Metal protection lubricant as well as preparation method and application thereof

A metal protection and lubricant technology, applied in the direction of lubricating compositions, etc., can solve the problems of metal forming surface and mold surface damage, lubricant erosion protection, metal blank erosion, etc., to prolong the protection time, avoid metal erosion, The effect of metal erosion reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

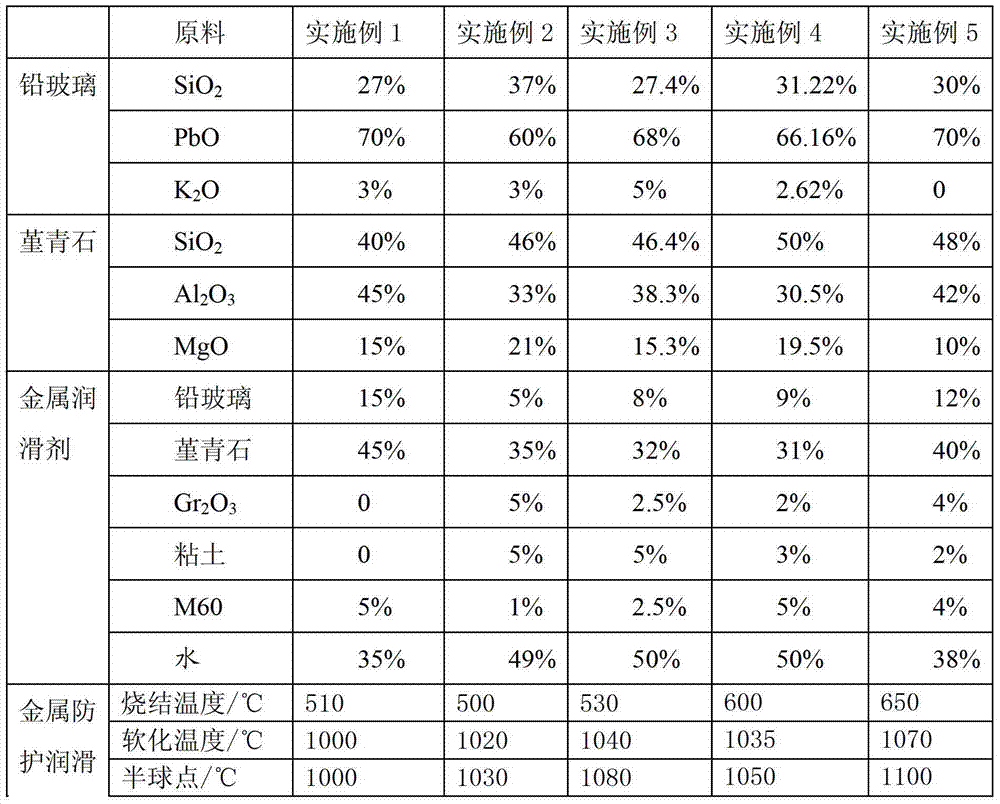

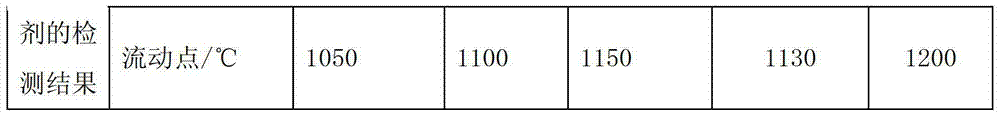

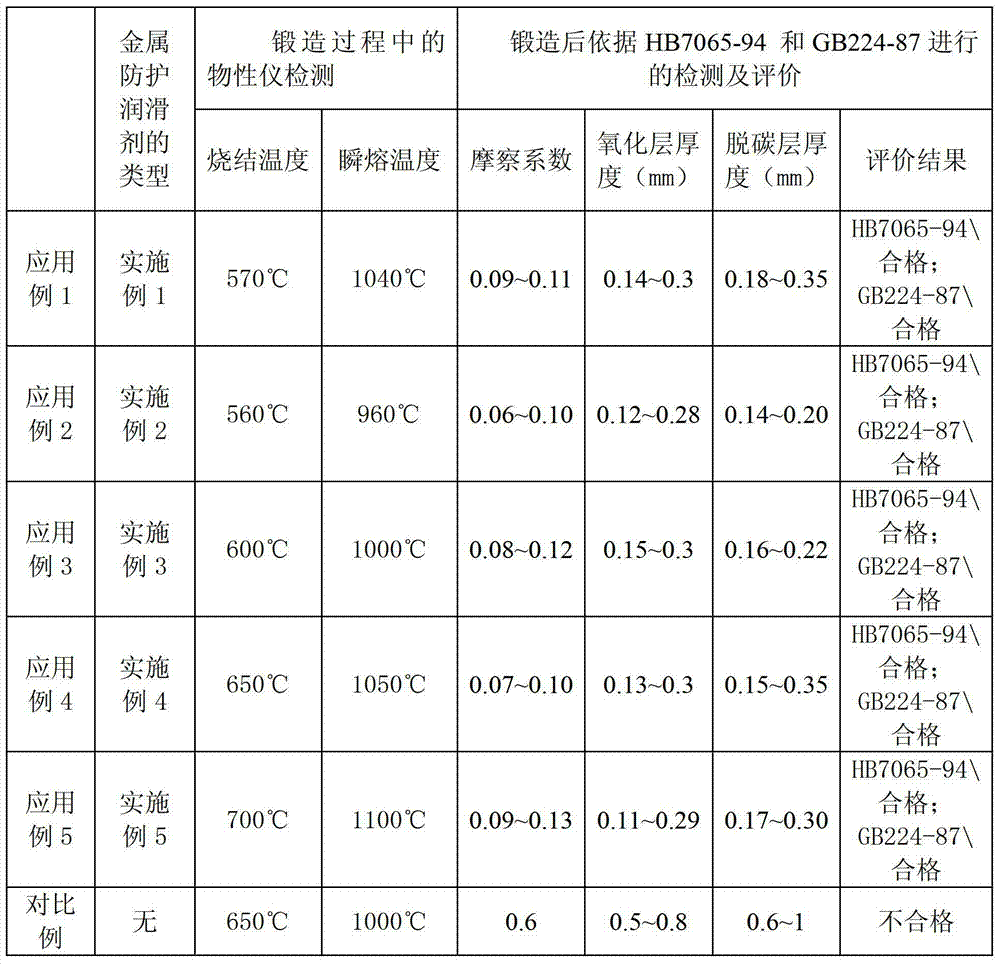

[0027] A kind of metal protection lubricant, its raw material component weight percentage is as shown in table 1.

[0028] Among the above-mentioned metal protection lubricants, the softening temperature of the raw material lead glass is 500°C, and the flow temperature is 800°C, so that it meets the softening range of 500°C to 600°C and the flow temperature range of 800°C to 880°C, so that the metal protection lubricant The softening temperature of the agent is controlled.

[0029] A method for preparing the above-mentioned metal protection lubricant is as follows: add the raw materials shown in Table 1 in the order of the mixture of lead glass and cordierite, chromium oxide, clay, and water into a ball mill jar for ball milling for 3 hours, and then add M60 to continue ball milling In 15 minutes, the metal protection lubricant was obtained.

[0030] In the preparation method of above-mentioned metal protection lubricant:

[0031] The preparation of raw lead glass is to mix ...

Embodiment 2

[0036] A metal protection lubricant, its raw material component weight ratio and performance testing results are shown in Table 1, its basic preparation method and performance testing method are the same as Example 1, the difference is:

