Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Slow down depreciation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Forging machining method of large-sized bar materials of TC4 (Ti-6Al-4V) titanium alloy

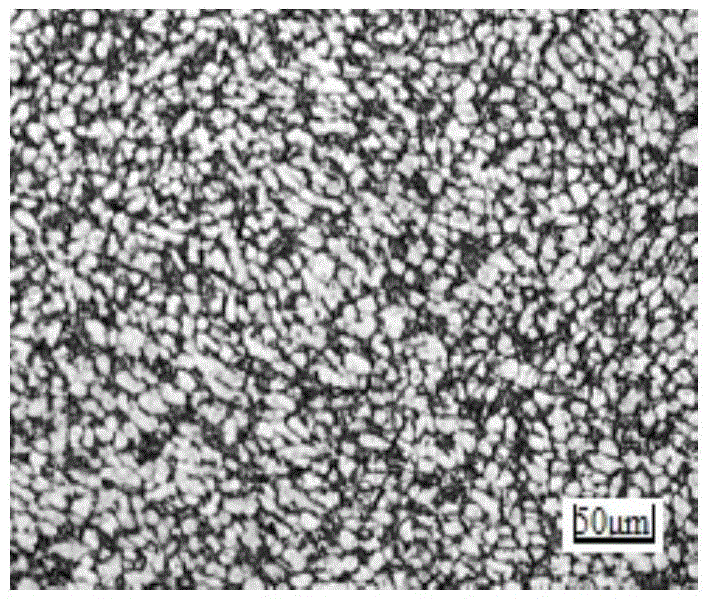

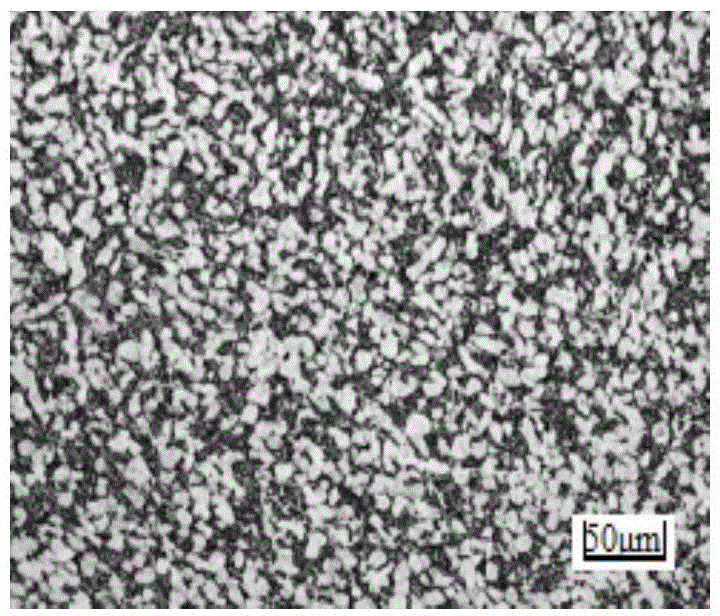

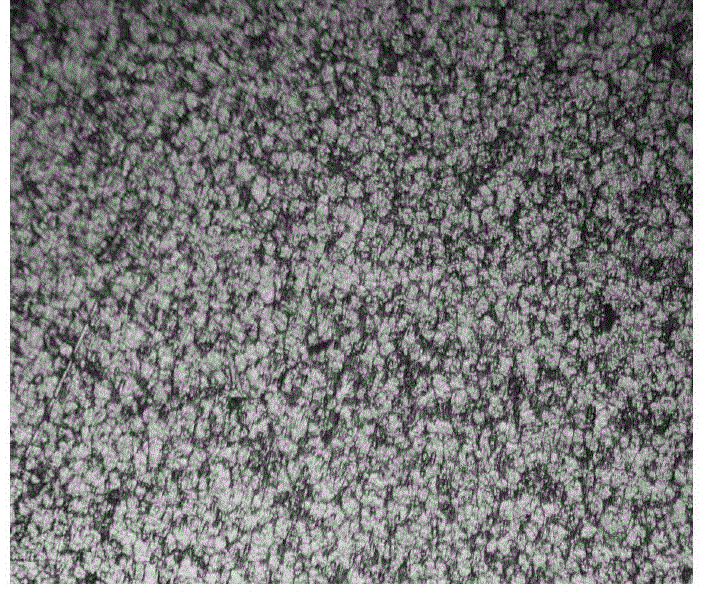

InactiveCN104070125ALess investmentSave energyForging/hammering/pressing machinesElectric arc furnaceIngot casting

The invention relates to bar material forging machining method of titanium alloy, particularly to a forging machining method of large-sized bar materials of TC4 (Ti-6Al-4V) titanium alloy. The forging machining method is characterized by comprising the following steps of step 1, performing cogging forging, step 2, performing intermediate forging above a phase transformation point, step 3, performing intermediate forging below the phase transformation point, step 4 and step 5, performing finished product forging and obtaining the phi 200 to 300 mm and 2000 to 3000 mm length of large-sized bar materials of the TC4 titanium alloy finally. Compared with the prior art, a large-sized ingot casting and a large-tonnage forging device are not required and the industrialized production can be achieved through an ordinary industrial 3 ton ingot and a small-tonnage forging press and the equipment investment is small, only a 3 tons of electric arc furnace and a 3000 tons of forming oil press which is matched with the electric arc furnace need to be invested in the phi 600 of 3 ton ingot, the small-tonnage forging press such as a 1600 tons of forging press needs to be invested in the forging process, and accordingly the equipment investment is significantly reduced.

Owner:宁夏中色金航钛业有限公司

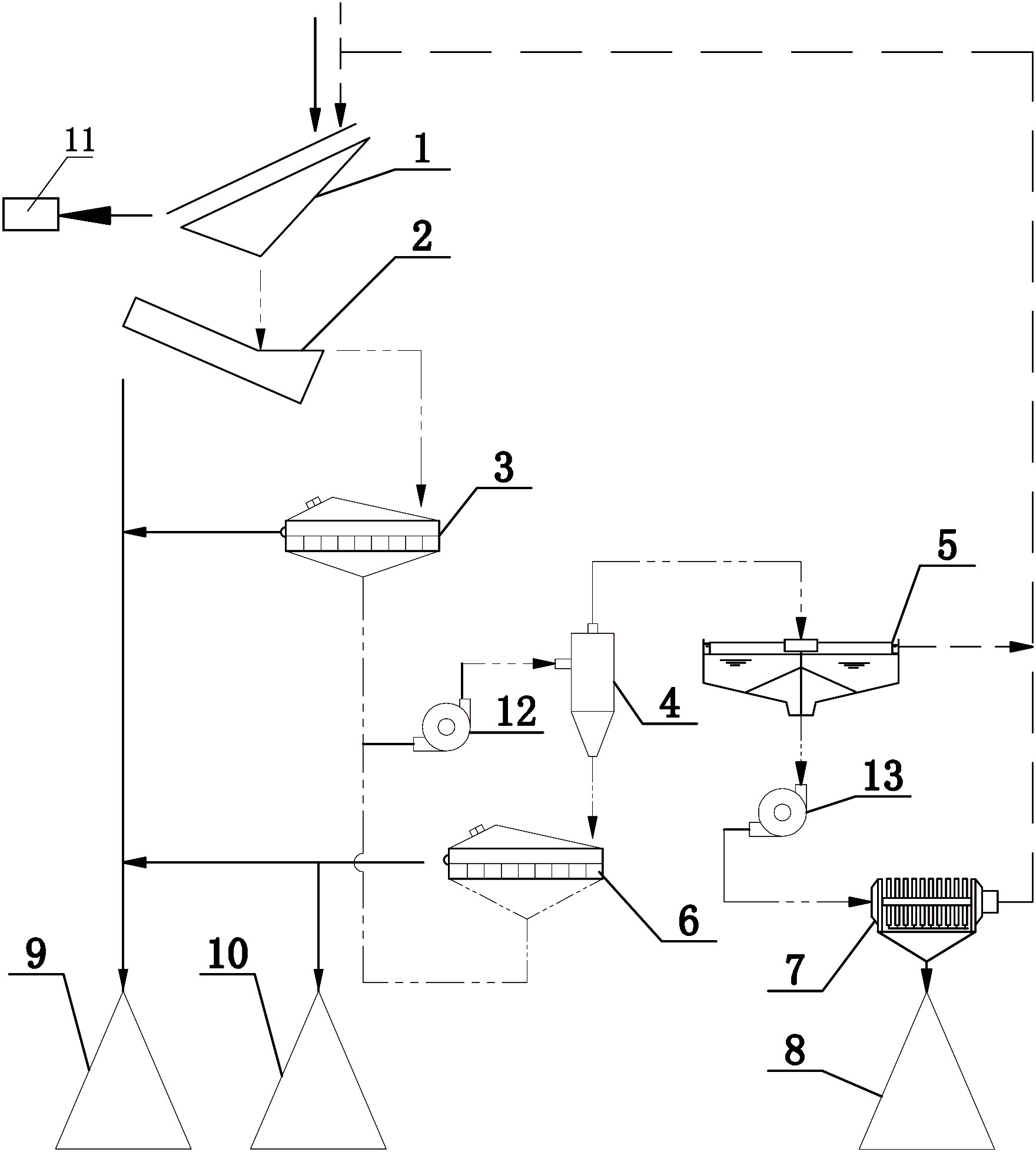

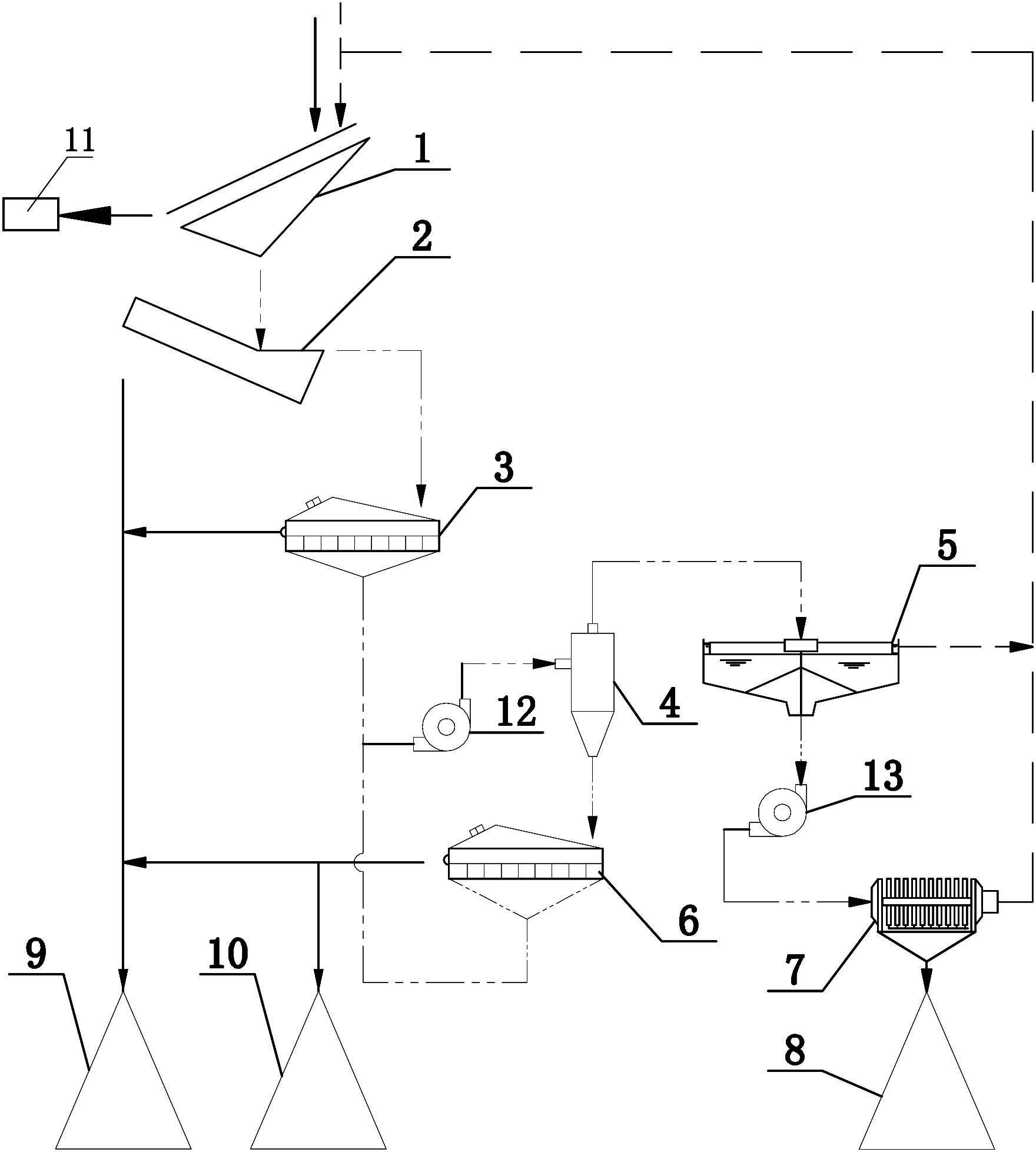

Method for grading and utilizing waste material of sandstone system production

InactiveCN101961674AAchieve recyclingImprove resource utilizationSievingScreeningWastewaterEngineering

The invention relates to a method for grading and utilizing waste material of sandstone system production, including the following steps: 1) sieving and washing are carried out; 2) slurry obtained by sieving is subject to separation of fine sand powder and slurry by virtue of a hydrocyclone grading device; 3) the fine sand powder is subject to high frequency sieving and dewatering, and the slurry is placed into a setting device, so as to further separate water and concentrated slurry; 4) water is returned to the washing step, and the concentrated slurry is subject to filter pressing or filtering and then is delivered to a waste material stock yard. In the method for grading and utilizing waste material of sandstone system production provided by the invention, a hydrocyclone grading device is added in slurry sand grading production process to separate fine sand powder and slurry, and a high frequency sieving dewater procedure is adopted, recycling of fine sand powder from slurry is realized, by adopting the method of the invention, more than 90% of useful material can be recycled from slurry, and more than 70% of recycling can be realized after waste water is purified.

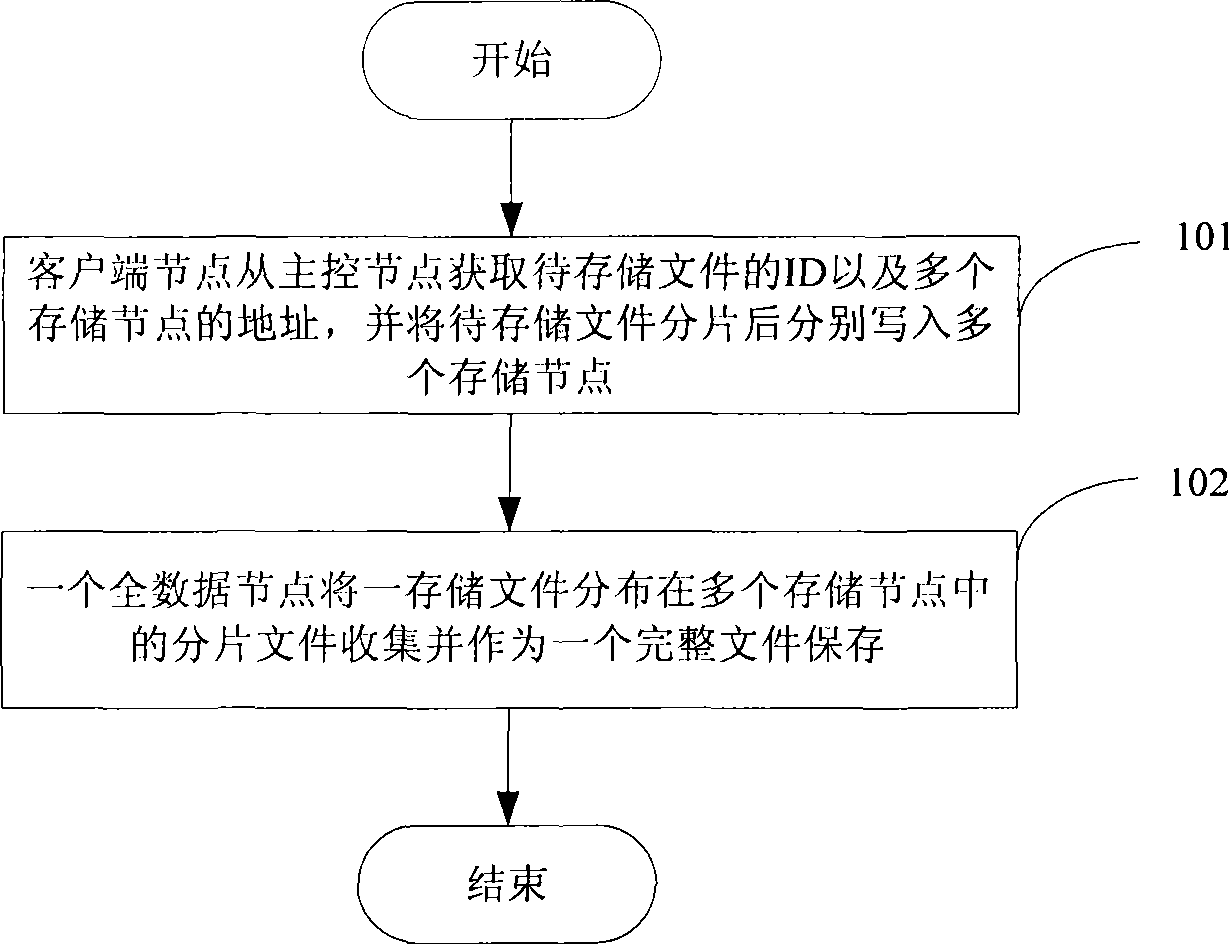

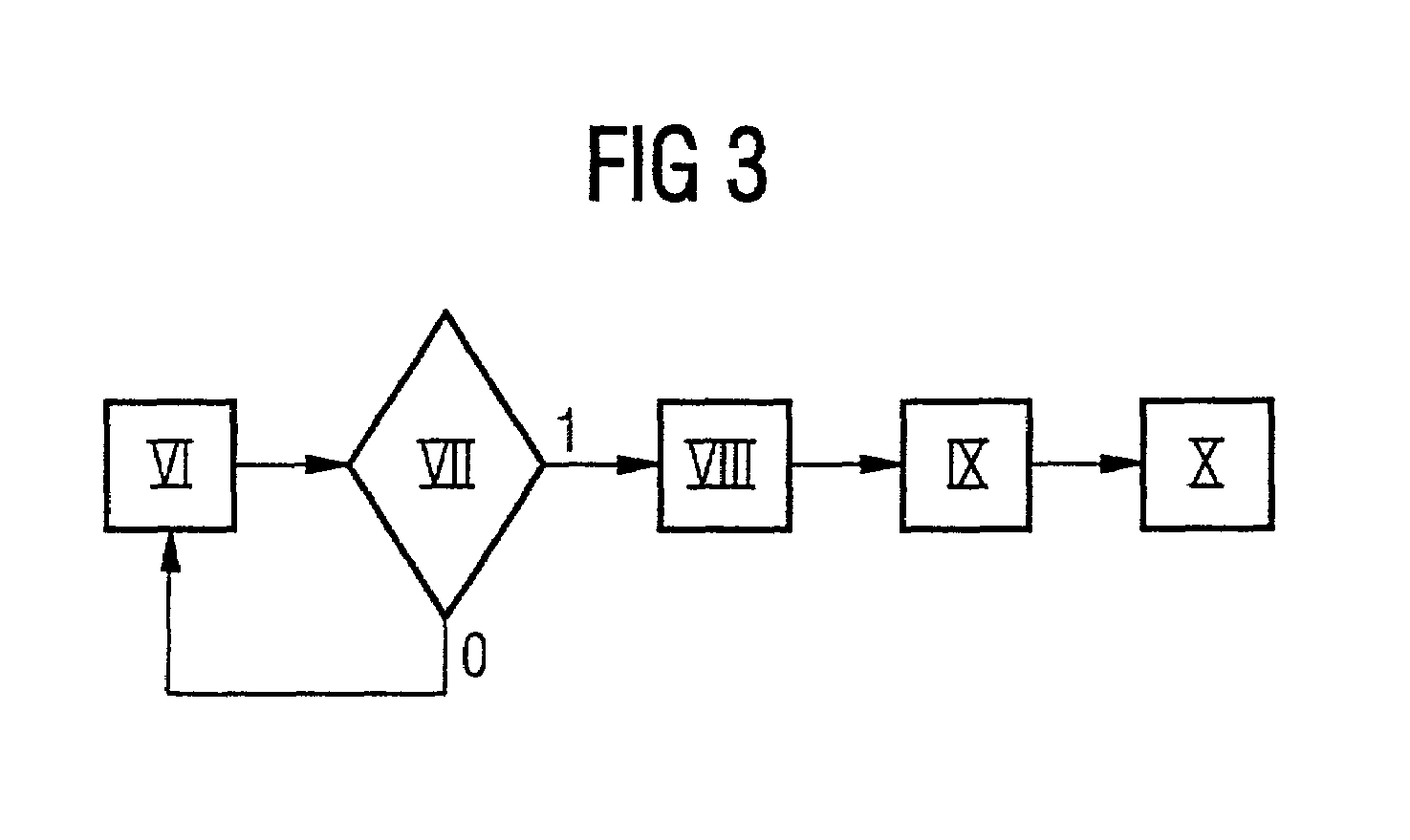

Data processing method and system

ActiveCN101510223AEnergy savingSlow down depreciationEnergy efficient ICTDigital data information retrievalClient-sideData processing

