Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

151results about How to "Play the role of diffusion strengthening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tool steel roller for rolling medium-thickness plate and manufacturing method thereof

ActiveCN103526126AImprove mechanical propertiesImprove wear resistanceRollsMetal rolling arrangementsTool steelChemical composition

The invention discloses a tool steel roller for rolling a medium-thickness plate and a manufacturing method thereof. The tool steel roller comprises a core part of nodular cast iron, a roller neck and a roller body work layer, wherein the roller body work layer comprises the following chemical components in percentage by weight: 1.60-2.2% of C, 0.50-1.00% of Si, 0.50-1.00% of Mn, 10.00-15.00% of Cr, 0.20-1.80% of Ni, 0.20-1.50% of Mo, 0.20-1.00% of V, less than or equal to 0.03% of S, less than or equal to 0.05% of P and the balance of Fe and unavoidable impurities. According to the tool steel roller and manufacturing method disclosed by the invention, by designing a reasonable alloy composition and processing technology, the mechanical properties of a working roller of a rolling mill are effectively improved, and the wear resistance and millimeter rolling amount of the roller are increased; moreover, the tool steel roller has good hot-crack resistance, and the working efficiency of a medium-thickness plate rolling mill can be remarkably improved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Binary leadless soldering plaster

InactiveCN101367158AReduce the temperatureLow melting pointWelding/cutting media/materialsSoldering mediaSurface mountingElectronic component

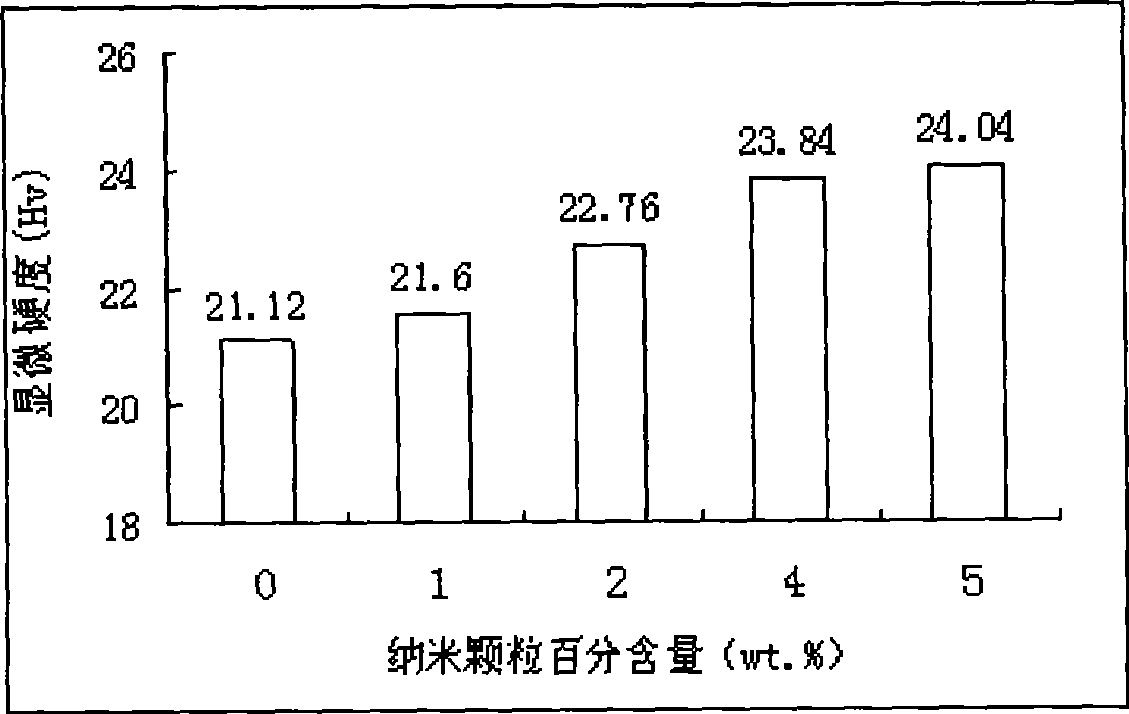

The invention relates to binary lead-free solder paste for welding and surface mounting of electronic components. Nanopowder is added based on micron lead-free solder paste; and the solder paste comprises the following compositions in percentage by mass: 90 to 99 percent of micron lead-free solder paste and 0.1 to 10 percent of the nanopowder, wherein the nanopowder is nanopowder of ordinary lead-free solder paste or nanopowder of metal or nanopowder of SiC, SiN, BN, and AL2O3. The binary lead-free solder paste has the entire basic performances of the ordinary lead-free solder paste, and reduces the cost and the melting point. Compared with the prior tin lead solder paste, the binary lead-free solder paste does not contain toxic element lead, and is particularly suitable for electronic packaging technology in the microelectronic industry.

Owner:SHANGHAI UNIV

High-plasticity two-phase yttrium-containing magnesium-lithium-aluminum alloy and preparation method thereof

The invention discloses high-plasticity two-phase yttrium-containing magnesium-lithium-aluminum alloy and a preparation method thereof. The alloy comprises the following specific components in percentage by weight: 9.50-10.80% of Li, 3.00-5.00% of Al, 0.50-0.70% of Y, 0.10-0.30% of Zr and the balance of Mg; the alloy has the structural characteristics that an alpha phase, a beta phase and a precipitated phase exist at the same time, wherein the alpha phase is a Mg-based solid solution and is in a close-packed hexagonal structure, the beta phase is a Li-based solid solution and is in a body-centered cubic structure, and the precipitated phase is a rare earth compound Al2Y; and the alloy has the characteristics of low density, high plasticity and higher strength. The preparation method disclosed by the invention is a normal-temperature plastic deformation method which combines casting with equal channel angular extrusion or traditional extrusion deformation process; and compared with the traditional high-temperature deformation process, the preparation method has good practicality and is simpler and more convenient to operate, and can be used for effectively lowering the production cost, thus the preparation method has good industrial production prospects.

Owner:SOUTH CHINA UNIV OF TECH

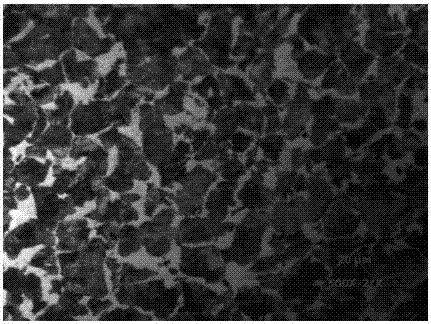

Steel and manufacturing method for Ca microalloying free-cutting high-strength expansion-breaking connecting rod

InactiveCN106939391AImprove breaking performanceReduce cutting actionChemical compositionHigh intensity

The invention relates to steel for a Ca microalloying free-cutting high-strength expansion-breaking connecting rod. The steel is prepared from, by mass percent, 0.25%-0.60% of C, 0.10%-1.20% of Si, 0.40%-1.50% of Mn, 0.05%-0.50% of Cr, 0.02%-0.15% of S, 0.02%-0.15% of P, 0.03%-0.55% of V, 0.0005%-0.0080% of Ca, 0.002%-0.035% of N, 0.002%-0.080% of Al, not larger than 0.02% of Ti and the balance Fe and inevitable impurity elements. The steel is subjected to smelting, continuous casting, heating, hot rolling and cooling, and the structure characteristic is uniform ferrite and pearlite. According to the steel, key elements in the steel are optimized, Ca microalloying is especially adopted, and the steel for the expansion-breaking connecting rod with high strength, good cutting machinability, good expansion-breaking performance and excellent comprehensive performance is obtained, and the design requirements for engine light weight, economical efficiency and driving comfort are met.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Preparation method of (TiV)C steel bond hard alloy

The invention provides a preparation method of (TiV)C steel bond hard alloy. Titanium and vanadium whose ratio is 1:1 are prepared, and a mixture and graphite powder are prepared into in-situ synthesized (TiV)C mixed powder, wherein the atomic mole ratio between C and Ti+V is 0.7-1.1; ferrovanadium powder, ferrochromium powder, ferromolybdenum powder, ferroboron powder, ferrous powder, ferrosilicon powder, ferromanganese powder, nickel powder, copper powder, colloidal graphite and a rare earth raw material are prepared according to a required mass ratio of bonded-phase metal chemical components, ball-milling is carried out by a steel ball, absolute ethanol as a medium and PVA (polyvinyl alcohol) are added, after the ball-milling is finished, slurry is dried and pressed for forming, and the steel bond alloy is obtained. In situ reaction synthesis technology and liquid phase sintering technology are combined, and the (TiV)C steel bond hard alloy is prepared. (TiV)C is synthesized in situ in a substrate through reaction in the sintering process, the fineness of particles is improved, no sharp angle is formed on the surface, and a substrate interface is relatively good in adhesion and clean. The comprehensive mechanical property of the alloy can be improved, the price is low, and the process is simple and convenient.

Owner:JIANGSU HUICHENG MACHINERY MFG

Preparation method of modified high-manganese steel base TiC steel bonded carbide

The invention relates to a preparation method of modified high-manganese steel base TiC steel bonded carbide. The preparation method is characterized by preparing in-situ synthesized TiC powder in a required proportion from titanium powder and graphite powder according to the atomic ratio of C to Ti, namely 0.8-1.0; preparing the raw materials including ferromolybdenum powder, ferrovanadium powder, ferrochrome powder, ferromanganese powder, ferrosilicon powder, ferrum powder, nickel powder, colloidal graphite and rare earth according to a required proportion of mass ratios of chemical components of bonding phase metals, filling steel balls, performing ball milling, adding absolute ethyl alcohol used as a medium and PVA (polyvinyl alcohol) to the steel balls, drying the slurry after ball milling, and then forming the slurry by pressing and sintering the product, thus obtaining steel bonded carbide. The preparation method has the advantages that the modified high-manganese steel base TiC steel bonded carbide is prepared by combining an in-situ reactive synthesis technology and a liquid phase sintering technology; as TiC is synthesized in situ inside a matrix through reaction in the sintering process, the reinforced particles have small sizes and do not have sharp corners on the surfaces, and the matrix is better in interface bonding and has a clean interface; the preparation method of steel bonded carbide is conductive to improving the comprehensive mechanical properties of carbide, is low in price and is simple and convenient in process.

