Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Act as a surfactant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing activated rubber crumb by catalysis and activation reaction

InactiveCN101381476AImprove dynamic performanceEasy to usePlastic recyclingPolymer sciencePlasticizer

The invention provides a method for preparing activated rubber powder by catalytic reaction and activating reaction, and relates to a method for comprehensive utilization of waste and scrap rubber. Compared with the production of regenerated rubber, the method reduces processes of desulfurizing, kneading and refining, thereby avoiding secondary pollution to the environment. The prepared activated rubber powder has excellent compatibility with matrix rubber, and improves the physical and mechanical properties of the product. The formulation comprises the following compositions in weight portion: 100 portions of 30 to 40 meshes of waste rubber powder, 8 to 17 portions of plasticizer-dipentene, 5 to 8 portions of dusting agent-pottery clay, 0.2 to 0.5 portion of catalyst-cuprous chloride, 7 to 1.0 portion of promoting agent-polyalkylphenol disulfide, and 1 to 2.5 portions of dispersing agent-ethanol. The method comprises the following steps: placing the 30 to 40 meshes of waste rubber powder into a high-speed stirring reactor, and heating the waste rubber powder to the temperature of between 80 and 100 DEG C; adding the plasticizer, the dusting agent, the catalyst, the promoting agent and the dispersing agent into the reactor sequentially for reacting for 10 to 20 minutes at a temperature of between 80 and 120 DEG C, and cooling and discharging to produce the activated rubber powder. The prepared activated rubber powder can be used in rubber industry and building industry.

Owner:TIANJIN RUBBER IND RES INST

Polybutadiene rubber modified waterborne polyurethane adhesive and preparation method thereof

ActiveCN103409101AIncrease elasticityImprove low temperature resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane adhesivePolymer science

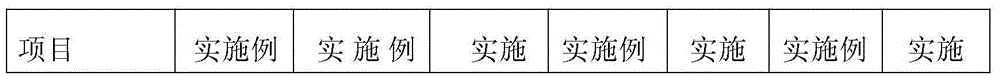

The invention discloses a polybutadiene rubber modified waterborne polyurethane adhesive and a preparation method thereof, which belong to the field of waterborne polyurethane adhesives and are used for solving the problems that an existing polybutadiene rubber modified waterborne polyurethane adhesive is high in thermal activation temperature, low in solid content and poor in primary viscosity and peeling strength. In order to solve the problems, the adhesive disclosed by the invention comprises the following components in parts by weight: 75-100 parts of polybutadiene rubber modified waterborne polyurethane, 3-5 parts of white carbon black, 0.2-0.5 part of 3-amino propyl triethoxysilane, 0.15-0.3 part of waterborne thickening agent, 8-15 parts of plasticizer and 3-7 parts of waterborne curing agent. The invention further provides a preparation method of the polybutadiene rubber modified waterborne polyurethane adhesive. After the adhesive disclosed by the invention is adhered with a sample and impacted for 5 cycles at a high-low temperature between -65 DEG C and 120 DEG C, the peeling strength is reduced by not more than 5%, the elongation at break is as high as 380%-510%, and the tensile strength is as high as 2.8 MPa-4.2MPa.

Owner:CHANGCHUN SANHUA IND

Ultrasonic-microwave assisted enzymatic extraction of green tea polyphenol and application thereof in shower gel

InactiveCN106806160AHigh speedHigh extraction rateCosmetic preparationsToilet preparationsWater bathsGreen Tea Polyphenols

The invention discloses an ultrasonic-microwave assisted enzymatic extraction method of green tea polyphenol. The method comprises the following steps: grinding weighed green tea leaves to obtain powder of which the particle size is 45 to 80 meshes, preparing the green tea powder into suspension liquid with water, at room temperature, using an ultrasonic-microwave extraction instrument of which the ultrasonic power is 45 to 60W, and the microwave power is 70 to 90W, after processing for 10 to 20 min, adding 1% to 3% of cellulase, carrying out ultrasound assisted enzymatic hydrolysis for 20 to 30 min, enzyme deactivation for 10 to 20 min under the conditions of a 100 DEG C-water bath, and centrifugation for 20 to 30 min at 5000 to 10000 r / min, performing pumping filtration after cooling, collecting filtrates, carrying out vacuum concentration to obtain a concentrated solution, then adding ethyl acetate to the concentrated solution to be extracted, and carrying out vacuum concentration, freeze concentration and freeze drying on organic phases, thereby being capable of obtaining the green tea polyphenol. The invention further provides shower gel containing the green tea polyphenol and a preparation method of the shower gel. The extraction method of the green tea polyphenol provided by the invention is simple to operate and high in extraction efficiency, furthermore, the green tea polyphenol extracted by the invention is applied to the shower gel, so that free radicals on the skin surface can be removed to play a good skin protective effect.

Owner:张仕英

Production method of pure titanium powder and low-sulfur titanium white powderfor catalyst

The invention provides a new production process of titanium white powder and low-sulfur titanium white powderfor a denitrification catalyst. The production process comprises the following steps: after obtaining competently washed metatitanic acid, neutralizing with ammonia water, heating materials to 70-75 DEG C, and curing for 1 hour while keeping the temperature; dry-pressing slurry through a filter press, removing filter cakes, crushing the filter cakes, and drying and calcining in a rotary kiln; and then, discharging, cooling, conveying to a storage bin, and pulverizing through a micron pulverizer to obtain the pure titanium powder finished product for a nano catalyst. Preferably, after completing the step of curing while keeping the temperature, the low-sulfur catalytic titanium white powder can be obtained by adding a step of washing with deionized water and keeping the subsequent process flow unchanged, and the sulfur content is less than 0.4%.