The invention discloses a data processing method and a data processing system which are used for saving energy and lowering equipment depreciation speed. The data processing method comprises the following steps: a global data node in a plurality of storage nodes obtains fragmented files corresponding to a storage file and distributed in the plurality of storage nodes, merges the fragmented files, and stores the merged file; and when a client node request for reading the stored file is learnt, the merged file is sent to the client node. By adopting the technical proposal provided by the embodiment of the data processing method and the data processing system, the merged file is stored, and consequently only one storage node needs to be started in file reading, thus saving energy and lowering equipment depreciation speed.

Owner:CHENGDU HUAWEI TECH

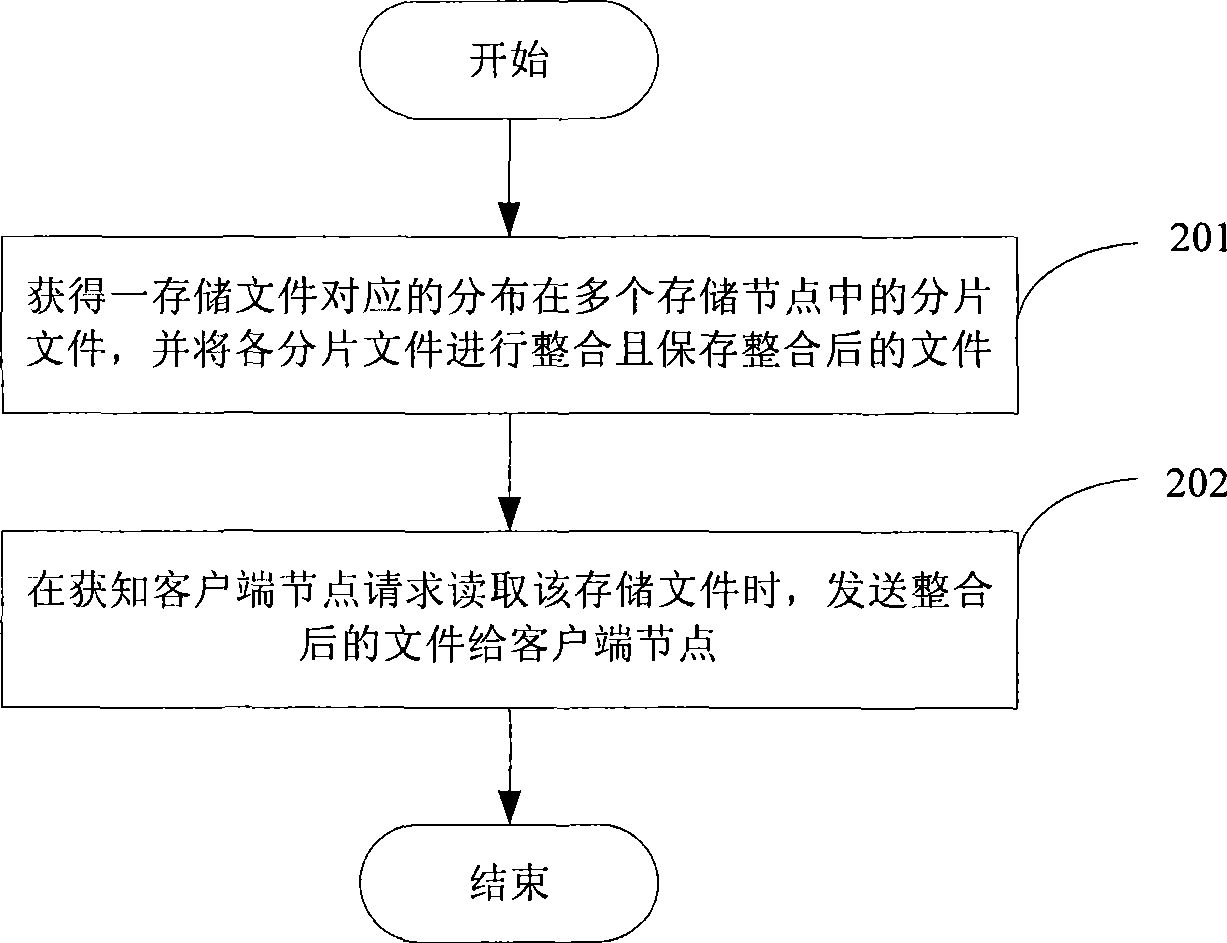

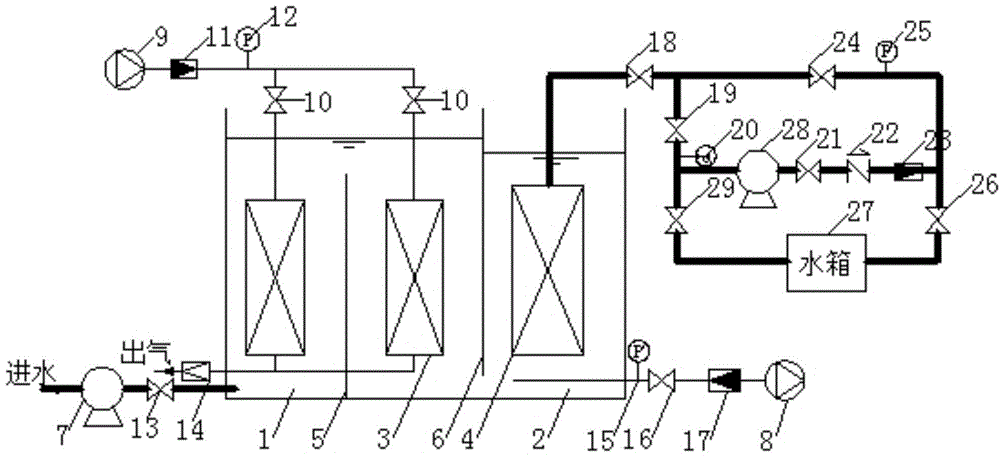

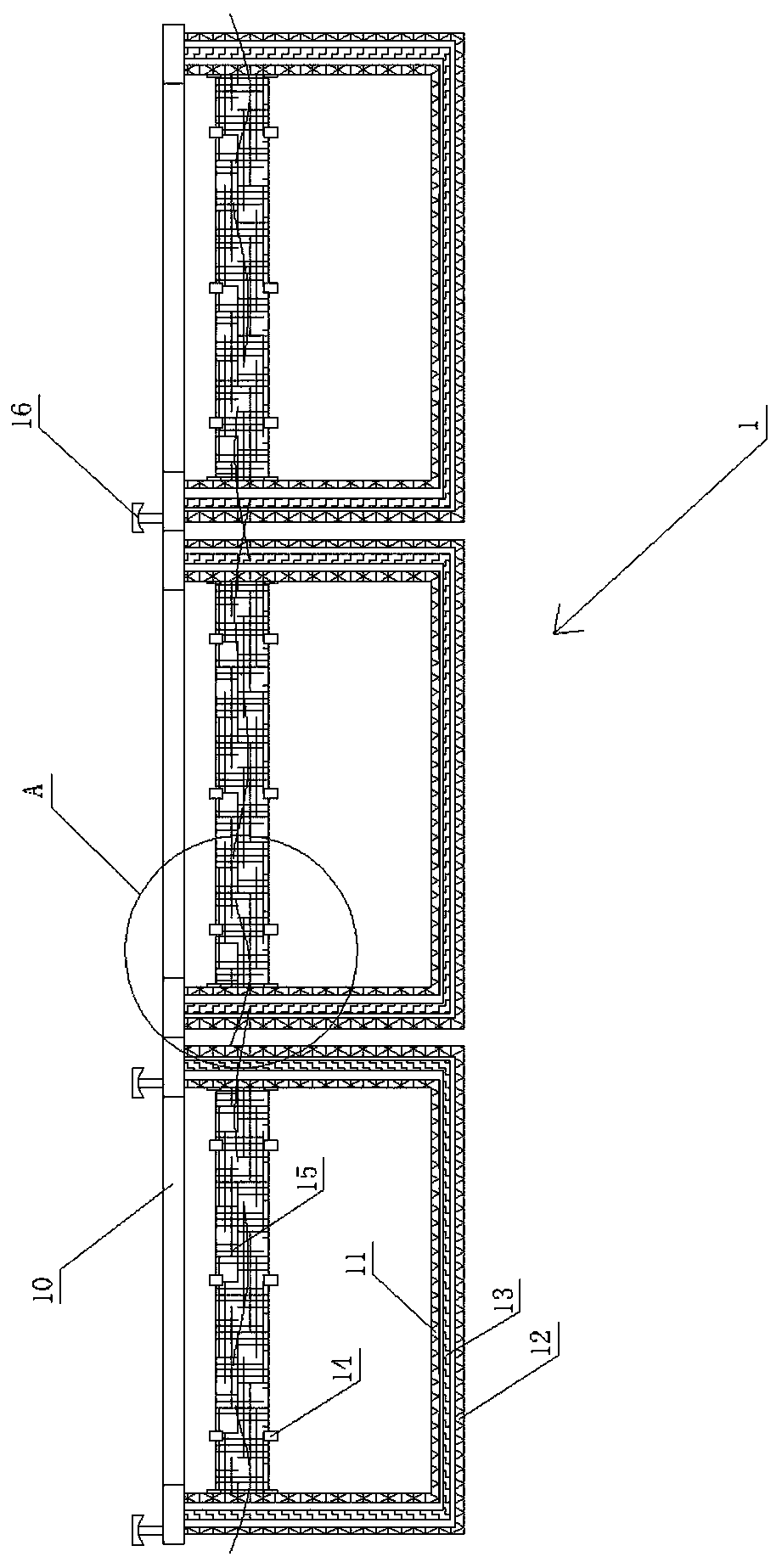

MABR-MBR combined type sewage treatment device and treatment method

InactiveCN104909520AReduce volume loadReduce energy consumptionMultistage water/sewage treatmentOxygenMembrane reactor

The invention belongs to the technical field of sewage treatment, and discloses an MABR-MBR combined type sewage treatment device. The device comprises a pre-treatment unit, an MABR unit, an MBR unit and a backflushing unit matched with the MBR unit, wherein the four units are arranged along a sewage flowing direction. The invention further discloses a control method thereof. The effect of removing nitrogen and phosphorous is well realized through the sufficient combination of advantages of two membrane reactors. Since the bubbleless aeration is adopted in an MABR pond, the utilization rate of the oxygen is high and nearly can achieve 100%. Since the mass transfer range of the oxygen is small, denitrifying bacteria and denitrifying phosphate-accumulating organism are mainly existent in the water to finish denitrification and phosphorous releasing process of the nitrate, and the performance of removing nitrogen and phosphorous in the next stage is strengthened. After entering an aerobic MBR pond, the aerobic bacteria further remove residual nitrite and ammonia nitrogen, and the aerobic phosphorous-accumulating bacteria finish the phosphorous removal work. Through the previous treatment of the MABR, the volumetric loading of the MBR is reduced.

Owner:TIANJIN CHENGJIAN UNIV

Mixed child-mother core assembly molding technology

ActiveCN107350429ASlow down depreciationIncrease the number ofAdditive manufacturing apparatusFoundry mouldsUltimate tensile strengthProduct Part

The invention discloses a mixed child-mother core assembly molding technology. A 3D printing molding technology and a sand mixing molding technology are combined, a part which is close to a product part having a plurality of structural features adopts 3D printing, and the other parts which have less structural features adopt the traditional sand mixing molding technology method, therefore an assembled sand mold which works through cooperative using of a mother core and a child core is formed. Based on the advantages of an original 3D printing molding technology, a traditional sand mixer production technology is introduced, the two molding technologies are combined with each other, further the cost of raw materials and the equipment investment cost are lowered, and meanwhile, child-mother separated core combination is conducted on a sand molding part which is brought out of a casting and the mold thickness which is brought out of a casting system and improves the strength so as to widen thinking for later multi-technology combination; the number of castings in a single sand box is increased, the sand box utilization ratio and the production efficiency are improved, the dependence on manual work is reduced at the same time, the cost of 3D printing raw materials and the depreciation of the equipment are reduced, and meanwhile, waste of molten iron is avoided, and the purposes of cost reduction and efficiency improvement are achieved.