Owner:JIANGSU HUICHENG MACHINERY MFG

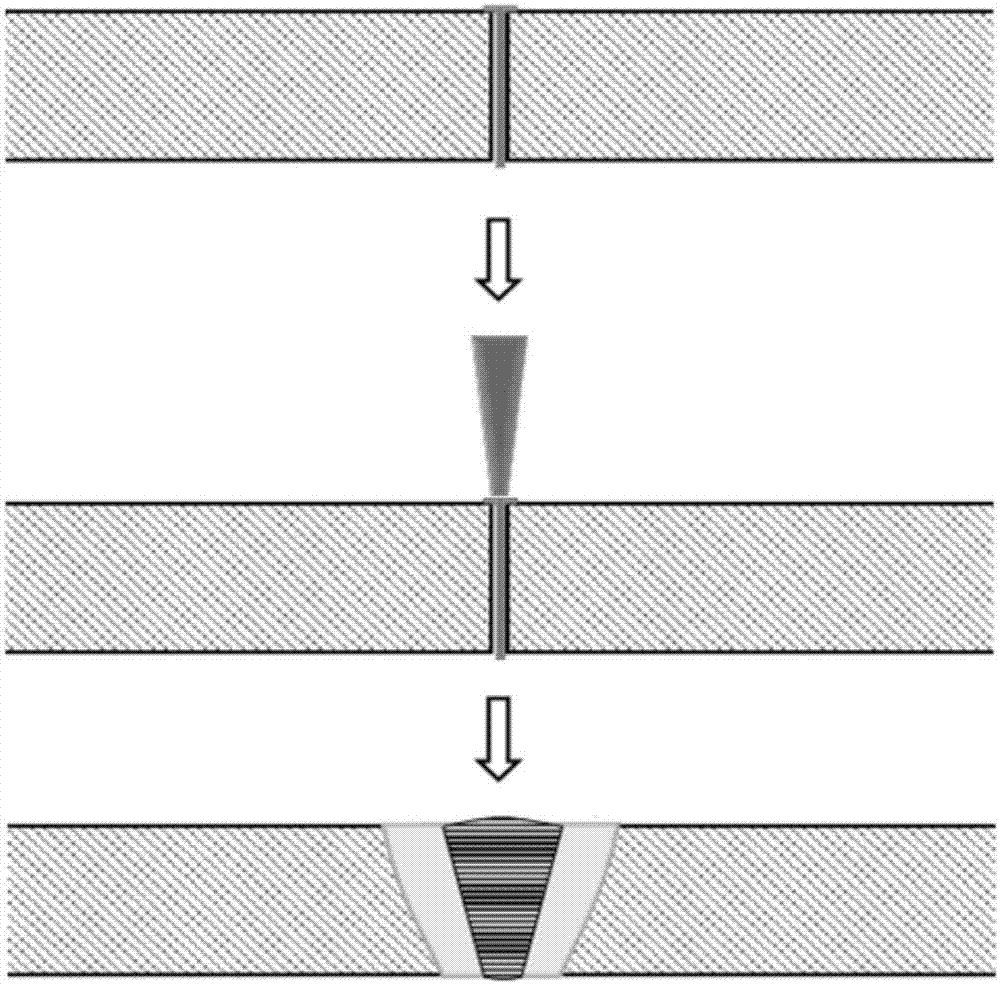

Microalloying method for improving toughness of molybdenum and molybdenum alloy fusion welding lines

ActiveCN107009025AImprove toughnessHigh bonding strengthWelding/cutting auxillary devicesArc welding apparatusRoom temperatureAlloy

The invention discloses a microalloying method for improving toughness of molybdenum and molybdenum alloy fusion welding lines. The microalloying method comprises the following steps: 1) the surfaces of areas to be welded on workpieces to be welded are pretreated, wherein the workpieces to be welded adopt materials of molybdenum or molybdenum alloys; 2) titanium layers are filled in the joined places of the workpieces to be welded; 3) the workpieces to be welded are placed in an inert gas protective atmosphere or a vacuum environment; and welding areas of the workpieces to be welded are preheated; and 4) the workpieces to be welded are welded; and welding line areas of the welded workpieces are insulated, and are cooled to reach the room temperature to finish microalloying of fusion welding lines of the workpieces. The method can eliminate the segregation problem of impurity elements in the grain boundary, and prominently improves the toughness of the molybdenum alloy fusion welding lines.

Owner:XI AN JIAOTONG UNIV

Preparation method of ultrahigh-manganese steel based TiC steel bond hard alloy

The invention relates to a preparation method of ultrahigh-manganese steel based TiC steel bond hard alloy. The preparation method is characterized by comprising the following steps: preparing titanium powder and graphite powder into in-situ synthesized TiC powder with the required proportion according to the C / Ti atomic ratio of 0.8-1.0; preparing ferromolybdenum powder, ferrovanadium powder, ferrochromium powder, ferromanganese powder, ferrosilicon powder, iron powder, nickel powder, colloidal graphite and rare earth raw materials according to the required mass ratio of bonded-phase metal chemical components, performing ball-milling by a steel ball, adding absolute ethanol as a medium and PVA (polyvinyl alcohol), after the ball-milling process is finished, drying slurry, pressing for forming, and sintering to obtain the steel bond alloy. According to the preparation method, the ultrahigh-manganese steel based TiC steel bond hard alloy is prepared by combining an in-situ reaction synthesis technology with a liquid-phase sintering technology; as TiC is synthesized in situ in a substrate through reaction in the sintering process, the fineness of particles is improved, no sharp angle is formed on the surface, and a substrate interface is relatively good in adhesion and clean; the comprehensive mechanical property of the alloy can be improved, the price is low, and the process is simple and convenient.

