Zn-Al alloy containing Ta and Te elements and preparation method thereof

A technology of aluminum alloy and tantalum alloy, which is applied in the field of zinc-aluminum alloy and its preparation, can solve problems such as the limitation of improving mechanical properties, and achieve the effects of improving mechanical properties, increasing nucleation rate, and enhancing particle nucleation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

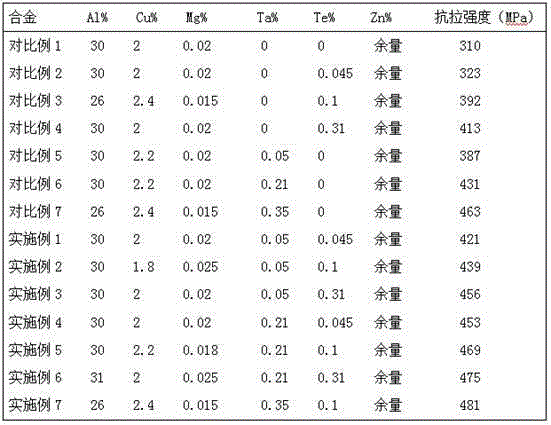

Examples

Embodiment 1

[0023] A zinc-aluminum alloy containing tantalum and tellurium elements, the mass percentage composition is Zn-30Al-2Cu-0.02Mg-0.05Ta-0.045Te, and the preparation process is as follows:

[0024] (1) Prepare raw materials according to the desired quality and chemical composition of zinc-aluminum alloy: zinc (purity 99.99%), aluminum (purity 99.7%), Al-40wt.%Mg alloy, Al-50wt.%Cu alloy, Zn -27wt.%Al-7wt.%Ta alloy and Al-6.5Te alloy;

[0025] (2) Put the three raw materials of zinc, aluminum and aluminum-copper alloy into the electric furnace for melting to obtain a zinc-aluminum alloy melt with a temperature in the range of 660-720°C;

[0026] (3) Add Al-40wt.%Mg alloy, Zn-27Al-7Ta alloy and Al-6.5Te alloy to the zinc-aluminum alloy melt in step 2), keep it warm at 690-750°C for 10-25min, and then use a carbon rod Stir the melt (60-150 rpm), pour the alloy melt into the mold, and obtain the zinc-aluminum alloy containing tantalum and tellurium elements in this embodiment after ...

Embodiment 2

[0028] A zinc-aluminum alloy containing tantalum and tellurium elements is composed of Zn-30Al-1.8Cu-0.025Mg-0.05Ta-0.1Te alloy in mass percent. Except for changing the amount of raw materials to match the composition of the alloy to be prepared, the rest of the preparation process is the same as in Example 1.

Embodiment 3

[0030] A zinc-aluminum alloy containing tantalum and tellurium elements is composed of Zn-30Al-2Cu-0.02Mg-0.05Ta-0.31Te alloy in mass percent. The rest of the preparation process is the same as in Example 1 except that the amount of raw materials is matched with the composition of the alloy to be prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com