Owner:四川共享铸造有限公司

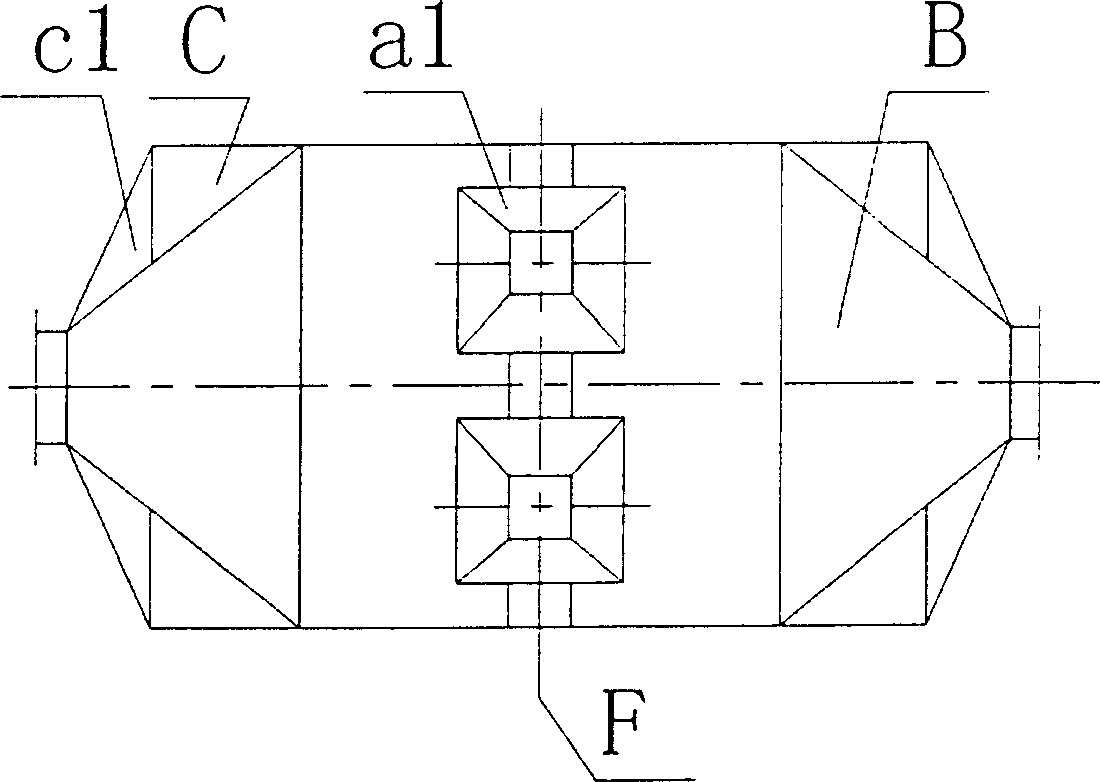

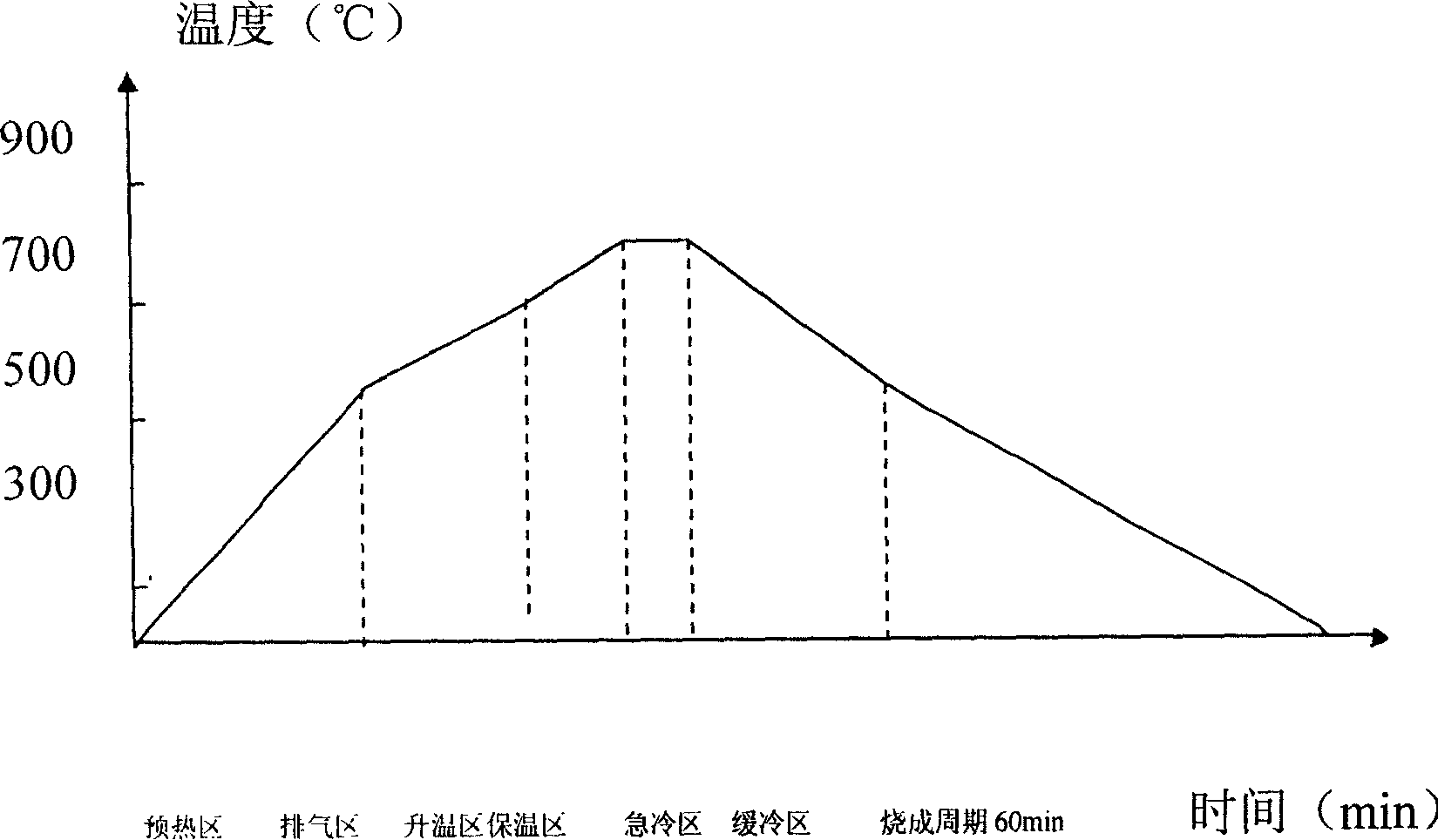

Method of producing polishing brick by low-temperature sintering

The invention discloses a production method for archaizing bricks by low-temperature sintering. The method comprises using cullet as a major raw material, sodium tripolyphosphate (Na3P5O10) as a secondary raw material, and other other low-priced ceramic raw materials, and producing archaizing bricks suitable for one rapid firing (burning time of 55 minutes and firing temperature <= 900DEG C). The raw materials comprise: waste glass 42-60%, cooked bauxite 18-25%, white mud 15-2%, bentonite 3-8%, sodium tripolyphosphate 5-8%, and pigment 3-4%. Prescription referred to the specific chemical composition, Al2O3 52-60%, SiO2 23-26%, Fe2O3 0-1%, CaO 6-8, MgO 0.5-1.0%, KNaO 8-10%, and others 3-4%. The formula can also include various plasticizers and electrolytes. The invention has the advantages of low energy consumption and simple process.

Owner:钟旭东

Daptomycin extraction method

ActiveCN105481950AReduce healthy stressLittle side effectsPeptide preparation methodsFiltrationGradient elution

The invention relates to the technical field of antibiotic production, in particular to a daptomycin extraction method. The method includes the following steps of firstly, filtering daptomycin fermentation liquor through a ceramic film; secondly, making filtered liquor pass through large-pore adsorption resin so that eluant can be collected; thirdly, mixing NM-Q anion exchange resin with the obtained eluant, and collecting eluant; fourthly, making the eluant obtained in the third step pass through a reverse phase silica gel MNsil-C18 column, conducting gradient elution on the column through an ammonium acetate ethanol solution, and collecting eluant; fifthly, concentrating the daptomycin eluant obtained in the fourth step, adding calcium acetate and isopropyl alcohol, and conducting standing, crystallization, suction filtration and drying to obtain daptomycin crystallization powder. The method has the advantages that the virulent acetonitrile solution is not used as the eluant, pressure on the environment and health of production personnel is reduced, the use of acid-base regulator is reduced, and the production cost is reduced.

Owner:LIVZON GROUP FUZHOU FUXING PHARMACEUTICAL CO LTD

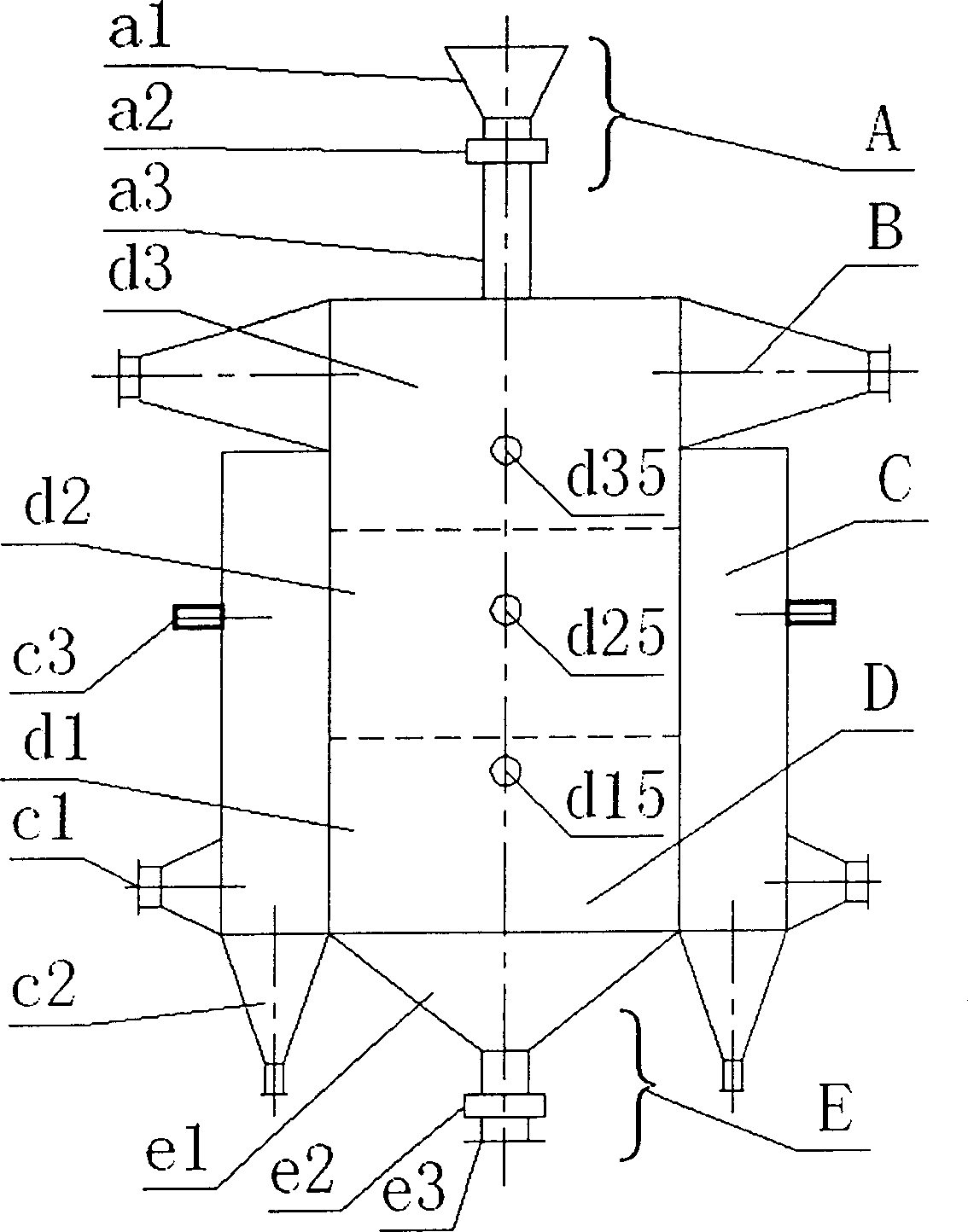

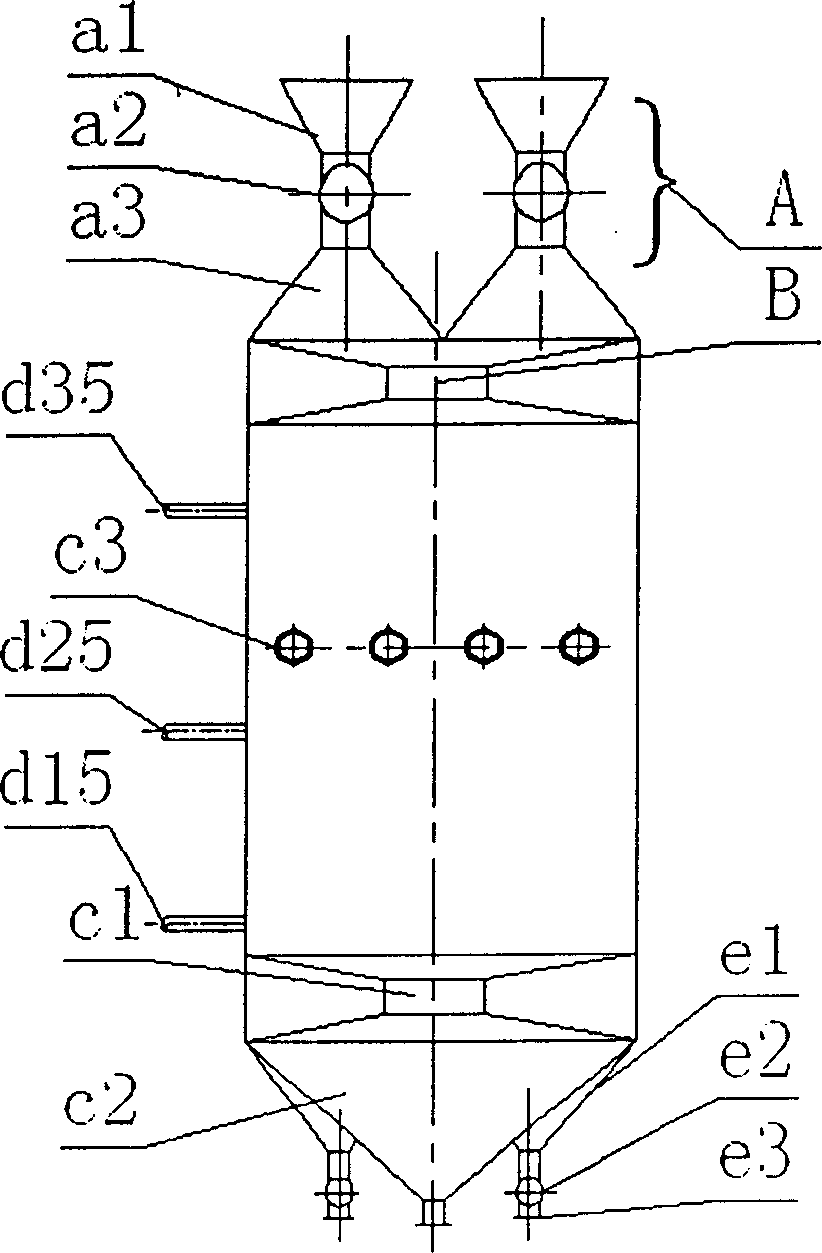

Coupling multistage device with active carbon purifying waste gas

InactiveCN1820819ATake advantage ofCompact structureDispersed particle separationActivated carbonMaterial distribution

The present invention provides coupling multistage apparatus with active carbon to purify waste gas, and the apparatus is used in desulfurizing, denitrating, dedusting, eliminating heavy metal and eliminating organic compound of waste gas. It consists of pre-purifying room, movable adsorption bed, purified gas outlet, material feeding mechanism, and discharging mechanism. Each of the material feeding mechanism and the discharging mechanism consists of material bin, material guide pipe and gas trap valve. The movable adsorption bed consists of one or several adsorption sections superposed sequentially, the material feeding mechanism is set on the top, the discharging mechanism is set in the bottom, and the pre-purifying room and the purified gas outlet are set in the side. The apparatus has compact structure, simple material distribution, complete functions, less resistance, high purifying effect, fully use of active carbon, long service life and low running cost.

Owner:史鱼海

Method of producing archaistic brick by low-temperature sintering

The invention discloses a production method for archaizing bricks by low-temperature sintering. The method comprises using cullet as a major raw material, sodium tripolyphosphate (Na3P5O10) as a secondary raw material, and other other low-priced ceramic raw materials, and producing archaizing bricks suitable for one rapid firing (burning time of 55 minutes and firing temperature <= 900DEG C). The raw materials comprise: waste glass 42-60%, cooked bauxite 18-25%, white mud 15-2%, bentonite 3-8%, sodium tripolyphosphate 5-8%, and pigment 3-4%. The method comprises proportioning the ingredients, ball-milling, sifting, removing iron, spray-drying, pressing and molding, drying, spraying water, proportioning glaze ingredients, ball-milling, sifting and removing iron, aging, spraying transparent glaze, washing edge, sintering, grinding edge, separating, and packaging. The invention has the advantages of low energy consumption and low cost.

Owner:钟旭东

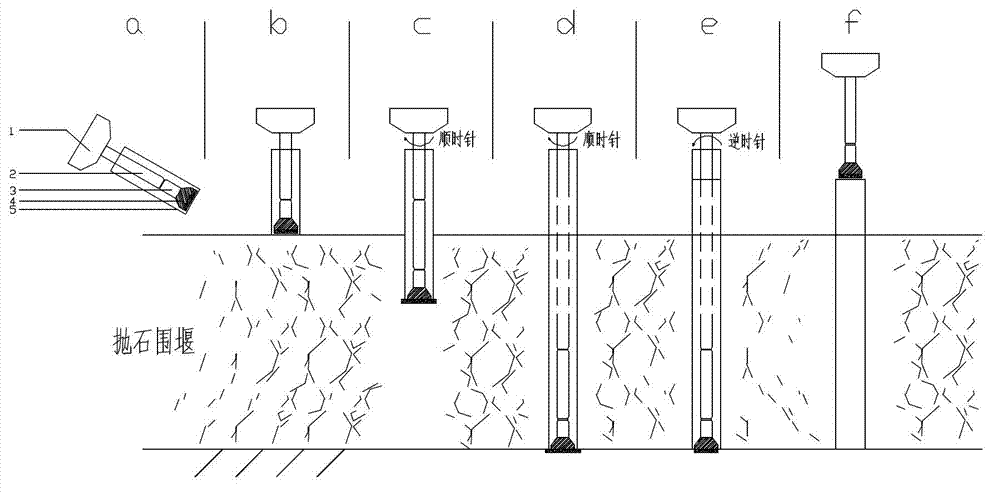

Eccentric drilling hole-forming method of down-the-hole drill

InactiveCN103114807AImprove drilling efficiencySlow down depreciationDrilling machines and methodsEffective radiusDrill hole

Disclosed is a hole-forming method of an earth-rock structural body. A down-the-hole drill is used for providing power. An eccentric drilling bit is used for punching and drilling in a rotary mode. When drilling, the eccentric drilling bit punches and smashes rocks, and smashed rock powder is blown away by gas from bottom to top and along gaps; the eccentric drilling bit clockwise rotates, and therefore the effective rotary radius of a drilling hole and the diameter of a drilled hole are increased, and a bushing is cast; after casting of one bushing is finished, a drilling rod and a bushing are connected, continuously, the eccentric drilling bit punches and drills in a rotary mode, and so on, until the eccentric drilling bit penetrates through the rocks. After penetrating trough the rocks, the eccentric drilling bit anticlockwise rotates, and effective radius of the eccentric drilling bit is reduced and retracts in the bushing, the drilling rod and the drilling bit are pulled out, and continuous bushings form a smooth hole duct. The method is convenient to construct and easy to operate, ensures that hole-forming efficiency is substantially improved and hole-forming expense is obviously reduced.

Owner:TIANJIN PORT ENG INST LTD OF CCCC FIRST HARBOR ENG +2

Heat pipe, manufacturing method of heat pipe and equipment comprising heat pipe

InactiveCN109764708AFlexible approachRich technical meansIndirect heat exchangersWaste productEnergy consumption

The invention discloses a heat pipe, a manufacturing method of the heat pipe and equipment comprising the heat pipe, mainly relates to a capillary core of the heat pipe and a manufacturing method of the capillary core, and belongs to the technical field of heat conduction. According to the manufacturing method, a positioning tool and a metal net are mainly used, metal powder is arranged and limited in a specific space position in a pipe shell, and the technical problems that in the sintering process in which a traditional method is adopted, the metal powder is bonded with a core rod, when thecore rod is pulled out after sintering, the capillary core is prone to damage, and even a waste product occurs, and the technical problems that core rod is used for separating the reducing atmospherefrom the metal powder, so that the reducing effect is poor, secondary sintering is generally needed, and the energy consumption and the thermal pollution are large can be comprehensively or correspondingly solved; and the technical situations that the capillary core of the sintered layer is damaged due to the deformation processes of bending, flattening and the like can be relieved or avoided, andthe process route in which bending is carried out first, and then sintering is carried out can be realized. The method is applied to manufacturing of the heat pipes (including hot columns and ultra-thin heat pipes). The heat pipe is applied to equipment or a device requiring heat transfer or heat dissipation through the heat pipe.