Owner:JIANGSU HUICHENG MACHINERY MFG

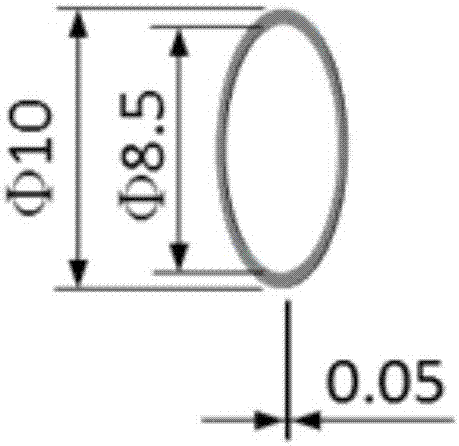

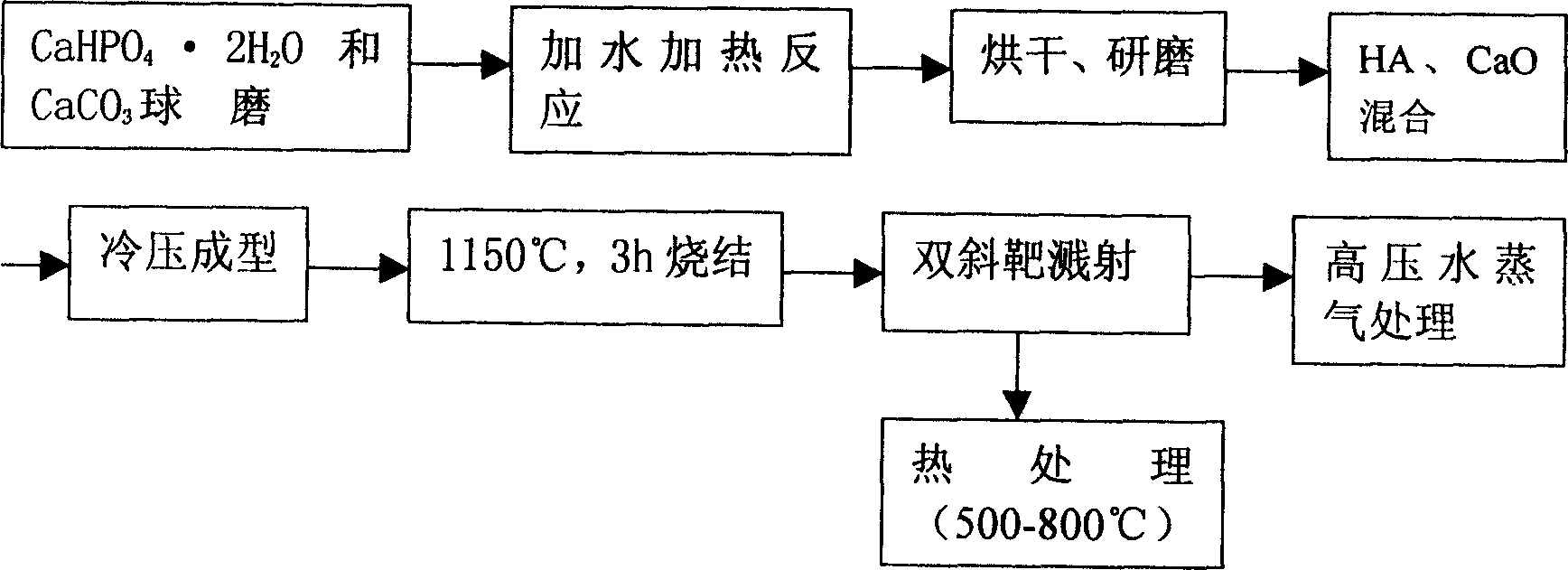

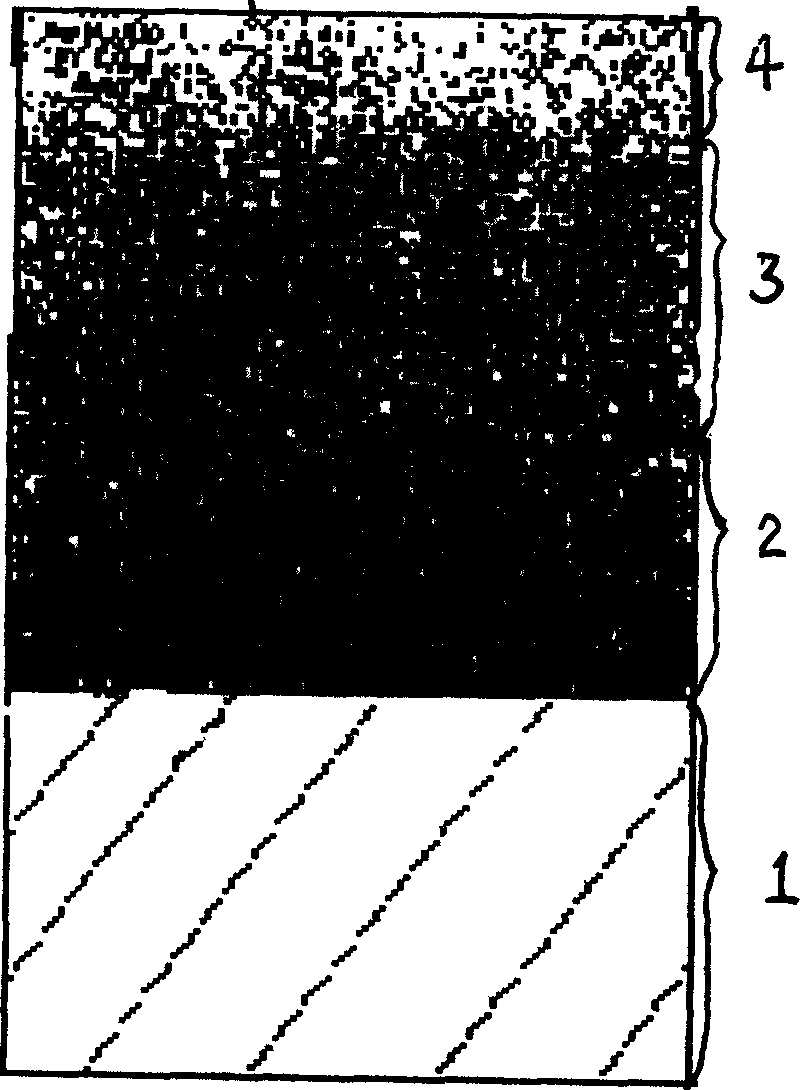

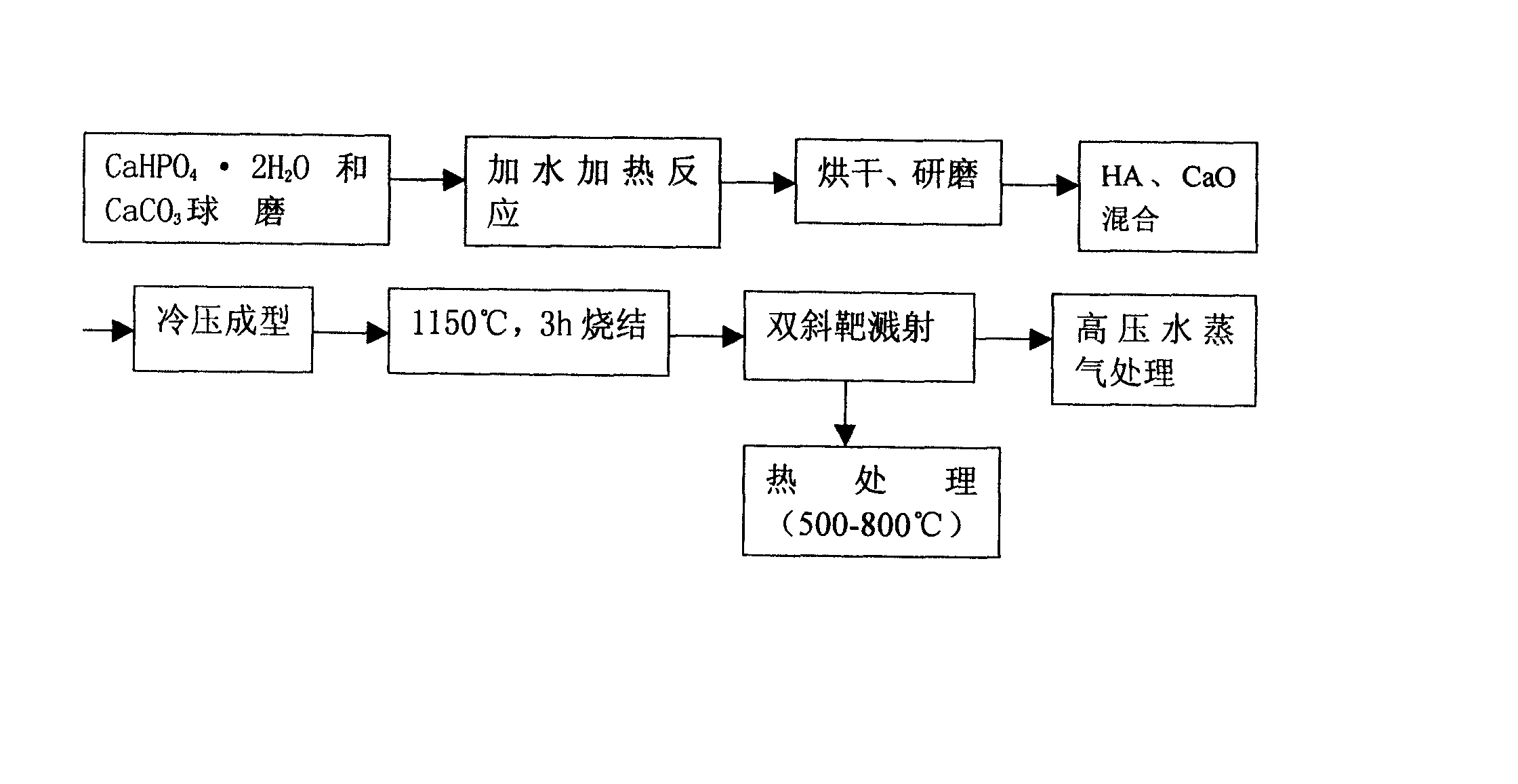

Method and product of sputtering and depositing bioactive gradient hydroxyapatite/Ti layer on Ti alloy surface

InactiveCN1487117AImprove stabilityWeakening interface mutationVacuum evaporation coatingSputtering coatingTitaniumBiological activation

The method of sputtering and depositing bioactive gradient hydroxyapatite / Ti layer on Ti alloy surface includes the following steps: mixing and ball milling material powder; hydrothermal reaction; stoving and grinding; mixing target material; cold pressing at 200-300 MPa to form; sintering; double-inclined target sputtering; and heat treatment of the sputtered film. The product has multilayer structure of Ti alloy matrix, compact transition TiO2 layer I with dispersed hydroxyapatite, TiO2 reinforced transition hydroxyapatite layer II, and porous hydroxyapatite layer. The present invention realizes the double gradient of both component and structure, and raises the interface binding strength effectively. The present invention has simple film preparing process and homogeneous film thickness, is suitable for surface activation of implant with complicated shape, and can prepare hard tissue for clinical need, especially as bearing bone repairing and substituting material.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Preparation method of TiC high-wear-resistant steel-bonded hard alloy

The invention relates to a preparation method of a TiC high-wear-resistant steel-bonded hard alloy. The preparation method is characterized by comprising the following steps: using titanium powder and graphite powder to prepare in-situ synthesized TiC powder according to the atomic ratio 0.7-1.1 of C to Ti; mixing ferrochromium powder, ferromolybdenum powder, ferrovanadium powder, ferrotungsten powder, ferroniobium powder, nickel powder, ferroboron powder, iron powder, colloidal graphite and a rare earth material according to the chemical component mass ratio of the bonding phase metals; filling the mixed powder in a steel ball mill; adding absolute ethyl alcohol as a medium and PVA (Polyvinyl Acetate) to the ball mill; after ball milling, drying the obtained slurry, pressing, molding and sintering the dried substance to obtain the steel-bonded hard alloy. The preparation method disclosed by the invention combines the in-situ reaction synthesis technology with the liquid-phase sintering technology to prepare the TiC high-wear-resistant steel bonded hard alloy. As TiC is prepared by in-situ synthesis inside the substrate through the reaction during the sintering process, the reinforced particle size is fine, the surface is free of sharp corners, the substrate interface bonding effect is good, and the interface is clean. The preparation method for the steel-bonded alloy can improve the comprehensive mechanical property of the alloy, and is low in price and simple and convenient in the technology.

Owner:JIANGSU HUICHENG MACHINERY MFG

Titanium alloy laser cladding surface reinforcing method

ActiveCN103668186AImprove surface qualityImprove organizationMetallic material coating processesHardnessWear resistance

The invention relates to a titanium alloy laser cladding surface reinforcing method which comprises the following steps: mixing the following components by weight: 50-100% of Co42 cobalt-based self-fluxing alloy powder, 0-50% of B4C0, 0-50% of SiC, 0-39% of TiN, 0-1.5% of Y2O and 0-1.5% of CeO2, uniformly blending the mixture powder into paste by using a sodium silicate solution, uniformly coating the paste mixture powder on the surface of a titanium alloy, keeping the coating uniform in thickness, drying in air naturally, and performing laser cladding on the coating on the surface of the titanium alloy. By the adoption of the method provided by the invention, the microstructure of a cladding layer can be improved, and the hardness and the wear-resistance of the cladding layer can be further improved.

Owner:SHANDONG UNIV

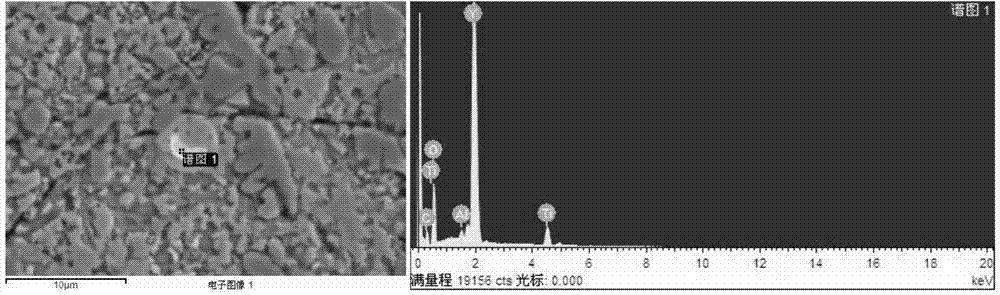

High-strength high-ductility CNTs-SiCp enhanced aluminum-based composite material and preparation method thereof

The invention discloses a high-strength high-ductility CNTs-SiCp enhanced aluminum-based composite material which comprises the following components: less than or equal to 5vol.% of a carbon nano tube, less than or equal to 5 vol.% of silicon carbide particles and the balance aluminum powder. A preparation method for the high-strength high-ductility CNTs-SiCp enhanced aluminum-based composite material comprises the following steps of: adding raw material components and grinding balls into a ball-milling tank in proportion, adding a process control agent into the ball-milling tank, ball-milling and dispersing under the protection of inert gases, thereby obtaining uniformly dispersed mixed powder; filling a graphite mould with the mixed powder, pre-pressing the mixed powder, and sintering pre-pressed block bodies; and pre-heating a sintered and formed composite material in a tubular furnace under the protection of inert gases, and carrying out thermal extrusion, thereby obtaining the CNTs-SiCp enhanced aluminum-based composite material. The CNTs-SiCp enhanced aluminum-based composite material has very good mechanical property, and also keeps high ductility and high electrical conductivity.

Owner:XIAN UNIV OF TECH

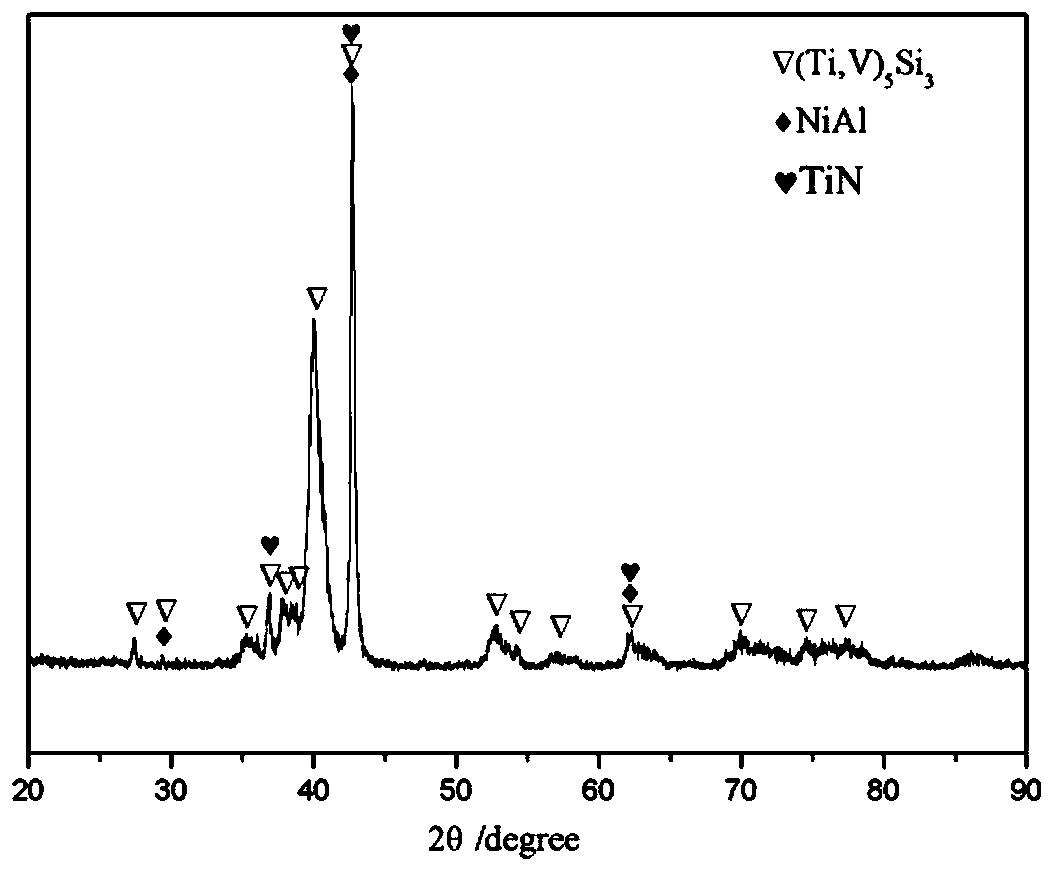

Molybdenum base nitride composite ganoine thin film and preparation thereof

InactiveCN101244644AReduce the temperatureNo holesLayered productsVacuum evaporation coatingMo elementArea ratio

The invention discloses a Mo-based nitride composite hard film and a preparation method, wherein the substrate is coated with nanometer composite hard film that is made of Mo-based metal nitride or nonmetal nitride, the crystallized size of the film is 5-40nm, the thickness of the film is 1-5Mum, the molar percentage between the Mo element and the substitution element in the film is 50 to 94% : 6 to 50%; the preparation method is that: (a) the target material (made of Mo and the substitution) and the substrate are respectively arranged on the cathode and sample table in vacuum room of magnetic control sputtering equipment, the area ratio of the Mo and the substitution in the target material is 1 to 8 : 8 to 1, the distance between the target material and the substrate is 40-80mm; (b) after the vacuum degree in the vacuum room is less than or equal to 8 x 10-4pa and substrate temperature reaches 300 to 500 DEG C, the vacuum room is made to be in the atmosphere of argon and nitrogen mixed gas and 30-130 minutes sputtering is made so as to prepare the Mo-based nitride composite hard film. The invention can widely be used for material protection and can improve abradability and durability of material obviously.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

High-entropy alloy coating resistant to high-temperature abrasion and preparation process and application thereof

ActiveCN109763125AHigh hardnessImprove wear resistanceMetallic material coating processesHigh entropy alloysRare earth

The invention relates to a high-entropy alloy coating resistant to high-temperature abrasion and a preparation process and application thereof. The preparation process comprises the following steps: (1) the surface of a titanium alloy sample is polished and washed; (2) metal powder, a ceramic hard phase and rare earth oxide are evenly mixed, and cladding material powder is formed to be flatly laidon the washed surface of a titanium alloy; and (3) the titanium alloy coating is prepared through laser cladding, wherein the metal powder includes Ti, Ni, Al, Si and V, a ceramic phase material is B4C or TiC or TiN, and the rare earth oxide is Y2O3. According to the high-entropy alloy coating, the hardness of a titanium alloy part can be remarkably improved, abrasion resistance of the titanium alloy part is improved, and the using range of the titanium alloy part is enlarged.

