Ozone generator for use in membrane electrode electrolysis

A technology of ozone generator and membrane electrode, which is applied in the electrolysis process, electrolysis components, cells, etc., can solve problems such as excessive force, leakage of gas and raw water, and sealing failure, and achieve the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

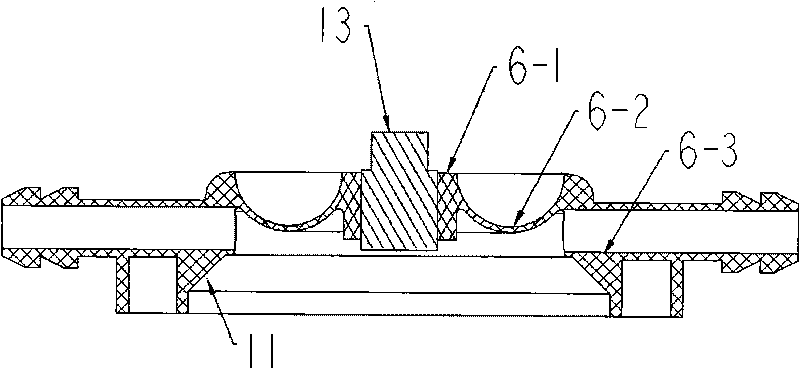

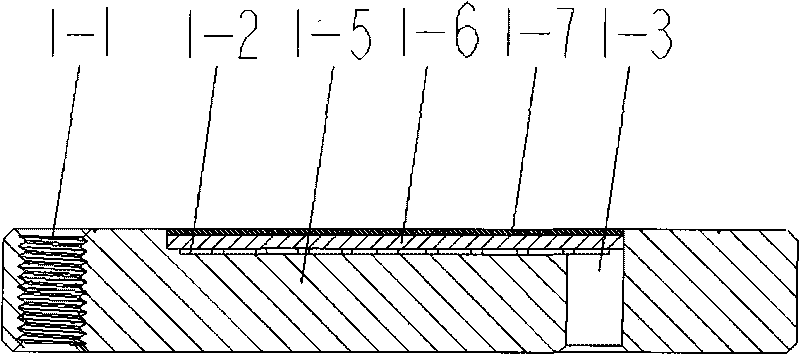

[0033] Embodiment: membrane electrode electrolysis ozone generator (see Figure 1-Figure 4), the cathode structure 1 is provided with a cathode fixed plate 1-5, the cathode fixed plate 1-5 is made of metal titanium material, the periphery of the cathode fixed plate 1-5 is uniformly provided with screw holes 1-1, the cathode fixed plate 1-5 5 is provided with an annular diversion groove 1-2, and the middle part of the annular diversion groove 1-2 is provided with a transverse groove 1-4, and the annular diversion groove 1-2 communicates with the drainage channel through the groove 1-4. Holes 1-3 are connected. Put cathode microporous plate 1-7 on cathode fixed plate 1-5, put cathode catalyst layer 1-8 on cathode micropore plate 1-7, its layer thickness is 0.1~5mm, put on cathode catalyst layer 1-8 Proton exchange membrane 2 (DuPont Nafion 117). On the opposite side of the proton exchange membrane 2 and the cathode structure of the electrolytic ozone generator, an anode cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com