Owner:GUANGXI JINMAO TITANIUM

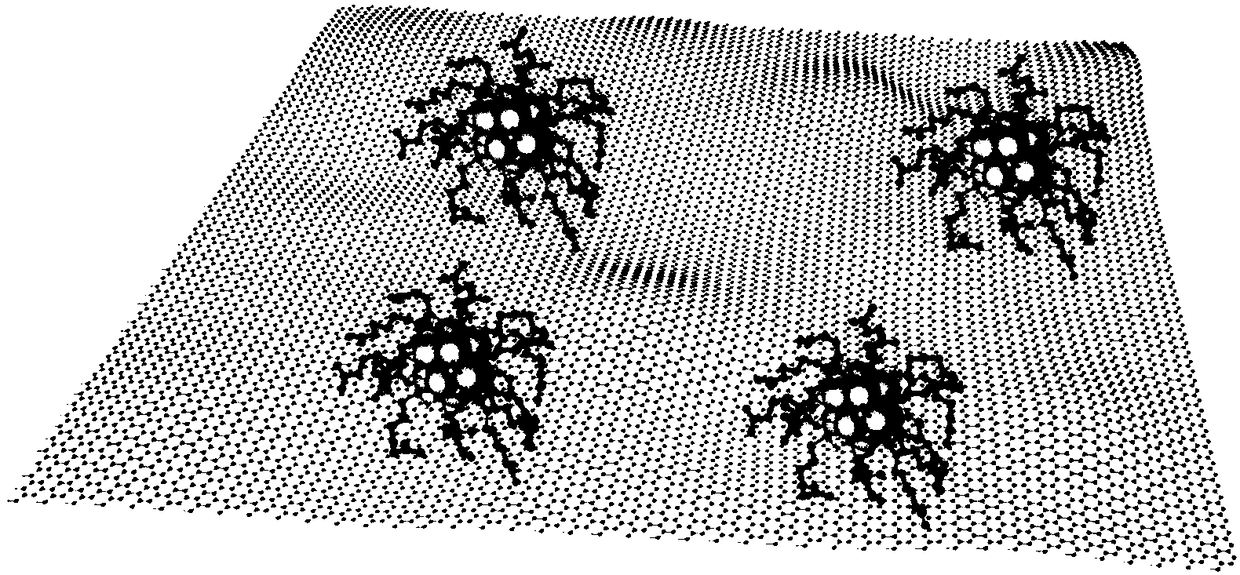

Gold cluster/graphene compound catalytic membrane preparation method

ActiveCN108404989AAct as a surfactantEvenly dispersedSemi-permeable membranesOrganic-compounds/hydrides/coordination-complexes catalystsGold clusterThiol

The invention relates to a gold cluster / graphene compound catalytic membrane preparation method which comprises the steps: (1) adding deionized water into oxidized graphene to be dispersed evenly andultrasonically dispersing to obtain dispersion liquid; utilizing a hydrothermal reduction method to reduce the oxidized graphene into reduced oxidized graphene rGO and freeze drying to obtain rGO powder; (2) adding the rGO powder into a gold cluster solution protected by thiol ligand, then adding ultrapure water and ultrasonically dispersing to obtain mixed liquid; utilizing vacuum filtration to load the mixed liquid on a base membrane and washing to obtain a gold cluster / graphene compound catalytic membrane. The preparation method disclosed by the invention has the advantages of convenient technological operation, large gold cluster load amount, high catalytic activity, easiness in being recycled and utilized, ability in achieving high-efficiency catalytic membrane construction and good application prospect.

Owner:DONGHUA UNIV

Chalking-resistant spray gel and preparation method thereof

ActiveCN107502231AImproved chalking resistanceImprove performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesElastomer(Hydroxyethyl)methacrylate

The invention discloses a chalking-resistant spray gel and a preparation method thereof. The chalking-resistant spray gel is prepared from the following raw materials in parts by weight: 10 to 16 parts of butadiene-stryrene copolymer elastomer, 10 to 18 parts of hydrogenated rosin, 3 to 16 parts of hydrogenerated pentaerythritol rosin resin, 1 to 5 parts of alkyl phenolic resin magnesium oxide chelating matter, 5 to 8 parts of styrene block graft polymer, a proper amount of dispersing solvent, and 1 to 2 parts of solvent, wherein the viscosity of the alkyl phenolic resin magnesium oxide chelating matter is greater than 3000cps when determining by a No.3 rotor at the temperature of 25 DEG C; the styrene block graft polymer is prepared from the following raw materials in parts by weight: 100 parts of styrene block copolymer, 2 to 6 parts of MAH (maleicanhydride) monomer, 10 to 20 parts of HEMA (hydroxyethyl methacrylate) monomer, 30 to 40 parts of MMA (methyl methacrylate) monomer, 0.3 to 0.4 part of initiator, and 350 to 400 parts of solvent; the styrene block graft polymer is prepared by firstly grafting the styrene block copolymer, the MAH monomer and the HEMA monomer and then grafting with the MMA monomer; the styrene block copolymer is selected from one or several of SBS (styreneic block copolymers) or SIS (styrene isoprene styrene). The chalking-resistant spray gel has good chalking-resistant property.