Owner:QINGDAO BINHAI UNIV

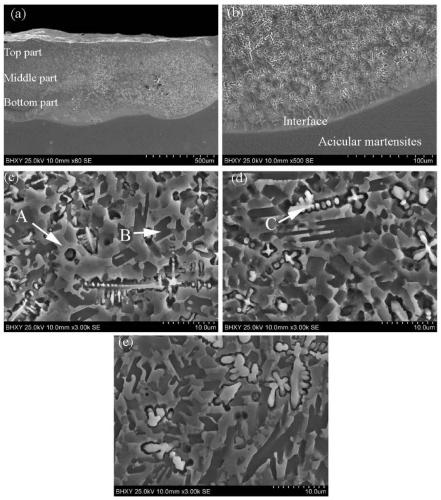

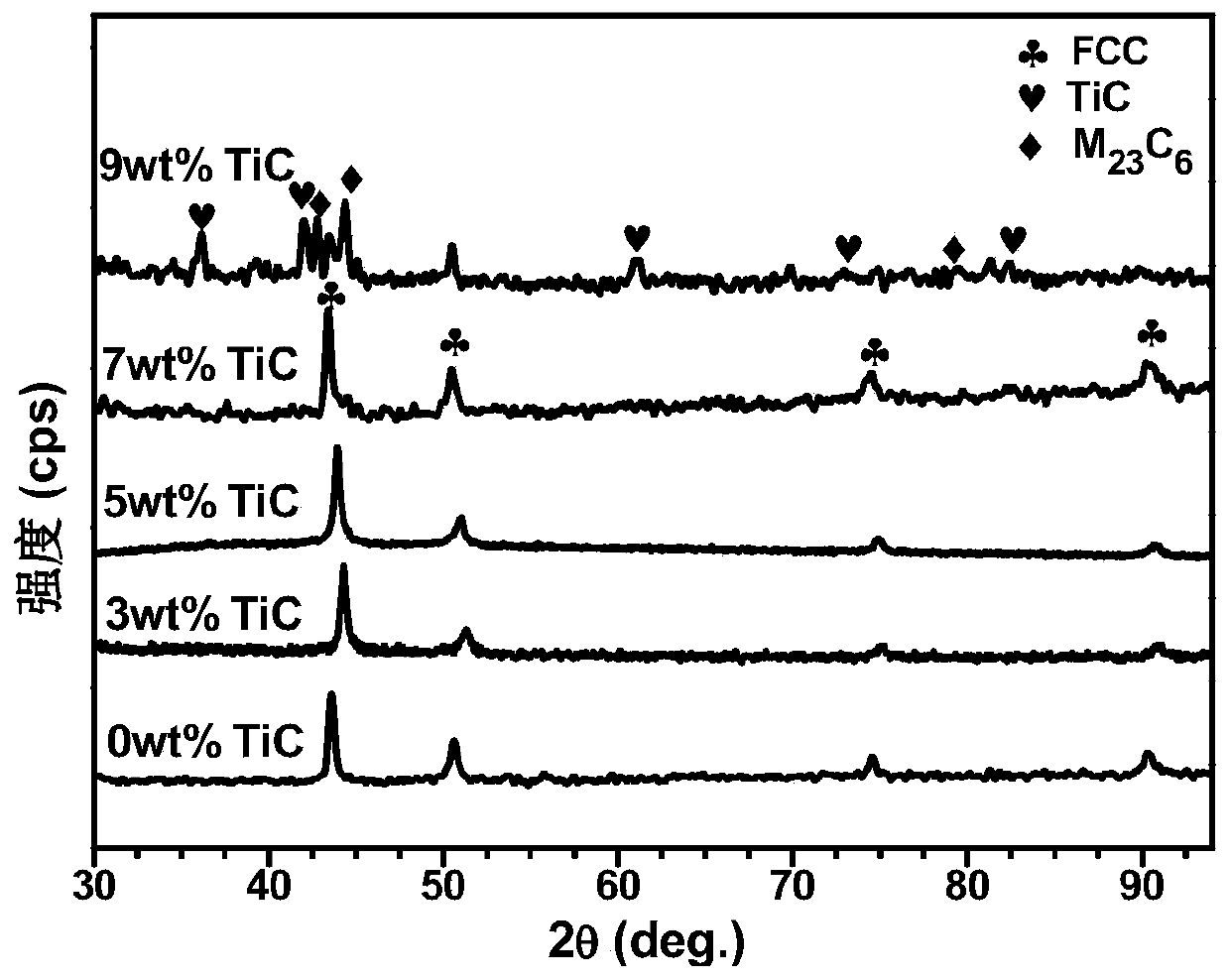

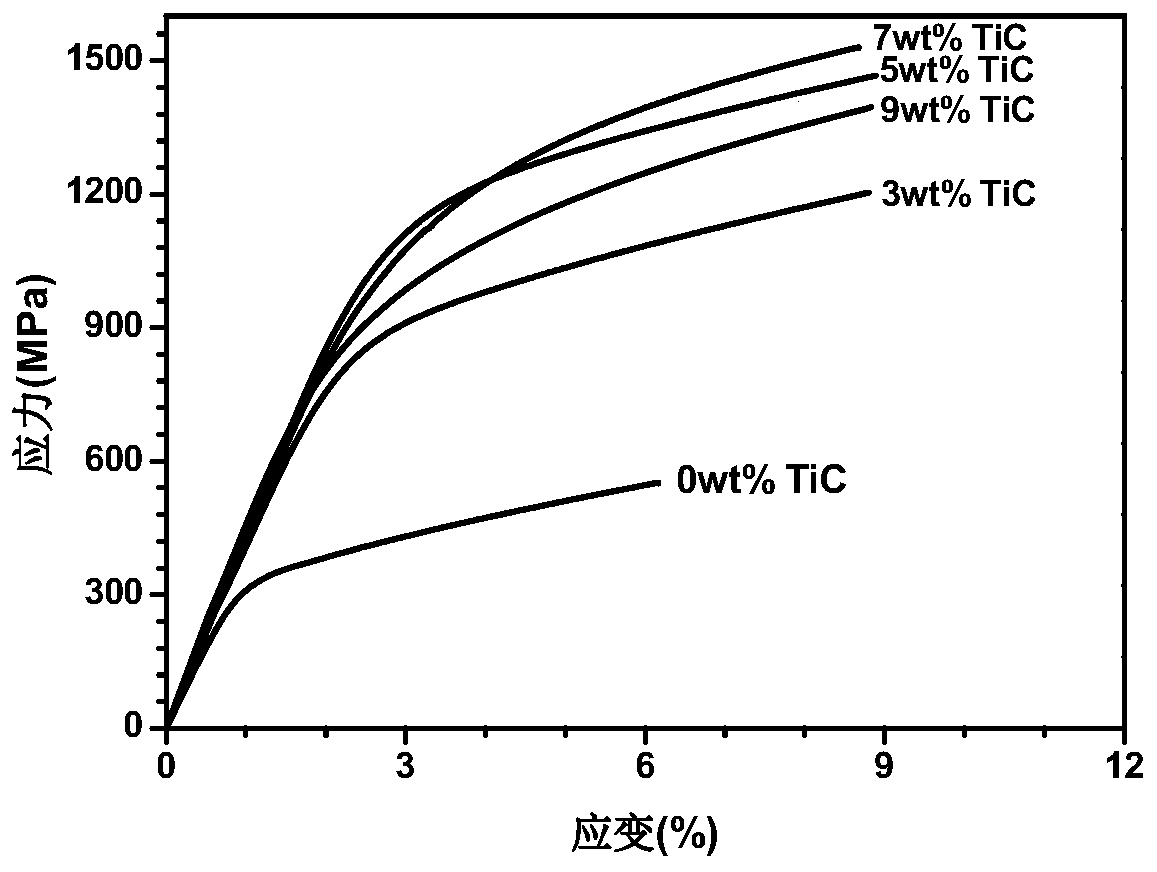

Preparation process of FeCrCoMnNi high-entropy alloy based composite material

ActiveCN110257684AImprove performanceSimple organizational structureHigh entropy alloysRoom temperature

The invention discloses a preparation process of a FeCrCoMnNi high-entropy alloy based composite material. The composite material is prepared from FeCrCoMnNi powder and nano TiC powder through a discharge plasma sintering process and comprises the raw materials including, by mass, 91%-97% of the FeCrCoMnNi and 3%-9% of the TiC. According to the preparation process, the performance of the FeCrCoMnNi high-entropy alloy based composite material obtained through discharge plasma sintering is better when the sintering temperature is 1000 DEG C, the loading pressure is 50 MPa, the holding time is 5 min and the TiC addition amount is 7%; and the hardness is 1092.4HV, the room temperature yield strength is 979.7 MPa, and the 600 DEG C high temperature yield strength is 563.6 MPa. The TiC and an M23C6 strengthening phase formed by a reaction are uniformly distributed in a FeCrCoMnNi high-entropy alloy base, and the effect of dispersion strengthening is achieved.

