Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

135results about How to "Improve forging quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Forging machining method of large-sized bar materials of TC4 (Ti-6Al-4V) titanium alloy

InactiveCN104070125ALess investmentSave energyForging/hammering/pressing machinesElectric arc furnaceIngot casting

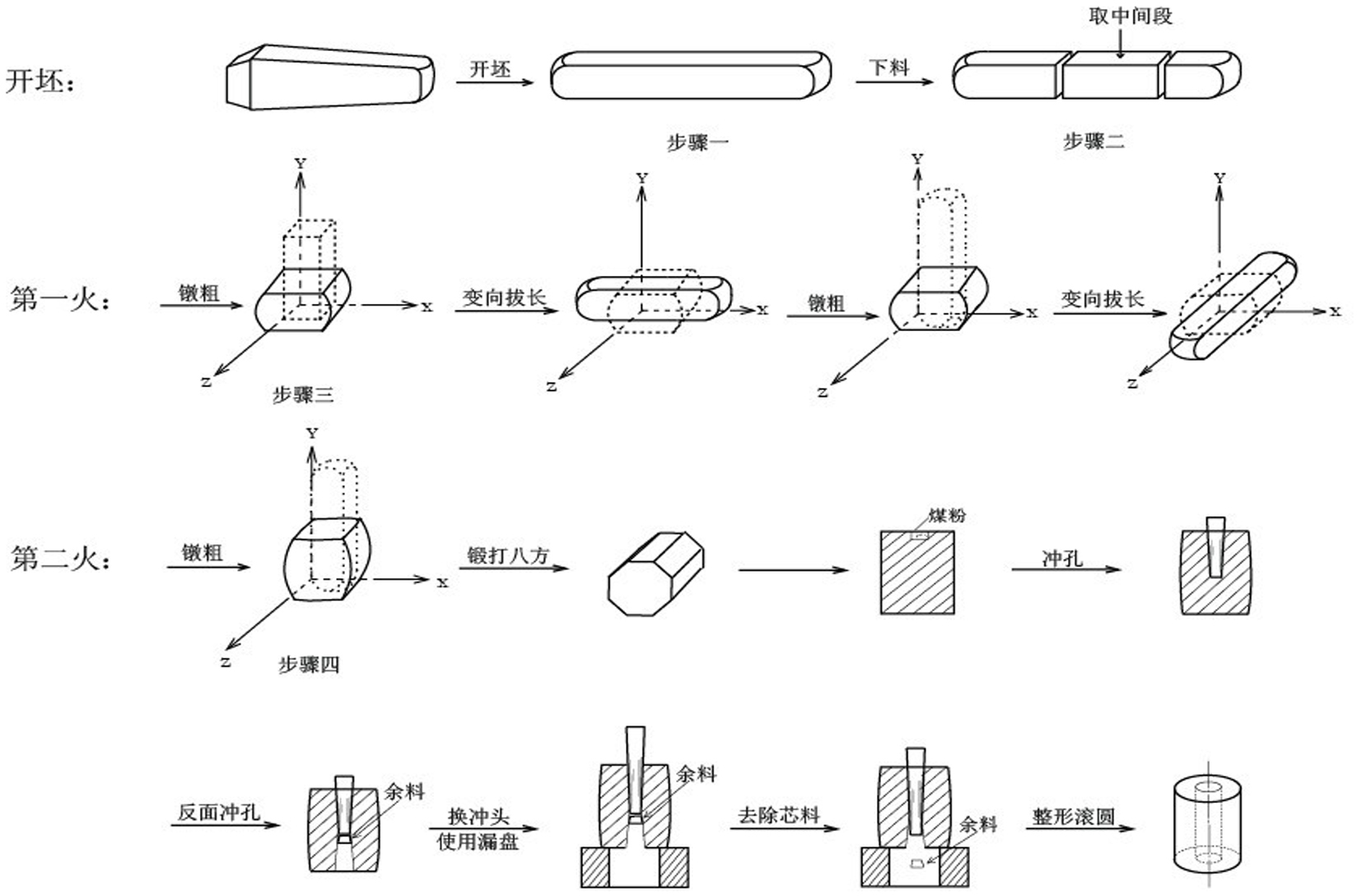

The invention relates to bar material forging machining method of titanium alloy, particularly to a forging machining method of large-sized bar materials of TC4 (Ti-6Al-4V) titanium alloy. The forging machining method is characterized by comprising the following steps of step 1, performing cogging forging, step 2, performing intermediate forging above a phase transformation point, step 3, performing intermediate forging below the phase transformation point, step 4 and step 5, performing finished product forging and obtaining the phi 200 to 300 mm and 2000 to 3000 mm length of large-sized bar materials of the TC4 titanium alloy finally. Compared with the prior art, a large-sized ingot casting and a large-tonnage forging device are not required and the industrialized production can be achieved through an ordinary industrial 3 ton ingot and a small-tonnage forging press and the equipment investment is small, only a 3 tons of electric arc furnace and a 3000 tons of forming oil press which is matched with the electric arc furnace need to be invested in the phi 600 of 3 ton ingot, the small-tonnage forging press such as a 1600 tons of forging press needs to be invested in the forging process, and accordingly the equipment investment is significantly reduced.

Owner:宁夏中色金航钛业有限公司

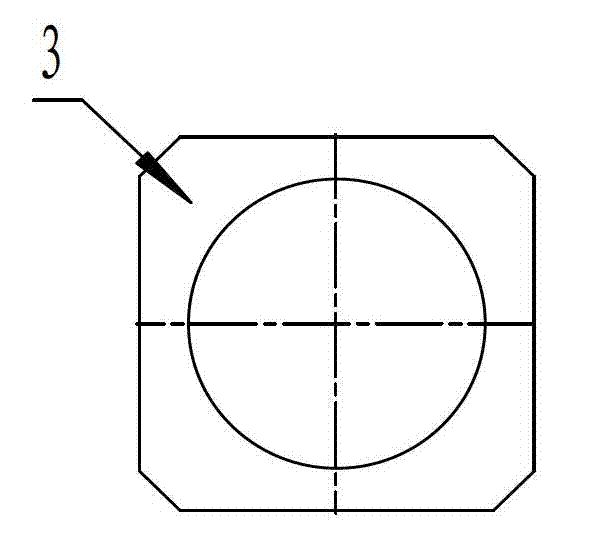

Steel forging manufacturing process for deep-sea Christmas tree equipment connectors

ActiveCN102071367AEliminate the problem of increased toughnessImprove forging qualityMetal-working apparatusPunchingEngineering

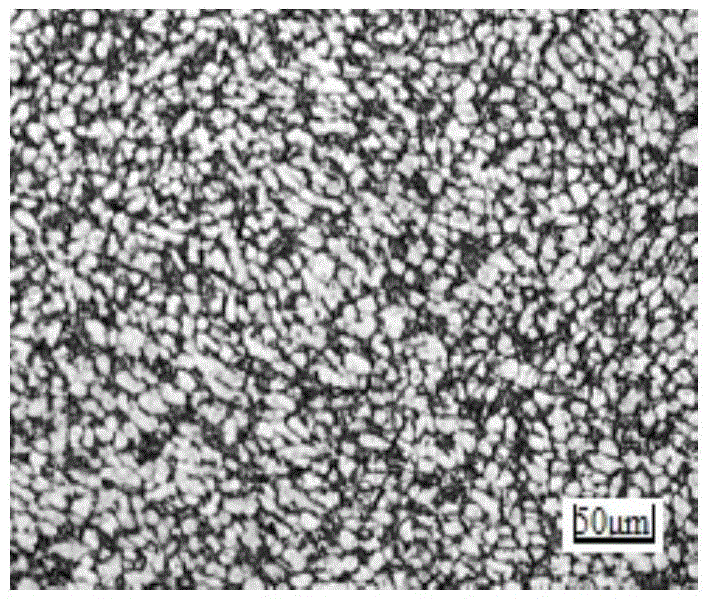

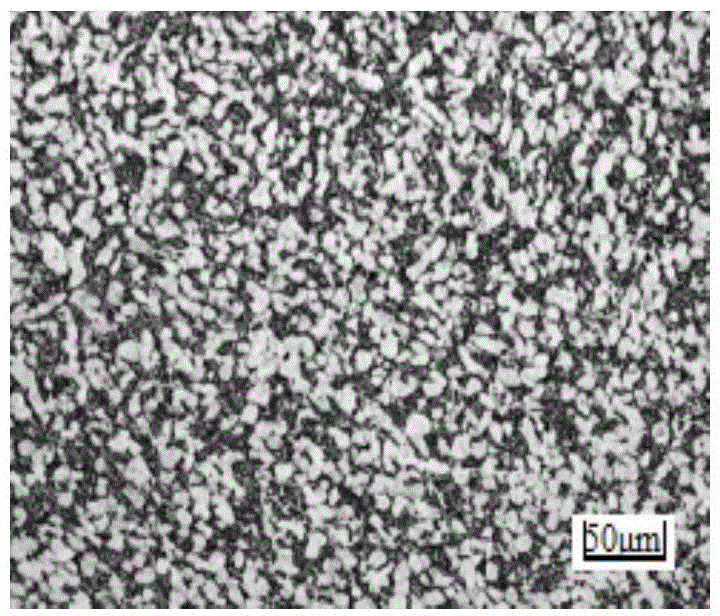

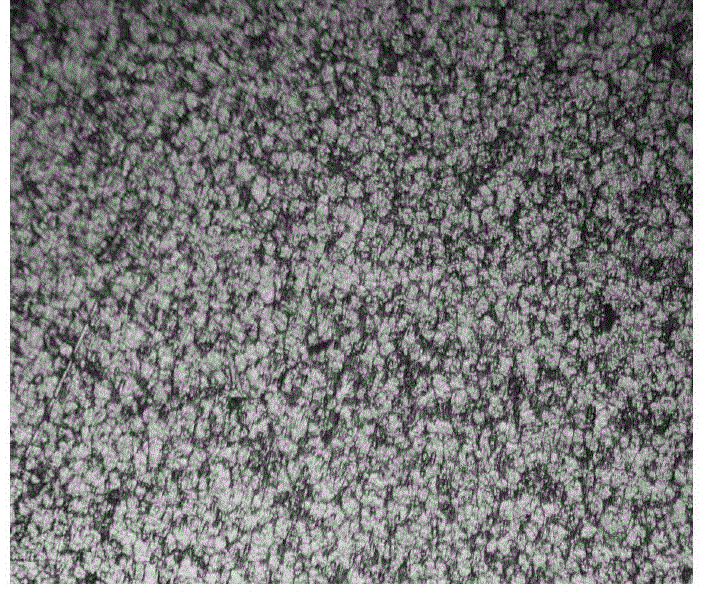

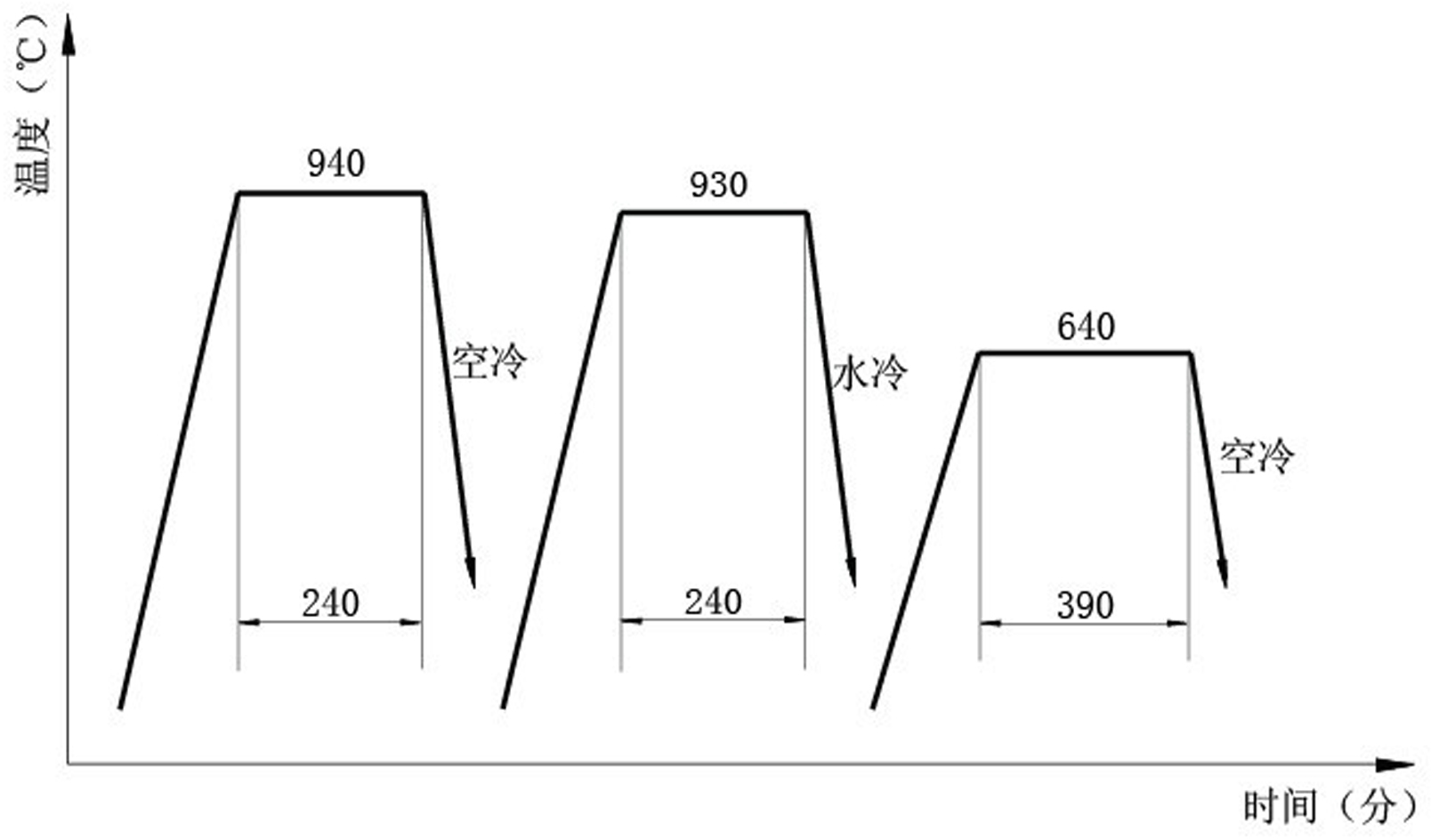

The invention relates to a steel forging manufacturing process for deep-sea Christmas tree equipment connectors, which comprises the following steps: (1) using chromium-nickel-molybdenum low-alloy steel as the blank material; (2) selecting square ingots, heating to 1220 DEG C, cogging, pulling out the material, sawing, and taking the middle section as the blank; (3) heating to the initial forging temperature, upsetting in the directions of three-dimensional coordinates, and drawing out to obtain the isotropic blank; (4) upsetting and forging the blank to obtain an octagonal prism, punching, circularly rolling and shaping to obtain a cylindrical forging stock with a hole; (5) carrying out rough machining on the cylindrical forging stock with a hole to obtain a cylindrical workpiece with a hole; (6) heating the cylindrical workpiece with a hole to 940 DEG C, and cooling in the air to room temperature; (7) heating the cylindrical workpiece with a hole subjected to the step (6), to 930 DEG C, and quenching with water; and (8) heating the cylindrical workpiece with a hole subjected to the step (7), to 640 DEG C, and cooling in the air to room temperature.