Owner:GUANGDONG ORIENT RESIN

Graphene heat conductive plastic and preparation method thereof

The invention provides a graphene heat conductive plastic and a preparation method thereof, relates to the technical field of heat conductive plastics, and specifically designs the graphene heat conductive plastic and the preparation method thereof. The graphene heat conductive plastic comprises the following components in percentages: 2%-10% of modified graphene, 88%-96% of organic synthetic resin, 0.1%-1% of a plasticizer, and 0.2%-2% of an auxiliary agent. The method for preparing the graphene heat conductive plastic comprises the following steps: a, preparing the modified graphene; and b,preparing the graphene heat conductive plastic: uniformly mixing 2%-10% of the modified graphene, 88%-96% of the organic synthetic resin, 0.1%-1% of the plasticizer and 0.2%-2% of the auxiliary agent,adding the mixed material into a twin-screw extruder barrel, performing a melt reaction at the temperature of 180-300 DEG C for mixing, and performing extrusion granulation in the twin-screw extruderbarrel to obtain the graphene heat conductive plastic. The graphene heat conductive plastic and preparation method thereof provided by the invention have the beneficial effects that the graphene heatconductive plastic has a simple structure, can achieve higher thermal conductivity under the condition of a low graphene content, and is beneficial to meeting packaging requirements of current products such as electronic products; and the method employs a simple preparation process.

Owner:太仓斯迪克新材料科技有限公司

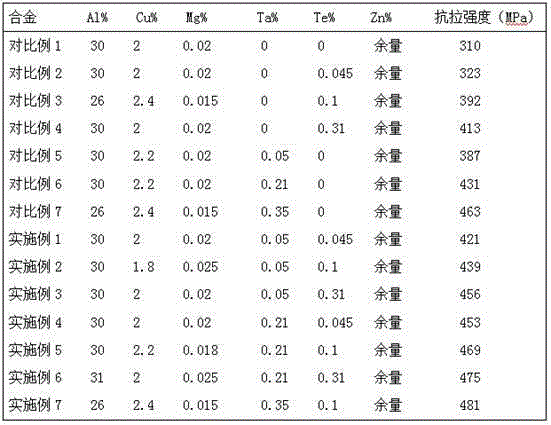

Zn-Al alloy containing Ta and Te elements and preparation method thereof

The invention discloses Zn-Al alloy containing Ta and Te elements. The Zn-Al alloy is formed by components of, by mass, 0.05-0.35% of Ta, 0.045-0.31% of Te, 0.015-0.025% of Mg, 1.8-2.4% of Cu, 26-31% of Al and the balance Zn. The invention further discloses a preparation method of the alloy. In the alloy, Ta forms TaAl(y-x)Znx compound particles, and a grain refinement effect is produced. Te can greatly improve the surface activity of the TaAl(y-x)Znx compound particles and is transformed into fine Al2Te3 particles after being solidified to be dispersed in a matrix, so that the nucleation capacity of the particles is greatly enhanced, and the nucleation rate is improved; compared with Zn-Al alloy without Ta and Te elements or with only one of the elements, the mechanical performance of the Zn-Al alloy with both Ta and Te elements added is improved.

Owner:UNIV OF JINAN

Carbonic composite hydrogen storage alloy and preparation method thereof, composite solid hydrogen storage tank and hydrogen storage performance testing method

ActiveCN110788329AGood securityHigh hydrogen storage densityReactant parameters controlVessel geometry/arrangement/sizeMetallurgyFuel cells

The invention discloses a carbonic composite hydrogen storage alloy and a preparation method thereof, a composite solid hydrogen storage rank made from the carbonic composite hydrogen storage alloy, and a method for performing hydrogen storage performance testing on the composite solid hydrogen storage tank. The carbonic composite hydrogen storage alloy is prepared from, by mass, 90-98% of hydrogen storage alloy powder and 2-10% of carbon materials. The method for preparing the carbonic composite hydrogen storage alloy comprises the following steps of preparing the hydrogen storage alloy powder, preparing the carbon materials and mixing the carbon materials and the hydrogen storage alloy powder to obtain the carbonic composite hydrogen storage alloy. The prepared composite solid hydrogen storage tank can be used for the fields of hydrogen purification, fuel cell hydrogen source storage, fixed energy storage and the like.

Owner:JIANGSU JICUI ANTAI CHUANGMING ADVANCED ENERGY MATERIALS RES INST CO LTD

Preparation method of heteromorphic microporous ceramic capillary

ActiveCN107324802AGuaranteed positionAppearance dimensionally stable and uniformMouldsCoupling light guidesMicrometerVolumetric Mass Density

The invention provides a preparation method of a heteromorphic microporous ceramic capillary. The preparation method comprises the steps of designing a special heteromorphic microporous ceramic capillary forming die, preparing special zirconia ceramic particles, matching a unique sintering forming technology to achieve primary sintering forming of a heteromorphic inner hole of the ceramic capillary without secondary processing, and designing a thimble positioning hole during forming green body preparation according to a product property of the heteromorphic microporous ceramic capillary to allow that an outside diameter grinding technology of the ceramic capillary is greatly simplified. For the ceramic capillary prepared by the method, the density reaches 6.0-6.10g / cm<3>; the hardness is greater than 1200HV; the bending strength is greater than 1200MPa; the dimensional tolerance of the inner hole is within 3 micrometers; the outside diameter grinding precision can reach 1-micrometer position precision; a glass capillary in a multi-core optical fiber collimator can be completely replaced; the matching precision with an optical fiber is high; the reliability meets a requirement of an optical passive device standard GR1209 / 1221.