Owner:HEFEI UNIV OF TECH

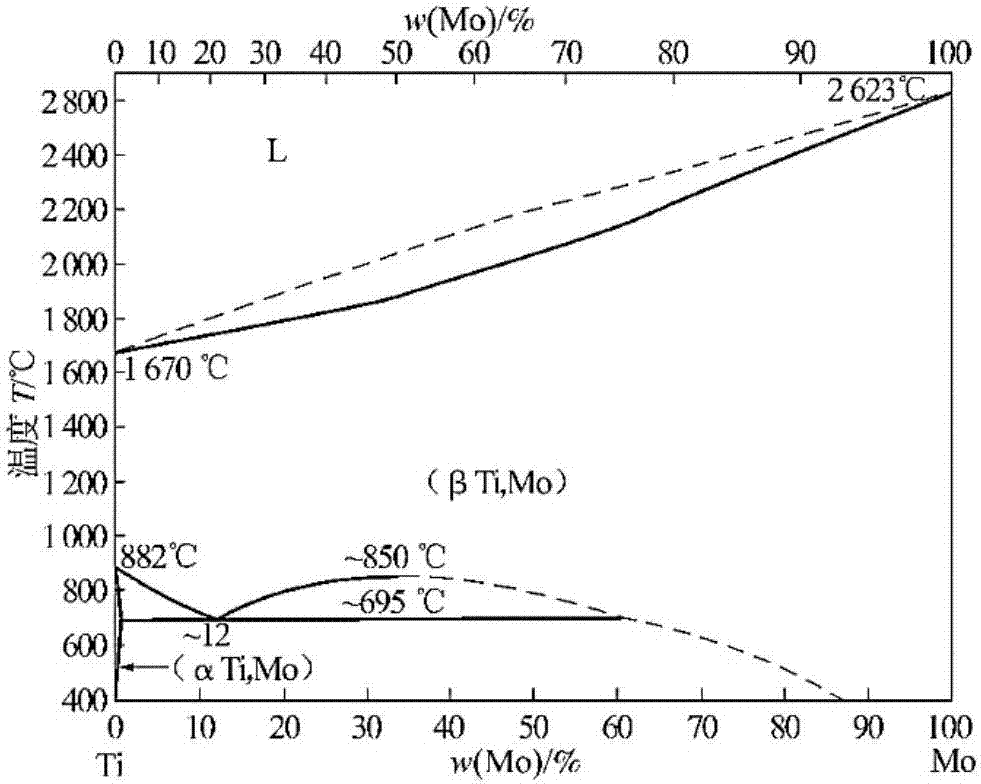

Microalloying method for improving molybdenum and molybdenum alloy fusion welding line toughness by adding Zr

InactiveCN106944741AStretch lightly enhancedHigh tensile strengthArc welding apparatusElectron beam welding apparatusRoom temperatureAlloy

The invention discloses a microalloying method for improving molybdenum and molybdenum alloy fusion welding line toughness by adding Zr. The microalloying method comprises the following steps: 1) an area to be welded of a workpiece to be welded is pretreated, wherein the workpiece to be welded adopts a material or pure molybdenum or a molybdenum alloy; 2) a zirconium layer or a zirconium foil is filled in the joint place of the workpiece to be welded; and then, the workpiece to be welded is assembled; 3) the workpiece to be welded is put in an inert protective atmosphere; and the area to be welded of the workpiece to be welded is preheated; and 4) a welding heat source is acted in a welding line of the workpiece to be welded to finish the fusion welding of the workpiece to be welded; and the welding line position of the workpiece to be welded is insulated, and is cooled to reach the room temperature to finish microalloying for improving the molybdenum and molybdenum alloy fusion welding line toughness by adding Zr. The method can eliminate the segregation phenomenon of impurity element grain boundary, and meanwhile, improves the molybdenum and molybdenum alloy fusion welding line strength.

Owner:XI AN JIAOTONG UNIV

High ferrochrome roller

ActiveCN108018482AImprove mechanical propertiesImprove wear resistanceFurnace typesRollsThick plateFerrochrome

The invention discloses a high ferrochrome roller used for a large-sized wide and thick plate rolling mill. The high ferrochrome roller comprises a roller core, a roller neck and a roller body workinglayer. The roller body working layer comprises, by mass, 2.40%-3.30% of C, 0.60%-1.00% of Si, 0.90%-1.20% of Mn, 15.00%-18.00% of Cr, 1.10%-1.70% of Ni, 0.80%-1.40% of Mo, 0.10%-0.60% of V, 0-0.10% of S, 0-0.05% of P, and the balance Fe and inevitable impurities. By adjusting the heat treatment technology, the mechanical property of the roller is improved, the abrasion resistance and millimeter rolling quantity of the roller are increased, and the service life of the roller is prolonged.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Laser cladding coating powder and preparation method thereof

ActiveCN109536943AGood macroscopic appearanceHigh hardnessMetallic material coating processesHardnessAlloy coating

The invention discloses laser cladding coating powder and a preparation method thereof. The laser cladding coating powder is prepared from the components by mole: 90%-99% of TiAl powder and 1%-10% ofB powder; and the preparation method comprises the steps of metal matrix selection and pretreatment, powder matching and ball milling, powder presetting, and laser cladding. TiAl and B make an in-situreaction through the effect of a CO2 laser beam, and a TiAl based alloy coating with TiB and TiB2 as reinforcing phases is prepared on the surface of a metal matrix. According to the laser cladding coating powder and the preparation method thereof, the hardness of the laser cladding coating is high, good wear resistance and corrosion resistance are achieved, and the laser cladding coating is bonded to the matrix in a metallurgical mode and the bonding condition is good.

Owner:KUNMING UNIV OF SCI & TECH

Preparing method for high-toughness and heat resisting TiC/TiN steel bond hard alloy

The invention relates to a preparing method for a high-toughness and heat resisting TiC / TiN steel bond hard alloy. The preparing method is characterized that one of TiO2 powder, TiH2 powder and Ti powder and colloidal graphite powder are prepared according to the C / Ti atomic ratio of 0.7-1.1, one of the TiO2 powder, the TiH2 powder and the Ti powder and urea ((NH2)2CO) are prepared according to the N / Ti atomic ratio of 0.4-1.1, and accordingly in-situ synthesized TiN mixed powder is prepared; ferro-molybdenum powder, ferro-vanadium powder, ferro-chromium powder, ferro-manganese powder, ferro-silicon powder, iron powder, ferro-boron powder, nickel powder, colloidal graphite and rare earth raw materials are prepared according to the needed proportion for the bonding phase metal chemical component mass ratio to be arranged into a steel ball mill, absolute ethyl alcohol serving as a medium and PVA are added, after ball milling and slurry drying, pressing forming is conducted, and the steel bond alloy is obtained through sintering. The in-situ reaction synthesizing technology and the liquid phase sintering technology are combined, reinforced particles are fine in size, the surfaces are free of sharp corners, base body interface bonding is good, and the interface is clean. Through the method for preparing the steel bond alloy, the comprehensive mechanical performance of the alloy can be improved, cost is low, and the technology is easy and convenient to conduct.

Owner:JIANGSU HUICHENG MACHINERY MFG

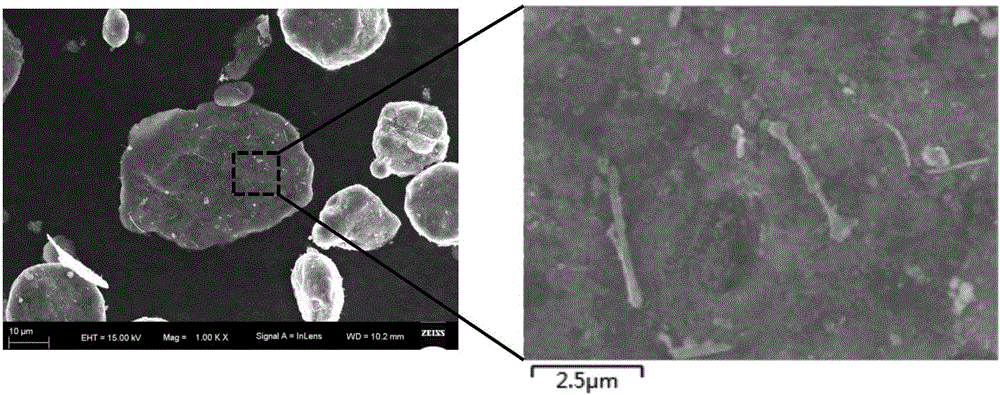

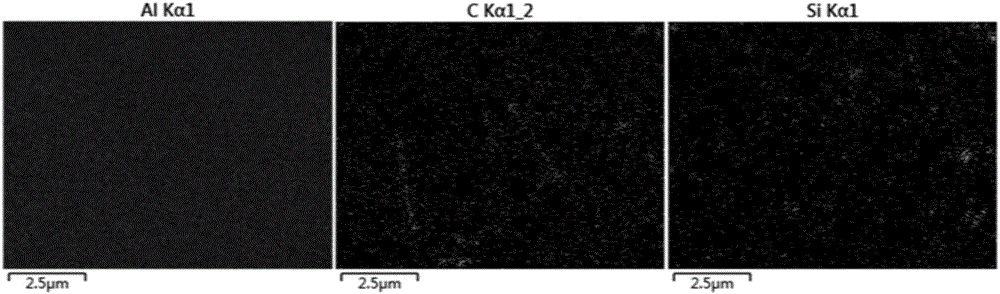

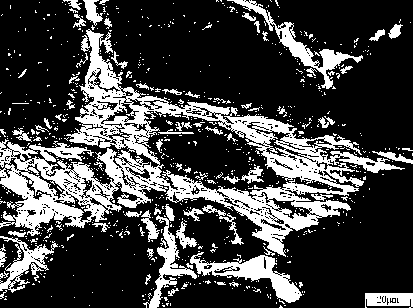

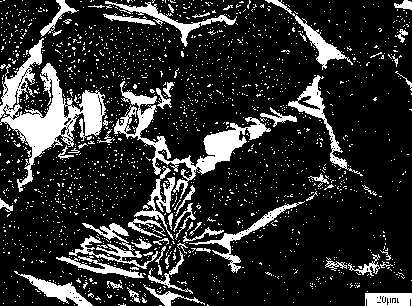

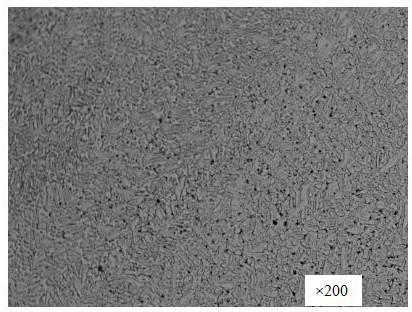

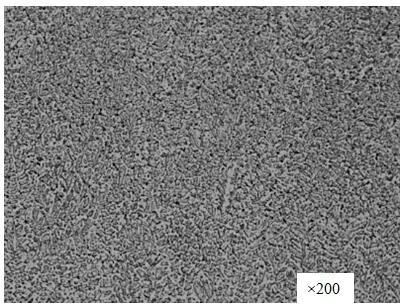

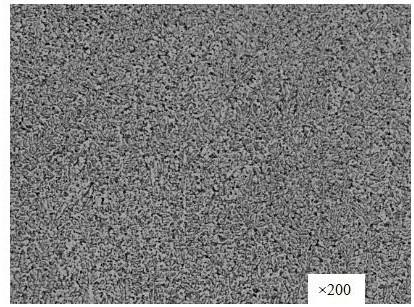

Method for restraining generation of A7N01 aluminum alloy surface coarse grain ring

InactiveCN107151753AImprove microstructurePlay the role of diffusion strengtheningRare-earth elementManganese

The invention relates to the production field of aluminum alloys, in particular to a method for restraining generation of an A7N01 aluminum alloy surface coarse grain ring. During alloy smelting, a trace rare earth element, namely scandium, is led in, the weight percentage of the scandium is 0.05%-0.15%, and a scandium contained A7N01 aluminum alloy casting ingot is prepared. The casting ingot is subject to homogenization treatment, extrusion forming, online air cooling and natural aging treatment, the defect of the coarse grain ring on the surface of an extrusion product is restrained, and the alloy microstructure is obviously refined. An A7N01 aluminum alloy comprises, by mass percentage, 4.0%-5.0% of zinc, 1.0%-2.0% of magnesium, not larger than 0.20% of copper, 0.20%-0.7% of manganese, not larger than 0.30% of chromium, not larger than 0.25% of zirconium, not larger than 0.20% of titanium, not larger than 0.10% of vanadium and the balance aluminum and inevitable impurities. According to the method, the trace rare earth element, namely scandium, is led in, a wee dispersed nanoscale Al3(Sc,Zr) phase is generated in an A7N01 aluminum alloy extrusion bar base, and the dispersion strengthening effect is achieved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