Owner:NANJING DEV ADVANCED MFG

Manufacturing process of forging stock of steel forging piece for oil extraction equipment in deep sea

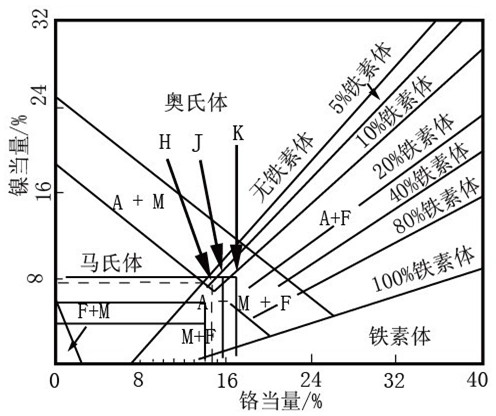

The invention discloses a manufacturing process of a forging stock of a steel forging piece for oil extracting equipment in a deep sea, which comprises the following steps of: with martensite precipitation hardening type stainless steel as a steel forging piece material, selecting a square ingot, heating to 1180DEG C, cogging along the length direction of the steel ingot to obtain an octagonal section steel billet, wherein the forging ratio is 2.0-2.2; heating the octagonal section steel billet to 1040DEG C and preserving heat for 360 minutes; carrying out oil cooling below 32DEG C; taking an intermediate section as a billet; axially upsetting the billet from the initial forging temperature of 1150DEG C to the final forging temperature of 990DEG C; when the billet is upset to half of the height of the original billet, drawing out the octagonal section of the upset billet according to the original axial direction; axially upsetting when the billet is drawn to the length of the original billet; when the billet is upset to half of the height of the original billet, drawing out the octagonal section of the upset billet according to the original axial direction; when axially forging and shaping the billet when the billet is upset to half of the height of the original billet, enabling the total forging ratio to be 5.5 and obtaining a rectangular forging piece; and air cooling to be 340-360DEG C, carrying out furnace insulating for 120 minutes and then carrying out furnace cooling to the room temperature.

Owner:NANJING DEV ADVANCED MFG

Process for manufacturing steel forge piece of vertical conveying pipe of deep sea oil extraction equipment

The invention discloses a process for manufacturing a steel forge piece of a vertical conveying pipe of deep sea oil extraction equipment. The process comprises the following steps of: 1, taking chrome molybdenum low alloy steel as a blank; 2, putting a square ingot into a furnace, heating to 1,200 DEG C, and cogging to pull the blank along the length direction of a steel ingot; 3, putting the blank into the furnace, heating, and discharging the blank to obtain a blank which is compacted and forged completely; 4, forging the blank which is compacted and forged completely to form an eight-directional edge shaft to obtain a stepped shaft forged blank; 5, performing rough machining on the stepped shaft forged blank to obtain a hollow stepped workpiece; 6, heating the hollow stepped workpiece to 900 DEG C, preserving the heat for 3 hours, discharging, and cooling to room temperature in the air; 7, heating the hollow stepped workpiece to 920 DEG C, preserving the heat for 3 hours, and performing water quenching, wherein the quenched water temperature is not more than 49 DEG C after the water quenching is finished; and 8, heating the hollow stepped workpiece to 625 DEG C, preserving the heat for 6 hours, and cooling to room temperature in the air. The forge piece manufactured by the process can be well suitable for a deep sea low-temperature working condition environment.

Owner:迪威尔(南京)精工科技有限公司

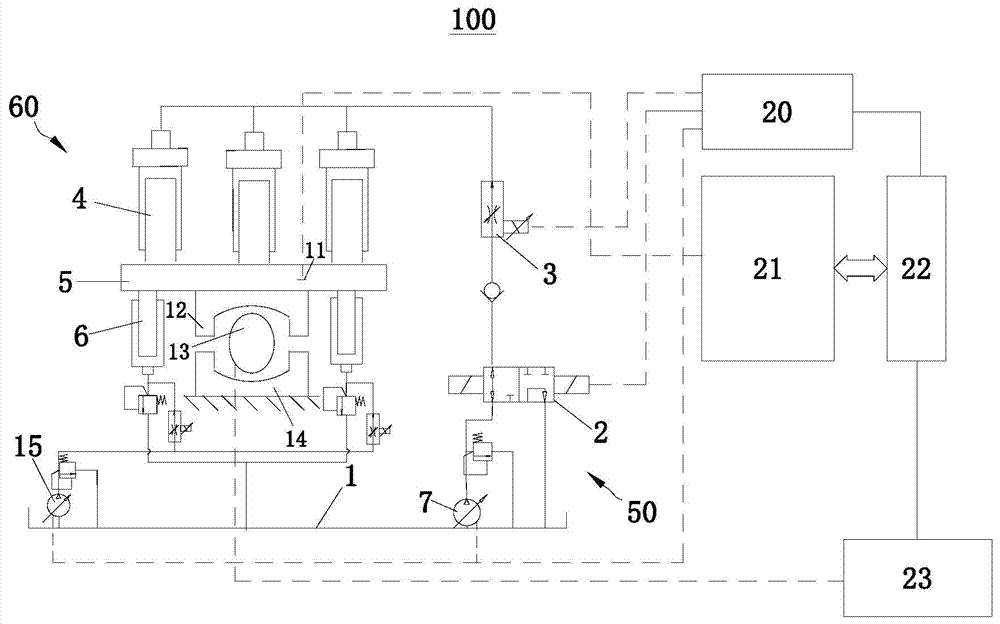

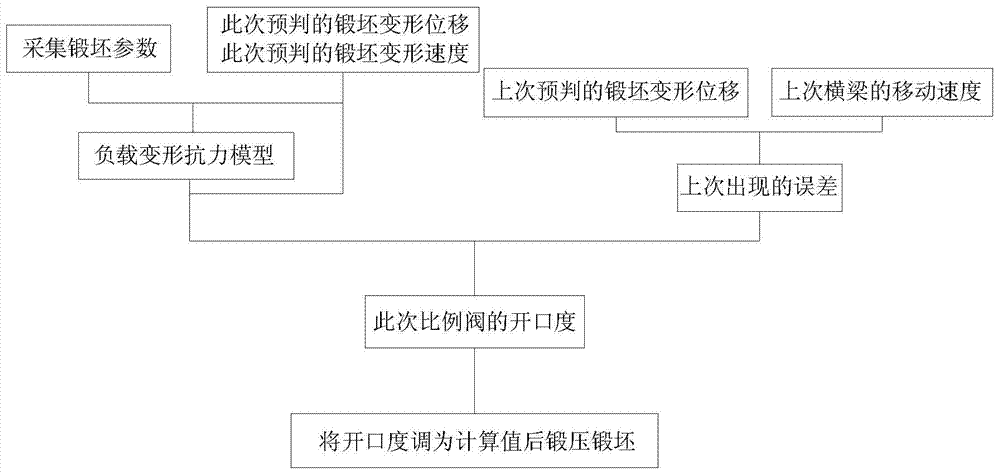

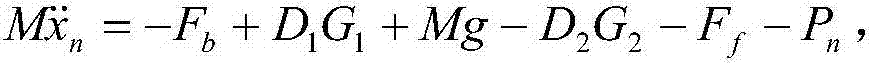

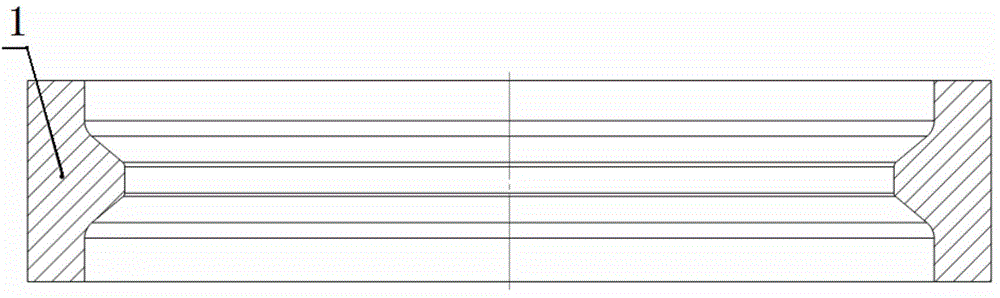

Forging press control method and control system of forging press

The invention provides a forging press control method and a control system of a forging press. The forging press control method includes steps of acquiring forging stock parameters, and calculating to obtain load deformation resistance model at the specific temperature according to the forging stock parameters, anticipated forging stock deformation displacement and forging stock deformation speed; calculating to obtain required opening degree of a proportional valve of a forging press in this forging according to the load deformation resistance model and an error appearing in the last forging process; adjusting the opening degree of the proportional valve to the calculated value and then forging the forging stock. According to the forging press control method and the control system of the forging press, forging process of a crossbeam can be frequently adjusted, the integral forging process is stable to run, and quality of forged pieces can be guaranteed.

Owner:CENT SOUTH UNIV

Manufacturing method for large internal T-shaped ring forge piece blank of SB564UNS N06690 alloy

The invention discloses a manufacturing method for a large internal T-shaped ring forge piece blank of SB564UNS N06690 alloy. Firstly, upsetting and drawing are performed through a hydraulic forging press, a punch with the diameter of 300mm is used for punching, then chambering and rounding are performed, twice rolling is performed on a ring rolling mill by the aid of a step mold, an original blank with a rectangular section is circularly rolled into a middle blank with a step, then the middle blank is rotated by 180 degrees, and second rolling is performed, so that the internal T-shaped annular forge piece blank is obtained. According to the manufacturing method for the large internal T-shaped annular forge piece blank of the SB564UNS N06690 alloy, the structure of the manufactured forge piece blank is uniform, grains are refined, shapes are rectangular, and the forge piece quality and the production efficiency are high.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

Tech. for forging forming of hook fastener flame of wagon and maould thereof

InactiveCN1792544AShorten the lengthSave materialForging/hammering/pressing machinesOther manufacturing equipments/toolsTruckRailway freight car

A technology for manufacturing the coupler tail frame of cargo train by forging includes such steps as blanking, heating, making raw coupler tail frame, die forging step by step, that is, forging one end and then another end, removing excessive edge, bending an welding. Its die set is composed of upper die with internal cavity whose length is equal to that of finished blank, and lower die with internal cavity having a central locating pit.

Owner:CHONGQING UNIV OF TECH

Processing method for crossed forged piece for supporting ITER magnet

ActiveCN105499478ASmall machining allowanceUniform tissueForging/hammering/pressing machinesDomestic articlesIngotMachine

The invention relates to a processing method for a crossed forged piece for supporting an ITER magnet. The processing method comprises the following steps: 1) manufacturing a set of moulds used for upset-extruding and forming; 2) getting and processing an alloy ingot into ring-shaped blank; 3) assembling the moulds; 4) putting the blank into the moulds, and utilizing a hydraulic press to carry out upset-extruding on the blank to obtain crossed ring blank; 5) manufacturing a second outer mould and an inner mould used for milled ring processing; 6) carrying out milled ring rolling on the crossed ring blank, and processing the crossed ring blank to obtain a crossed ring part; 7) splitting the crossed ring part in a height direction, controlling the hydraulic press to press by enabling a core rod to pass through an inner hole of the crossed ring part, and gradually expanding the crossed ring part into the crossed forged piece; and 8) leveling the crossed forged piece by use of a leveling machine, and finally obtaining the crossed forged piece which is in the shape of a flat plate, and is symmetrically provided with bulges at two sides.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