Owner:黄石晨信光电股份有限公司

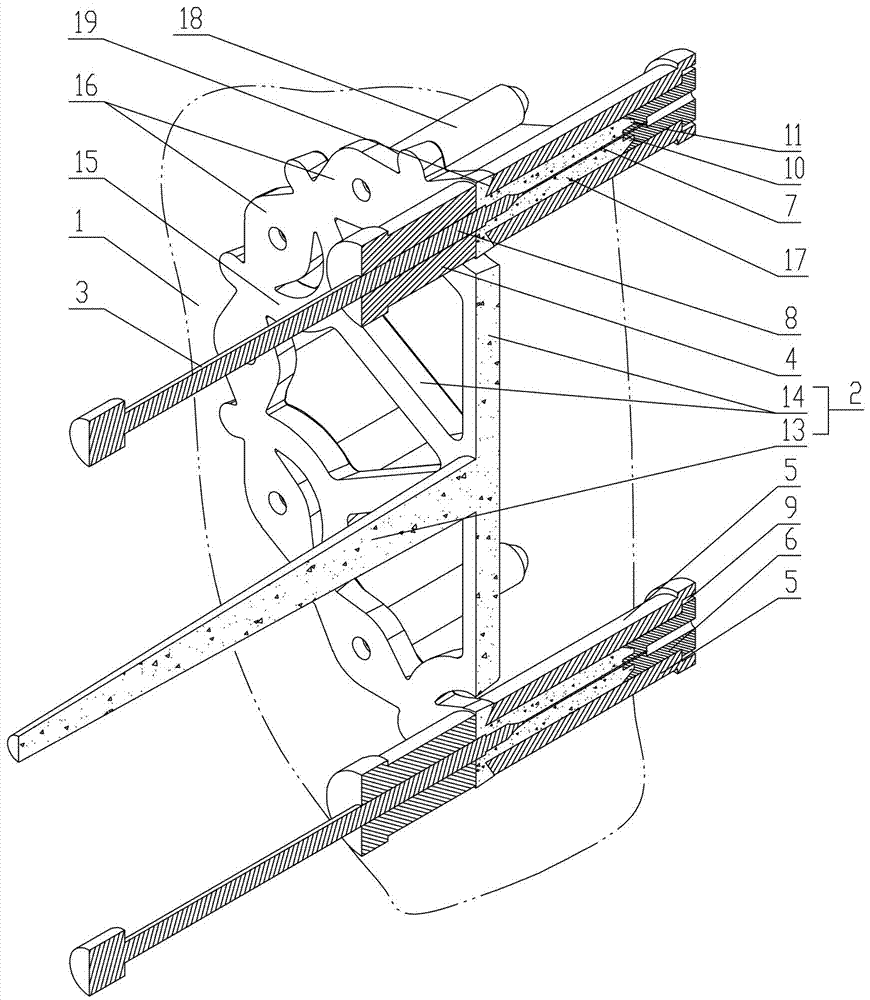

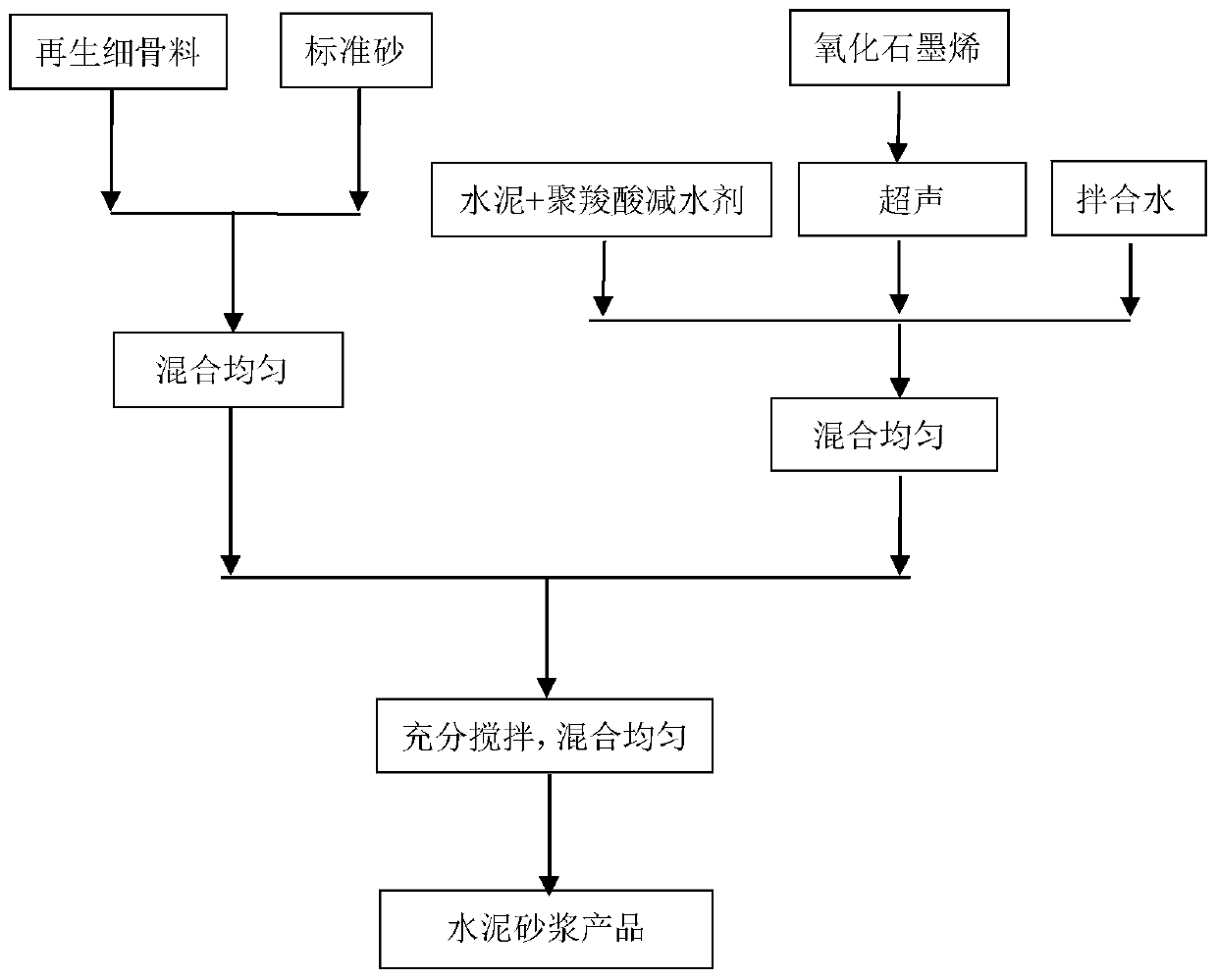

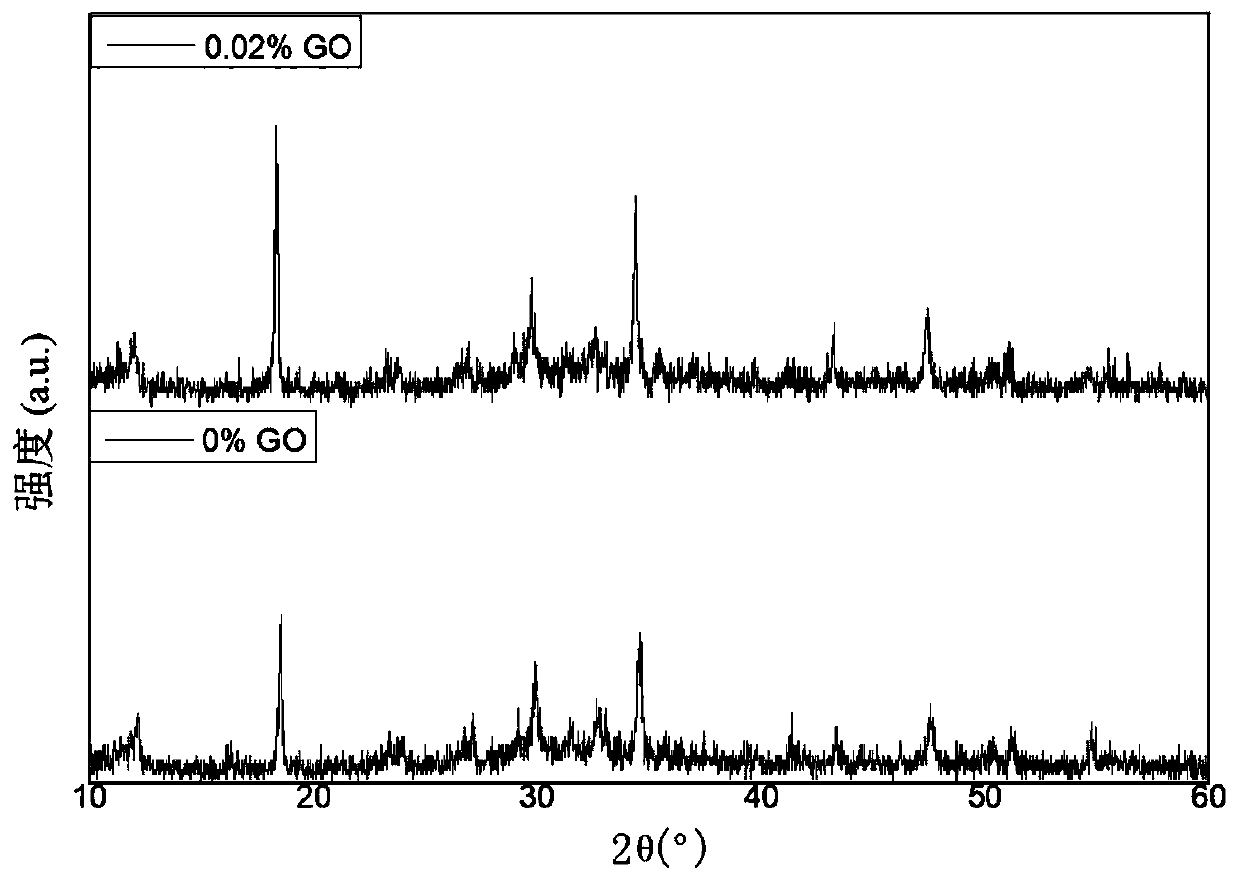

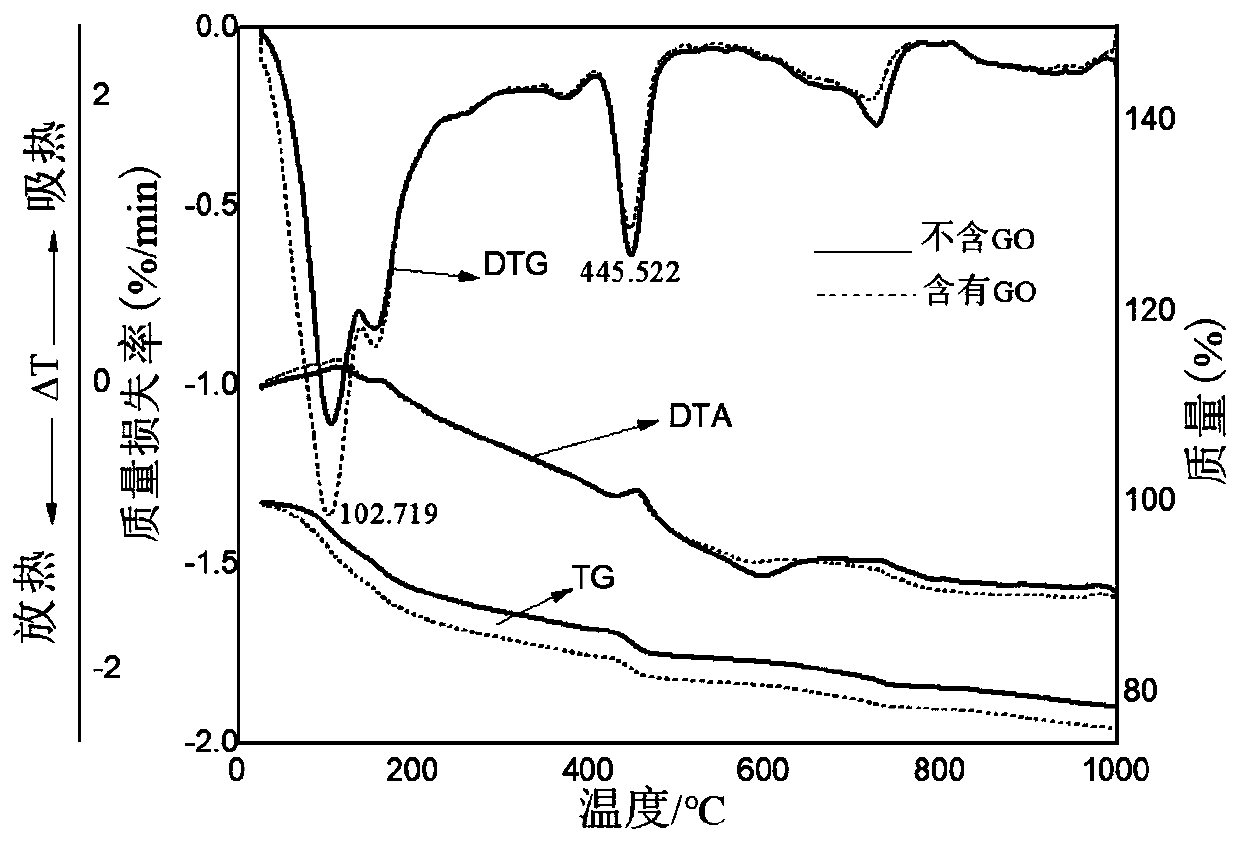

Composite graphene high-strength construction waste cement mortar and preparation method thereof

ActiveCN111410478AGood dispersionReduce frictional resistanceSolid waste managementAggregate (composite)Compressive resistance

The invention discloses composite graphene high-strength construction waste cement mortar and a preparation method thereof, the composite graphene high-strength construction waste cement mortar is prepared by mixing construction waste and standard sand as aggregate, using graphene oxide as a modifier, and then adding a polycarboxylate superplasticizer, cement and water. The performance indexes ofthe cement mortar disclosed by the invention meet the requirements that the 28-day standard compressive strength is 57.6 MPa, and the breaking strength is 9.03 MPa (tested according to GB / T17617-1999and JGJ / T70-2009); the mass loss and the strength loss of 150 times of anti-freezing cycles are both less than 5% (according to GB / T50476-2008 test); and the Cl<-> content in the product is 0.0067%, and the IRa is 0.08, and the Ir is 0.15 (tested according to GB6566-2010).

Owner:ANHUI UNIV OF SCI & TECH

Epitaxial growth method of high-resistance GaN thin film