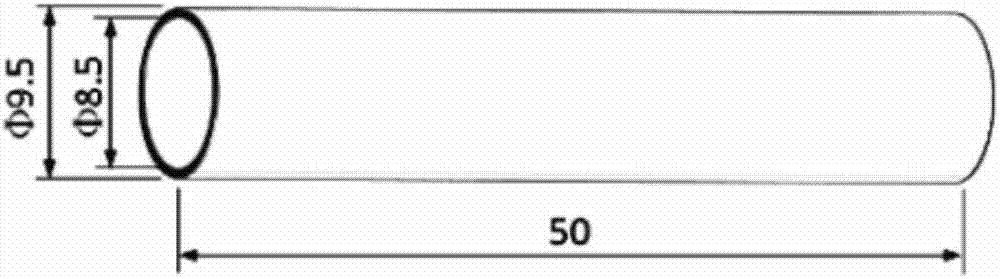

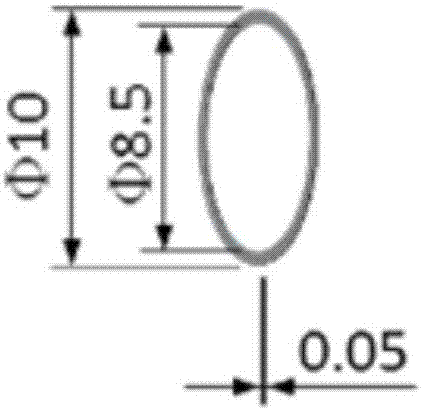

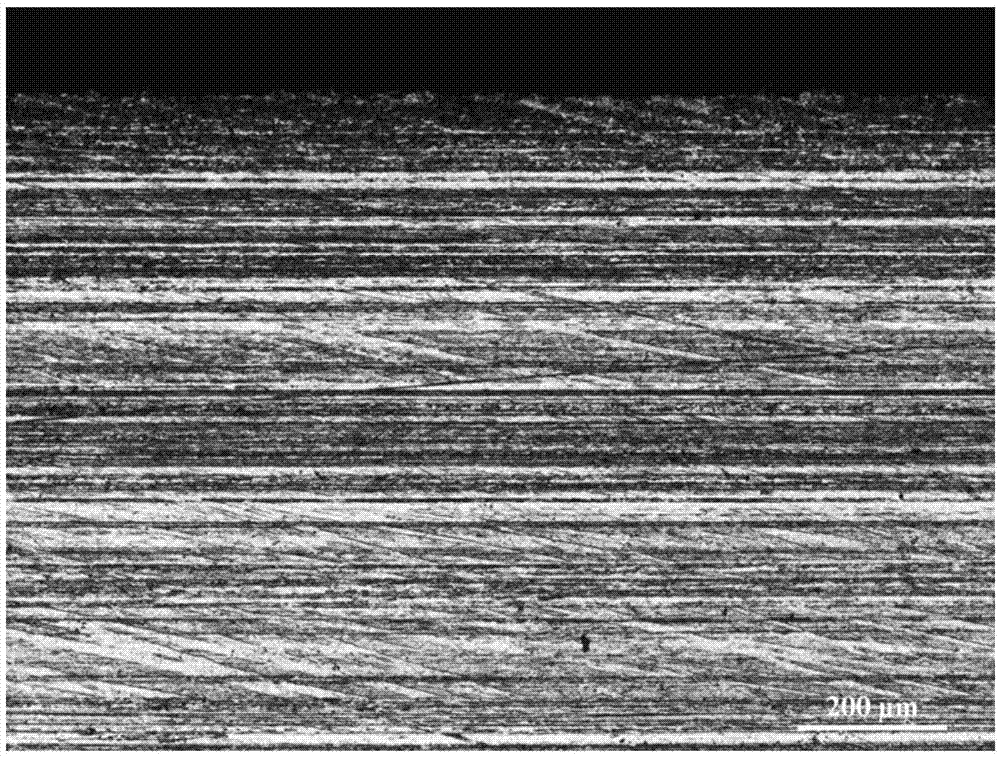

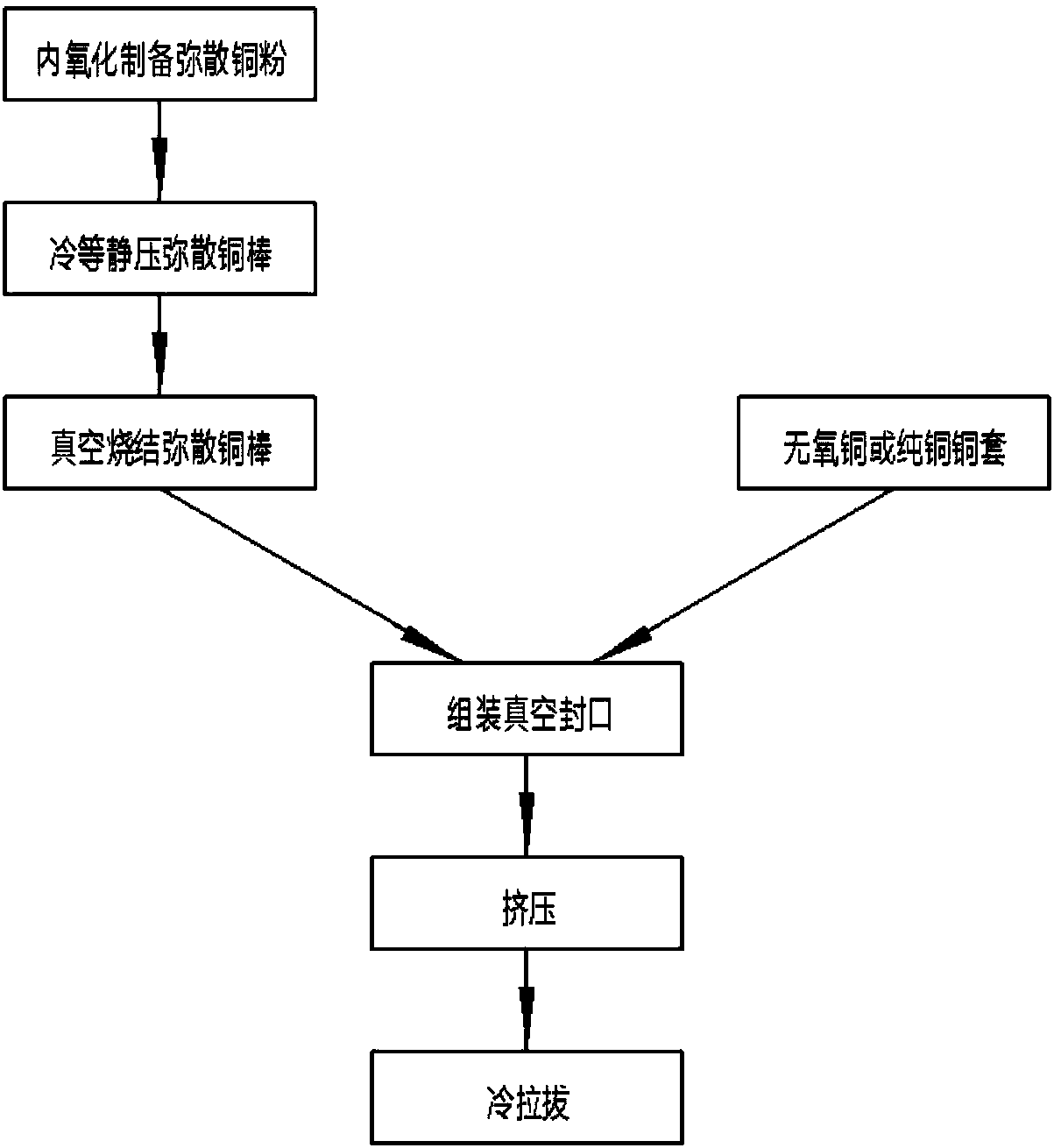

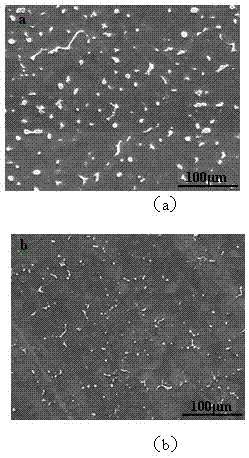

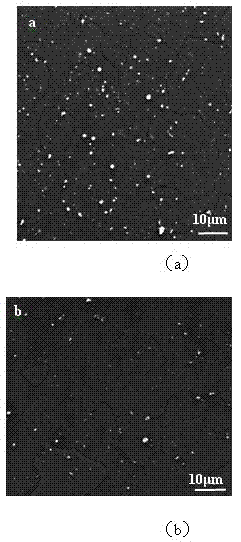

Preparation method of high-strength high-conductivity high-softening-temperature copper-clad dispersion copper conductive rod

ActiveCN107863199AMake up for the shortcomings of poor brazingHigh strengthConductive materialMetal/alloy conductorsSolderingVacuum switch

The invention relates to a preparation method of a high-strength high-conductivity high-softening-temperature copper-clad dispersion copper conductive rod, and specifically relates to the technical field of vacuum switch arc extinguish chamber conductive rod materials. The method comprises the following steps: 1) preparation of dispersion copper alloy powders; 2) preparation of a core dispersion copper rod through a cold isostatic pressing method, pressing pressure being 150-300 MPa, and pressure dwell time being 3-10 min; 3) vacuum sintering of the core dispersion copper rod, maximum sintering temperature being 800-1080 DEG C, temperature holding time being 30-240 min, and vacuum degree being larger than 5 pa; 4) preparation of an outer copper sleeve; 5) embedding the core dispersion copper rod into the outer copper sleeve and carrying out vacuum electron beam sealing; 6) extrusion, extrusion temperature being 600-1050 DEG C; and 7) cold drawing. The conductive rod has the advantagesof high strength, high conductivity, high softening temperature and good soldering performance and the like, and fully meets use requirements of the arc extinguishing chamber conductive rod.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Process for improving age hardening effect of high-zinc deformed magnesium alloy

The invention discloses a process for improving an age hardening effect of a high-zinc deformed magnesium alloy. The method comprises the following steps of: firstly, carrying out homogenization treatment onto an alloy ingot; then, crushing non-equilibrium compounds in the alloy by thermally processing; and finally, facilitating the compounds to dissolve as much as possible by adopting two-step gradient-type solid solution treatment. The process disclosed by the invention can be used for effectively facilitating the dissolving of non-equilibrium eutectic crystals in a high-zinc Mg-ZN-Al ternary alloy, improving the super-saturation degree of Zn and Al elements in the matrix and strengthening the age hardening effect of the high-zinc deformed magnesium alloy. Compared with the conventional T6 treatment, the treatment time is greatly shortened and the production efficiency is effectively improved.