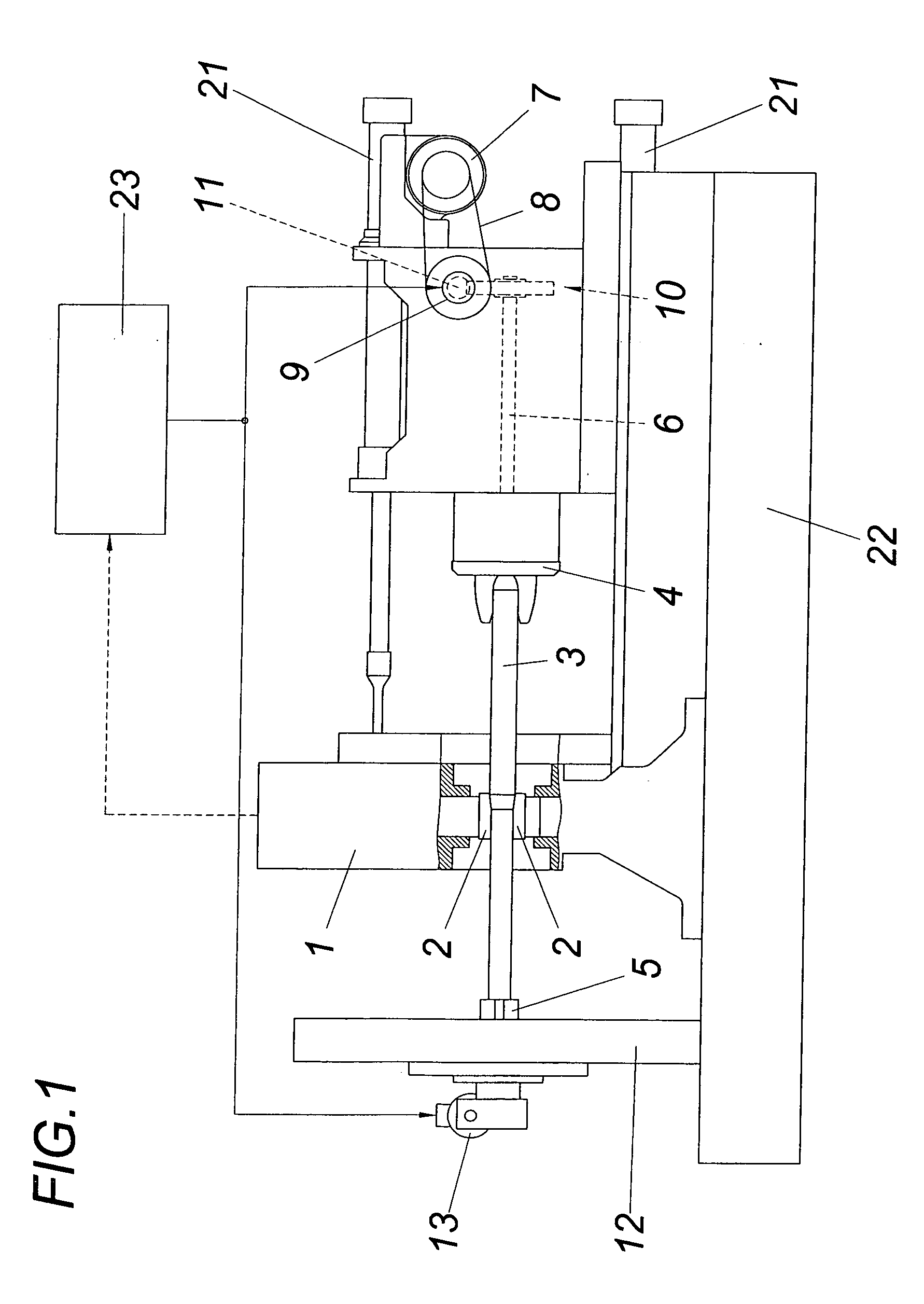

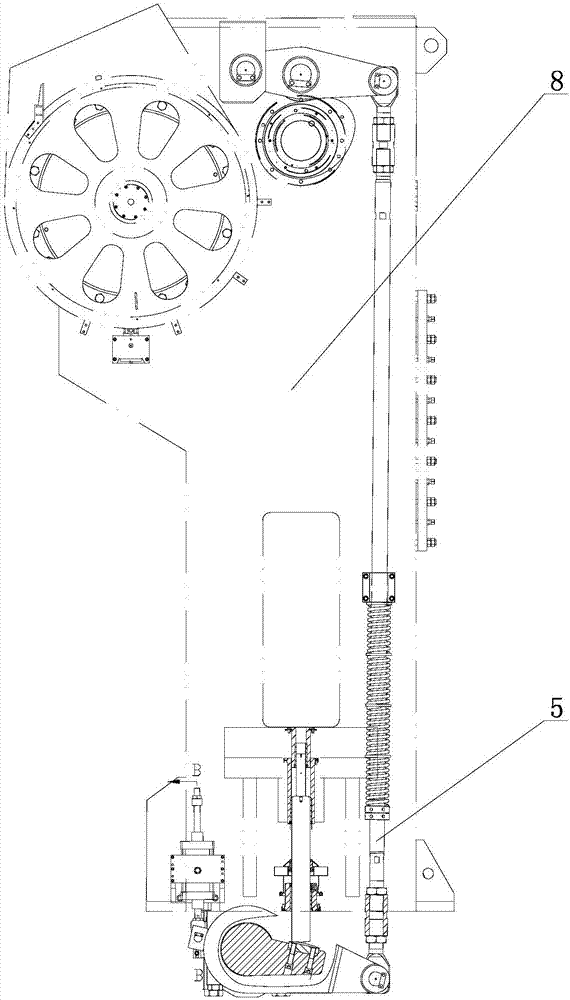

Intelligent control method for die hammer and intelligent die hammer produced according to said method

ActiveCN1544180AExtended service lifeGuaranteed Strike ForgedHammer drivesEquipment temperatureMonitoring system

Disclosed are an intelligent control method for a die hammer and an intelligent die hammer produced according to said method. The method comprises the following steps: (1) initialization: controlling oil temperature, pressure, cleaning degree and die equipment temperature, and determining the striking energy, times, order and frequency frequency according to the material quality, size and deformation degree of the forgeable pieces; (2) striking: heating the forgeable piece until it reaches the temperature for forging, moving the workpiece to a model chamber chamber for striking through a manipulation mechanical arm, after that, transferring the forgeable piece to a final product box through the manipulation mechanical arm; (3) intelligence controlling: detecting on-line the forgeable piece thickness, machine frame vibration movement and forgeable piece temperature parameters, and automatically optimizing the striking parameters. For the die hammer which is equipped with a behavior monitoring apparatus comprising a sensor mounted at the die hammer, wherein the sensor is connected to the behavior monitoring apparatus, the monitoring apparatus includes an expert system, a hydraulic-oil executive supervisor, a temperature executive supervisor , a forgeable piece size monitoring system, an intelligence control system and the like, and a mechanical arm. The invention has the following beneficial effect: it can realize automatization and intelligentization of a hammer and the parameter optimization control, avoid man's activity. One can select optimal the starting and final forging temperature and the striking energy, time, order and frequency, according to the forgeable piece material and the deformation degree. The striking energy, forgeable piece striking direction and size and the forgeable piece temperature are detected, and then corrected to realize the high automatization and the optimized control.

Owner:NANTONG UNIVERSITY

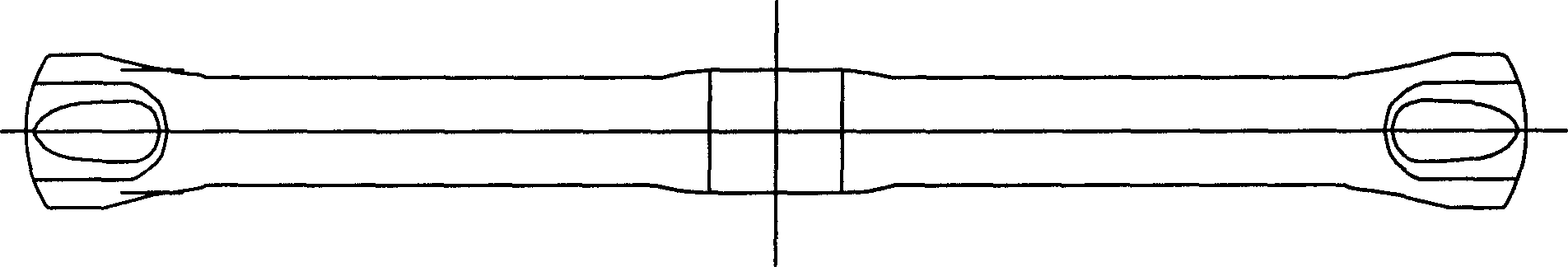

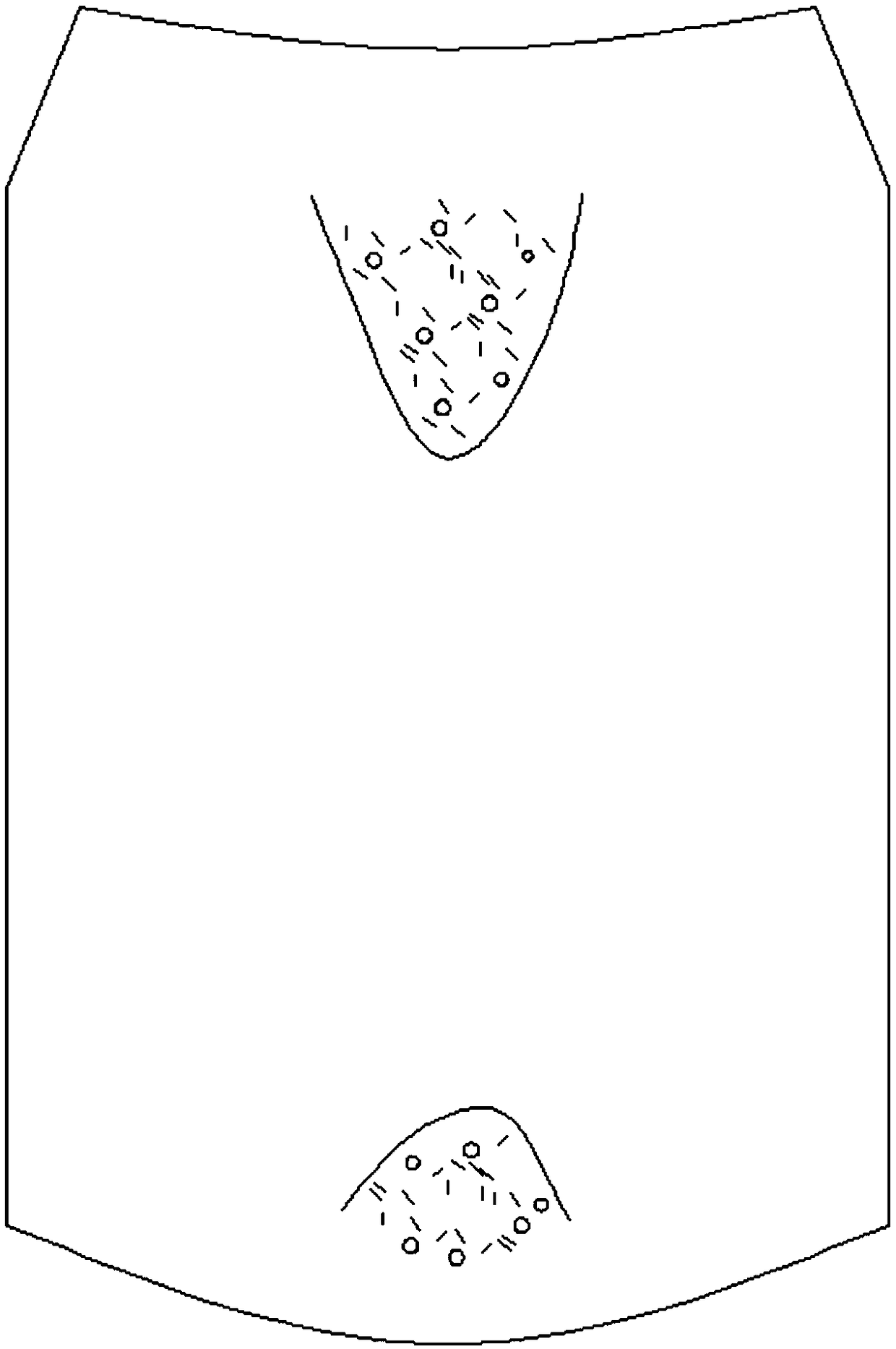

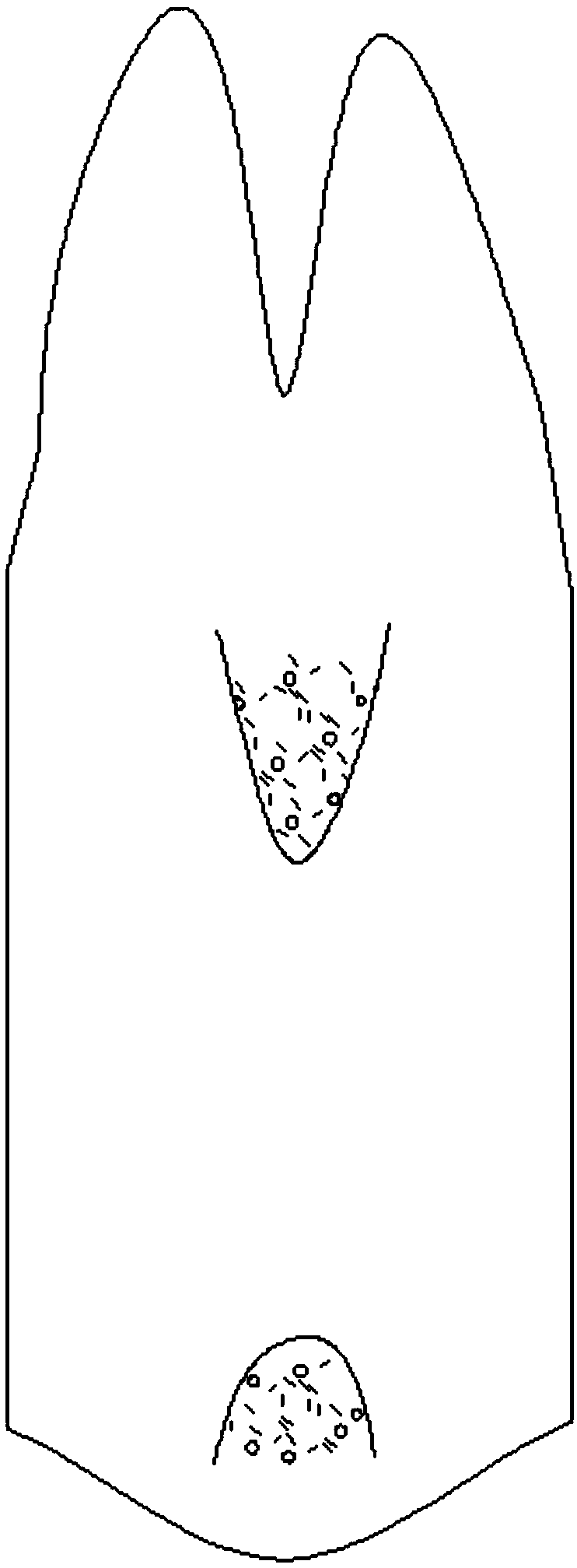

Method for forging double-lug U-shaped forged piece for thermonuclear fusion reactor

ActiveCN104162616AUniform deformationMeet the use requirementsMetal-working apparatusMetal fibersIngot

The invention discloses a method for forging a double-lug U-shaped forged piece for a thermonuclear fusion reactor. The method comprises the steps that firstly, a raw material ingot is heated to an initial forging temperature; secondly, a circular-ring-shaped blank is manufactured through the process of upsetting, punching, chambering and rounding, the circular-ring-shaped blank is forged into a rectangular-ring-shaped blank, the rectangular-ring-shaped blank is sawn off from the middle, and U-shaped blanks are obtained; thirdly, pressing is conducted through a hollow punch, so that the bottom of each U-shaped blank deforms to meet the size requirement; fourthly, the U-shaped blanks and the hollow punch are turned over together, each U-shaped blank is stretched, so that double-lug U-shaped blanks are obtained, and each double-lug U-shaped blank and the hollow punch are placed into a double-lug upsetting forming die together for overall upsetting; finally, the double-lug U-shaped forged piece is obtained. According to the method for forging the double-lug U-shaped forged piece for the thermonuclear fusion reactor, the metal fiber flow of the forged piece is distributed according to the shape of the product through integrated forging forming of complicated-structure parts, the structure is even, grain refinement is achieved, the shape is regular, and the special use demand of the thermonuclear fusion reactor can be met.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

Method for upsetting high-temperature alloy round ingot

InactiveCN101633029AReduce deformation resistanceHigh yieldMetal-working apparatusMetals industryIngot

The invention provides a method for upsetting a high-temperature alloy round ingot, belonging to the technical field of hot processing forging of high-temperature alloy in the metal industry. The method comprises the following steps that an alloy round ingot blank is preprocessed, before the blank is heated in a furnace, the alloy round ingot is subjected to top crops and end crops, so that end faces of two ends of the alloy round ingot blank which is subjected to top crops and end crops are flat to a degree vertical to the axial line of the alloy round ingot, thereby obtaining an alloy round ingot to be heated in the furnace; a ceramic insulation blanket is coated, the ceramic insulation blanket is coated in the middle of the alloy round ingot to be heated in the furnace so as to obtain a ceramic insulation blanket coated alloy round ingot to be heated in the furnace; the ingot is heated in the furnace, the ceramic insulation blanket coated alloy round ingot to be heated in the furnace is fed into the furnace for heating; the ingot is discharged from the furnace; the time from discharging to upsetting is controlled to obtain the alloy round ingot to be upset; the ingot is upset, the alloy round ingot to be upset is upset to obtain an upset intermediate blank. The method has the advantages of improving the yield and forging efficiency of alloy forging, improving the quality of a forge piece, and reducing energy consumption.