ActiveCN107887255AFree installationImprove economySemiconductor/solid-state device manufacturingHigh resistanceImpurity doping

The invention relates to an epitaxial growth method of a high-resistance GaN thin film. The method is performed in MOCVD equipment and includes a substrate baking stage, a nucleation stage and an epitaxial growth stage. The method is characterized in that a metal organic matter trimethylindium is used as a C impurity doping source during the epitaxial growth stage. With the method adopted, the high resistance of the GaN thin film can be achieved; the TMIn is unlikely to form In-N bonds in crystal lattices under high temperature, and therefore, high growth temperature can assist in avoiding theformation of InGaN alloys and ensuring the integrity of the lattice structure of the GaN thin film; the concentration of C impurities in a GaN epitaxial layer can be effectively controlled by changing the flow rate of the dopant TMIn, and therefore, doping efficiency is high, and repeatability is stable; and a doping source pipeline is not required to be added into an MOCVD system, other C dopingsources are not required to be installed, and therefore, the resources of existing device can be fully utilized. The method is of simplicity and easy to operate. The epitaxial material has good performance. The high-quality and low-cost growth of the high-resistance GaN thin film can be realized.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Graphene nano silver transparent soap and preparation method and application thereof

InactiveCN106939260AWith decontamination abilityHas a bactericidal effectCosmetic preparationsPolymeric surface-active compoundsPolyphenolCvd graphene

The invention belongs to the technical field of commodity processing, and in particular relates to graphene nano silver transparent soap and a preparation method and application thereof. The graphene nano silver transparent soap prepared by the method not only has the decontamination capability of general transparent soap, but also has the bactericidal function because of the addition of graphene nano silver. In addition, the graphene nano silver transparent soap has effect of moisturizing and beautifying due to excess reducing agents such as glycerin, tea polyphenols and red dates extract. According to the preparation method of one-step reduction of graphene oxide and silver ions, the added reducing agents can not only reduce the graphene oxide and the silver ions, and the excess reducing agents also can bring special effects. In addition, the preparation method has the advantages of low production cost, little danger, cheap and easily-obtained raw materials, greenness and no pollution, and is suitable for large-scale industrial production.

