A kind of forging processing method of tc4 titanium alloy large size bar

A processing method and technology of titanium alloys, applied in metal processing equipment, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of uneven structure and performance, difficult deformation of titanium alloys, high investment costs, and achieve depreciation of fixed assets. Reduce, shorten the production cycle, shorten the effect of the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

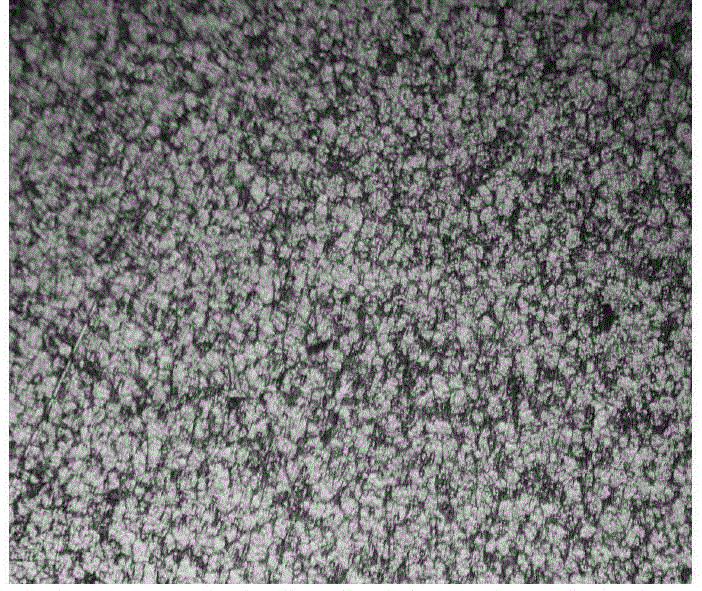

Image

Examples

Embodiment 1

[0038] In this embodiment, a 1600-ton fast forging machine is used to process TC4 titanium alloy rods with a diameter of 600 mm (the ingot is a cylinder and a length of 1200 mm) as raw materials to process TC4 titanium alloy rods of Φ215 mm×3000 mm. The processing method is as follows:

[0039] Step 1: Preheat a TC4 titanium alloy ingot with a diameter of 600mm at 820°C for 1 hour, then heat it at 1150°C for 4 hours, and use a 1,600-ton fast forging machine for billet forging. The ratio is 1.7, the total forging ratio is 2.8, the final forging temperature is 900°C, after forging, chop and cut into thirds, and then use water cooling;

[0040] Step 2: Preheat the billet forged in step 1 at 820°C for 1 hour, then heat and hold it at 1050°C for 3 hours, use a 1600-ton fast forging machine to start forging above the phase transition point, upsetting times 2 times, each upsetting ratio 1.7, the total forging ratio is 2.8, the full anvil is used for feeding when drawing, the final fo...

Embodiment 2

[0045] In this embodiment, a 1,600-ton fast forging machine is used to process a TC4 titanium alloy bar with a diameter of 600mm×780mm as a raw material to process a TC4 titanium alloy bar with a diameter of 600mm×780mm. The processing method is as follows:

[0046] Step 1: Preheat a TC4 titanium alloy ingot with a diameter of about 600mm at 820°C for 2 hours, then heat and hold at 1170°C for 6 hours, use a 1600-ton fast forging machine for blank forging, upsetting times 3 times, each upsetting The drawing and forging ratio is about 1.7, the total forging ratio is about 4.6, the final forging temperature is 900°C, and water cooling is used after forging;

[0047] Step 2: Preheat the billet forged in step 1 at 820°C for 2 hours, then heat and hold at 1050°C for 4 hours, use a 1600-ton fast forging machine for forging, upsetting and drawing times are 3 times, and the upsetting and drawing ratio of the first two times is about 1.7. The third drawing length forging ratio is about ...

Embodiment 3

[0052] In this embodiment, a TC4 titanium alloy ingot with a diameter of 600 mm is used as a raw material to process a TC4 titanium alloy rod with a diameter of Φ300 mm×2000 mm. The processing method is as follows:

[0053] Step 1: Preheat a TC4 titanium alloy ingot with a diameter of about 600mm×1100mm at 820°C for 1 hour, then heat and hold it at 1170°C for 5 hours, and use a 1600-ton fast forging machine for billet forging. Upsetting times are 3 times, each The first upsetting and drawing ratio is about 1.7, the total forging ratio is about 4.6, the final forging temperature is 900°C, and water cooling is used after forging;

[0054] Step 2: Preheat the blank forged in step 1 at 820°C for 1 hour, then heat and hold at 1100°C for 4 hours, use a 1600-ton fast forging machine for intermediate forging above the phase transition point, upsetting times 4 times, each upsetting ratio Not about 1.7, the total forging ratio is about 7.8, the full anvil is used to feed when drawing, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com