Owner:江苏苏南特种金属保温锻造研发中心有限公司

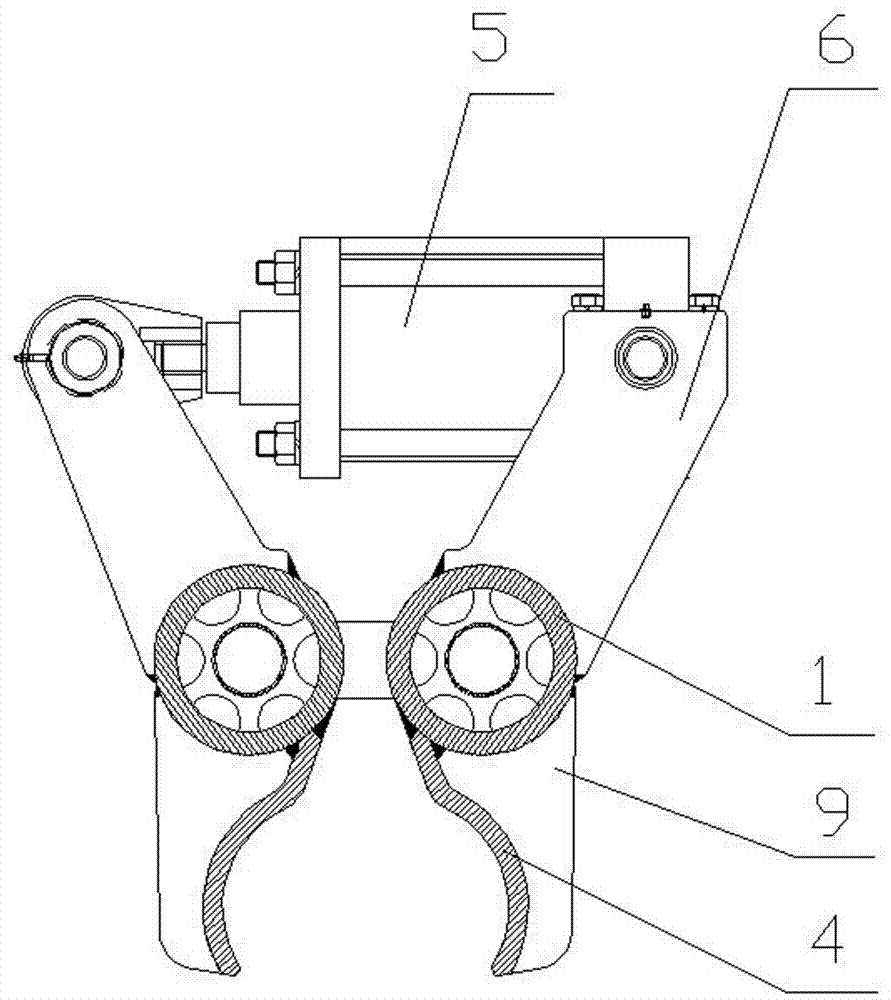

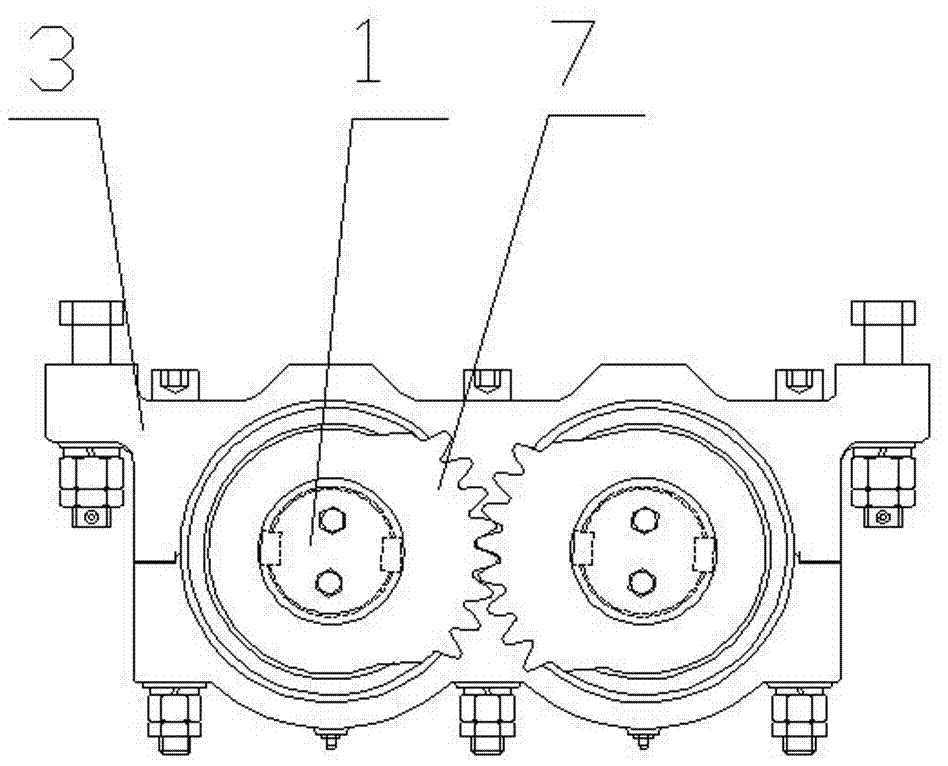

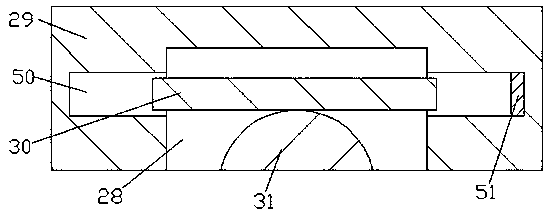

Apparatus for cutting a workpiece

ActiveUS20060065037A1Improve forging qualityHigh strengthMetal-working feeding devicesForging/hammering/pressing machinesEngineeringHead parts

An apparatus is described for forging a workpiece (3) with an intermittently drivable clamping head (4) for the workpiece (3) and with a counter-holder (5) for receiving the end of the workpiece (3) averted from the clamping head (4), which counter-holder is rotatably held in a frame (12). In order to provide advantageous constructional conditions it is proposed that the counter-holder (5) is connected with an intermittent rotational drive (13) which can be triggered synchronously to the clamping head (4).

Owner:GFM BETEILIGUNGS & MANAGEMENT

Forging process and equipment for high-temperature-resistant and high-pressure-resistant stainless steel ring

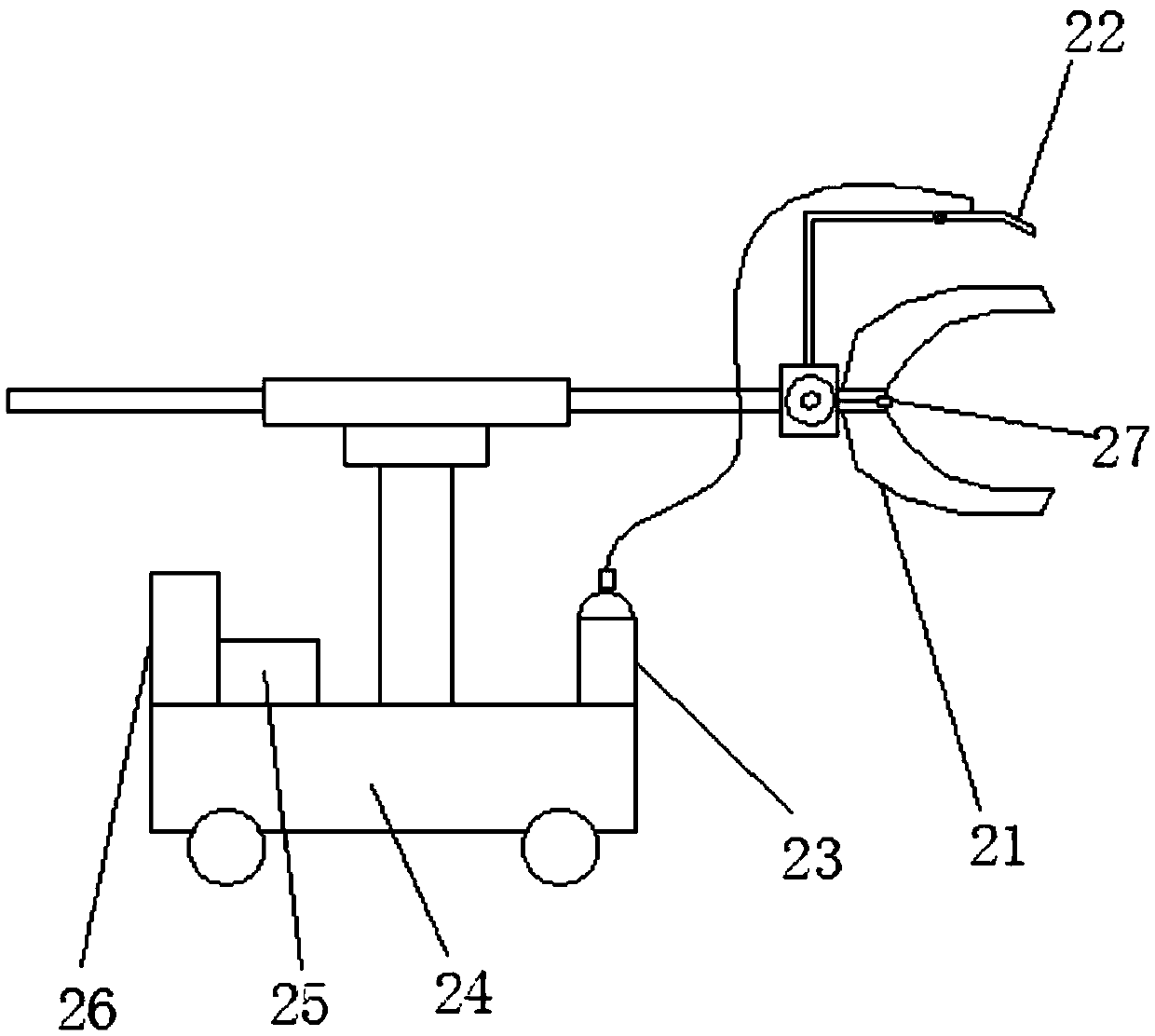

InactiveCN109590417ARealize the heating effectRealize the insulation effectPiercing pressesHeating/cooling devicesPunchingForging manipulator

The invention relates to the technical field of forging and discloses forging process and equipment for a high-temperature-resistant and high-pressure-resistant stainless steel ring. The forging process comprises the following process steps of step 10, blanking, step 20, heating before upsetting, step 30, upsetting, step 40, punching, step 50, heating before ring milling, step 60, ring milling andstep 70, slow cooling. The stainless steel ring is transferred in each forging workstage and between workstages by using a forging manipulator, the front end of the forging manipulator is provided with an infrared thermometer for online measuring of the temperature of a blank and a flame heating device for online heating and heat preservation of the blank, and the forging manipulator turns on theflame heating device in the process of transferring the blank to carry out heating and heat preservation on the blank of the stainless steel ring. By the adoption of the forging process and equipment, good control over the temperature of the blank of the stainless steel ring in the forging process is realized, so that the forging quality is improved, and the forging energy consumption is reduced.

Owner:JIANGYIN HENGRUN RING FORGING

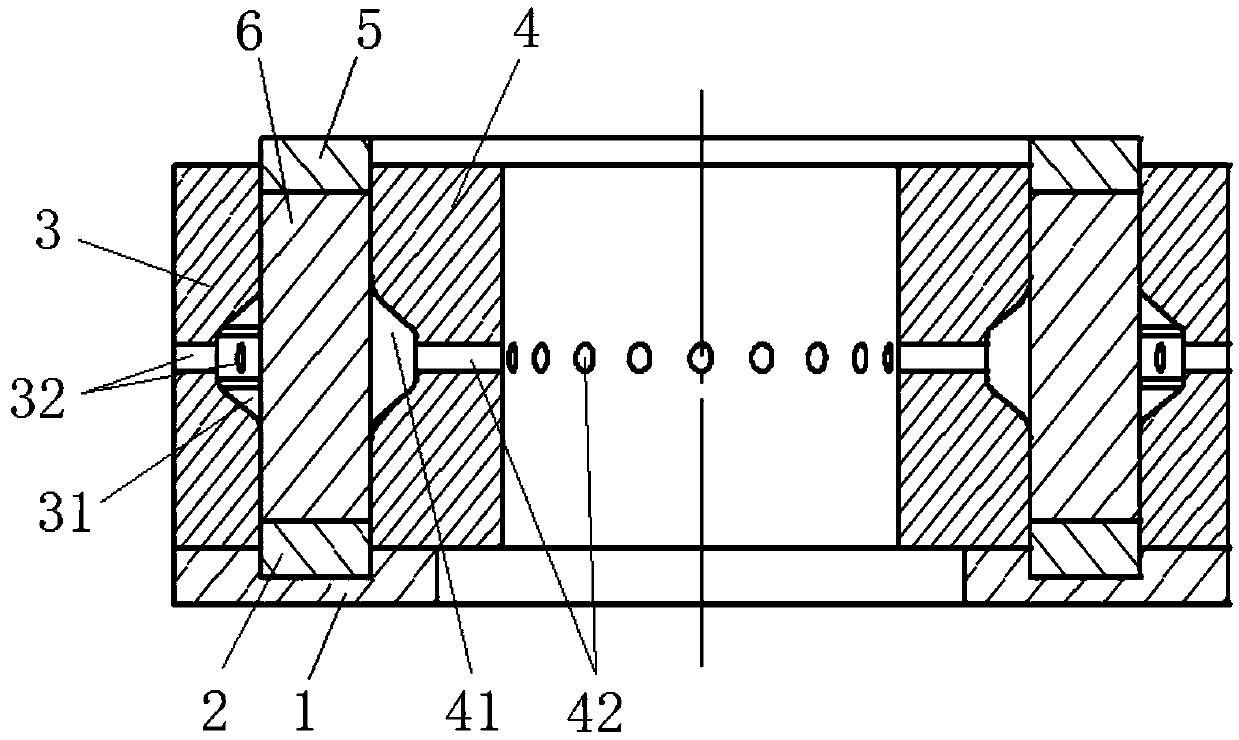

Mechanical lower forging extrusion and material ejection device of forging mechanical press

ActiveCN107470531AExtended service lifeImprove forging qualityForging hammersUpsetting pressesMachine pressMechanical press

A mechanical lower forging extrusion and material ejection device of a forging mechanical press comprises a crank shaft arranged on a machine body; one end of the crank shaft penetrates through the machine body and is provided with an eccentric sleeve; a connection rod is installed on the eccentric sleeve, an upper pull rod is hinged to the lower end of the connection rod, and the lower end of the upper pull rod is connected with a lower pull rod through a belleville spring; the lower end of the lower pull rod is hinged to one end of a lever; the upper pull rod and the lower pull rod are installed on a bracket, and the bracket is connected with the machine body; a long hole is formed in the middle of the lever and internally provided with a third pin shaft, and the third pin shaft is arranged on a support fixedly connected with the bottom of the machine body; and the other end of the lever is provided with a rolling wheel making contact with the bottom of a material ejection seat, an ejection plate is arranged at the upper end of the material ejection seat, the two sides of the ejection plate are provided with air cylinders correspondingly, and a plurality of upper ejection rods are arranged at the upper end of the ejection plate and are installed in a workbench. The mechanical lower forging extrusion and material ejection device has the advantages of having a synchronous forging extrusion function or a drawing function or a asynchronous ejection function, and being diversified in purpose, adjustable in lower forging extrusion force or ejection force, capable of preventing overload, long in service life, high in product quality and the like.