Owner:刘康

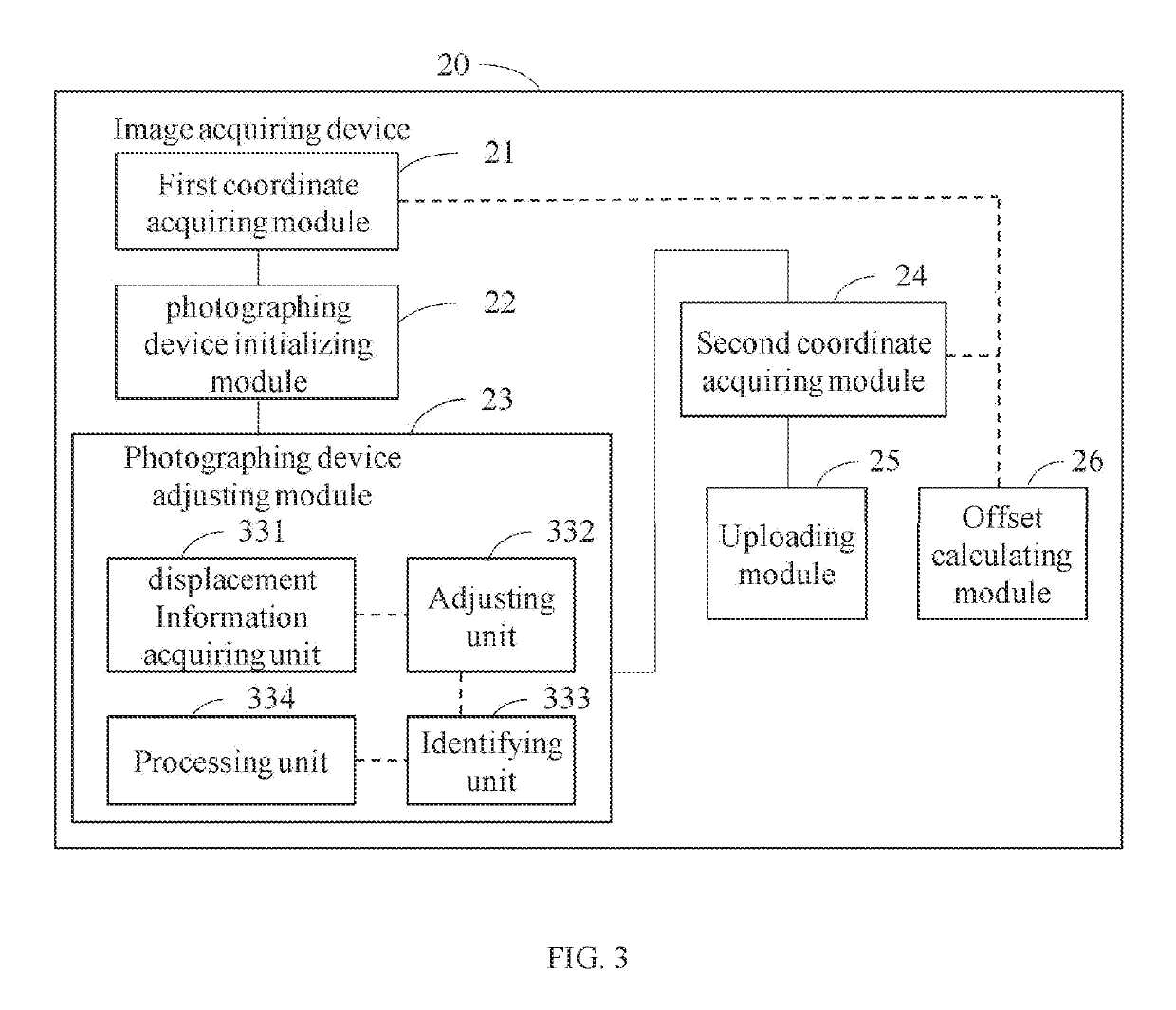

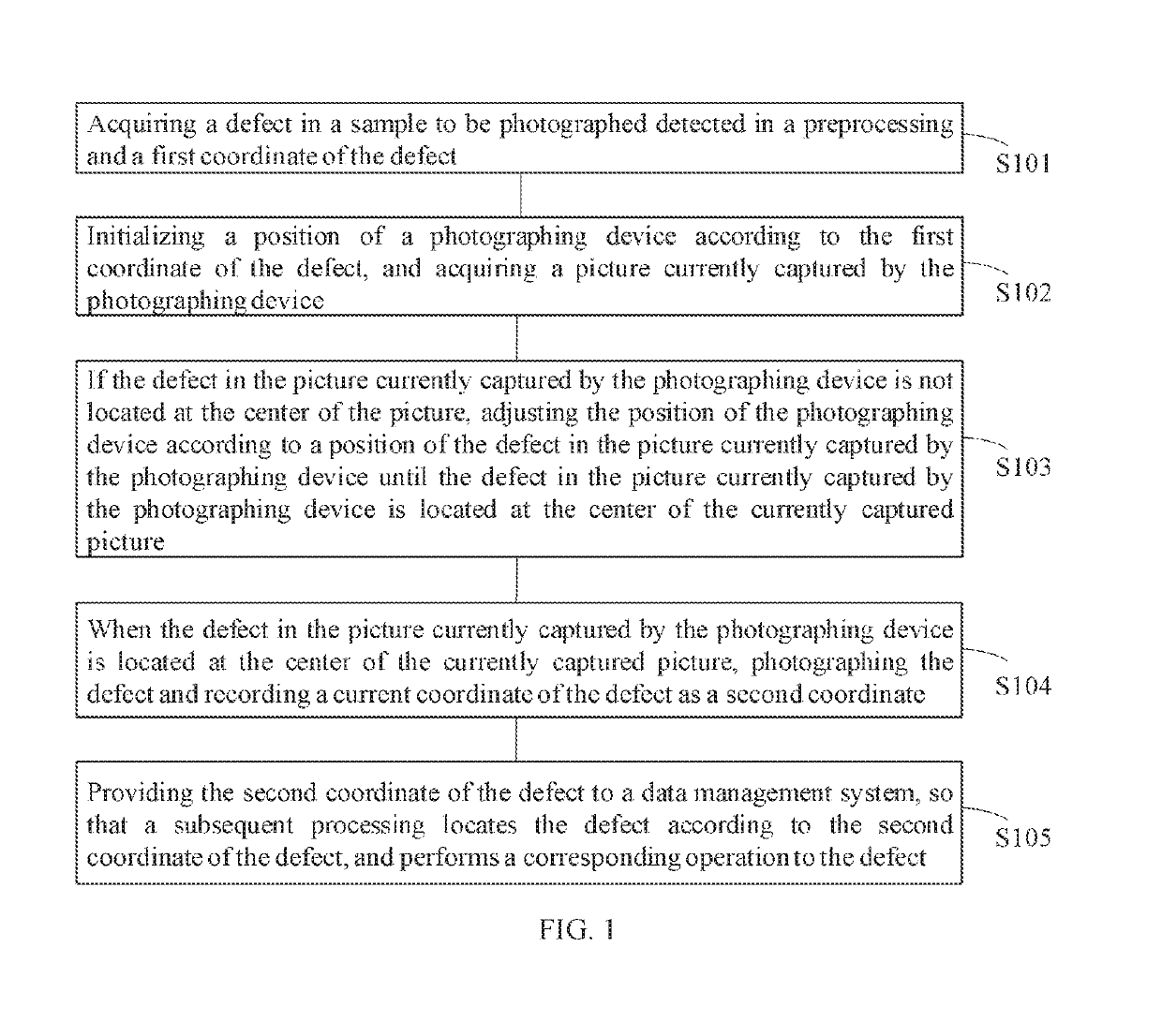

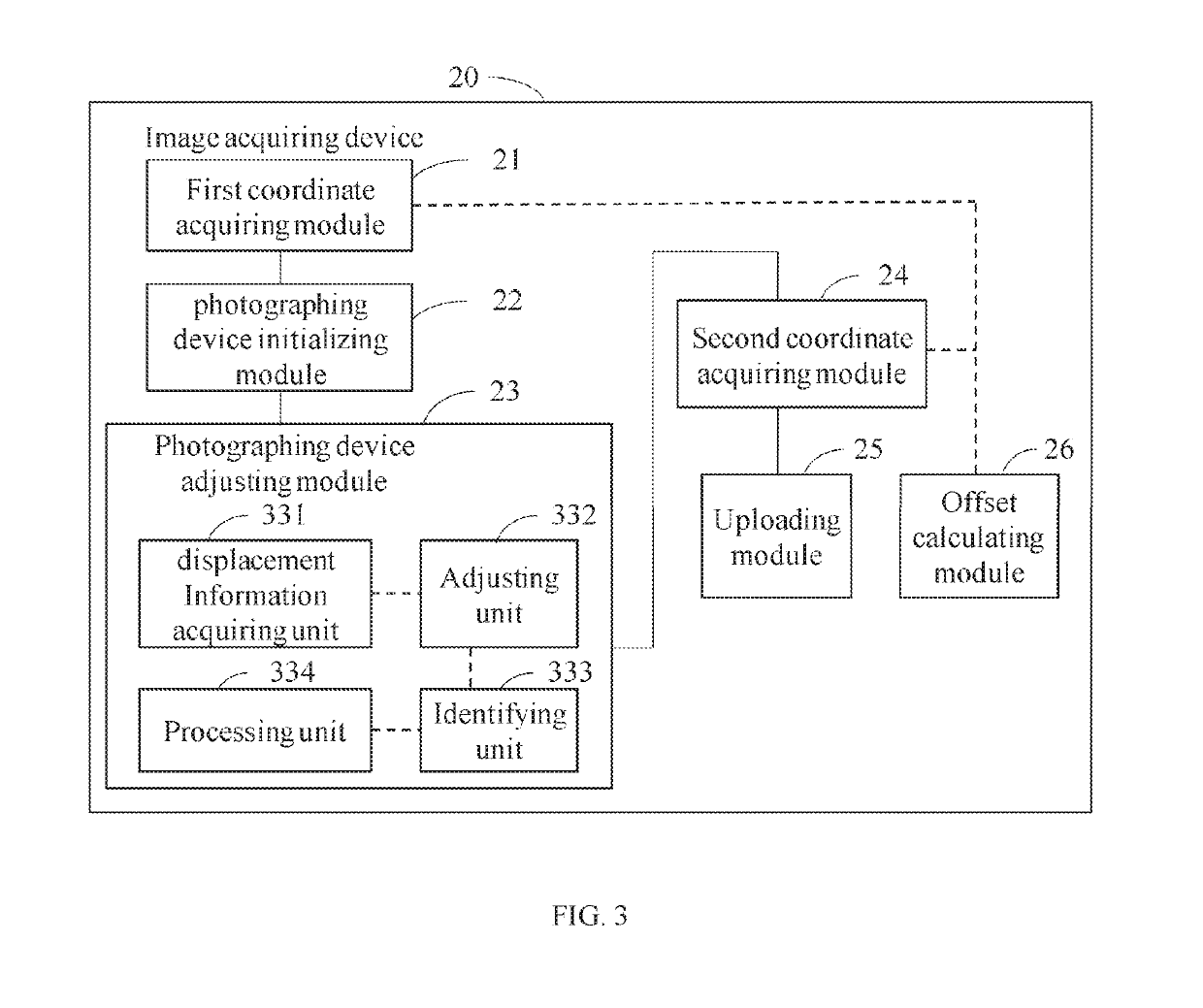

Image acquiring device and method of correcting coordinates thereof

ActiveUS20190096054A1Improve efficiencyReduce equipment depreciationTelevision system detailsImage enhancementData managementComputer vision

The present application provides an image acquiring device and a method of correcting coordinates of the image acquiring device, wherein the method includes: detecting a coordinate of a defect detected in a process; initializing a position of a photographing device according to the coordinate of the defect detected in a preprocessing; then adjusting the position of the photographing device according to a position of the defect in the picture currently captured by the photographing device, so that the defect is located at the center of the picture currently captured by the photographing device; recording the coordinate of the defect at the center of the picture; and providing the coordinate of the defect at the center of the picture to a data management system.

Owner:CHONGQING HKC OPTOELECTRONICS TECH CO LTD +1

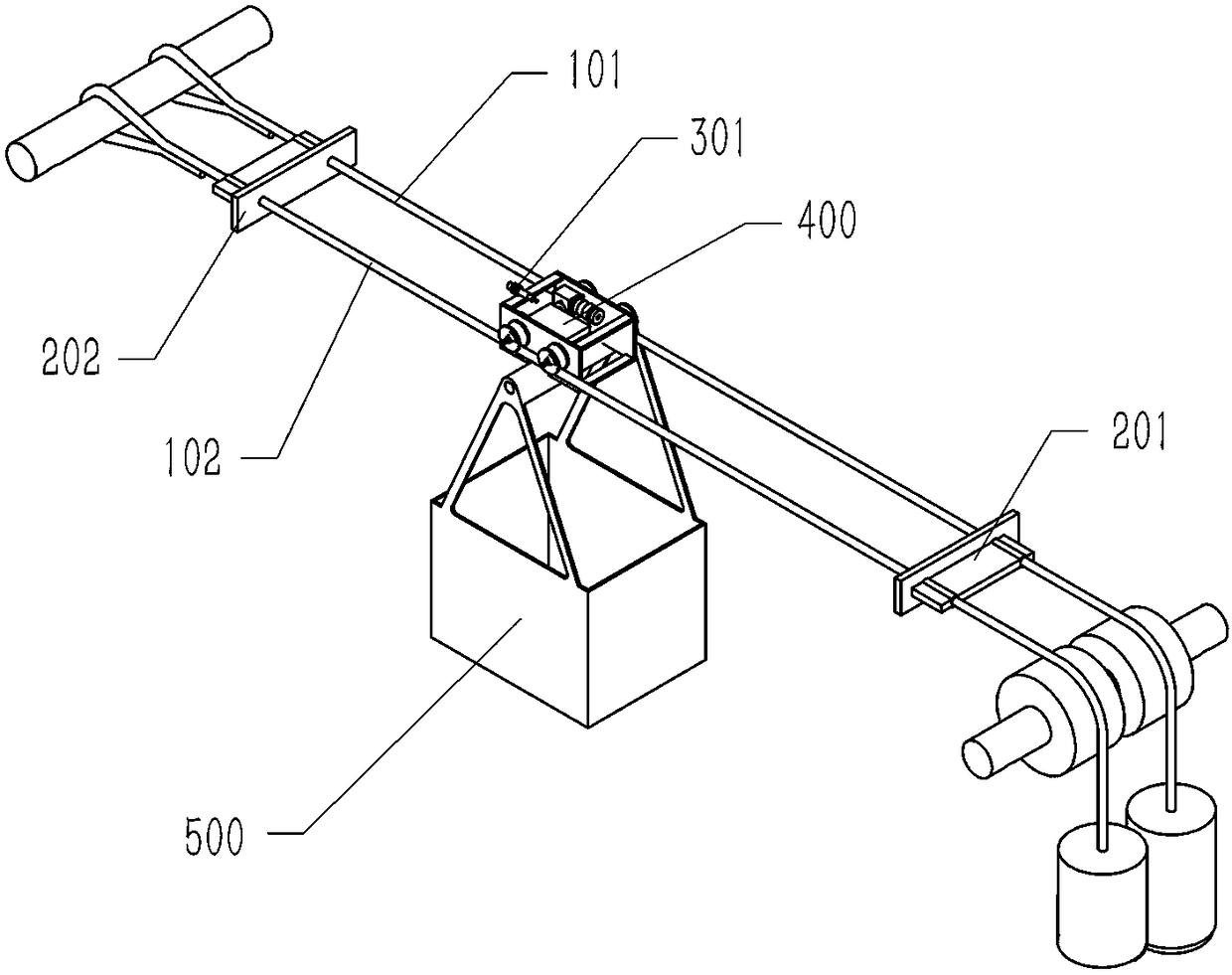

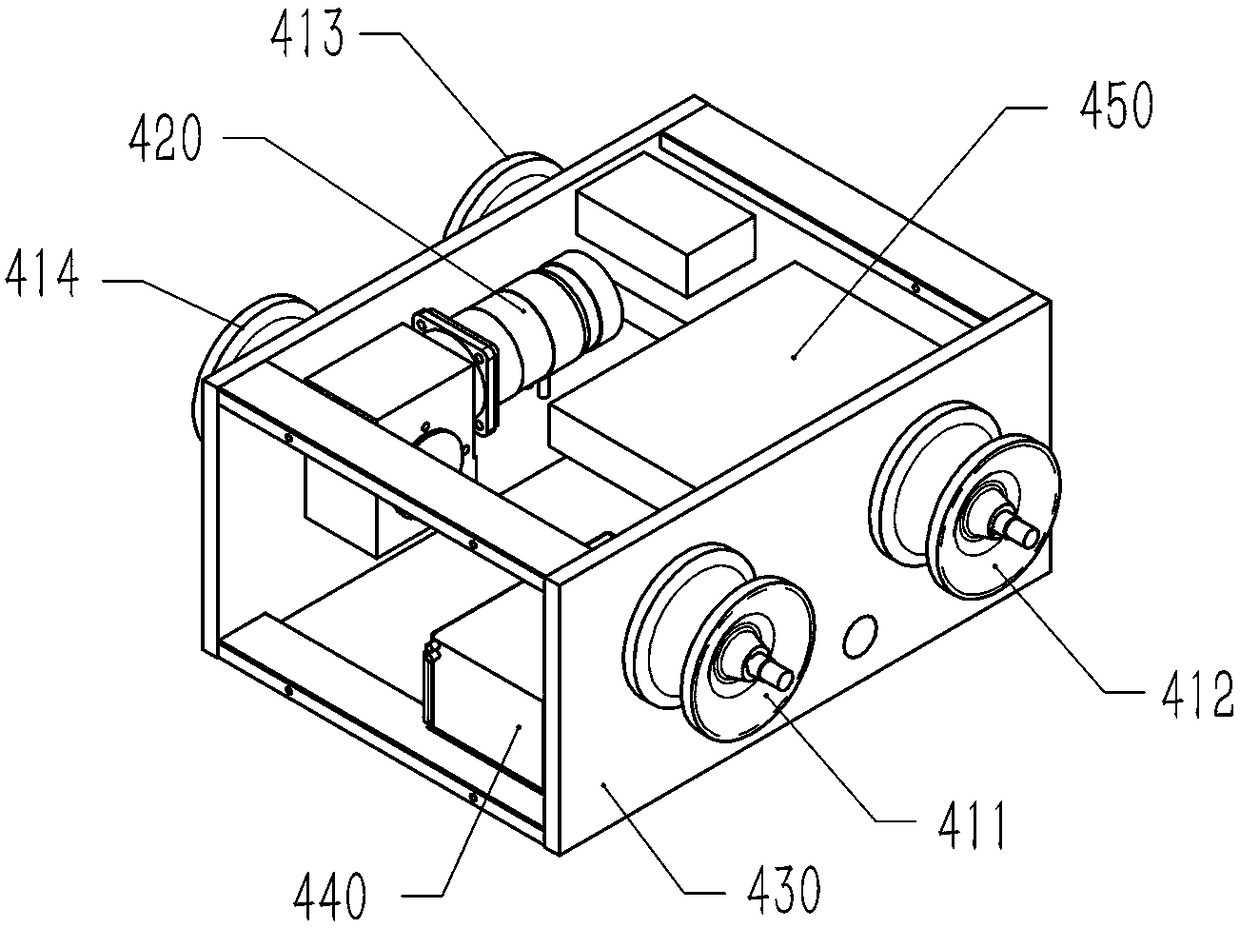

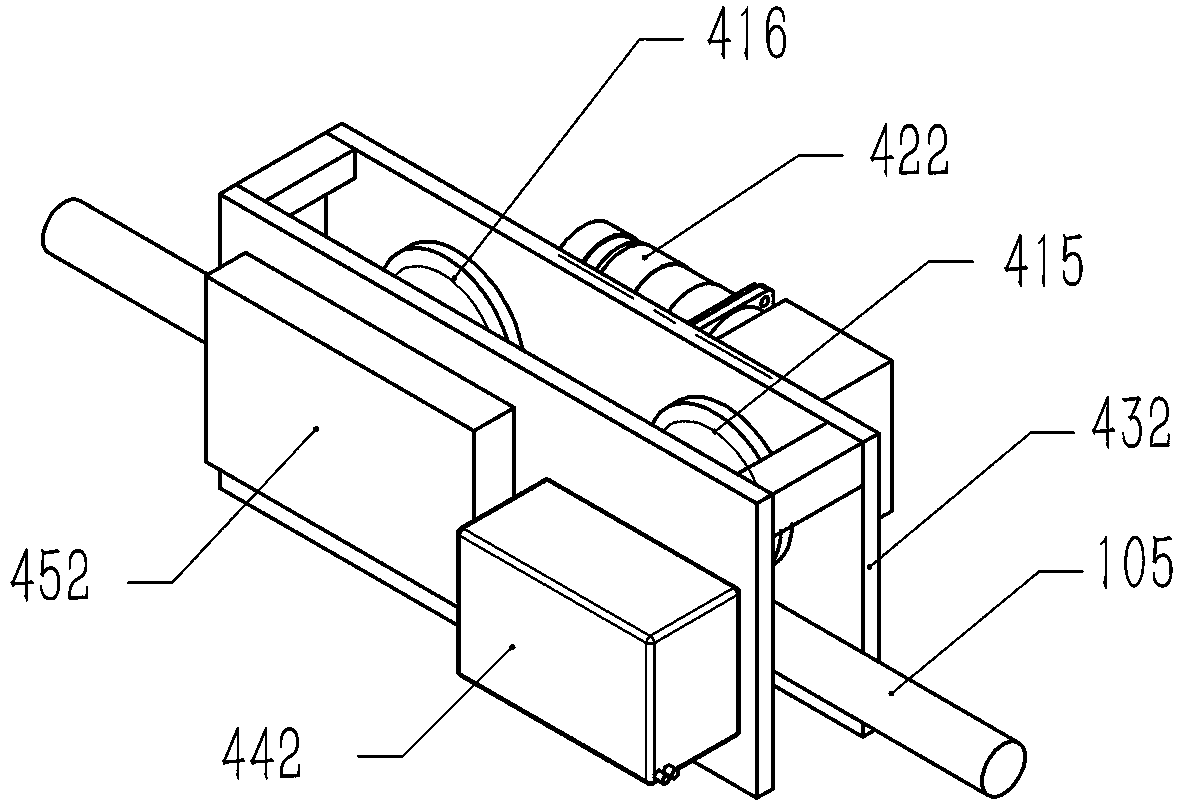

Cableway trolley transport system

InactiveCN109017823AImprove transmission efficiencyImprove securityRope railwaysTransport systemEngineering