Owner:HUBEI UNIV FOR NATITIES

Preparation method of high-purity micron-scale spherical molybdenum powder

The invention discloses a preparation method of high-purity micron-scale spherical molybdenum powder. The preparation method comprises the following steps of S1, sequentially dropwise adding ammoniumhydroxide into ammonium paramolybdate and ageing, carrying out purification by a resin column adsorption to obtain a purified ammonium paramolybdate solution; S2, adjusting the pH of the purified ammonium paramolybdate solution to be neutral, adding citric acid to adjust the pH value to be 1.0; S3, carrying out airflow-type atomization on the purified ammonium paratungstate solution with the pH value of 1.0 to obtain ammonium paramolybdate powder; and S4, placing the ammonium paramolybdate powder in a tubular rotary furnace to be reduced to obtain the molybdenum powder. According to the method, ammonium paramolybdate is prepared into a solution to purify, the quality purity of the molybdenum powder is improved from the source, then the surfactant citric acid is added, the surface tension of the purified ammonium paramolybdate solution is reduced, more uniform drops with higher spherical degree, smaller particle size of the ammonium paramolybdate solution is generated in the airflow type atomization process, so that the spherical degree of the molybdenum powder is improved, molybdenum powder which is high in purity, micron-sized and uniform in particle size distribution is obtained;and meanwhile, the granularity controllability of the molybdenum powder is improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Method for extracting perillaldehyde from perilla

InactiveCN110590526AHigh extraction rateHigh purityCarbonyl compound separation/purificationPerillaldehydeCell wall

The invention belongs to the technical field of extraction, and particularly relates to a method for extracting perillaldehyde from perilla. The method comprises the following steps: pretreatment, acidification and enzymolysis, primary treatment of an enzyme, secondary treatment, extraction, decolorization and impurity removal, vacuum distillation, and deodorization and purification, an extractionrate is up to 24.76%, the purity is up to 99.3% or more, and quality and a utilization rate of perillaldehyde are significantly improved. The activity of the enzyme is improved through pretreatment,the enzyme has relatively high efficiency in a process of enzymatic destruction of cell walls, enzymolysis is relatively complete, the extraction rate is improved while chemical properties of perillaldehyde is maintained to the maximum, introduction and residue of organic reagents are greatly reduced, and thereby purity and quality of the perillaldehyde finished-product are improved.

Owner:贵州侗乡生态农业科技发展有限公司

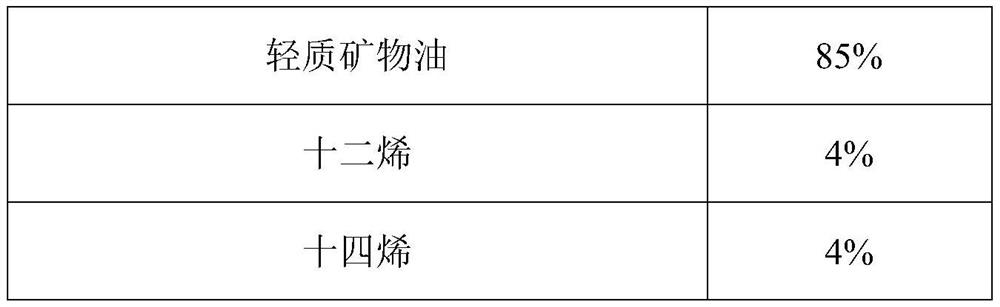

Aluminum foil and copper foil no-clean oily cutting fluid and preparation method thereof

The invention relates to an aluminum foil and copper foil no-clean oily cutting fluid and a preparation method thereof. The invention belongs to the field of lubricating oil for metal processing, and is suitable for cutting aluminum foils, copper foils, tabs and the like in lithium ion batteries, capacitors and other devices. The invention discloses a special no-clean oily cutting fluid for aluminum foils and copper foils, which uses light mineral oil as base oil and comprises long-chain olefin, alkanol, polyfatty acid ester and an antirust agent. According to the invention, the selected base oil is light mineral oil composed of isoparaffin containing side chains and produced by petroleum refining, and has the advantages of small viscosity, easy volatilization and good lubricity. A gas chromatography-mass spectrometry test verifies that the cutting fluid can be completely volatilized within 30 minutes at room temperature after being coated on an aluminum foil, and no residue is left, so that a cleaning process after the aluminum foil is cut is omitted, and the processing cost is greatly saved.

Owner:XI AN JIAOTONG UNIV +1

Carbon quantum dot-loaded nano material lubricating additive and preparation method thereof

The invention discloses a carbon quantum dot-loaded nano material lubricating additive and a preparation method thereof. The preparation method comprises the following steps: step 1, preparing antioxidant carbon quantum dots by utilizing one-step hydrothermal synthesis; 2, nickel hydroxide powder is prepared through a chemical precipitation method; and 3, ultrasonically stripping nickel hydroxide in an NMP (N-Methyl Pyrrolidone) solvent by using the carbon quantum dots as an auxiliary stripping agent to form the nickel hydroxide composite material loaded with the carbon quantum dots. According to the method, the carbon quantum dots are creatively used as a stripping aid, the layered nickel hydroxide material is ultrasonically stripped in the NMP solvent by controlling the temperature, and the stripping efficiency of the layered nickel hydroxide is improved, so that the dispersion performance of the layered nickel hydroxide in an oil product is greatly improved. A diphenylamine functional group grafted on the surface of the carbon quantum dot can be used as an antioxidant for slowing down oxidative cracking of an oil product, and meanwhile, the carbon quantum dot loaded nickel hydroxide composite material prepared after ultrasonic exfoliation can effectively improve the lubricating property of the oil product when being used as a lubricating oil additive due to the friction synergistic effect of carbon sphere particles and a layered material. The preparation method of the material is simple to operate, wide in raw material source, safe, pollution-free and easy for large-scale production.