Owner:RONGCHENG HUADONG METAL FORMING MACHINERY

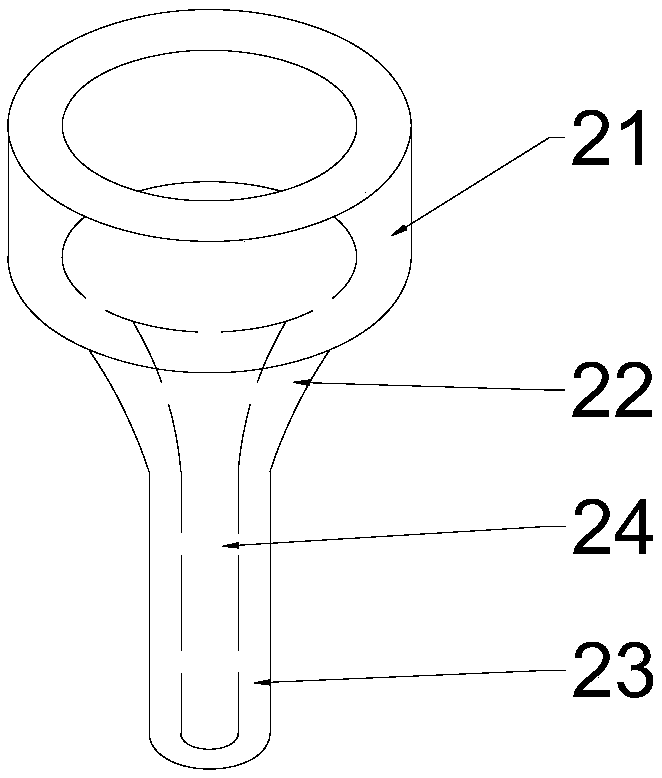

Machining technology for electrified railway overhead line system metal die forging porcelain insulator lower steel cap

The invention provides a machining technology for an electrified railway overhead line system metal die forging porcelain insulator lower steel cap. The machining technology comprises the steps that a blank with the diameter being 70mm*125mm is cut, a ceramic fiber blanket wraps the blank to slow down the heat loss, upsetting is carried out on the heated blank, an oxide skin on the outer circular surface of a middle blank is removed through a steel brush after upsetting to improve the quality of a forge piece, die forging is carried out, a cylindrical part is forged into the circular cone cylindrical shape and then is forged into the cylindrical shape with the equal diameter, forging quality is good, forging efficiency is high, quenching is carried out on a finished forge piece, an oxide skin on the surface of the finished forge piece is removed through a grinding brush, a through hole and the inner wall of the cylindrical part are machined, the surface is processed, galvanization is carried out, and then machining of the lower steel cap is finished.

Owner:SHANDONG SHENLI RIGGING

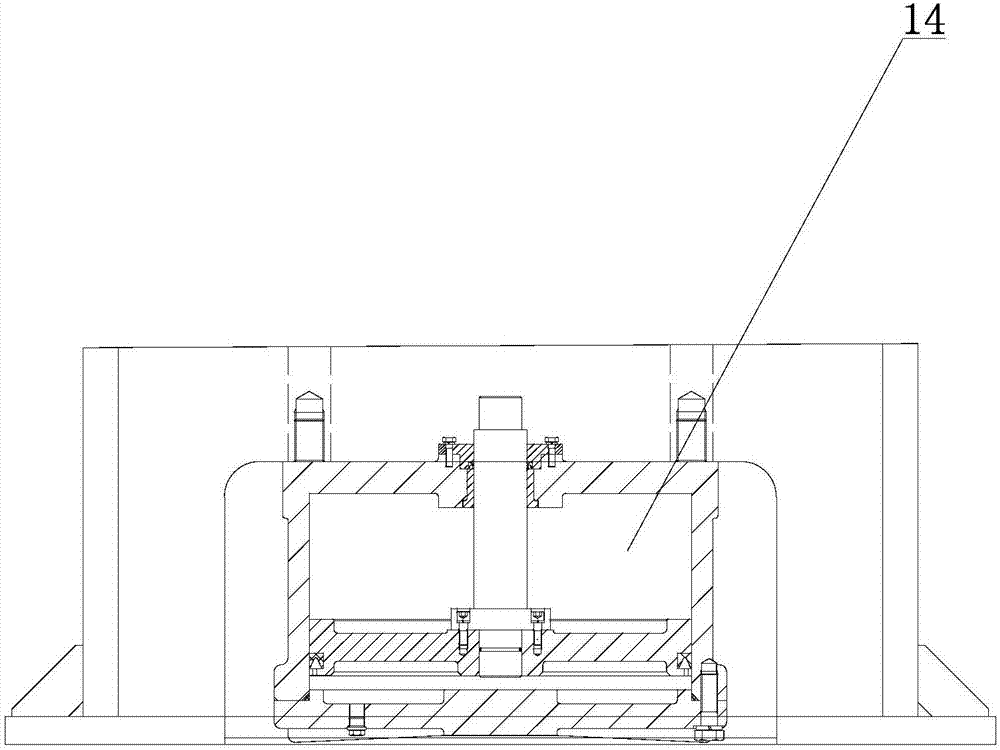

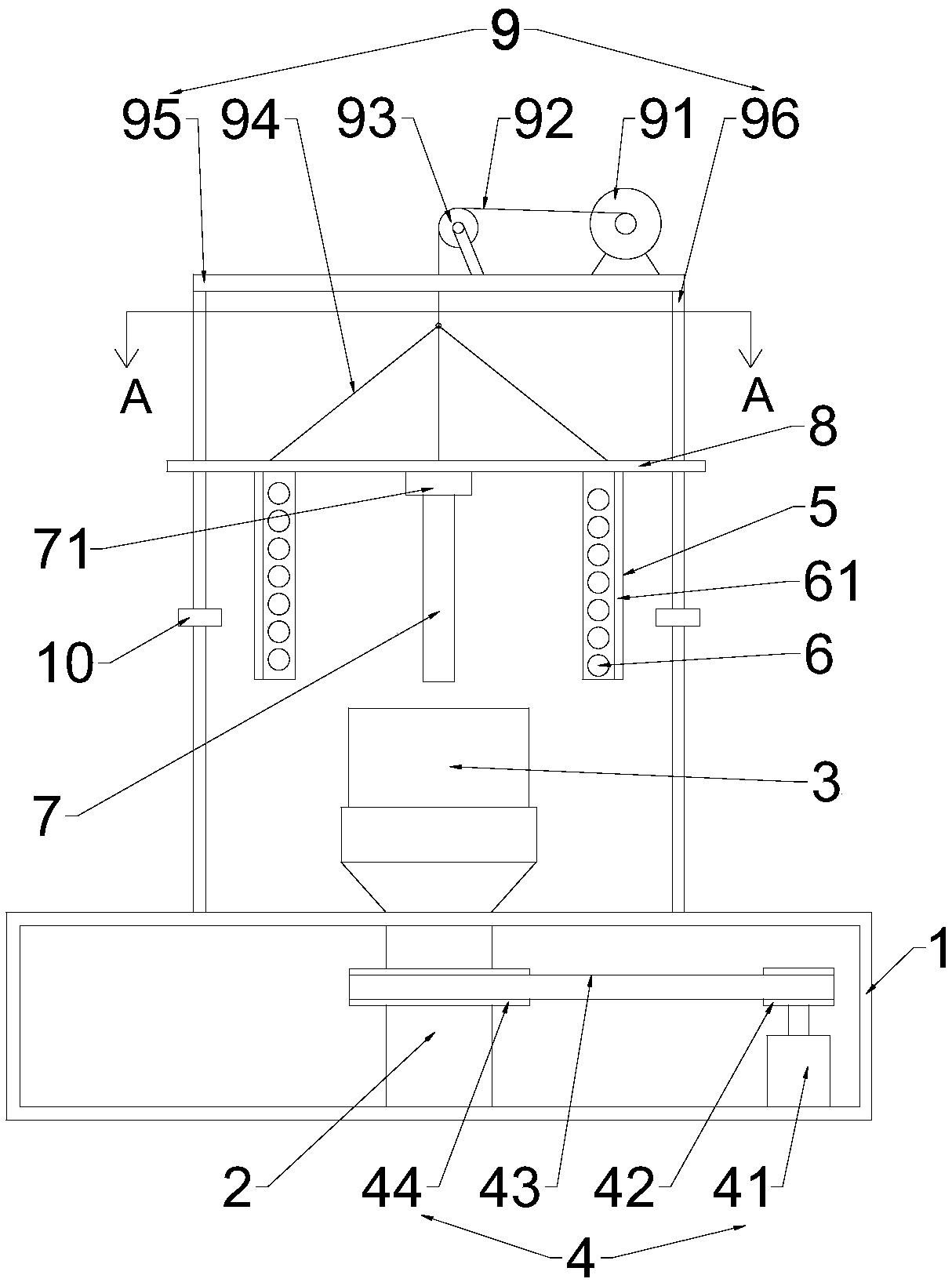

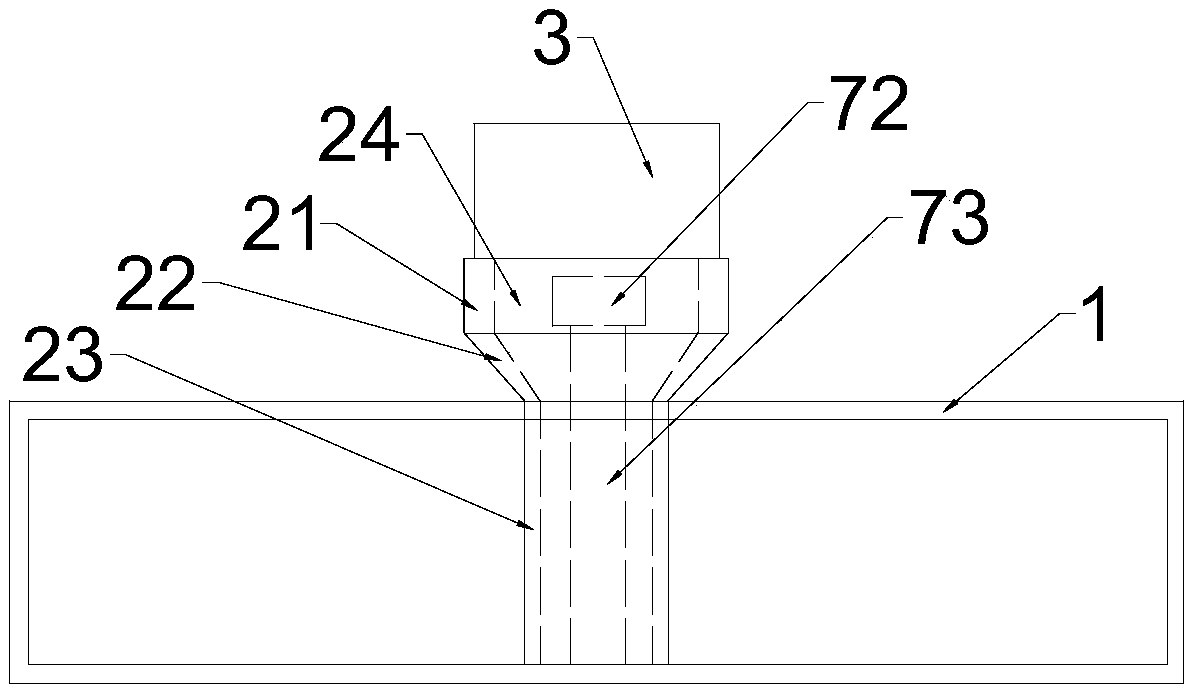

Full-automatic multi-station forging hydraulic press

ActiveCN108580776AReduce temperature dropIncrease productivityUpsetting pressesSwagging pressesHydraulic cylinderPunching

The invention discloses a full-automatic multi-station forging hydraulic press. The full-automatic multi-station forging hydraulic press mainly comprises a main machine, a swinging rotary formwork, piece moving manipulators and a moving worktable. The swinging rotary formwork mainly comprises a bracket, an upper support, a lower support, a main shaft, a swing arm and a punching seat. Each piece moving manipulator mainly includes a sliding seat, a vertical hydraulic cylinder, a horizontal hydraulic cylinder, a guide rod and a clamping seat. The full-automatic multi-station forging hydraulic press has an automatic conversion function of forging stations, and can complete a plurality of forging processes such as upsetting, perforating, trimming and turning and squeezing in a production line mode.