Owner:CHONGQING UNIV

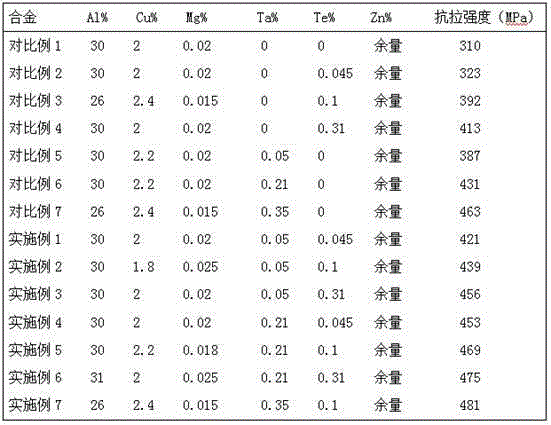

Zn-Al alloy containing Ta and Te elements and preparation method thereof

The invention discloses Zn-Al alloy containing Ta and Te elements. The Zn-Al alloy is formed by components of, by mass, 0.05-0.35% of Ta, 0.045-0.31% of Te, 0.015-0.025% of Mg, 1.8-2.4% of Cu, 26-31% of Al and the balance Zn. The invention further discloses a preparation method of the alloy. In the alloy, Ta forms TaAl(y-x)Znx compound particles, and a grain refinement effect is produced. Te can greatly improve the surface activity of the TaAl(y-x)Znx compound particles and is transformed into fine Al2Te3 particles after being solidified to be dispersed in a matrix, so that the nucleation capacity of the particles is greatly enhanced, and the nucleation rate is improved; compared with Zn-Al alloy without Ta and Te elements or with only one of the elements, the mechanical performance of the Zn-Al alloy with both Ta and Te elements added is improved.

Owner:UNIV OF JINAN

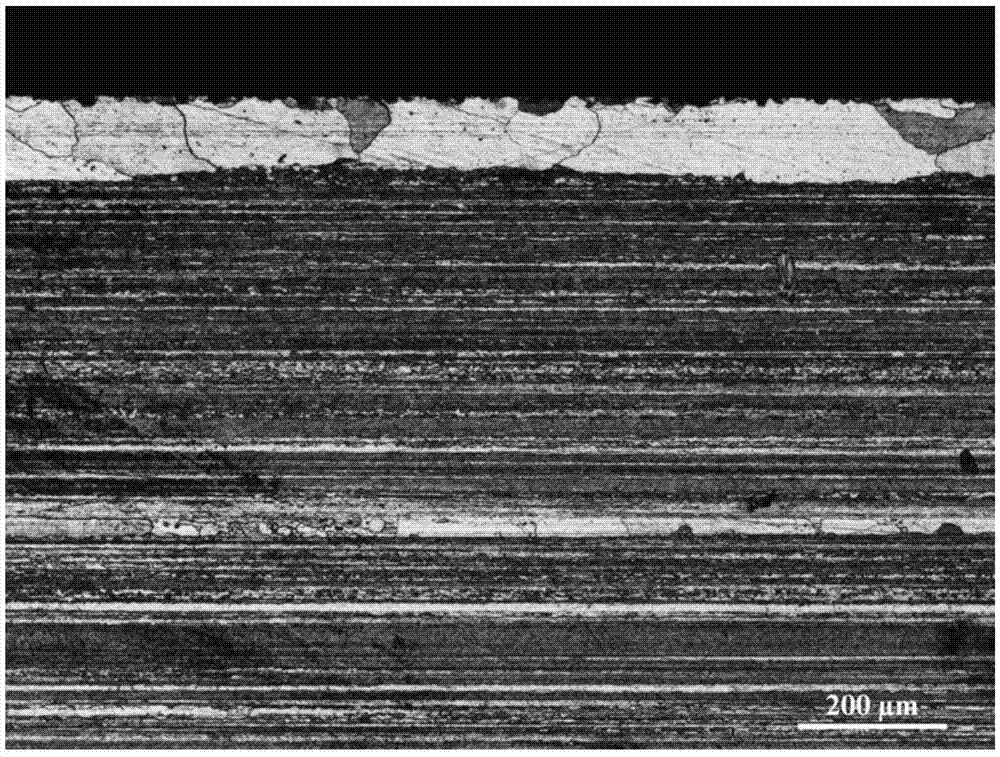

Monoblock cast all-purpose horizontal high-chromium cast iron collar and preparation method

InactiveCN106282747AGuaranteed uniformityGood casting performanceFurnace typesHeat treatment furnacesWear resistanceImpurity

The invention discloses a monoblock cast all-purpose horizontal high-chromium cast iron collar. The monoblock cast all-purpose horizontal high-chromium cast iron collar is composed of two mixing components, one component comprises, by mass, 1.70-2.10% of C, 0.40-1.00% of Si, 0.70-1.20% of Mn, 0.20-1.30% of Ni, 10.00-20.00% of Cr, 0.50-1.50% of Mo, less than or equal to 0.03% of S, less than or equal to 0.03% of P and the balance Fe and inevitable impurities; and the other mixing component comprises, by mass, 0.70-1.20% of C, 1.30-1.90% of Si, 0.50-0.80% of Mn, less than or equal to 0.50% of Ni, less than or equal to 0.50% of Cr, less than or equal to 0.15% of Mo, less than or equal to 0.03% of S, less than or equal to 0.03% of P and the balance Fe and inevitable impurities. Meanwhile, the preparation method of the high-chromium cast iron collar is further disclosed. The produced high-chromium cast iron collar is high in hardness and good in abrasion resistance, and meanwhile the high-chromium cast iron collar has long service life.

Owner:JIANGSU GONGCHANG ROLL

Six-series aluminum alloy template and production process thereof

ActiveCN110983125AImprove mechanical propertiesReduce solid solutionUltimate tensile strengthMaterials science

The invention belongs to the technical field of aluminum alloy production process, and relates to a six-series aluminum alloy template and a production process thereof. The six-series aluminum alloy template is prepared from the following elementary compositions in percentage by weight: 0.50-0.55 % of Si, 0.10-0.15 % of Fe, 0.05-0.10 % of Cu, 0.05-0.10 % of Mn, 0.55-0.60 % of Mg, less than or equal to 0.05 % of Cr, less than or equal to 0.05 % of Zn, less than or equal to 0.05 % of Ti, less than or equal to 0.25 % of La, less than or equal to 0.05 % of other single impurity content, less thanor equal to 0.15 % of total impurity, and the balance of Al. Through the improvement of alloy composition and production process, the final six-series aluminum alloy template has tensile strength of 280 Mpa, yield strength of 255 Mpa and elongation after fracture of 12.5 %, the mechanical properties are significantly improved, and the production needs of customers can be met.

Owner:YINGKOU ZHONGWANG ALUMINUM CO LTD

Low-density high-strength magnesium lithium alloy and preparing method thereof

The invention provides a low-density high-strength magnesium-lithium alloy and a preparation method thereof. The components and mass percentages of the magnesium-lithium alloy are: 11-15% Li, 0.5-4% Al, 0.05-0.5% Zr, 0.2~1.2%La, 0.1~0.6%Ce, the total amount of impurity elements Fe, Ni, Cu, Si≤0.2%, and the balance is Mg. The preparation method of the magnesium-lithium alloy involved in the present invention includes vacuum induction melting and plastic deformation treatment. The magnesium-lithium alloy processed by means of alloying, crystal grain refinement and deformation treatment in the present invention has high strength and plasticity under the premise of ensuring low density, and at the same time has excellent machining performance.

Owner:江苏立美航材科技有限公司

Preparing method for TiC matrix steel base steel bond hard alloy

InactiveCN106811659AUniform pore size distributionImprove uniformityTransportation and packagingMetal-working apparatusCemented carbideSolvent

The invention relates to a preparing method for a TiC matrix steel base steel bond hard alloy. The preparing method includes the following steps that titanium carbide powder and matrix steel matrix powder are weighed according to the proportion, alloy powder is put into a ball grinding machine to be mixed and smashed, added absolute ethyl alcohol is a process control agent, and the wet mixed powder is put into a vacuum drying box to be dried after ball grinding and is used for standby use after drying; an organic monomer and an initiator are added into a solvent to prepare pre-mixed liquid; an additive improving slurry fluidity and dispersity is added; a catalyst and a pH modifier are added and are evenly stirred, and slurry is obtained; and the slurry is injected into an injection and coagulation die, vacuum suction or vibration gas removing is conducted, after the slurry is cured to be formed, a blank is put into the vacuum drying box to be dried, the dried blank is subjected to integrated degumming and sintering in a vacuum sintering furnace, and the steel bond hard alloy is prepared. The preparing method has the beneficial effects that the technology is simple, the cost is relatively low, and parts large in size and complex in shape are easy to prepare on the basis that the macro performance of the steel bond hard alloy is ensured.

Owner:丹阳惠达模具材料科技有限公司

Medium chrome multi-component alloy wear-resistant ball

ActiveCN104109794AImprove corrosion resistanceHigh hardnessFurnace typesMetallic material coating processesWear resistantPore water pressure

The invention discloses a medium chrome multi-component alloy wear-resistant ball. The medium chrome multi-component alloy wear-resistant ball comprises the following components of steel scrap, ferrochrome, ferromolybdenum, ferrovanadium, ferromanganese, ferrosilicon and metallic zinc. In the preparation process, the vacuum cladding process parameters are as follows: the temperature is 1050-1250 DEG C, the time is 3-5 hours, the vacuum degree is 5-6*10<-4>Pa, inflow water pressure of cooling water is 0.45-0.55MPa during warming, inflow water pressure 1 minute before temperature reduction is 2.2-2.5MPa and air-cooling is performed at 120-145 DEG C and discharge out of a furnace is performed; the primary laser cladding process parameters are as follows: the laser power is 1800-2300W, the defocusing amount is plus (20-45), the scanning speed is 250-290mm / min, the powder feeding voltage is 5-10V, the powder feeding speed is 5-9.5g / min and the argon flow is 200-280L / h; the secondary laser cladding process parameters are as follows: the output power is 1600-2500W, the scanning speed is 20-50mm / s, the spot diameter is 5-10mm and the thickness of a cladding layer is 2-3mm. The wear-resistant ball is high in hardness, impact toughness, corrosion resistance, heat resistance and wear resistance.

Owner:宁国市宁武新材料科技有限公司

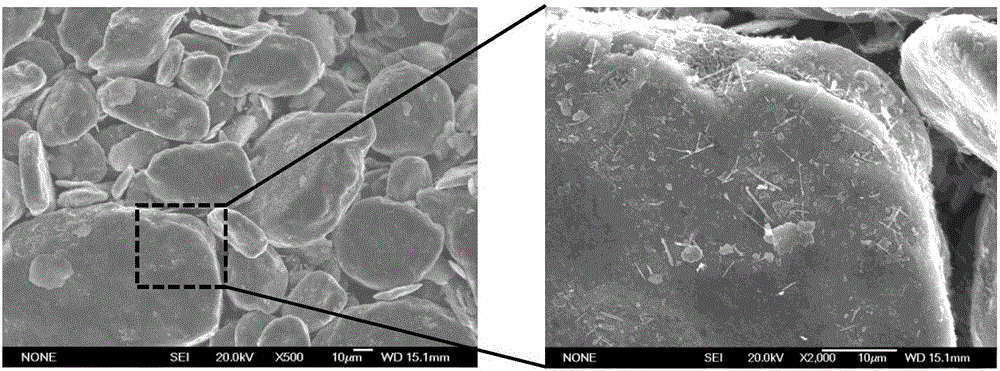

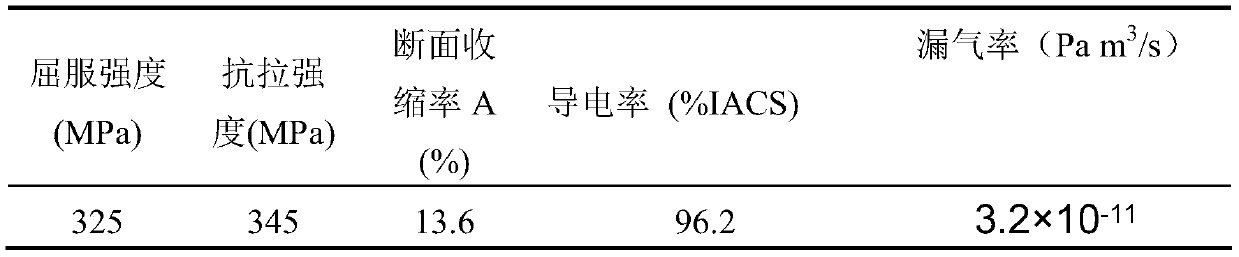

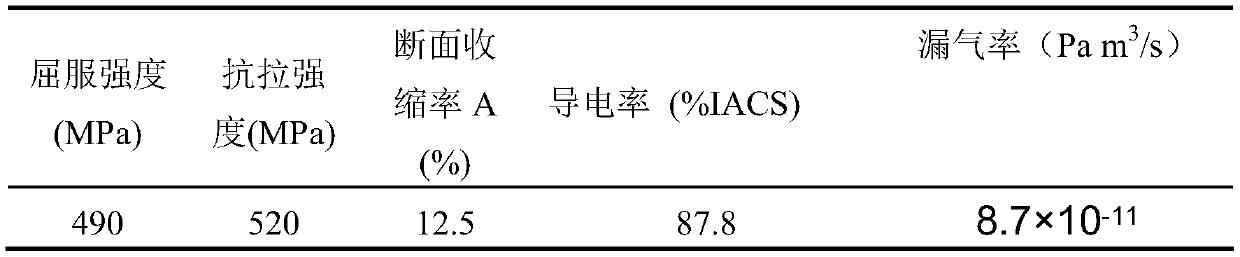

High-air-tightness low-free-oxygen-content nano disperse copper alloy and short-process preparation technology