[0037]In the above-mentioned metal protection lubricant, the softening temperature of the raw material lead glass is 600°C, and the flow temperature is 880°C;

[0038] In the preparation method of above-mentioned metal protection lubricant:

[0039] The ball milling time of each raw material shown in Table 1 in the ball milling tank was 3.5 hours, and the ball milling time was continued for 25 minutes after adding M60;

[0040] In preparing raw material lead glass, the raw material of lead glass shown in Table 1 is fully melted in carbon rod furnace at 1050 ℃;

[0041] In the preparation of raw material cordierite, the raw material of cordierite shown in Table 1 was fully melted in a molybdenum rod furnace at 1650°C;

[0042] Make lead glas...

Embodiment 3

[0044] A metal protection lubricant, its raw material component weight ratio and performance testing results are shown in Table 1, its basic preparation method and performance testing method are the same as Example 1, the difference is:

[0045] In the above-mentioned metal protection lubricant, the softening temperature of the raw material lead glass is 550°C, and the flow temperature is 840°C;

[0046] In the preparation method of above-mentioned metal protection lubricant:

[0047] The ball milling time of each raw material shown in Table 1 in the ball milling jar is 4 hours, and the ball milling time after adding M60 is 40 minutes;

[0048] In preparing raw material lead glass, the raw material of lead glass shown in Table 1 is fully melted in carbon rod furnace at 1000 ℃;

[0049] In the preparation of raw material cordierite, the raw material of cordierite shown in Table 1 was fully melted in a molybdenum rod furnace at 1550°C;

[0050] Make lead glass, cordierite, Gr ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com