The invention discloses a cableway trolley transport system including a steel cable, characterized by, but also a tram, blocking device, The trolley is driven on a steel cable, Person or goods can betransported, The locking device is fixed at the end part of the cable in order to prevent the tram from rushing out of the cable due to out of control.The trolley comprises a frame, wheels, an electric motor, a battery, a controller, frame supporting wheels and carrying goods, wherein the wheels are mounted on the steel cable, the electric motor drives the wheels to rotate, the trolley is drivenby the friction force between the wheels and the steel cable, the battery provides electric power, and the controller controls the operation of the trolley. The invention has the advantages of simplestructure and low construction difficulty.

Owner:苏州博艇智能科技有限公司

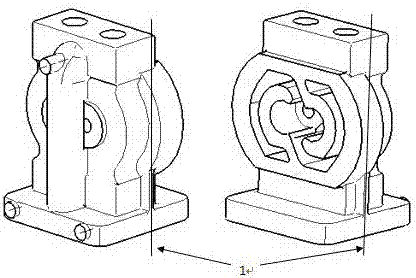

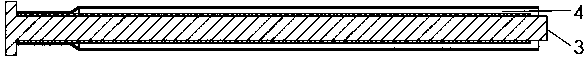

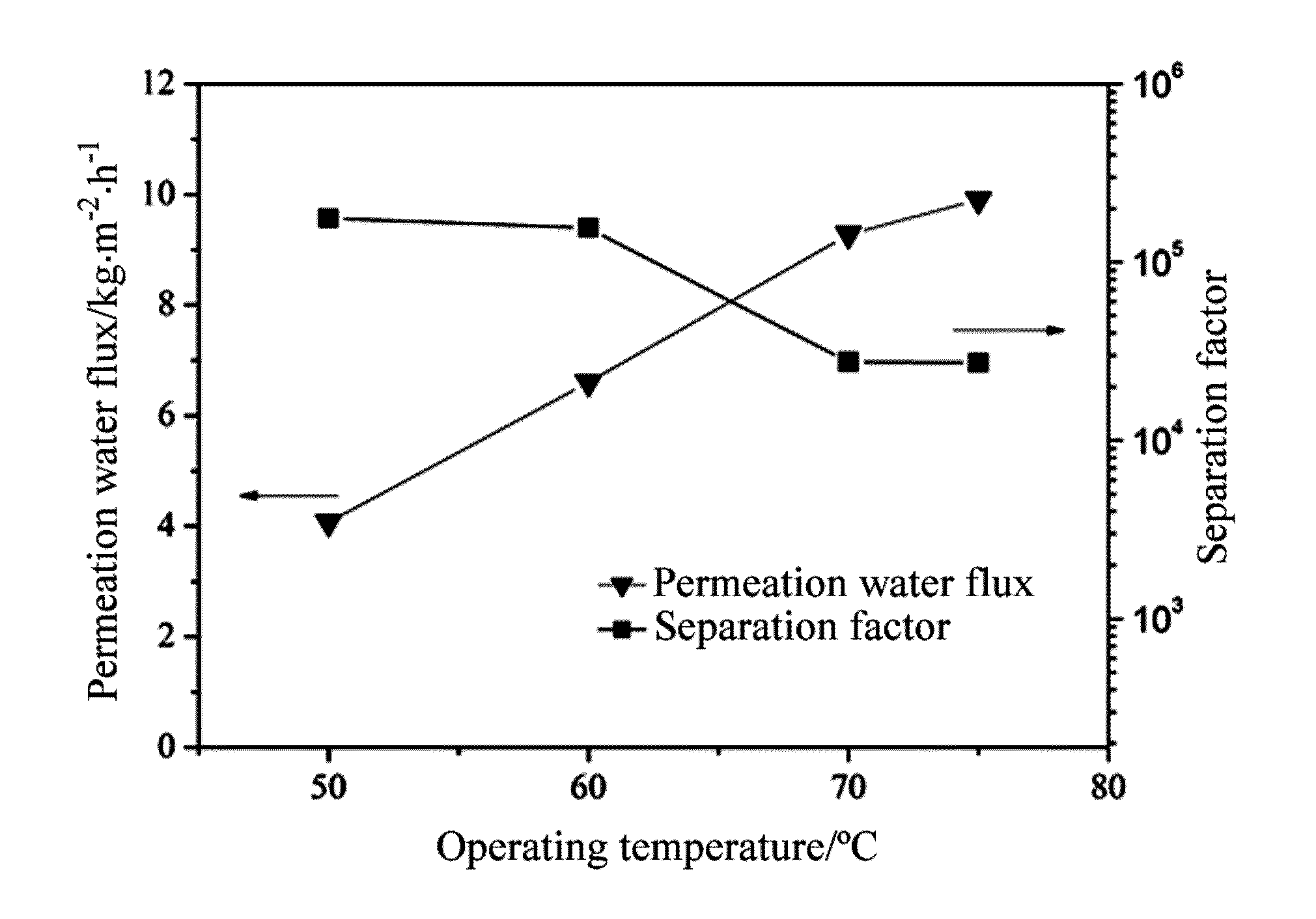

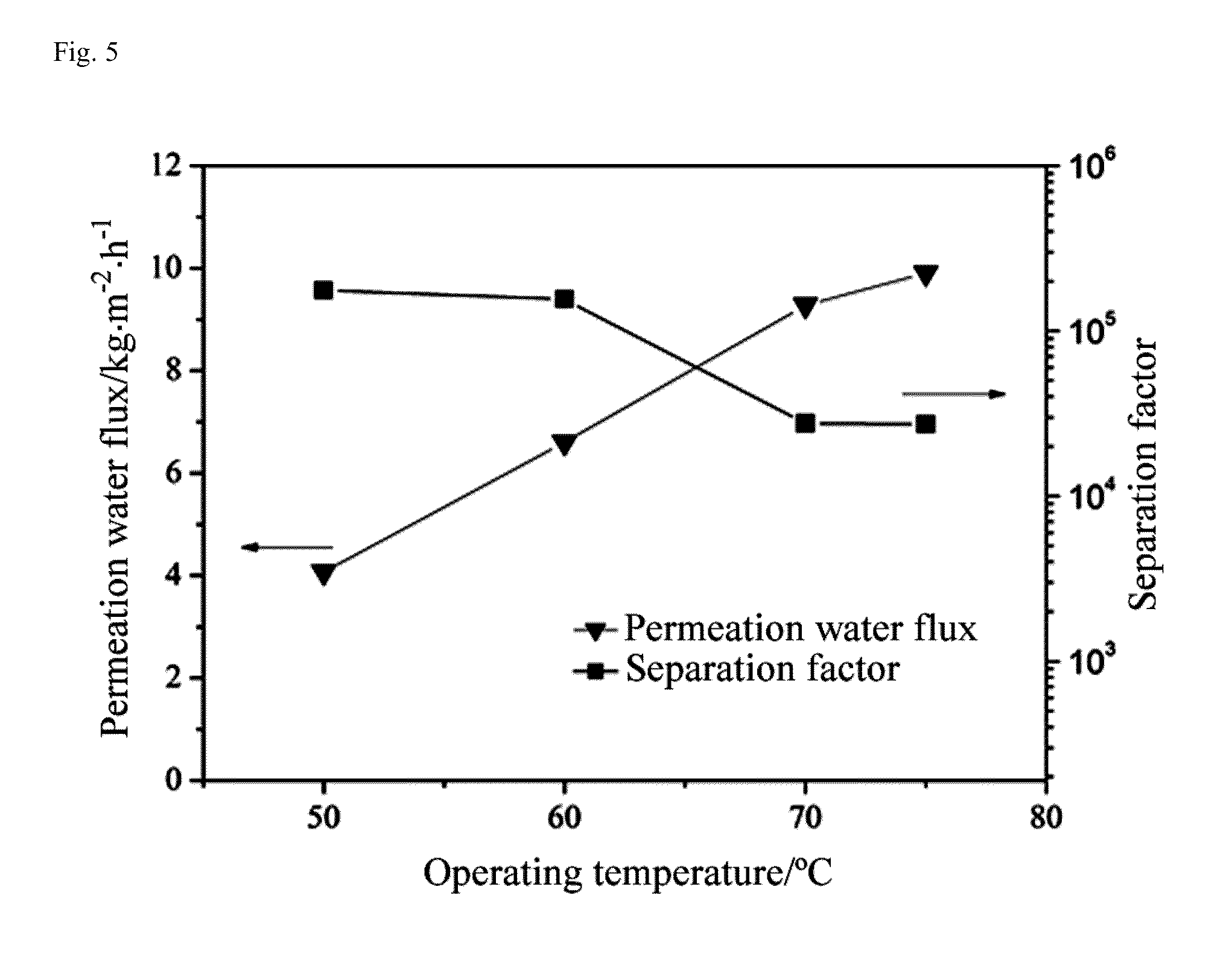

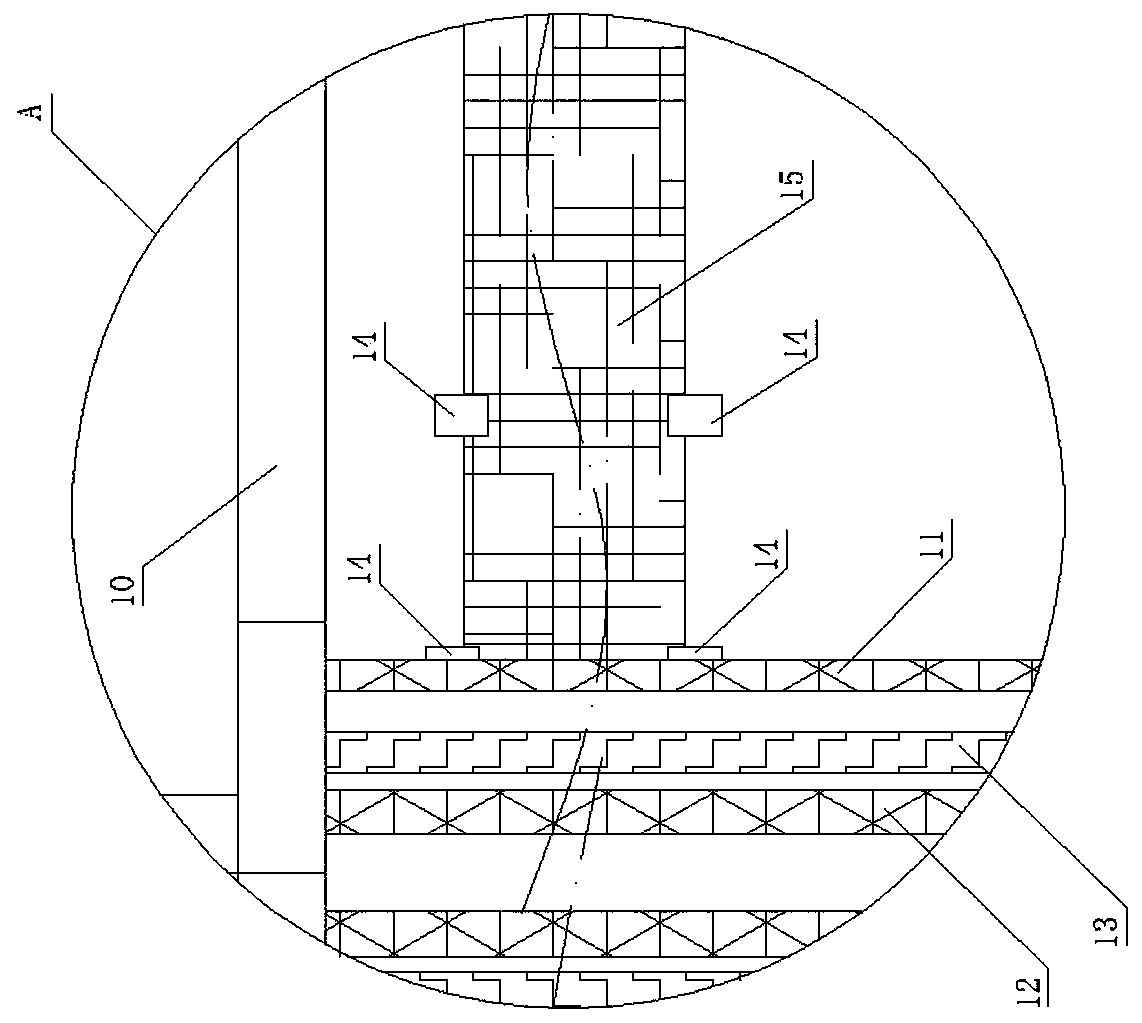

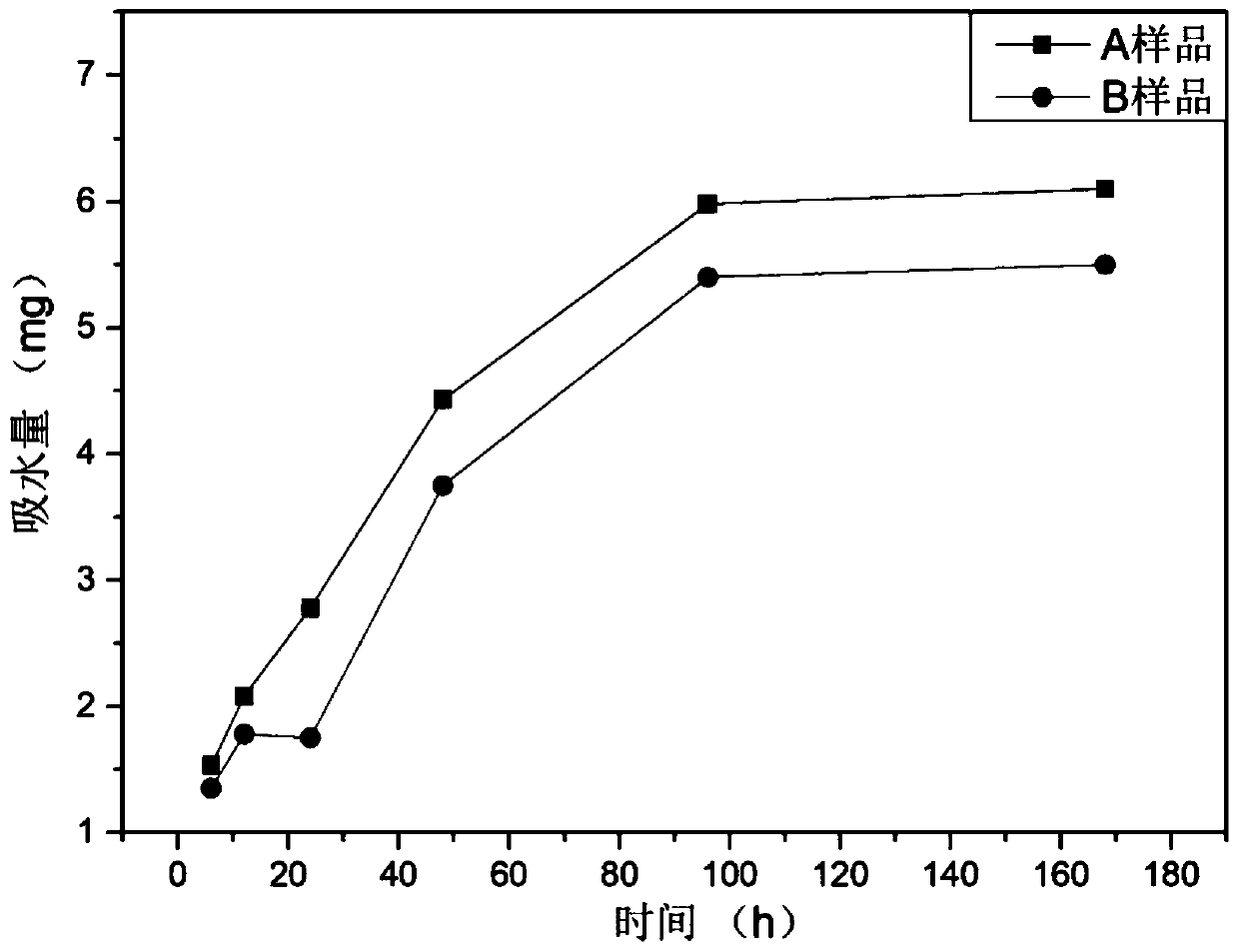

High-Strength Hollow Fiber Zeolite Membrane And Its Preparation Method

ActiveUS20160214064A1Slow down depreciationImprove mechanical propertiesMembranesDistillationFiberHollow fibre

The invention relates to a high-strength hollow fiber zeolite membrane and its preparation method, characterized in that the support of the high-strength zeolite membrane has a multi-channel hollow fiber configuration. The preparation method comprises first preparing a crystal seed solution, then immersing the dry support with the multi-channel hollow fiber configuration in the crystal seed solution, and extracting and drying the support to obtain a crystal-seeded support; and finally placing the crystal-seeded support in a zeolite membrane synthetic fluid, performing hydrothermal synthesis, and taking out, washing and drying the product to obtain the high-strength hollow fiber zeolite membrane. The multi-channel hollow fiber support can provide high mechanical property, which greatly reduces the depreciation rate of the hollow fiber zeolite membrane equipment during use. Meanwhile, the multi-channel hollow fiber zeolite membrane prepared by the Invention possesses high loading density of permeation flux and membrane module and can reduce the production cost and improve the separation efficiency significantly, and thus lays the foundation for promoting the industrial application of the hollow fiber zeolite membrane.