Owner:NANTONG METALFORMING EQUIP

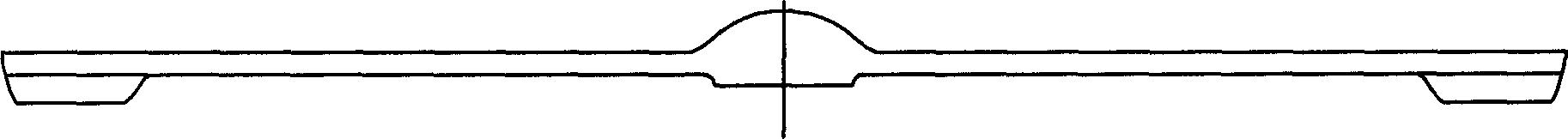

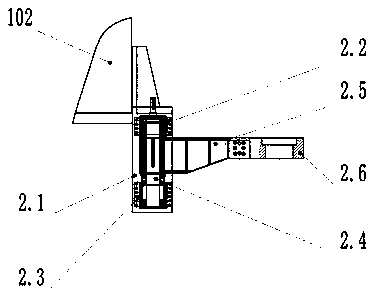

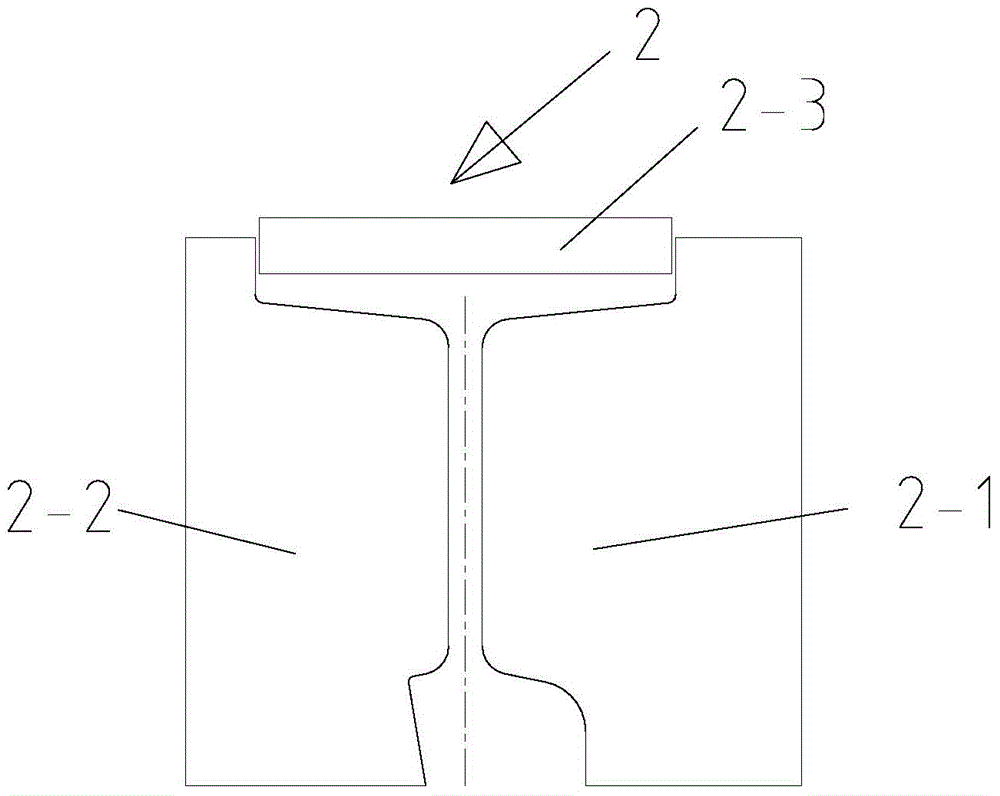

59R2 special-shaped rail and forming method thereof

ActiveCN104452486AImprove forging qualityEasy to processRailsForging/hammering/pressing machinesRoom temperatureEngineering

The invention provides a 59R2 special-shaped rail and a forming method thereof. The 59R2 special-shaped rail is composed of a raw material section, a profiling transition section and a forming section. The rail waist centerline of the forming section and the rail waist centerline of the raw material section have 20 mm offset, and the cross section of the forming section is an asymmetric cross section. The forming method of the 59R2 special-shaped rail includes the following steps of inductive heating or natural gas fuel heating before forging, preforging conducted through an asymmetric preforging die, finish forging conducted through an asymmetric finish forging die, normalizing heat treatment after forging, air cooling of a forged piece to a room temperature after forging and machining after forging, an asymmetric movable block combination die structure is adopted for the forging dies, the problems that according to an existing forming method, blank metal of a die is not prone to flow, the quality of a forged piece is low and process precision is poor are solved, and the forming method is suitable for high-precision, high-quality and high-efficiency production of the 59R2 special-shaped rail matched with 50kg / m-59R2 type steel rails.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

Mould preheating device

The invention provides a mould preheating device. The mould preheating device comprises a hollow base, a mould supporting shaft for fixing a mould is arranged at the center of the base, the mould supporting shaft sequentially comprises a supporting column, a transition shaft and a rotary shaft from top to bottom, the bottom end and the mid-upper side wall of the rotary shaft are rotatably fixed onthe base , the rotary shaft inside the base is connected with a rotating device, a ring-shaped heating housing is arranged above the mould, the heating housing is internally provided with heating wires, the top surface of the heating housing is fixed on a lifting plate, an electromagnetic heating rod is coaxially arranged at the center of the heating housing, the top end of the electromagnetic heating rod is fixed to an upper heating seat, the upper heating seat is fixed on the lifting plate, a cavity accommodating a lower heating seat is arranged at the center of the mould supporting shaft,the lower heating seat is arranged at the top of the cavity, the lower heating seat is fixed to the bottom surface of the base, the two heating seats serve as electrodes of the electromagnetic heatingrod, and the lifting plate is connected with a lifting device. The mould preheating device is capable of heating the inside wall and the outside wall of the mould at the same time, and the mould heating uniformity is improved.

Owner:TIANJIN MOTOR DIES

Stabilizing treatment technology of forged piece machining

The invention aims at providing a stabilizing treatment technology of forged piece machining. The process of the stabilizing treatment technology comprises the steps of 1, protection coating smearing; 2, preheating before forging; 3, forged piece forging; 4, finish forging treatment; 5, preheating before finish turning, wherein a forged piece is placed in an electric furnace to be preheated to 560 DEG C-580 DEG C, and then the forged piece is discharged out of the furnace after being subjected to furnace cooling to 150 DEG C or below; and 6, finish turning treatment. Stabilizing treatment is carried out on stability of forged piece machining, and therefore the forging ratio is reduced, grains are refined, the mechanical property of the forged piece is improved, special shapes are reduced, the stability of the forged piece is improved, and the forging quality is improved.

Owner:ANHUI RUIJIE FORGING

Composite fiber fabric for large-pressing-machine forging and production method and application of composite fiber fabric

PendingCN110835844AReduce coefficient of frictionExtend your lifeHeat resistant fibresForging/hammering/pressing machinesThermal insulationBasalt fiber

The invention relates to composite fiber fabric for large-pressing-machine forging and a production method and application of the composite fiber fabric and belongs to pressing machine large forge piece forming forging. The composite fiber fabric is composited by basalt fiber fabric and graphite powder, wherein the graphite powder evenly attaches to two surfaces of the basalt fiber fabric. The composite fiber fabric is small in friction coefficient, good in thermal insulation and lubricating effects, high in pressure resistance, good in softness, high in elongation at high temperature and thelike.

Owner:中国第二重型机械集团德阳万航模锻有限责任公司

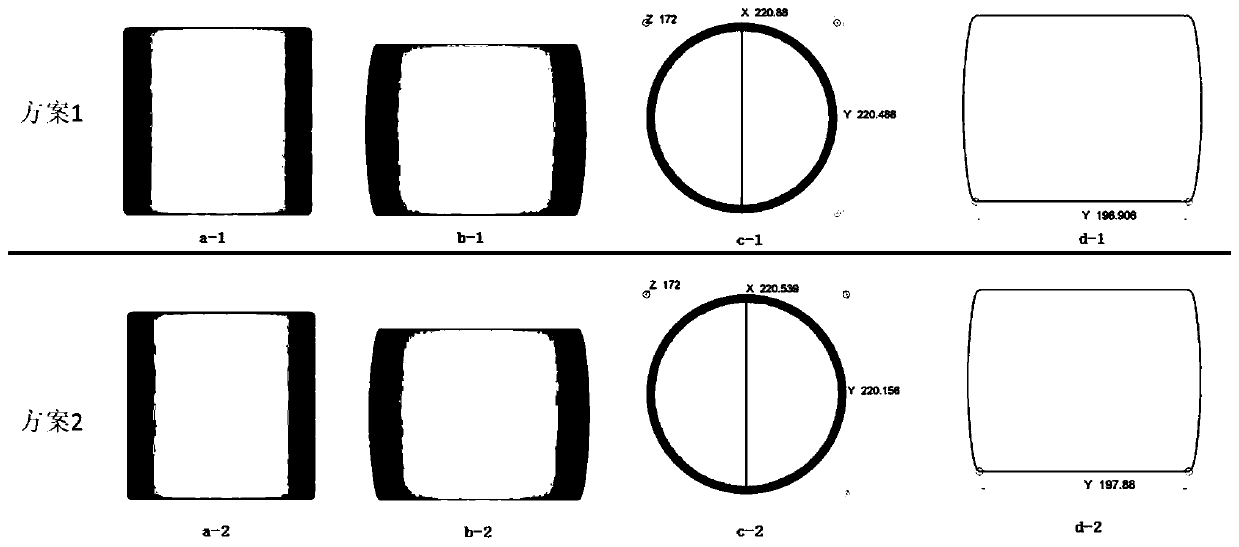

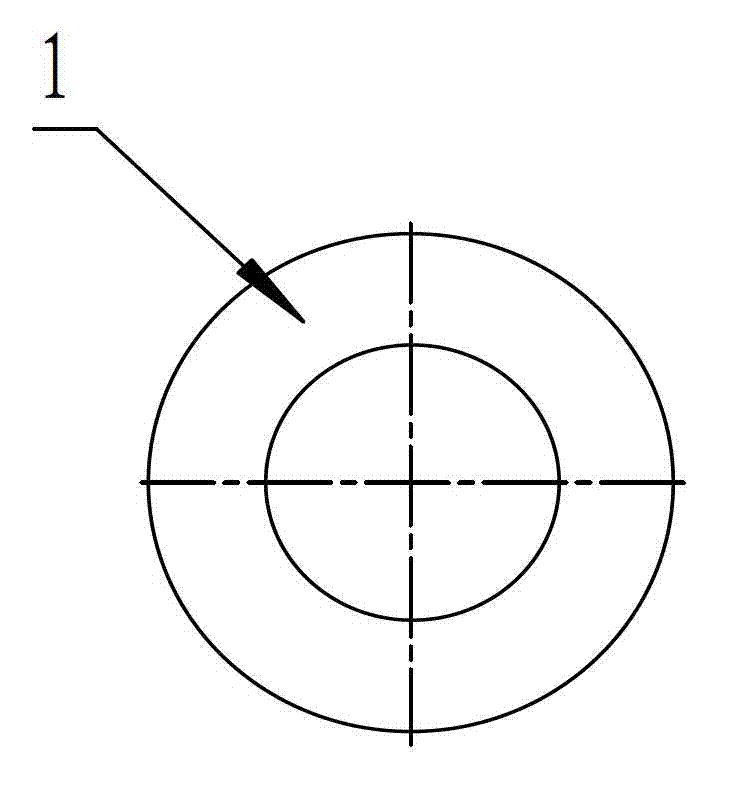

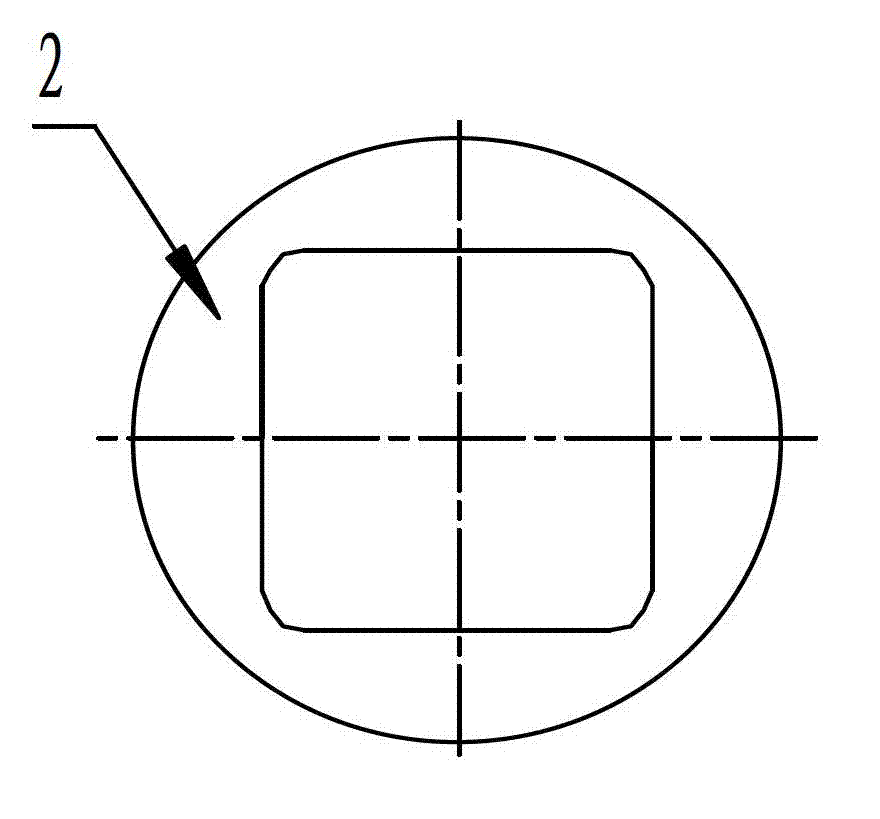

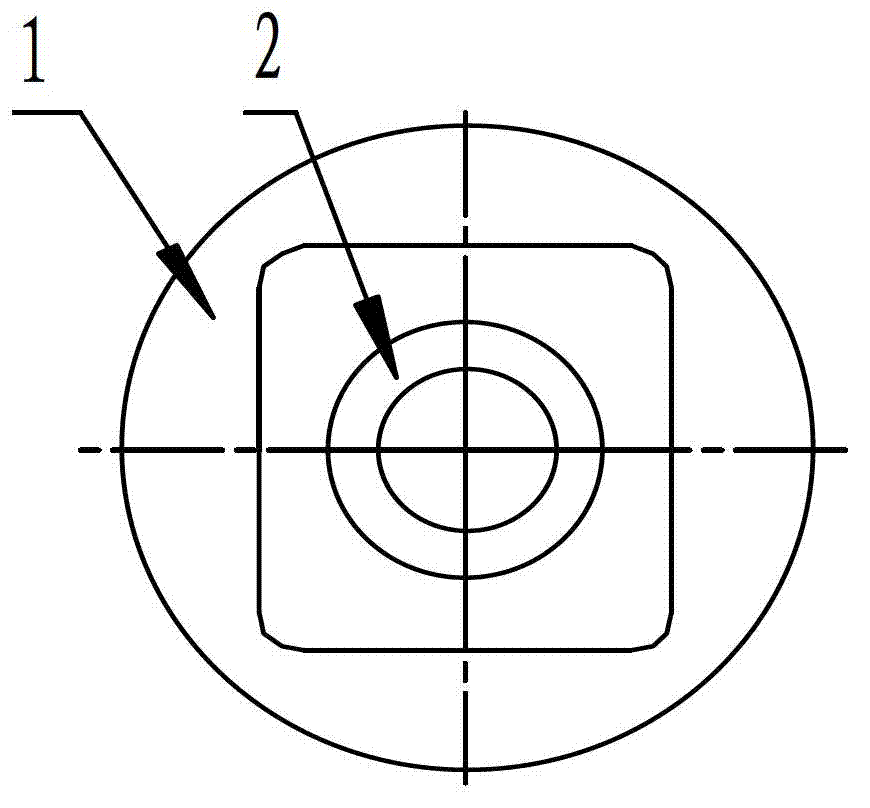

Ring rolling forming process of square-exterior circular-interior forge piece

The invention provides a ring rolling forming process of a square-exterior circular-interior forge piece. The ring rolling forming process comprises the following steps that a square-exterior circular-interior mould which is preheated to 300-400 DEG C is sleeved on a core roller of a numerical control ring rolling machine; a manufactured circular-exterior circular-interior blank is arranged in the square-exterior circular-interior mould; the numerical control ring rolling machine is started to position the square-exterior circular-interior mould and the circular-exterior circular-interio blank so that the wall thickness of the square-exterior circular-interior forge piece is reduced to a predetermined size finally, and the work automatically stops; the numerical control grinding ring machine stops and the square-exterior circular-interior forge piece is taken out; after the square-exterior circular-interior forge piece is subjected to a normalizing heat treatment of 880-920 DEG C for carrying out mechanical machining after being cooled, so that a square-exterior circular-interior part is obtained. A metal flow line of the forge piece is not cut off, and the forge piece has the advantages of uniform structure, grain refinement, strong comprehensiveness, high forge piece quality, less cutting quantity of mechanical machining operation, material saving, high production efficiency, and long service life.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