ActiveCN109897982AReduced free oxygen contentPlay the role of diffusion strengtheningTransportation and packagingMetal-working apparatusInternal oxidationHigh dimensional

The invention discloses a high-air-tightness low-free-oxygen-content nano disperse copper alloy and a short-process preparation technology, and wherein the alloy components comprise Al2O3, Ca and La.The preparation technology is made by the following steps that preparing Cu-Al2O3 alloy powder by adopting an internal oxidation method, and then mixing the Cu-Al2O3 alloy powder with Cu-Ca-La alloy powder, wrap covering the mixed powder under the protection of argon, carrying out hot extrusion at 900-920 DEG C and then rotary forging, after rotary forging, the wrap covering is vacuumized to be less than or equal to 10<-3>Pa, the wrap covering is sealed and is placed in a nitrogen atmosphere with the temperature of 450-550 DEG Cand the pressure intensity of 40-60 Mpa for 3-5 hours. According to the preparation technology disclosed by the invention, the secondary solid reduction of Ca and La is utilized, so that residual free oxygen is effectively removed and the dispersion strengthening effect is achieved, and finally the high density is obtained through vacuum medium-temperature creep deformation. The disperse copper prepared by the invention has the advantages that low free oxygen content (<= 15ppm), high dimensional stability and good air tightness after hydrogen annealing, good in gas tightness, the gas leakage rate is less than or equal to 1.0*10<-10> Pa.m<3> / s, the preparation technology is suitable for industrial production and can be used as a variety of sealing device materials such as an electric vacuum shell sealing device and a novel energy automobile high-voltagedirect-current relay.

Owner:湖南高创科惟新材料股份有限公司

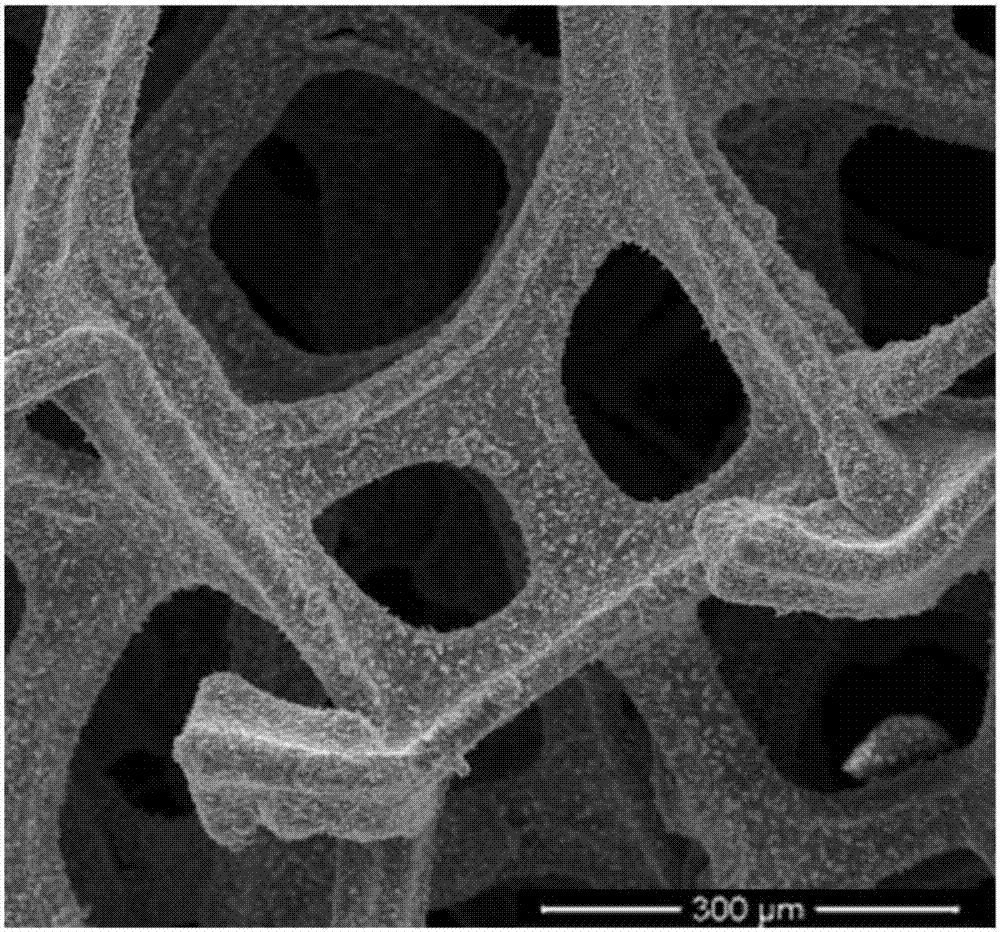

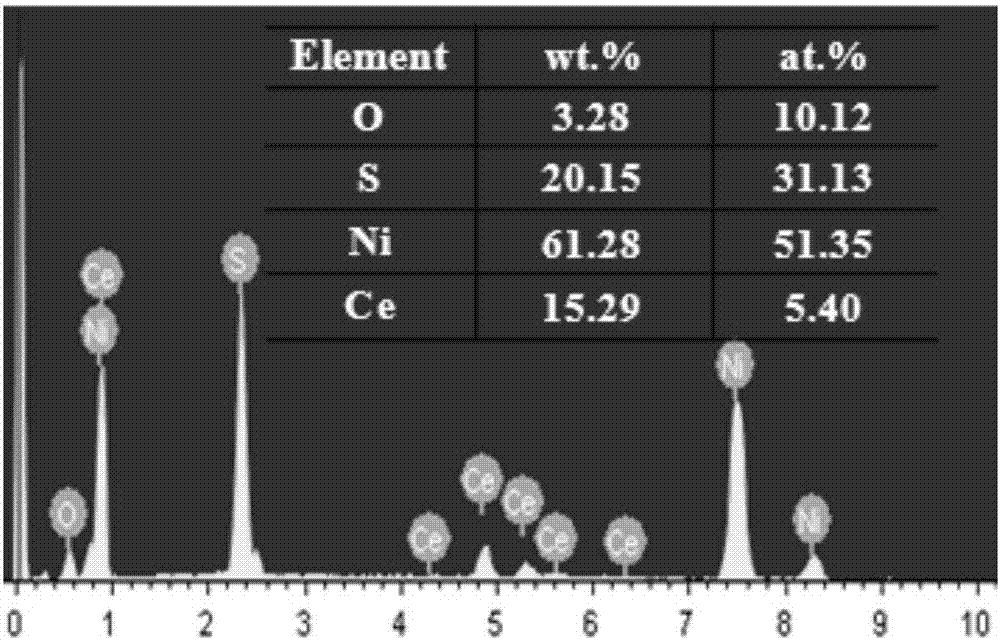

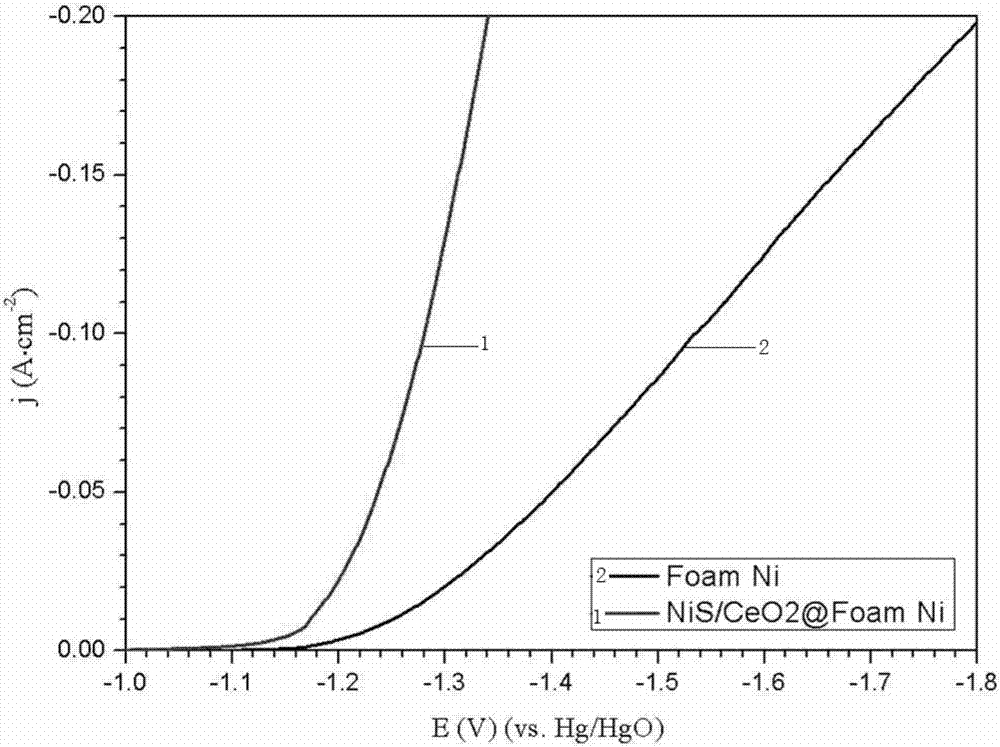

Nickel-sulfur composite hydrogen evolution electrode doped with foamed nickel load CeO2 and preparation method

InactiveCN107475743AGood hydrogen evolution catalytic performanceAvoid electrode deactivationPhysical/chemical process catalystsElectrolytic inorganic material coatingNickelHydrogen production

The invention relates to a nickel-sulfur composite hydrogen evolution electrode doped with foam nickel load CeO2and a preparation method, and belongs to the technical field of material science and the field of electrocatalysis hydrogen production. The electrode takes three-dimensional foam nickel as a carrier and a nickel-sulfur coating as a surface active layer, andCeO2 is compounded and doped into the nickel-sulfur coating through a composite electrode position method to form a foam nickel-based Ni / CeO2 composite electrode. The nickel-sulfur coating was deposited on the surface of the three-dimensional foam nickel through the composite electrode position method. Meanwhile, in the electrode position process, the nano-scale CeO2in a composite plating solution is doped into the nickel-sulfur coating by magnetic stirring. The hydrogen evolution electrode has the characteristics of being low in overpotential, high in electrode stability and the like, and the preparation process is simple and suitable for large-scale production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com