Owner:NANJING UNIV OF TECH

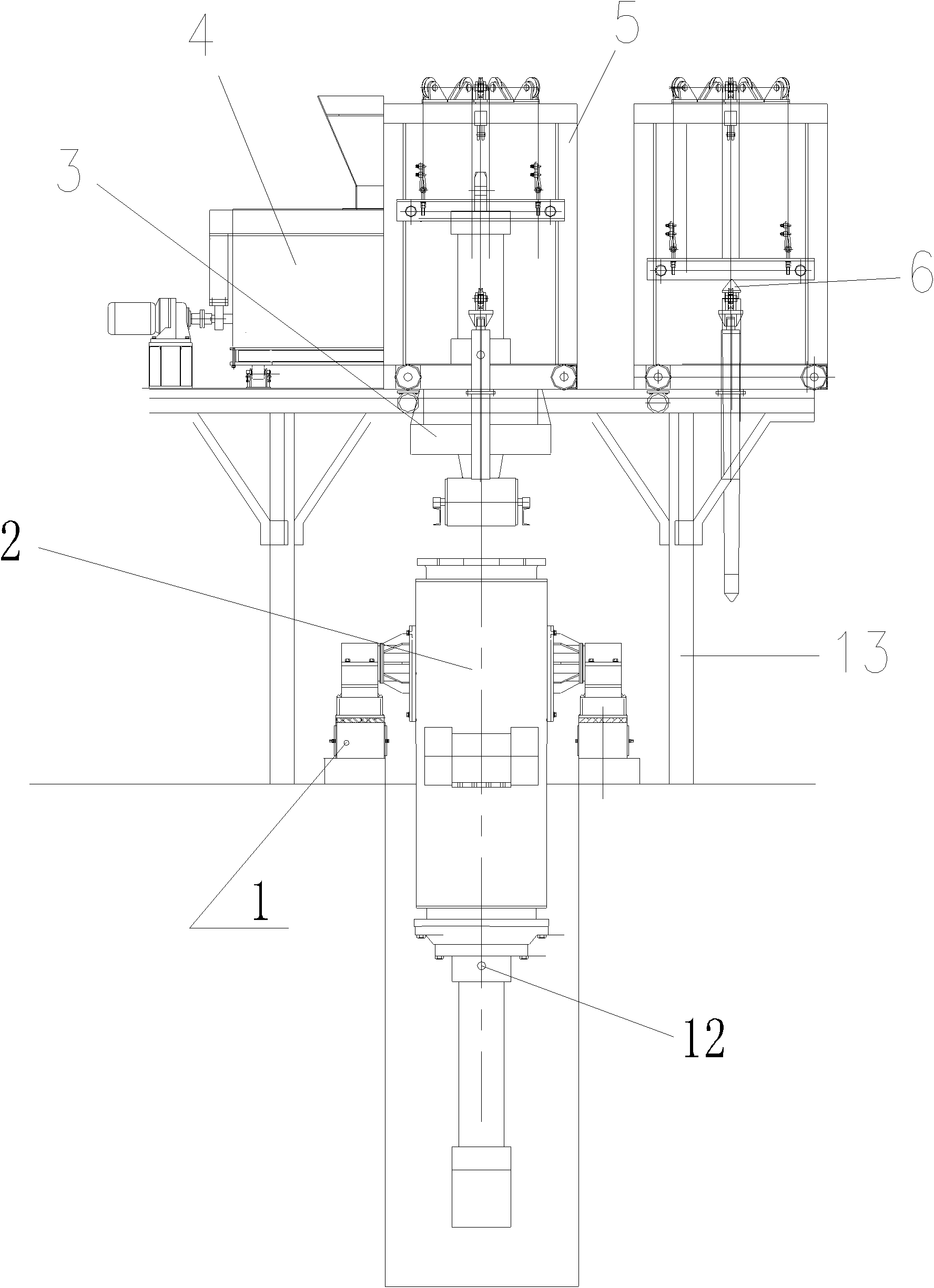

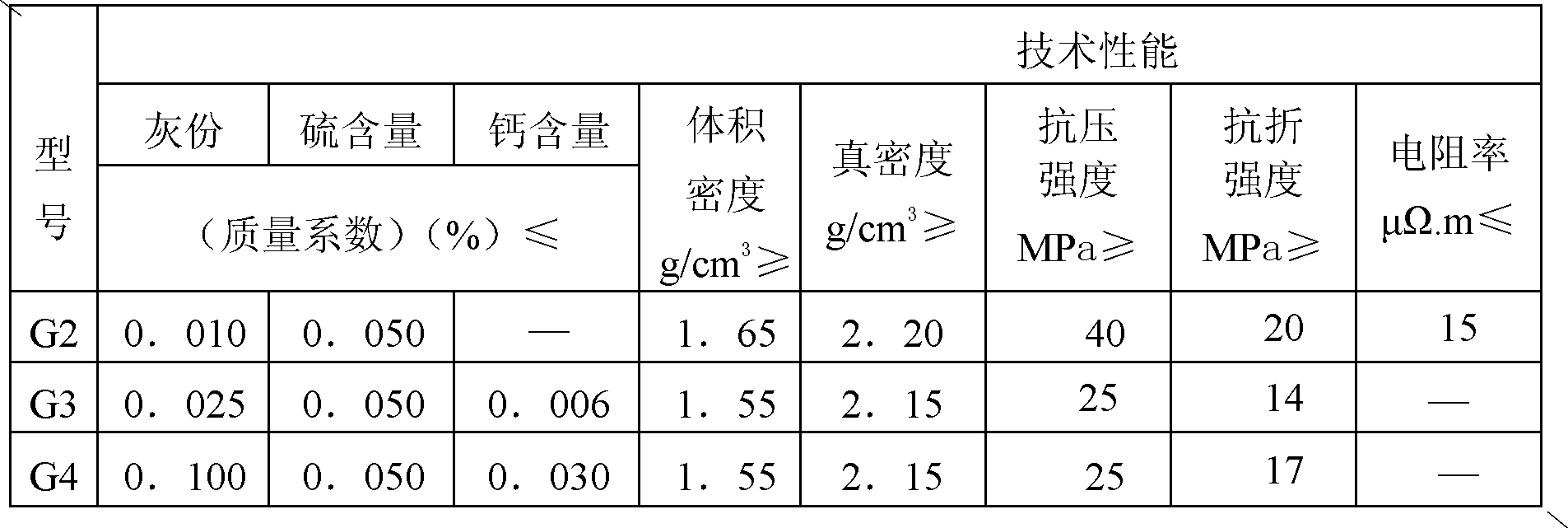

Molding method of fine grain graphite

The invention provides a molding method of fine grain graphite, relating to graphite. The molding method of the fine grain graphite comprises the following steps of crushing and then pulverizing raw material petroleum coke so as to obtain petroleum coke powder; adding F3O2 powder to the petroleum coke powder so as to obtain a mixture of the petroleum coke powder and the F3O2 powder; putting the mixture of the petroleum coke powder and the F3O2 powder into a mixing kneading pot to be heated; and then adding liquid asphalt; discharging a paste out of the pot after mixing kneading of the mixture; putting the obtained paste on a heated tablet rolling machine to be rolled; cooling the rolled tablet in a natural environment to normal temperature; grinding the cooled rolled tablet so as to obtain the ground powder; filling the ground powder into a mold cylinder after preheating the ground powder; sealing the mold cylinder; vacuumizing to eliminate gas in the paste; pressurizing two ends of the mold cylinder; starting a vibrating platform; and releasing the mold and cooling to obtain a fine grain graphite product, wherein the dimension of the fine grain graphite product can reach phi 1000 mm*800 mm.

Owner:福建兴朝阳硅材料股份有限公司

Machining method for 5-12 oz thick copper power circuit board drilling

InactiveCN104607684AAvoid glitchesThere will be no problem of blocking the vacuum lineThermodynamicsCopper

The invention belongs to a machining method for 5-12 oz thick copper power circuit board drilling. The machining method is characterized by comprising the following steps that firstly, when the drilling diameter is larger than 2.0 mm , a drill bit 3 with the diameter phi of 1.55 mm is selected, and a first pre-drill hole 4 with the diameter phi 1of 1.55 is drilled; secondly, after the first pre-drill hole 4 with the diameter phi 1 of 1.55 is drilled and when the difference between the designed drilling diameter and the diameter of 1.55 mm of the first pre-drill hole is larger than 0.45-0.6 mm, a drill bit with the diameter phi 2 of 1.55 mm plus 0.45-0.6 mm is selected to drill a second pre-drill hole; thirdly, equally, when the difference between the diameter of the second pre-drill hole and the designed hole diameter is larger than 0.45-0.6 mm, a drill bit with the diameter phi3 to which phi 2 plus 0.45-0.6 mm equals is selected to drill a third pre-drill hole; fourthly, the rest can be done in the same manner till the difference between the pre-drill hole diameter and the designed hole diameter is smaller than or equal to 0.45-0.6 mm, and a drill bit with the diameter equal to the designed hole diameter is selected to finish the final sequential machining. Copper scraps do not block a vacuum pipe, the machining precision is high, and cost is saved.

Owner:DALIAN CHONGDA CIRCUIT

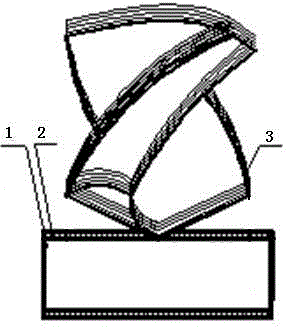

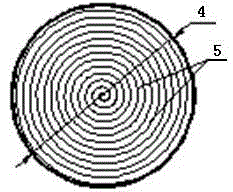

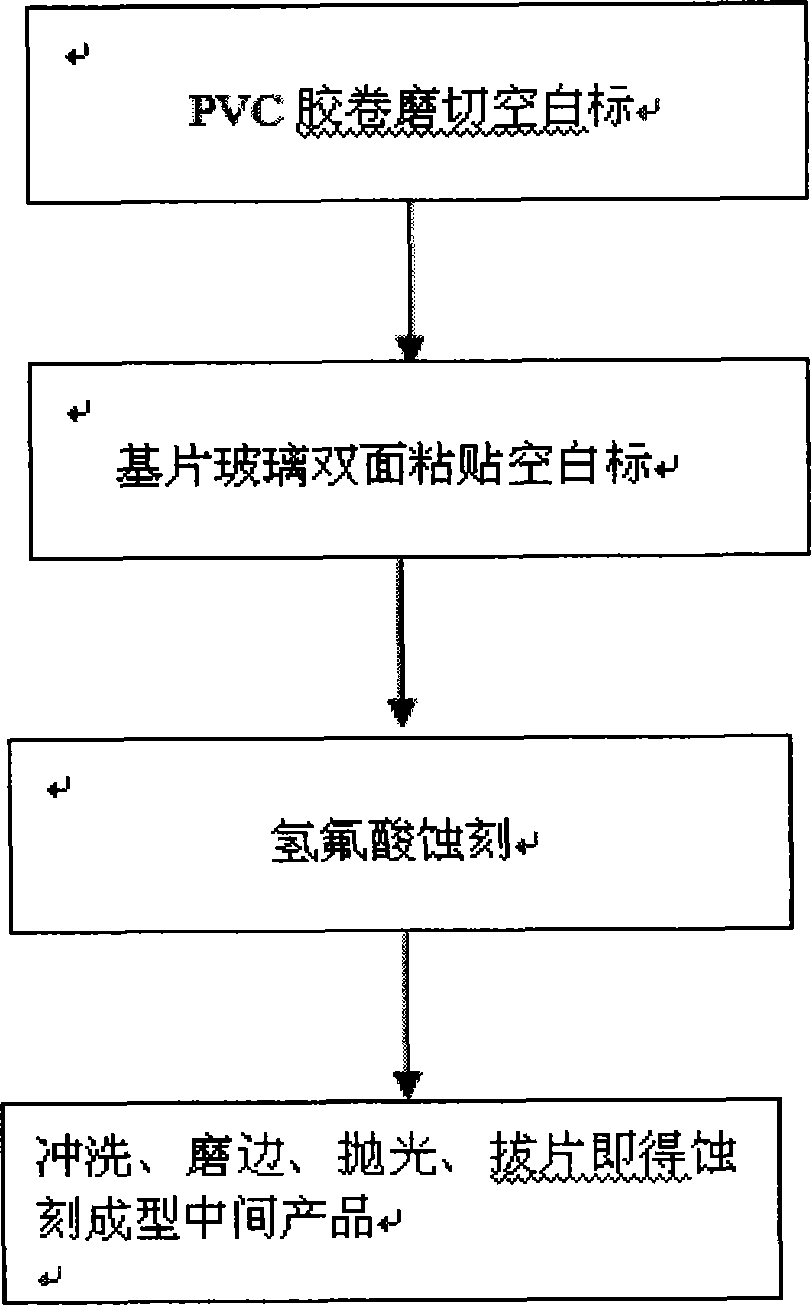

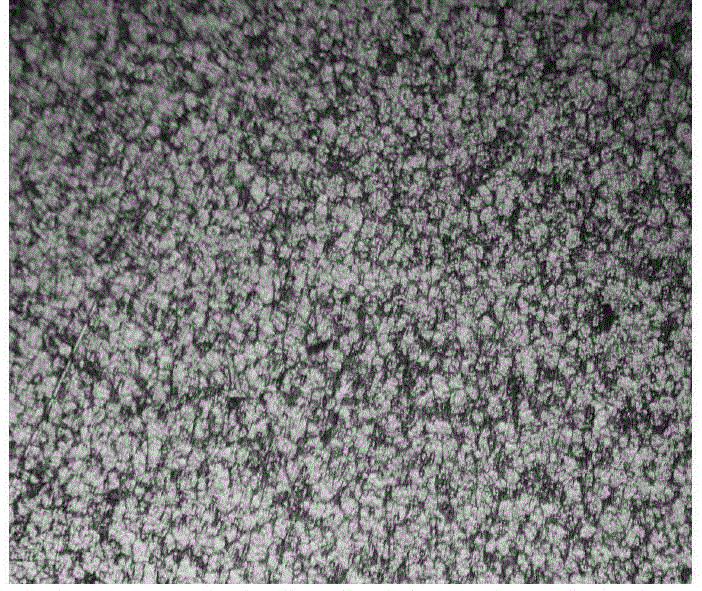

Method for generating protective layer for etching forming of toughened glass cover plate

The invention discloses a method for generating a protective layer for etching forming of a toughened glass cover plate. The protective layer generation method comprises the following steps: grinding and cutting PVC (polyvinyl chloride) films to obtain blanks; bonding the blanks on the two surfaces of substrate glass; etching with hydrofluoric acid; and rinsing, edging, polishing, and withdrawing to obtain an etching forming intermediate product. According to the method, touch screen glass cover plates can be simultaneously processed in large quantity, the processing efficiency and the nondefective rate are increased, the equipment investment cost is saved, the material consumption and the production cost are obviously reduced, obvious economic benefits can be achieved, and the technology gets ahead of the same industry and can form an enterprise standard. The hydrofluoric acid chemical forming and the protective layer generation involved in the invention belong to processing techniques which can be widely used in forming of capacitive touch screen glass cover plates.

Owner:城步新鼎盛电子科技有限公司

A kind of forging processing method of tc4 titanium alloy large size bar

InactiveCN104070125BSlow down depreciationImprove performance uniformityForging/hammering/pressing machinesElectric arc furnaceIngot casting

Owner:宁夏中色金航钛业有限公司

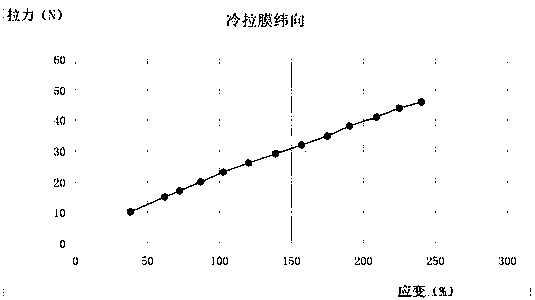

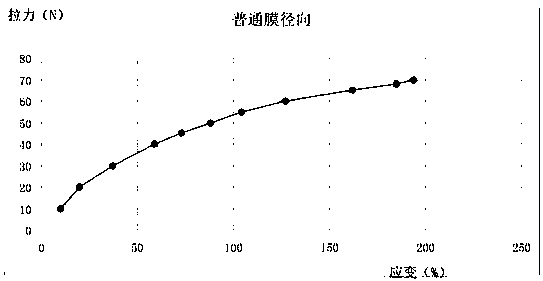

Formula, preparation process, use method and application of high-elasticity membrane

The invention discloses a formula, a preparation process, a use method and application of a high-elasticity membrane. The formula comprises the following components in parts by weight: 80-120 parts ofpolyvinyl chloride (PVC) and 2-8 parts of liquid rubber, wherein the polymerization of the polyvinyl chloride (PVC) is 1300-2100. Compared with the prior art, the membrane of the formula is very goodin elasticity and elongation at break at a relatively low temperature when the amount of calcium powder and the content of the liquid rubber are accurately controlled, and in addition, due to the adoption of an environmental-friendly plasticizer and a stabilizer, the product is also good in environment protection. The high-elasticity membrane disclosed by the invention has the advantages of highuse security. Fuel gas equipment is dangerous to use in a residential community, and life-threatening explosion can be resulted, and the risk can be avoided if a cold draw membrane is mounted.