A kind of forging processing method of tc4 titanium alloy large size bar

InactiveCN104070125BSlow down depreciationImprove performance uniformityForging/hammering/pressing machinesElectric arc furnaceIngot casting

Owner:宁夏中色金航钛业有限公司

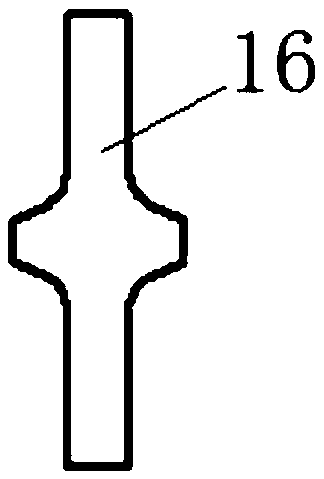

Vertical forging process of double-shaft-coupling tooth blank with deep blind holes

ActiveCN111360190AQuality improvementAvoid formingForging/hammering/pressing machinesWheelsStructural engineeringMachining

The invention discloses a vertical forging process of a double-shaft-coupling tooth blank with deep blind holes. The process comprises the steps that precise blanking is carried out, specifically, precise blanking is carried out according to the weight of the blank after forging molding, and the blanking error does not exceed 1%; heating is carried out to reach a forging temperature; material aggregating is carried out, specifically, the cavity volume of a material aggregating mold is 1%-2% larger than the total volume of the blank; pre-forging is carried out, specifically, the cavity volume of a pre-forging mold being 1%-2% larger than the total volume of the blank; and finish forging is carried out, specifically, the cavity volume of a finish forging mold is 1%-2% larger than the total volume of the blank. By precisely blanking and strictly controlling relationships of the cavity volumes of the forming molds of material aggregating, pre-forging and finish forging and the volume of the blank, the double-shaft-coupling tooth blank with the deep blind holes can be directly forged by combining the special molds of material aggregating, pre-forging and finish forging, fins are avoided, working procedures are reduced, and the material cost and the machining cost are reduced.

Owner:四川弘信能源装备制造有限公司

Automobile steering knuckle structure and machining process thereof

InactiveCN107963121AImprove wear resistanceImprove securitySteering linkagesEngineeringControl theory

The invention discloses an automobile steering knuckle structure and a machining process thereof and relates to the technical field of automobile parts and machining processes of the automobile parts.The automobile steering knuckle structure comprises a bearing journal, flange plates and a fork frame which are formed in an integrally forged mode, and the fork frame is composed of a lower swing arm connection pair, a steering gear push rod connection pair and an upper swing arm connection pair. The machining process comprises the following process steps of material detection, blanking, heatingblank-making, vertical forging, edge cutting, rectifying, heat treatment and electroplating. The automobile steering knuckle structure is optimized and improved, and an automobile steering knuckle produced through the machining process is more stable in quality and more reliable in structure.

Owner:上海嘉仕久企业发展有限公司

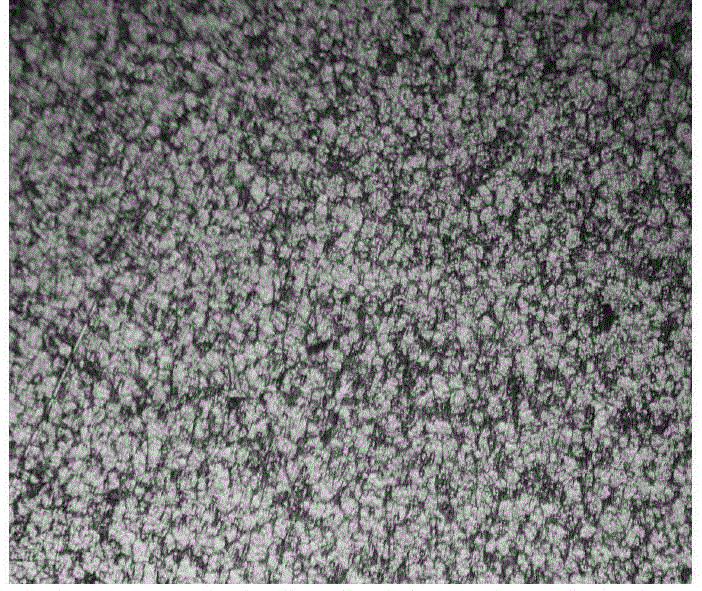

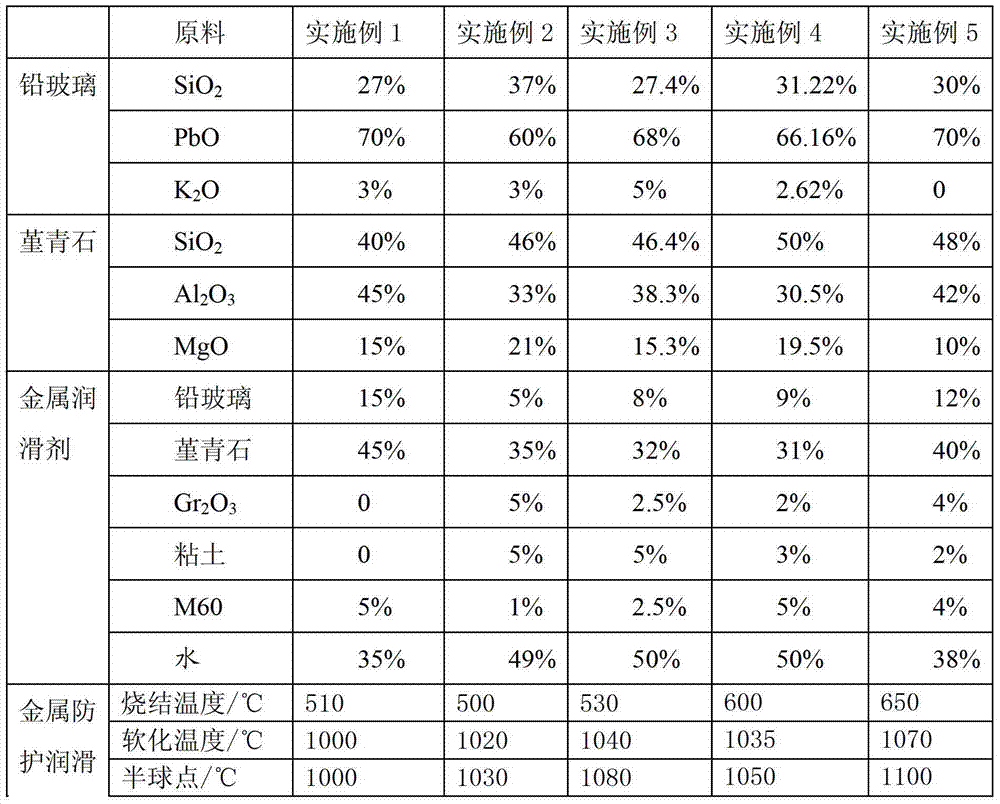

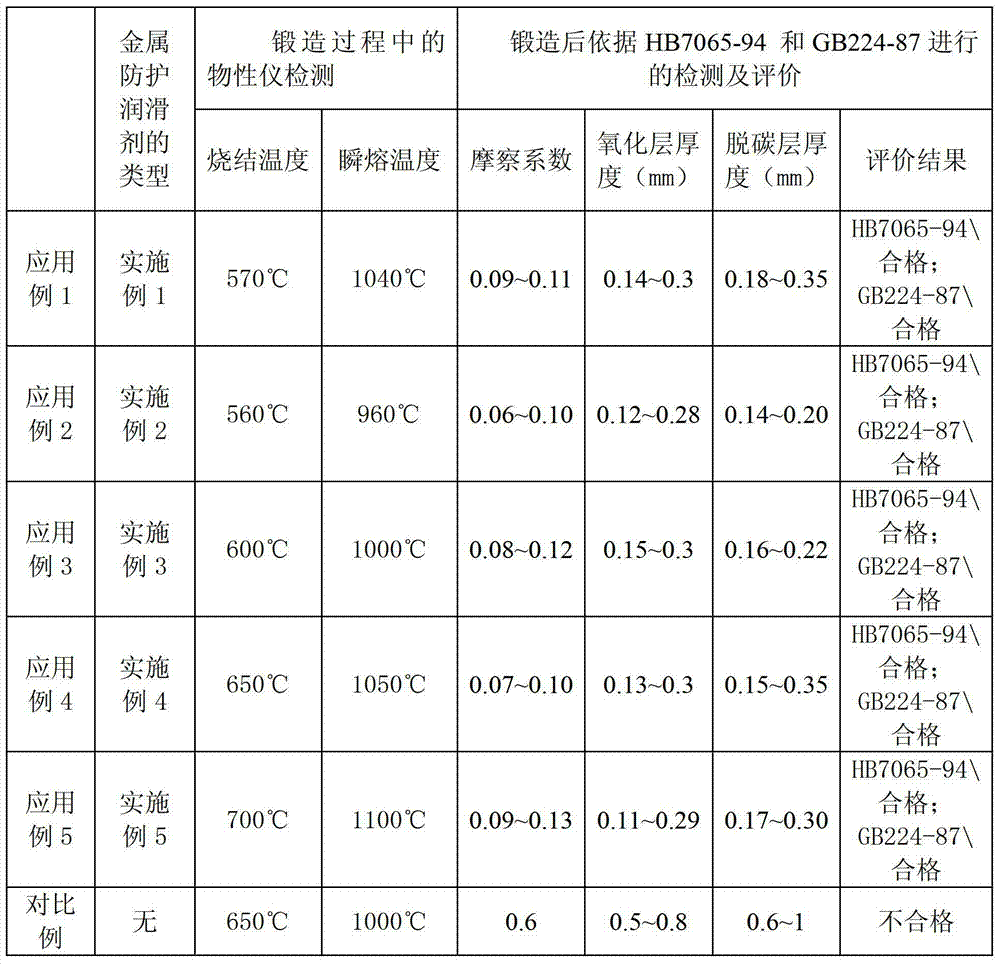

Metal protection lubricant as well as preparation method and application thereof

ActiveCN103242943AAnti-friction effectImprove uniformityLubricant compositionMetal formingThermal deformation

The invention relates to a metal protection lubricant for preventing metals from being damaged when being machined and forged as well as a preparation method and an application of the metal protection lubricant. The metal protection lubricant comprises the following raw material components: lead glass, cordierite, Gr2O3, clay, methylcellulose and water. The metal protection lubricant not only isolates the external atmosphere to protect metal profile matrixes, but also functions as a good lubricant which has the abrasion reduction function in thermal deformation machining, the metal protection time is greatly prolonged, metal erosion is prevented, and moreover the metal protection lubricant can automatically drop off after being forged, so that later treatment procedures caused by coating are canceled, the protection of the properties of metals is sufficiently achieved, the forging quality is effectively improved, the surface effect in metal forming is optimized, and the quality of a product is improved, and the service life of a product, such as a die, which is forged in such a mode is prolonged, and therefore, the metal protection lubricant is applicable to popularization and application in relevant fields.

Owner:北京玻璃研究院有限公司 +1

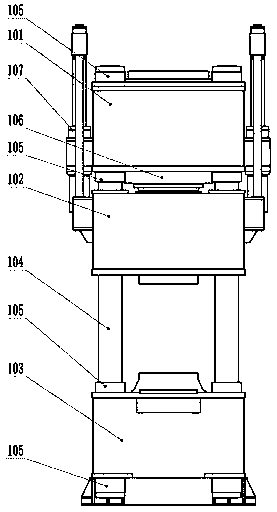

Material clamping pliers for annular heating furnace material charging and taking device

InactiveCN107571274AStable range of motionImprove applicabilityGripping headsCharge manipulationEngineeringHeating furnace

The invention relates to the field of steel processing equipment, in particular to a pair of material clamping pliers for an annular heating furnace material charging and taking device. The material clamping pliers for the annular heating furnace material charging and taking device comprises two pliers rods, wherein the pliers rods are arranged in parallel. The portions, close to the middle portions, of the pliers rods are arranged in a first double-hole bearing pedestal in a sleeving mode. The ends, close to the first double-hole bearing pedestal, of the pliers rods are arranged in a second double-hole bearing pedestal in a sleeving mode, a clamp is arranged at the other end of each pliers rod, and notches of the clamps are arranged in a face-to-face mode. A driving mechanism which is used for controlling the two pliers rods to rotate so as to control the clamps to be combined and separated is further arranged between the pliers rods. The material clamping pliers for the annular heating furnace material charging and taking device is simple in structure and low in cost, and can meet the material clamping requirement of the annular heating furnace material charging and taking device.

