot plugging under water

ActiveCN106785658AAchieving tightnessRealize live plugging and unpluggingCouplings bases/casesCavity pressureEngineering

The invention relates to a water-tight electric connector for an ocean field, and provides an oil-charging jack capable of hot plugging under water. The oil-charging jack comprises a plug and a socket which are matched mutually; the plug comprises an outer shell and an inner shell; the inner shell comprises an elastic outer wall and a rigid inner container; a plurality of independent cylindrical jack components are arranged in an oil cavity. When the jack is plugged into water, out of water or under water, by the deformation of a plug oil-charging cavity pressure balance membrane, balance of pressures inside and outside an oil-charging cavity is regulated, so that a pressure gradient does not exist inside and outside the oil cavity, deep sea sealing and plugging under water are realized, switching on and switching off of a contact pin and the jack are carried out in insulating oil, an electric arc generated during switching on and separating can be effectively annihilated, and hot plugging is realized.

Owner:SHANDONG LONGLI ELECTRONICS

Engine oil consumption measuring device and automobile oil consumption management system

ActiveCN103674148AAccurately measure real-time fuel consumptionOvercome high oil temperatureRelative volume flow measurementsMeasurement precisionManagement system

The invention discloses an engine oil consumption measuring device and an automobile oil consumption management system using the engine oil consumption measuring device. The engine oil consumption measuring device comprises a flow meter, a one-way valve and an oil storage box, wherein the flow meter and the one-way valve are arranged on an oil supply pipe of an engine, the oil storage box is used for collecting fuel returning from an oil return pipe of the engine and conveying the fuel to the oil supply pipe of the engine, the upper portion of the oil storage box is provided with an oil inlet connected with the oil return pipe, the bottom of the oil storage box is provided with an oil outlet connected with the oil supply pipe, the connecting portion of the oil outlet and the oil supply pipe is located on the downstream of the one-way valve, and a control part used for controlling the opening and closing state of the oil outlet according to the height of the fuel in the oil storage box is arranged in the oil storage box. Due to the fact that the oil storage box is additionally arranged, the problem that measurement precision is influenced due to that the engine return oil is high in temperature and contains bubbles is effectively solved, real-time fuel consumption amount of the engine is precisely measured, and accurate oil consumption measurement is provided for engines of different types.

Owner:厦门华磊达汽车管理服务有限公司

Low temperature co-fired ceramic-based micro-electromechanical system (MEMS) packaging method

InactiveCN101875481ARealize transportationExchangeDecorative surface effectsChemical vapor deposition coatingCo-fired ceramicOpen cavity

The invention discloses a low temperature co-fired ceramic-based micro-electromechanical system (MEMS) packaging method. The method comprises the following steps of: preparing an upper low temperature co-fired ceramic substrate and a lower low temperature co-fired ceramic substrate respectively and forming a three-dimensional electrically-interconnected network, an embedded micro-channel and an open cavity in the upper substrate and / or the lower substrate; aligning the upper substrate with the lower substrate for packaging, packaging components and parts in the cavity and communicating the micro-channel with the cavity and the outside of a packaged body; and connecting an external micro-tube to the outlet of the micro-channel, which leads to the outside of the package body, and realizing gas or liquid flow between the cavity and the outside through the external micro-tube. The method has the advantages of improving the integration level, the stability and the flexibility of MEMS packaging, realizing vacuum packaging and heat dissipation of the components and parts in the cavity by conveying a circulating radiating medium through the micro-channel and conveying detection samples and the like to medical, biological or chemical MEMS components and parts in the packaging cavity through the micro-channel.

Owner:PEKING UNIV

Sliding part

Provided is a sliding part providing functionality for both leak prevention and lubrication with no relation to the magnitude of the pressure difference between the inner and outer circumference of a sliding face by drawing in a fluid with a cavitation region on the upstream side of a depressed portion, such as a dimple formed on the sliding face, and generating positive pressure between the sliding faces on the downstream side of the dimple. A sliding part is characterized in that: dimples are provided on the sliding face on one of a pair of sliding parts that slide relative to each other; a cavitation forming region on the upstream side of each dimple is disposed near a low pressure fluid side and a positive pressure generating region on the downstream side is disposed near a high pressure fluid side; and the fluid drawn in with the cavitation forming region of the dimple is returned to the high pressure fluid side from the positive pressure generating region by passing through the inside of the dimple.

Owner:EAGLE INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com