Owner:ZHEJIANG HAILIDE NEW MATERIAL

Image acquiring device and method of correcting coordinates thereof

ActiveUS10388010B2Improve efficiencySlow down depreciationImage enhancementTelevision system detailsData managementComputer vision

Owner:CHONGQING HKC OPTOELECTRONICS TECH CO LTD +1

Processing method of instant vacuum dried penaeus aztecus

InactiveCN102669743BMaintain colorGuaranteed hygienic performanceFood preservationFood preparationBiotechnologyMaillard reaction

Owner:FUZHOU JINFULIN FOOD

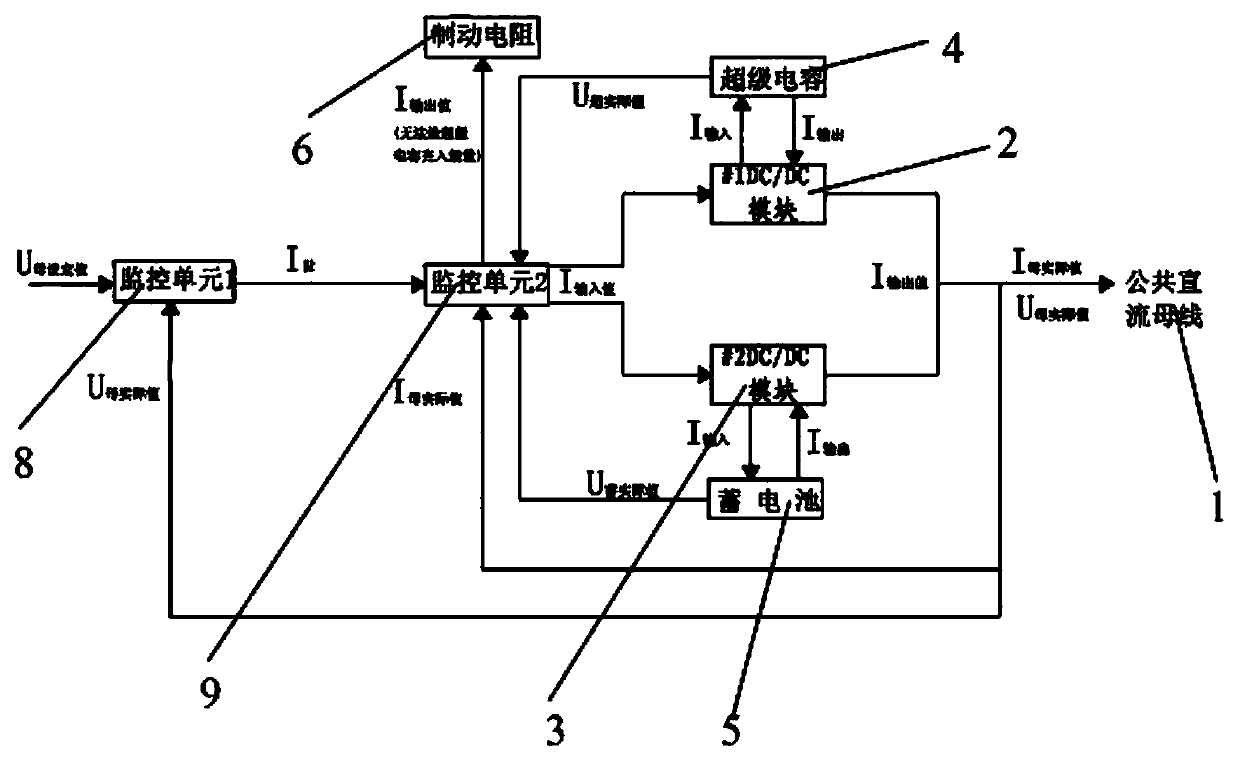

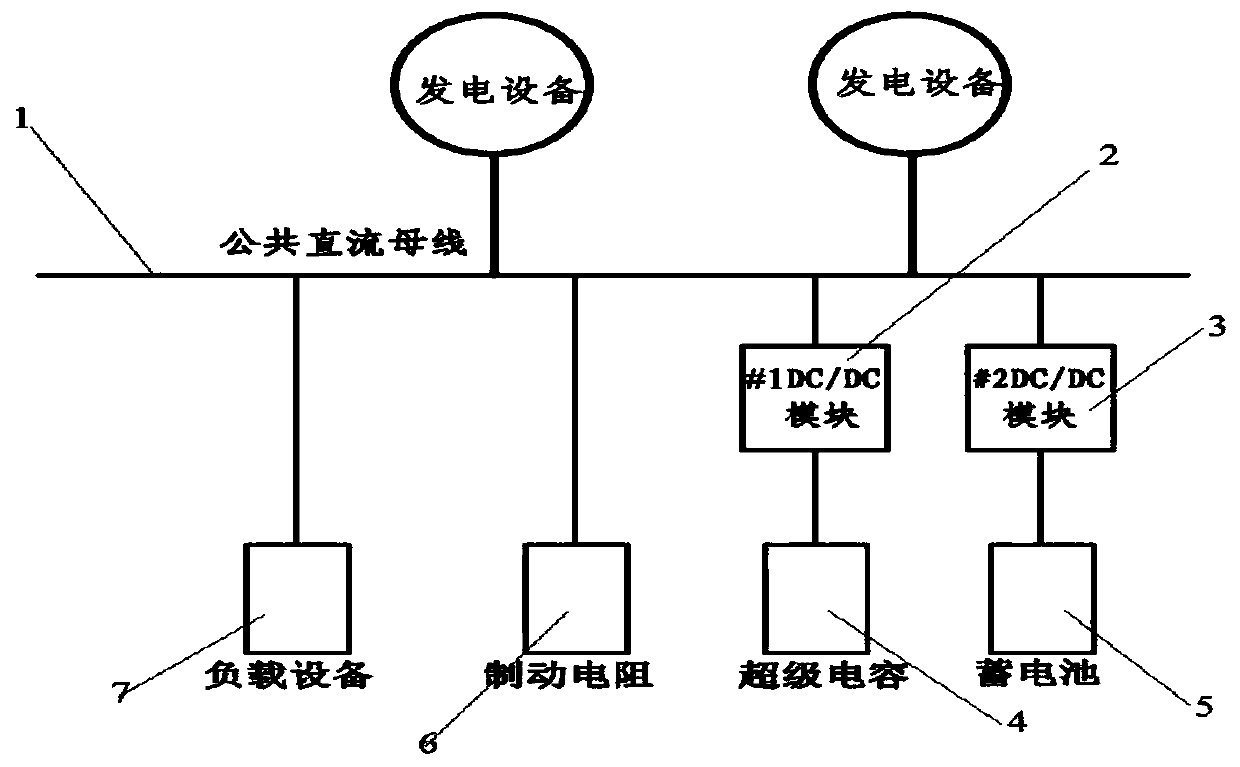

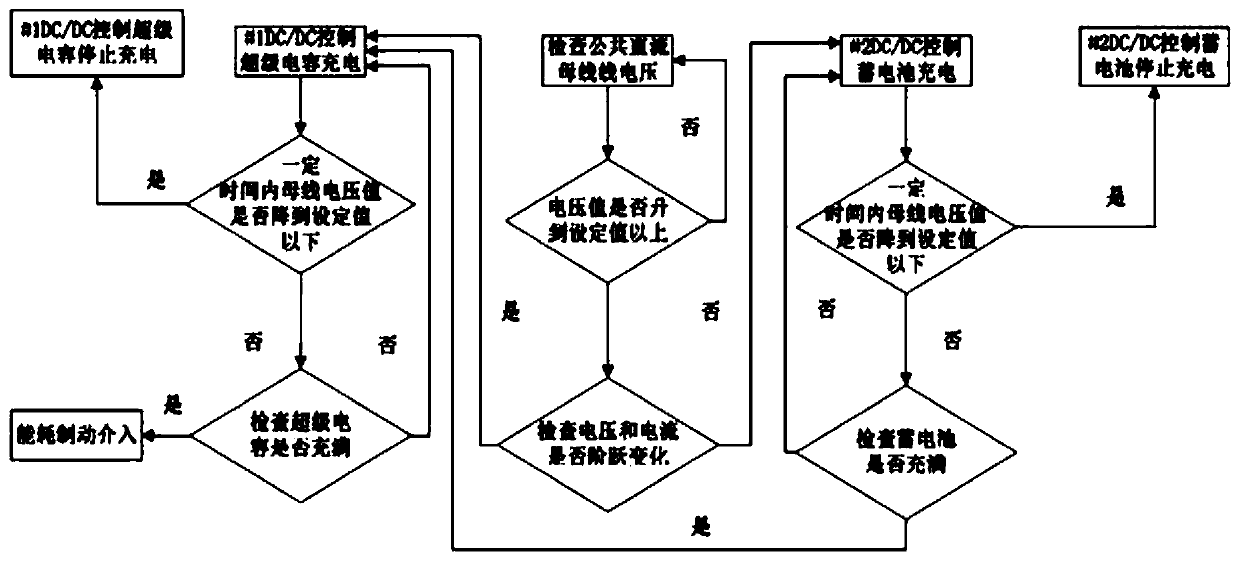

Control system and method for recycling of braking energy of drilling machine

PendingCN109962472AReduce purchasing expensesReduce the impactBatteries circuit arrangementsDc source parallel operationElectrical resistance and conductanceControl system

The invention discloses a control system for recycling of the braking energy of a drilling machine. The system comprises a monitoring unit a and a monitoring unit b, which are both connected with a common DC bus. The monitoring unit b connected with a brake resistor is connected with a # 1 DC / DC module and a # 2 DC / DC module; the # 1 DC / DC module is also connected with an energy storage element a,the # 2 DC / DC module is also connected with an energy storage element b, and the # 1 DC / DC module and the # 2 DC / DC module are connected with a public direct current bus. The invention further discloses a control method of the control system, and the method comprises the steps: connecting the input device to the monitoring unit; then installing the control system between power generation equipment and load equipment; starting the two pieces of equipment at the same time; and employing a closed-loop control mode to keep the voltage of the common DC bus stable. The control system disclosed by the invention effectively reduces the impact influence on the common DC bus during the operation of the drilling machine, effectively recovers and utilizes redundant energy, and saves the cost.

Owner:BAOJI PETROLEUM MASCH CO LTD +2

Running-water culture system with effect of prolonging service life of feeder

ActiveCN107549074AAvoid the sun and windReduce wearClimate change adaptationPisciculture and aquariaFishingService life cycle

The invention discloses a running-water culture system with an effect of prolonging the service life of a feeder. The running-water culture system comprises a culture net cage, the fish bait feeder and a makeshift house. The fish bait feeder is matched with the culture net cage, the makeshift house is used for placing fish feed bags and daily fishing tools, the culture net cage comprises a cage, the cage comprises a plurality of unit net cages, the fish bait feeder comprises a plurality of single feeder bodies, a plurality of feeding regions and a supply region with a ceiling, fish bait can befed into the unit net cages by the single feeder bodies, the feeding regions are positioned in the unit net cages and are in one-to-one correspondence to the single feeder bodies, and the supply region is arranged on a side of each unit net cage. The running-water culture system has the advantages that each single feeder body can freely roll to the supply region or the feeding regions, the supplyregion is provided with the ceiling, accordingly, machines can be prevented from being exposed to the weather, and abrasion and depreciation of the machines can be reduced.

Owner:魏发宝

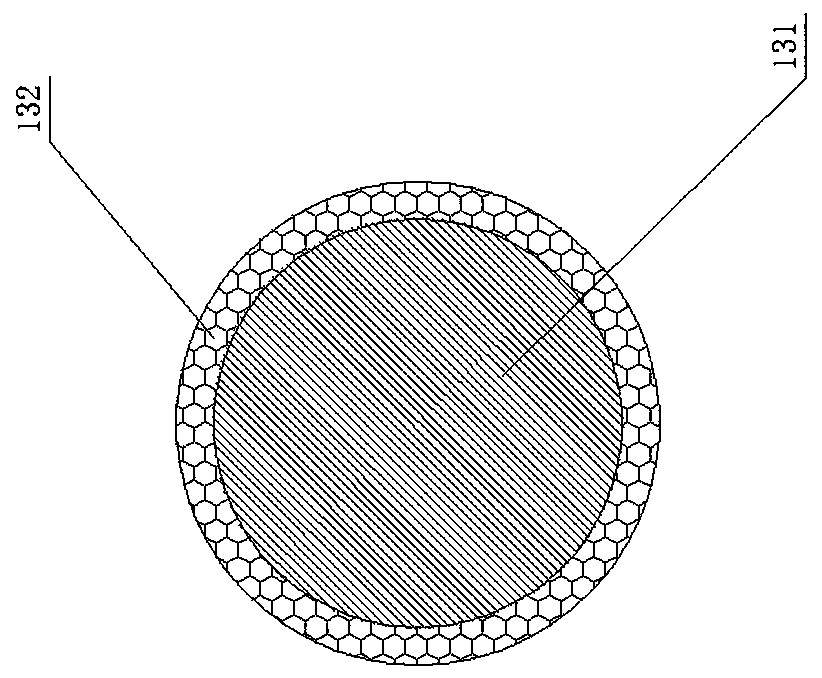

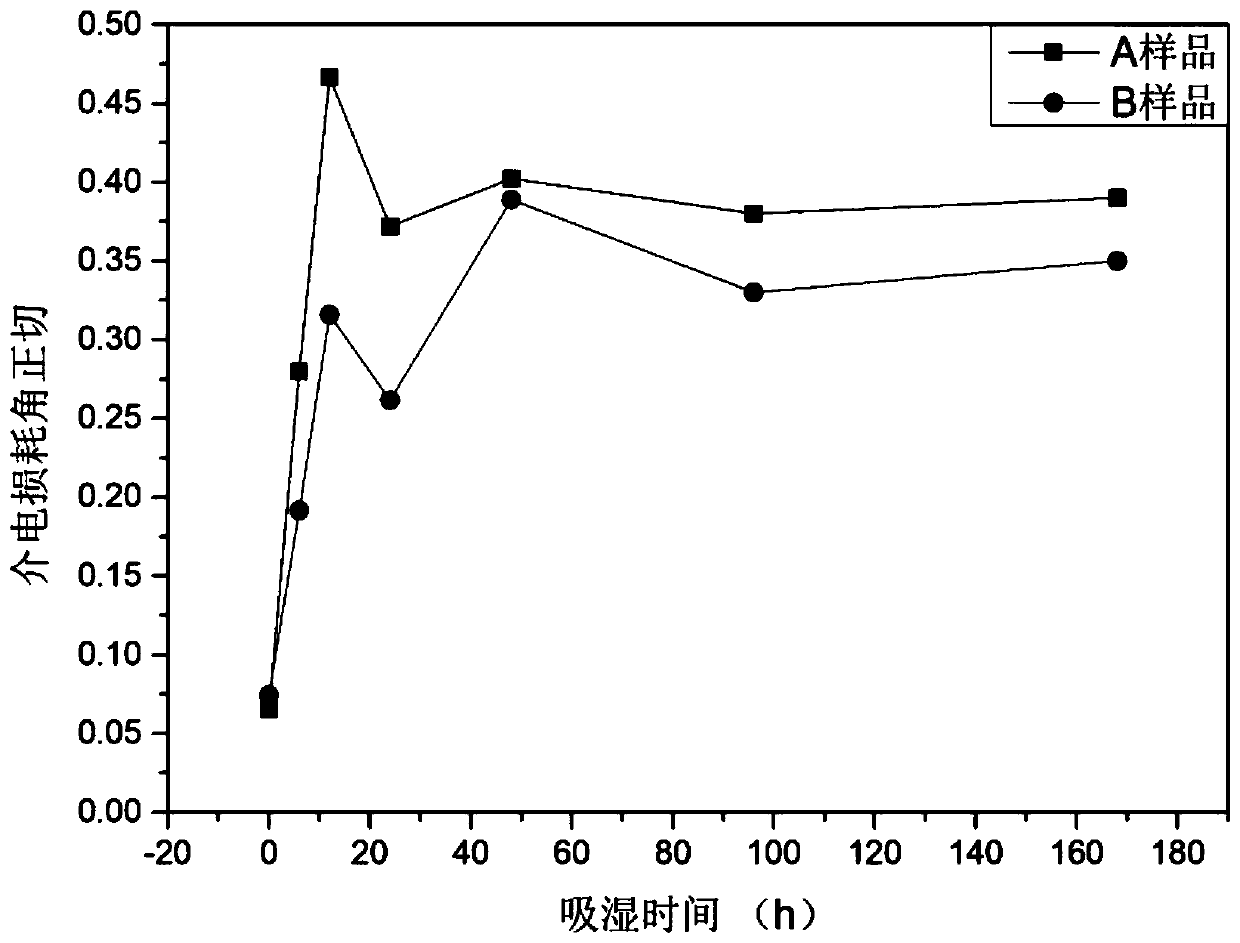

Method for evaluating electrical performance of insulated mandrel

InactiveCN110243747AImprove reliabilityGuaranteed operational safetyMaterial analysis using wave/particle radiationPermeability/surface area analysisPower gridEngineering

The invention provides a method for evaluating the electrical performance of an insulated mandrel. The method for evaluating the electrical performance of the insulated mandrel comprises the following steps: testing the pores of the insulated mandrel; and evaluating the electrical performance of the insulated mandrel according to the test results. The method for evaluating the electrical performance of the insulated mandrel can satisfy the further evaluation of the electrical performance of the insulated mandrel of the national standard, can screen out the insulated mandrel with better electrical performance, and can increase the service life of the insulated mandrel in practical applications, thereby ensuring the safe operation of the power grid.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

A kind of daptomycin extraction method

ActiveCN105481950BReduce healthy stressLittle side effectsPeptide preparation methodsEthylic acidSilica gel

The invention relates to the technical field of antibiotic production, in particular to a daptomycin extraction method. The method includes the following steps of firstly, filtering daptomycin fermentation liquor through a ceramic film; secondly, making filtered liquor pass through large-pore adsorption resin so that eluant can be collected; thirdly, mixing NM-Q anion exchange resin with the obtained eluant, and collecting eluant; fourthly, making the eluant obtained in the third step pass through a reverse phase silica gel MNsil-C18 column, conducting gradient elution on the column through an ammonium acetate ethanol solution, and collecting eluant; fifthly, concentrating the daptomycin eluant obtained in the fourth step, adding calcium acetate and isopropyl alcohol, and conducting standing, crystallization, suction filtration and drying to obtain daptomycin crystallization powder. The method has the advantages that the virulent acetonitrile solution is not used as the eluant, pressure on the environment and health of production personnel is reduced, the use of acid-base regulator is reduced, and the production cost is reduced.