Owner:LUOYANG INST OF SCI & TECH

Forging method for large and medium steel ingot

The invention discloses a forging method for a large and medium steel ingot and belongs to the technical field of forging. The problems that in a large and medium steel ingot forging technology, the center of a tong handle inwards contracts, and the material utilization rate is low are solved. The forging method for the large and medium steel ingot can improve the internal product quality of a large and medium forge piece and increase the steel ingot material utilization rate. The forging method comprises the following steps of steel ingot producing, residue clearing, pre-upsetting, tong handle pressing, upsetting, drawing out and cap section cutting. Pre-upsetting is conducted before tong handle pressing operation of the large and medium steel ingot, thus the probability of inward contraction of the center of the tong handle of the steel ingot is decreased greatly, the steel ingot material utilization rate is increased, and the quality of the forge piece is improved.

Owner:四川丰元机械制造有限公司

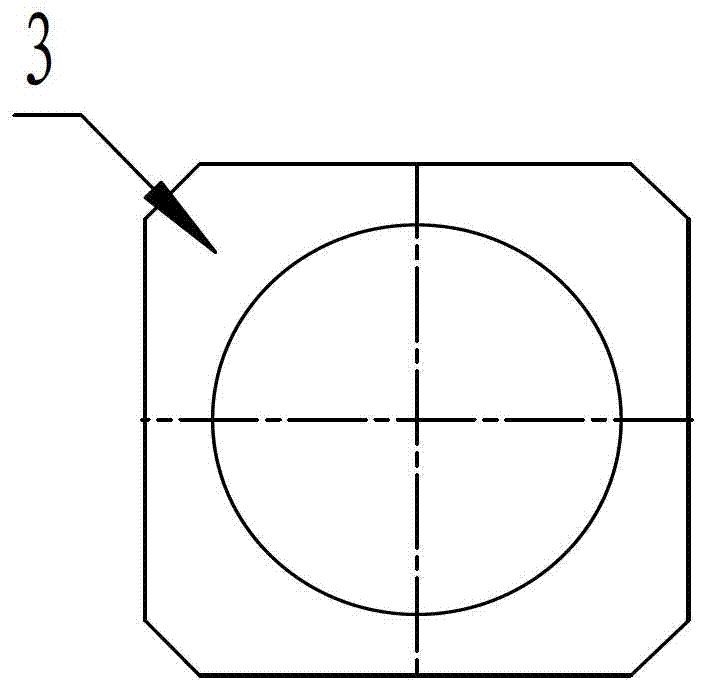

Die-sleeve type ring rolling forming process for externally square and internally circular forged piece

InactiveCN102806288ALess amount of cutting in machiningExtended service lifeMetal rollingStopped workRoll forming

The invention provides a die-sleeve type ring rolling forming process for an externally square and internally circular forged piece. The die-sleeve type ring rolling forming process includes preheating an externally circular and internally square die and a die sleeve to the temperature ranging from 300 DEG C to 400 DEG C, sleeving the preheated die sleeve on a core roll of a ring rolling mill; placing a blank which is heated to the temperature ranging from 1150 DEG C to 1180 DEG C on the die sleeve, and sleeving the externally circular and internally square die on the blank; starting the ring rolling mill, positioning the externally circular and internally square die, the die sleeve and the blank, driving the externally circular and internally square die and the die sleeve to rotate at a set speed ranging from 2mm / s to 10mm / s by the ring rolling mill, and setting exerted force to range from 500KN to 4200KN so that the ring rolling mill stops working when the wall thickness of the externally square and internally circular forged piece is thinned to a set dimension; and turning off the ring rolling mill, taking out the externally square and internally circular forged piece, cooling the externally square and internally circular forged piece by heat treatment at the temperature ranging from 880 DEG C to 920 DEG C, and machining the externally square and internally circular forged piece to obtain an externally square and internally circular part. The die-sleeve type ring rolling forming process has the advantages that machining and cutting amounts are low, materials are saved, a metal flow line is not cut off, the externally square and internally circular part is uniform in texture and high in comprehensive performance, grains are fine, work efficiency is high, and the forged piece is high in quality and long in service life.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

Manual and automatic integrated clamping and turning-over forging machine

ActiveCN110842130AReduce consumptionSimple structurePower hammersForging/hammering/pressing machinesEngineeringMachine

The invention discloses a manual and automatic integrated clamping and turning-over forging machine which comprises a beating box. A fixing table is fixedly connected to the right end of the beating box. An operation table is further fixed to the right end of the fixing table. A beating mechanism capable of forging materials placed at the upper end of the fixing table is arranged in the beating box. A moving cavity with the left end wall and the right end wall penetrating through a transmission cavity is formed in the transmission cavity. A clamping mechanism capable of clamping the materialsor driving the materials to rotate is arranged in the moving cavity. The clamping mechanism comprises a moving block. A rotating cavity is formed in the moving block, wherein the rotating cavity is opened upwards, and the left end wall of the rotating cavity communicates with the moving cavity. A ring-shaped cavity opened leftwards is formed in the right end wall of the rotating cavity. The forging machine is simple in structure and convenient to operate, switching can be achieved between automatic forging and manual auxiliary forging, the application range of the device is widened, when automatic forging is carried out, consumption of labor is saved, forging efficiency is improved, when automatic forging is carried out, manual auxiliary forging is carried out, and forging quality can be improved.

Owner:济南中航远洋船舶机械有限公司

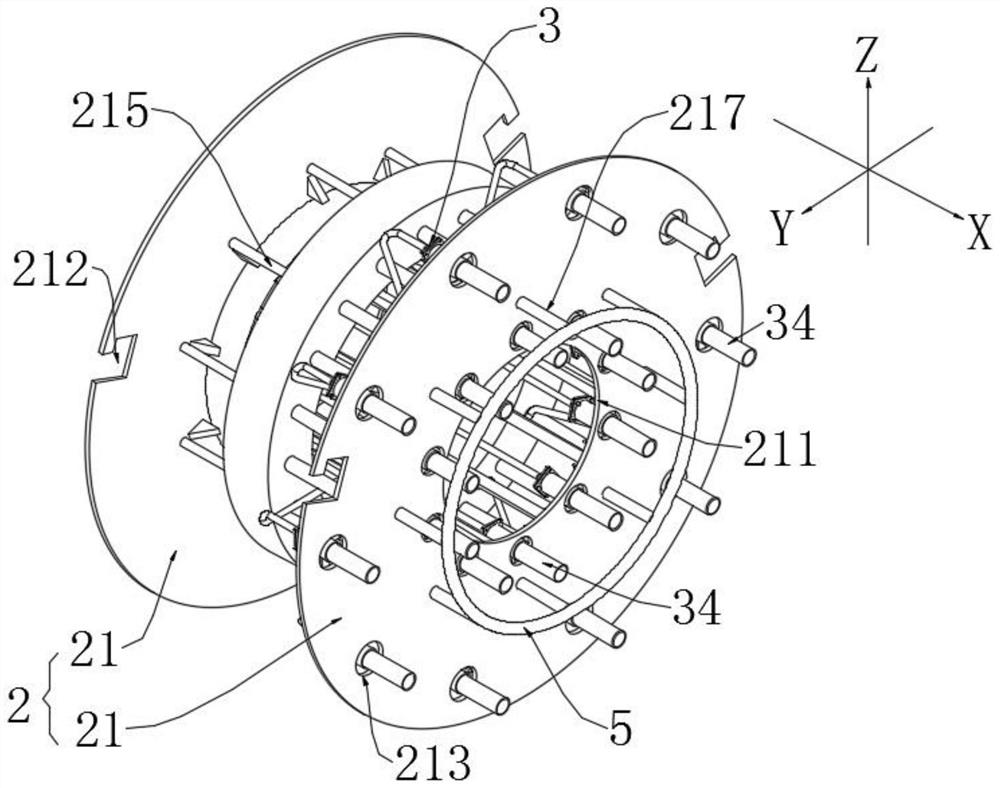

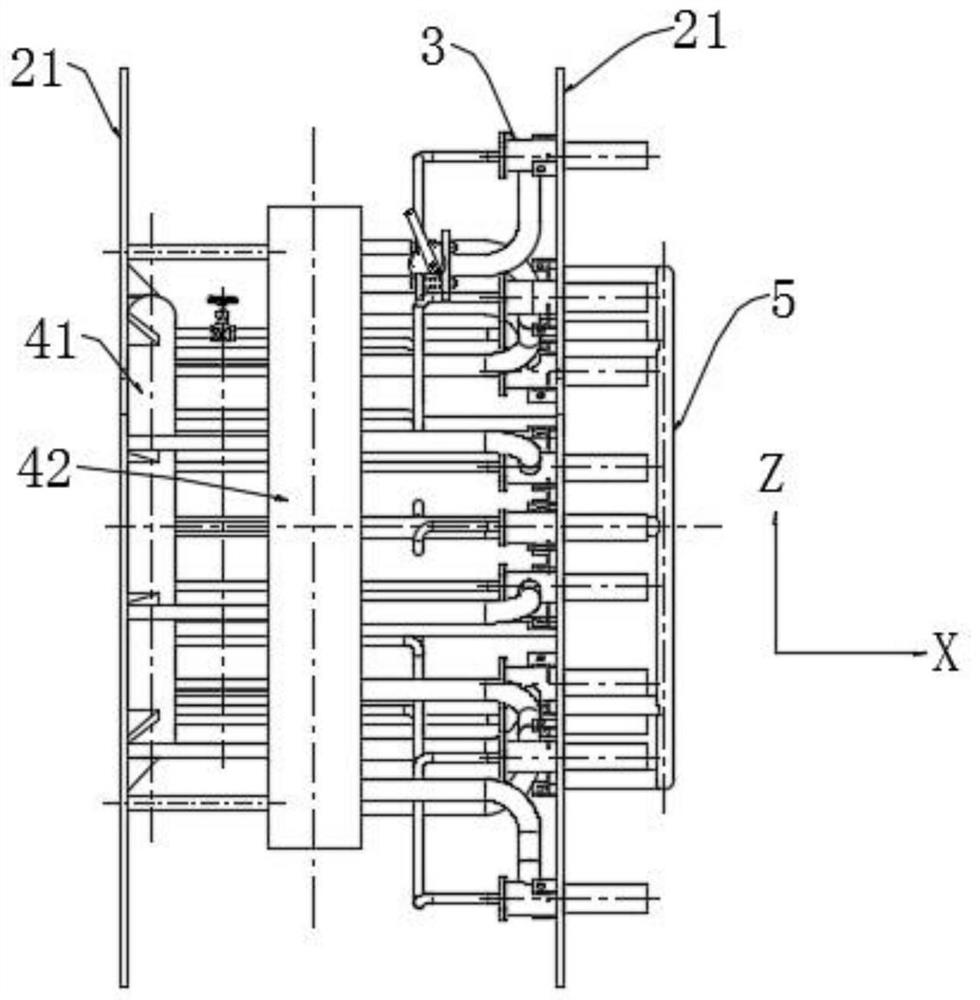

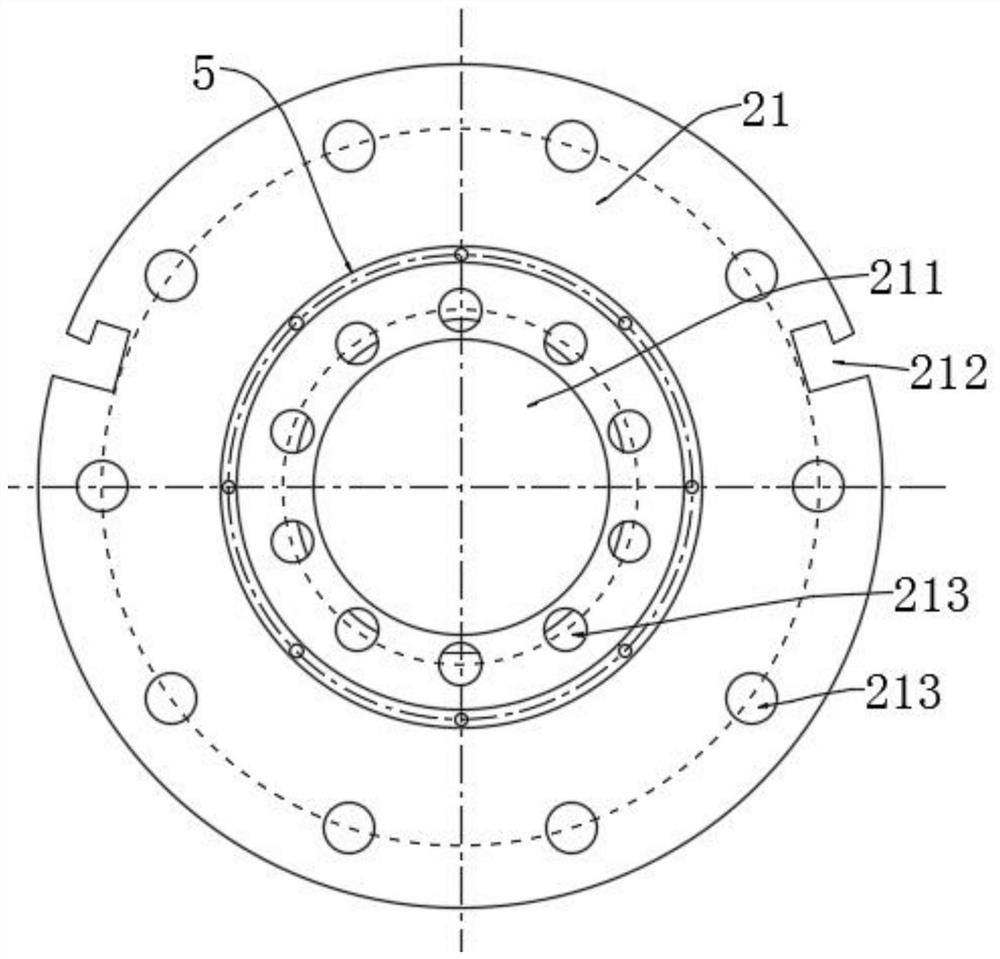

Heating device for forging hollow forge pieces and forging device

ActiveCN111618233AAvoid temperature dropCrack suppressionEngine componentsHeating/cooling devicesEngineeringForge

The invention provides a heating device for forging hollow forge pieces and a forging device, and particularly relates to the technical field of free forging. The heating device for forging the hollowforge pieces comprises a supporting mechanism and a plurality of heating mechanisms, wherein a first through hole is formed in the supporting mechanism; the plurality of heating mechanisms are connected with the supporting mechanism, the plurality of heating mechanisms are arranged around the first through hole, the heating ends of the plurality of heating mechanisms are arranged towards one sideof the supporting mechanism, and the first through hole penetrates through one side of the supporting mechanism; and the end part of the steel forge piece sleeving a mandrel is heated by the heatingdevice for forging the hollow forge piece. Compared with the prior art, the technical scheme has the advantage that the function of preserving heat of the end face of the steel forge piece at the endof the mandrel is realized.

Owner:CHINA FIRST HEAVY IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com