High temperature resistant self-lubricating coating on titanium alloy surface and preparation method thereof

A technology of self-lubricating coating and high temperature resistance, which is applied in the coating process and coating of metal materials, can solve the difficult problems of boron nitride retention and other problems, achieve good surface quality, improve plasticity and toughness, and improve wear resistance at room temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The present invention adopts the most widely used Ti-6Al-4V titanium alloy in the industry as the base material, and cuts the Ti-6Al-4V plate into 10mm×10mm×20mm and 25mm×25mm×10mm sample blocks with wire cutting, the latter for wear tests. with SiO 2 The surface of the sample was polished with sandpaper to remove the oxide skin on the surface of the sample, and the sample block was cleaned with alcohol and dried for later use.

[0046] h-BN@Ni powder was used as alloying material. The mass fraction of hexagonal boron nitride (h-BN) in the h-BN@Ni is 30wt.%, and the balance is Ni. The alloyed powder is pre-spread on the surface of the sample, and the thickness is controlled to be about 1mm.

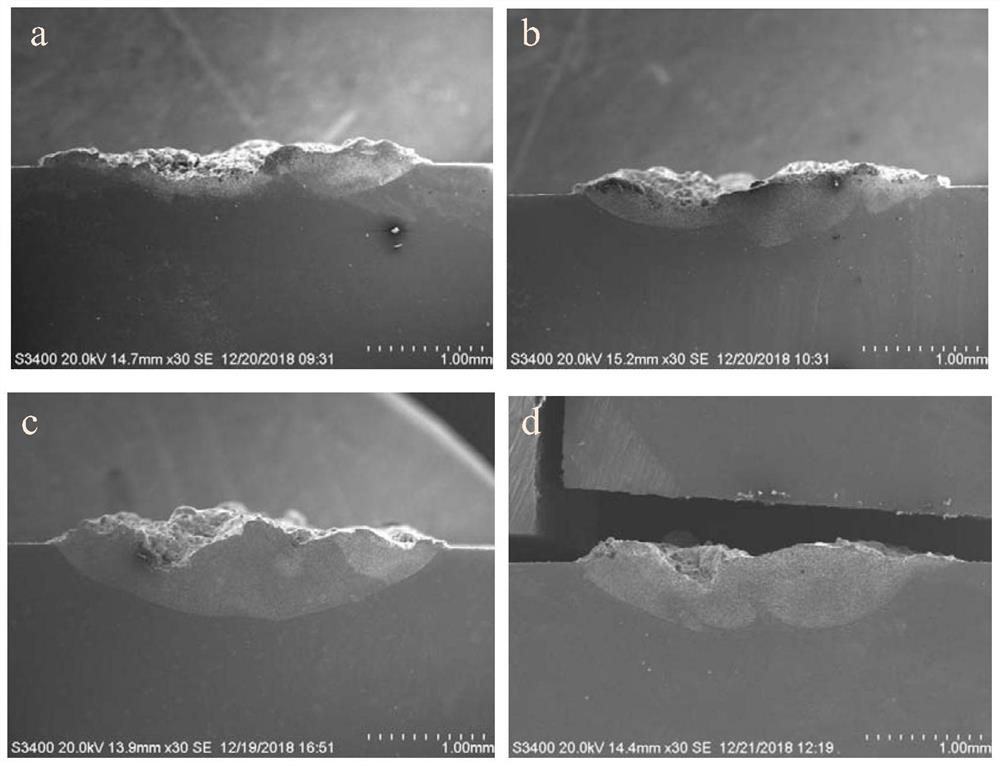

[0047] Using TFL-H6000 type cross-flow CO 2 The laser is used for laser alloying, and the molten pool is protected with argon to prevent the molten pool from oxidizing CO 2 The power of the gas laser is 4kW, the scanning speed is 300mm / min, the spot diameter is 4mm; the argon ...

Embodiment 2

[0054] The difference with embodiment 1 is:

[0055] In the h-BN@Ni powder, the mass percentage of h-BN is 40wt.%, and the balance is Ni. The surface quality of the coating is good, more hard phases are formed, the hardness is higher, and the wear resistance is greatly improved.

Embodiment 3

[0057] The difference with embodiment 1 is:

[0058] In the h-BN@Ni powder, the mass percentage of h-BN is 50wt.%, and the balance is Ni. The surface quality of the coating is good, more hard phases are formed, the hardness is the highest, and the wear resistance is the best.

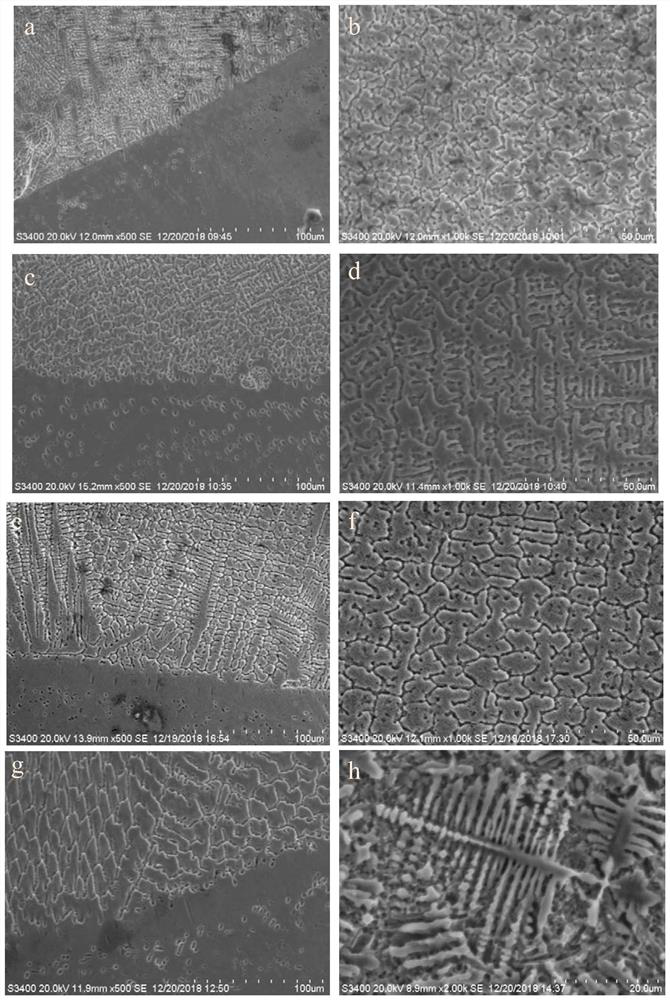

[0059] The morphology of the coating is as image 3 In, g and h are shown. The X-ray diffraction results of h-BN@Ni powder and alloyed layer are as follows Figure 5 , Figure 6 shown. The results show that the alloyed layer is mainly composed of γ-Ni, TiN, NiTi, NiTi 2 , TiB, h-BN and other phase compositions. Compared with the X-ray diffraction results of the h-BN@Ni alloyed material used in the test, TiN, TiB, and Ni-Ti intermetallic compounds were formed in the alloyed layer. The most easily formed TiB is not found in the alloyed layer 2 , which may be because at higher laser energy density, more matrix is melted, and there are excess Ti atoms in the molten pool, which is different from Ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com