Owner:LIVZON GROUP FUZHOU FUXING PHARMACEUTICAL CO LTD

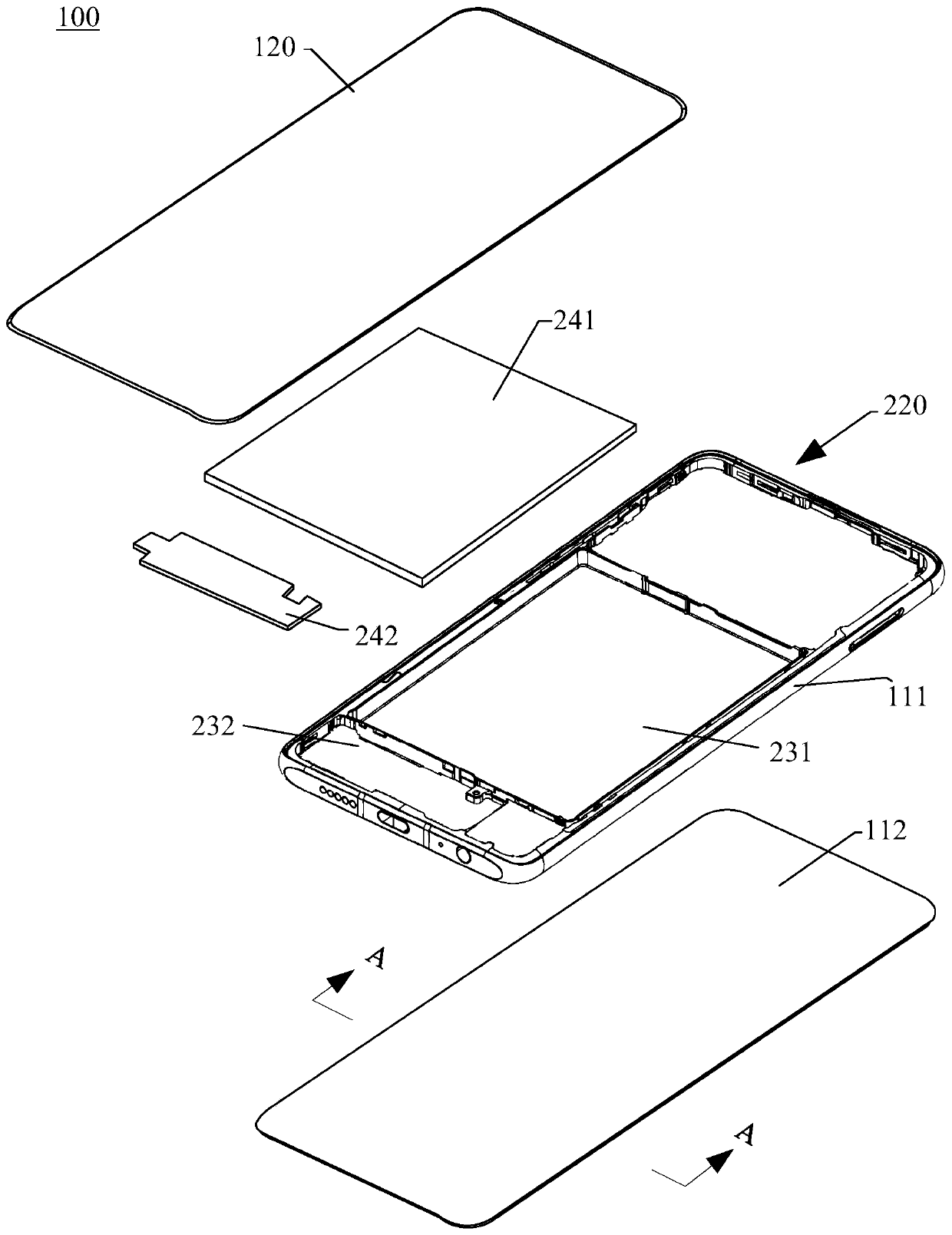

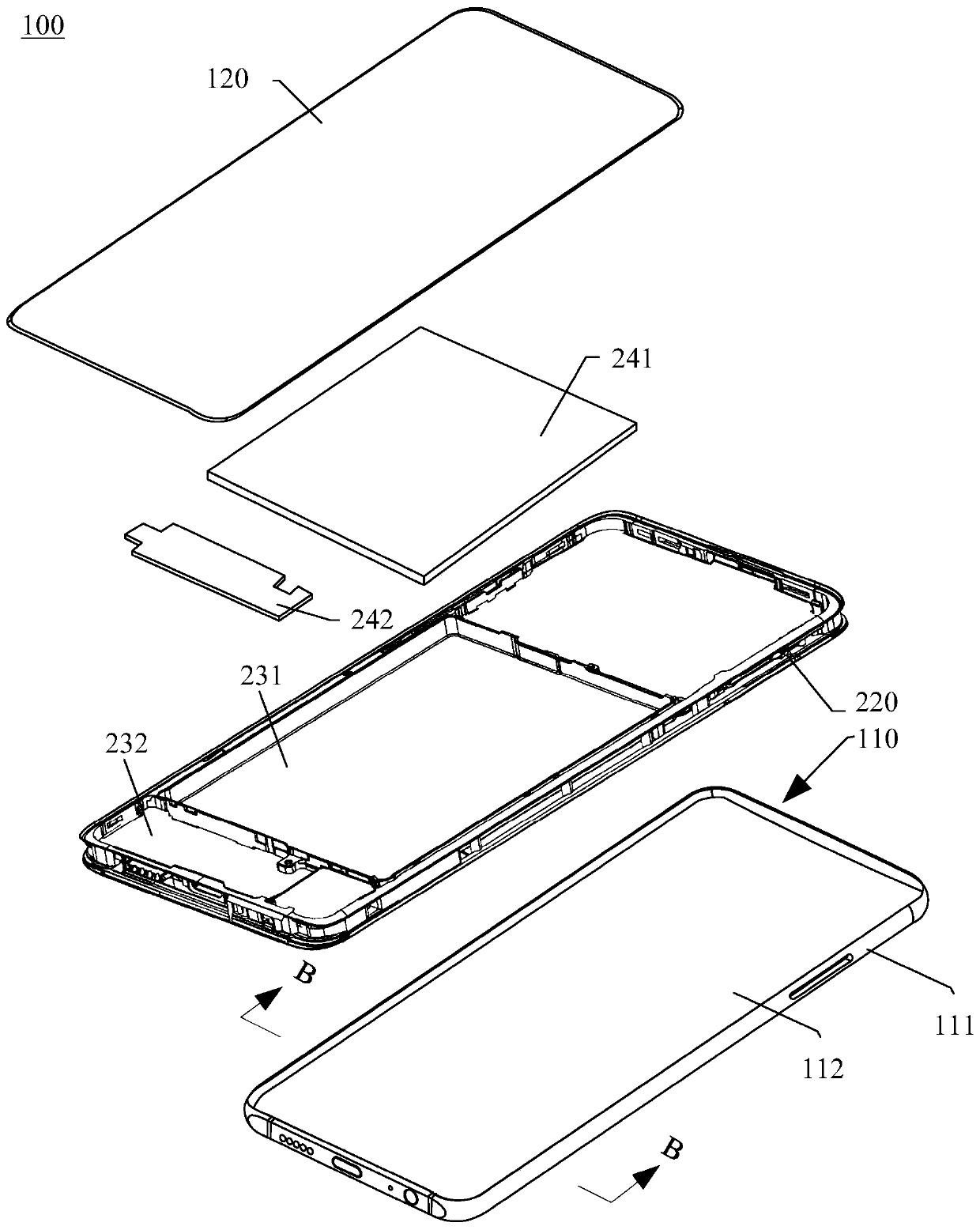

Cover plate, electronic equipment and method for processing cover plate

InactiveCN111526228AOptimize processing technologyWith other decorative effectsLaminationLamination apparatusInterference colorMaterials science

The invention provides a cover plate (800), electronic equipment (100) and a processing method of the cover plate (800). The cover plate (800) provided by the invention has a first texture (811), thefirst texture (811) belongs to a glare micro-texture; the first texture (811) comprises concave valleys (813) with the width being smaller than or equal to 25 microns, and the distance between every two adjacent concave valleys (813) is less than or equal to twice the width of the concave valleys (813). The first texture (811) has an interference color, which is helpful for a user to perceive a colorful effect. Therefore, the appearance decoration of the electronic equipment (100) comprising the cover plate (800) can be improved. The processing method of the cover plate (800) provided by the invention comprises the step of forming glare micro-textures on the glass layer (810) in an etching manner.

Owner:HUAWEI TECH CO LTD

Anticorrosion aqueous solution for circulating system

The invention relates to anticorrosion aqueous solution for a circulating system, and belongs to the technical field of preservatives. The anticorrosion aqueous solution for the circulating system is a metal preservative, and is characterized in that: the preservative is an aqueous solution product; and the aqueous solution comprises the following components in part by weight: 0.4 to 10 parts of benzotriazole, 5 to 15 parts of sodium nitrite, 10 to 20 parts of sodium silicate and 60 to 100 parts of borax. The anticorrosion aqueous solution has the advantages of simple formulation, easily-obtained raw materials, low cost, convenient usage, energy conservation, corrosion resistance, health, environmental protection, broad application range and the like, prolongs the service life of sets, and reduces the depreciation and maintenance costs of equipment.

Owner:TIANJIN PORT GOODS & MATERIALS SUPPLYING

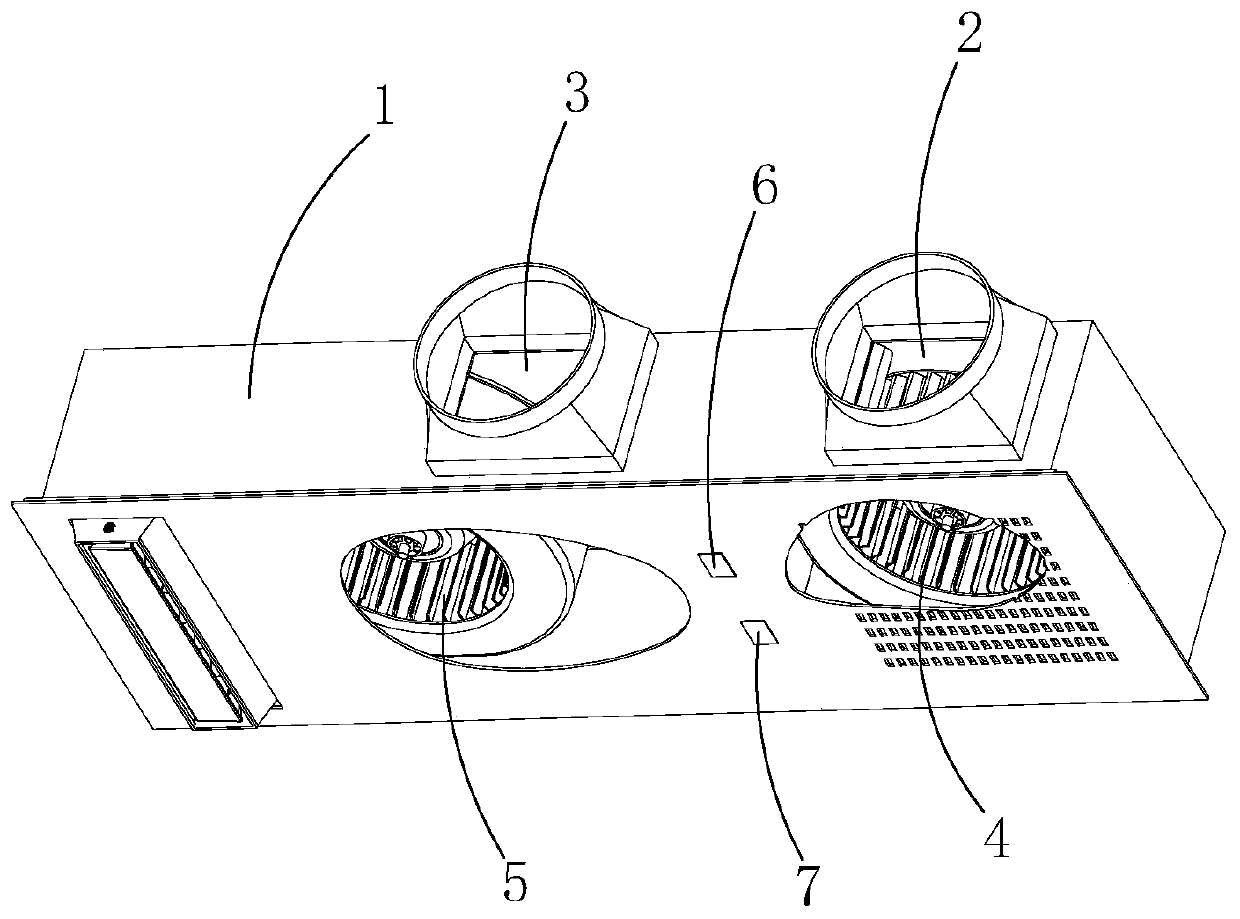

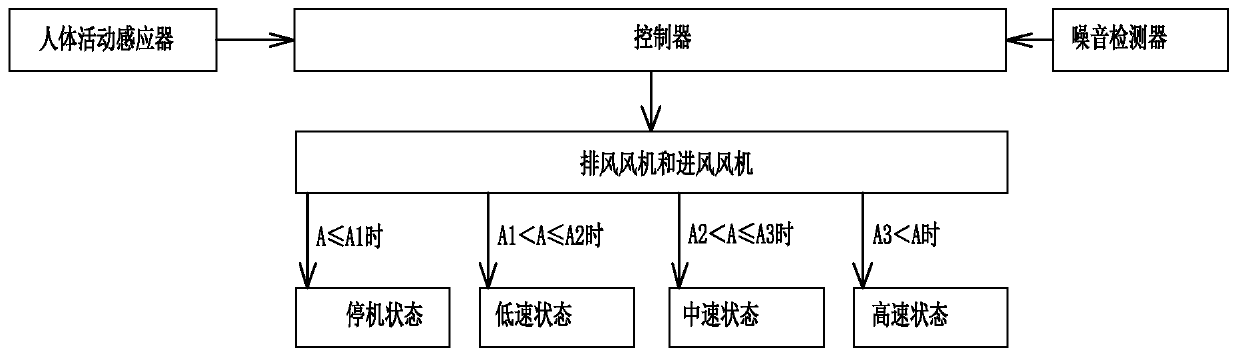

Fresh air ventilator and control method thereof

PendingCN109737552ASlow down depreciationReduce wearMechanical apparatusSpace heating and ventilation safety systemsFresh airSolid particle

The invention relates to a fresh air ventilator and a control method thereof. Existing fresh air ventilators cannot automatically adjust the operating state as needed. The fresh air ventilator comprises a casing and an exhaust air duct; the fresh air ventilator comprises an environment detecting component; and a human body activity sensor and the environment detecting component sense the real-timehuman body activity state and environmental parameters, so that the exhaust fan can be switched between a shutdown state and operating states with different powers. The environmental detecting component is additionally arranged on an existing fresh air ventilator, air with steam or solid particles in a first inner space is discharged through the exhaust air duct, the operating states of the freshair ventilator can be adjusted according to actual needs, steam and solid particles in the first indoor space can be discharged out by the fresh air ventilator in time, the cleanliness of air in thefirst indoor space is ensured, the health of a user is ensured, depreciation and abrasion of the fresh air ventilator can be reduced by reducing the operation load and duration of the exhaust fan, andthe service life of the fresh air ventilator is prolonged.

Owner:ZHEJIANG YOUBANG INTEGRATED CEILING

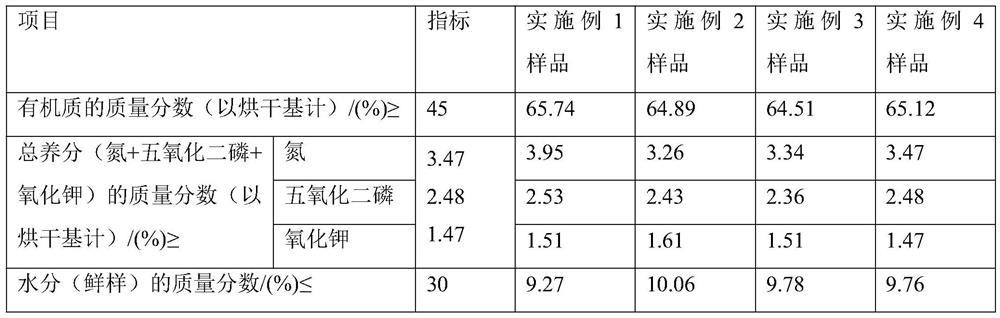

Molecular film fermentation method of bio-organic fertilizer

InactiveCN112939698ALow fermentation infrastructure requirementsImprove qualityBio-organic fraction processingExcrement fertilisersBiotechnologyPoultry manure

The invention relates to a molecular film fermentation method of a bio-organic fertilizer. The method comprises the following specific steps: crushing fermentation raw materials livestock and poultry manure and carbon organic wastes; uniformly mixing organic zymophyte, brown sugar and water to prepare a microbial inoculum, and spraying the microbial inoculum into the fermentation raw materials; pushing into a fermentation tank, piling, and covering with a molecular film for fermentation; and fermenting for 15-25 days to reach an odorless state, namely completely fermenting and thoroughly decomposing. The bio-organic fertilizer is free of pathogenic bacteria, worm eggs, weed seeds and other diseases and pests, and it is ensured that after the molecular film fermentation organic fertilizer is applied, soil is not polluted, weeds are not grown, and germs and pests are not brought to crops. Ammonia, hydrogen sulfide and other nutrient-containing substances generated in the fermentation process are fully retained in the compost. Organic matters in the fermentation raw material carbon organic wastes are fully and effectively mineralized and converted into humic acid, so that the organic matters which can be utilized by crops and are useful for soil are fermented.

Owner:福建泉智生物科技有限公司

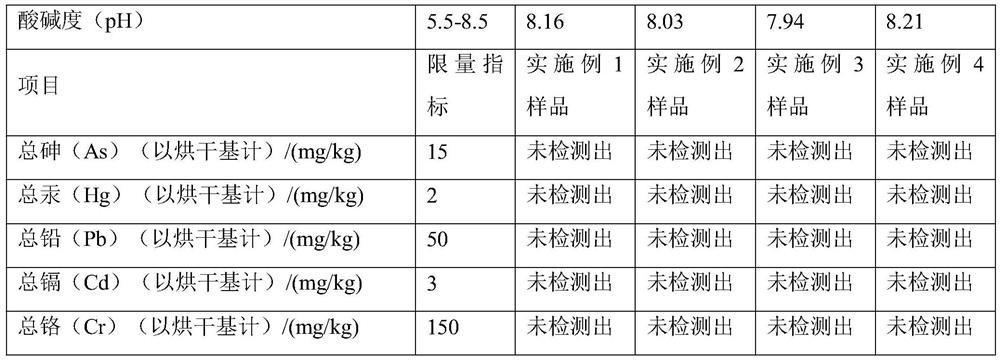

Method of controlling the costs arising during operations of an installation

InactiveUS7058554B1Minimal expenseLower requirementForecastingComputation using non-denominational number representationEngineeringActual cost

A method of keeping a check on the costs arising during the operation of an installation involves recording the operating state of least one component of the installation by use of a status message. This status message is fed to a computer model of the installation, in which the actual cost values arising are determined and compared with predeterminable set values. The deviation between actual values and set values is then indicated.

Owner:SIEMENS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com