Owner:SHANGHAI GREENSUN ENVIRONMENTAL PROTECTION TECH CO LTD +1

Method for preparing activated rubber crumb by catalysis and activation reaction

InactiveCN101381476BEasily brokenImprove dynamic performancePlastic recyclingPolymer sciencePlasticizer

The invention provides a method for preparing activated rubber powder by catalytic reaction and activating reaction, and relates to a method for comprehensive utilization of waste and scrap rubber. Compared with the production of regenerated rubber, the method reduces processes of desulfurizing, kneading and refining, thereby avoiding secondary pollution to the environment. The prepared activatedrubber powder has excellent compatibility with matrix rubber, and improves the physical and mechanical properties of the product. The formulation comprises the following compositions in weight portion: 100 portions of 30 to 40 meshes of waste rubber powder, 8 to 17 portions of plasticizer-dipentene, 5 to 8 portions of dusting agent-pottery clay, 0.2 to 0.5 portion of catalyst-cuprous chloride, 7 to 1.0 portion of promoting agent-polyalkylphenol disulfide, and 1 to 2.5 portions of dispersing agent-ethanol. The method comprises the following steps: placing the 30 to 40 meshes of waste rubber powder into a high-speed stirring reactor, and heating the waste rubber powder to the temperature of between 80 and 100 DEG C; adding the plasticizer, the dusting agent, the catalyst, the promoting agent and the dispersing agent into the reactor sequentially for reacting for 10 to 20 minutes at a temperature of between 80 and 120 DEG C, and cooling and discharging to produce the activated rubber powder. The prepared activated rubber powder can be used in rubber industry and building industry.

Owner:TIANJIN RUBBER IND RES INST

VN/Ni3P/Ni three-phase composite electrocatalyst as well as preparation method and application thereof

PendingCN114214660AProcess flow is simple and easyHigh reaction yieldMaterial nanotechnologyElectrodesOxideSodium phosphates

The invention discloses a VN / Ni3P / Ni three-phase composite electrocatalyst and a preparation method and application thereof.The preparation method adopts a hydrothermal method and subsequent heat treatment and comprises the steps that firstly, a nickel source, urea and ammonium fluoride are dissolved in water to obtain a uniform solution, then a hydrothermal reaction is conducted, after the reaction is finished and cooled, suction filtration and collection are conducted on a product, and cleaning and drying are conducted to obtain the VN / Ni3P / Ni three-phase composite electrocatalyst. A nickel-containing hydroxide precursor is obtained; and then weighing the nickel-containing hydroxide precursor, dicyandiamide, sodium hypophosphite and vanadium chloride, and carrying out high-temperature vacuum calcination reaction in an inert atmosphere to obtain the VN / Ni3P / Ni three-phase composite electrocatalyst. The obtained material has excellent electrical conductivity and chemical stability and has great development prospects as an electrocatalyst, and the whole technological process is simple, convenient and easy to control, high in reaction yield, low in cost, environmentally friendly, free of large-scale equipment and suitable for large-scale production.

Owner:SHAANXI UNIV OF SCI & TECH

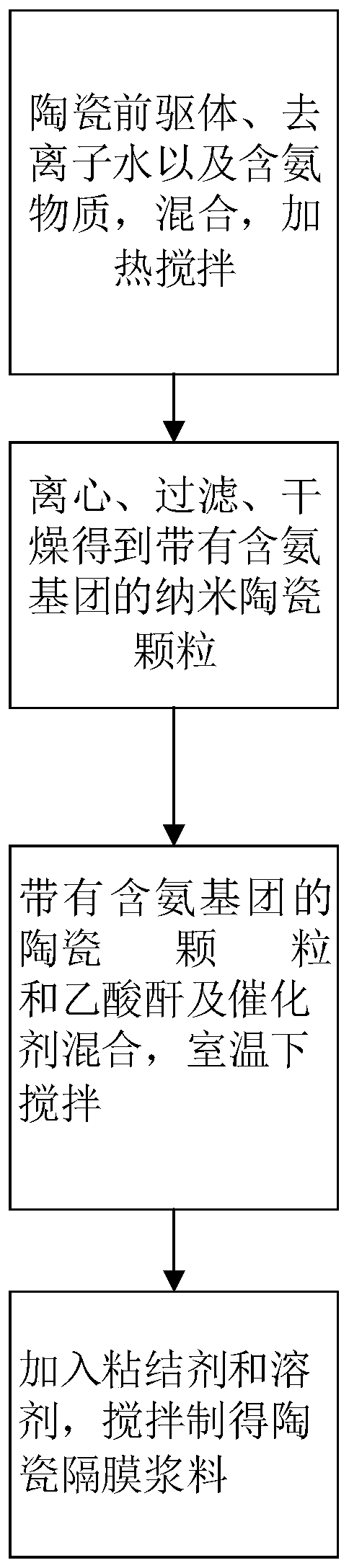

Modified nano ceramic particles, preparation method thereof, ceramic diaphragm slurry, preparation method thereof, diaphragm and lithium ion battery

ActiveCN111574230AHigh speedImprove liquid retention capacitySecondary cellsCell component detailsPtru catalystNanoceramic

The invention provides modified nano ceramic particles, a preparation method thereof, ceramic diaphragm slurry, a preparation method thereof, a diaphragm and a lithium ion battery. The modified nano ceramic particles contain polar groups; the polar groups comprise acetyls. The preparation method of the modified nano-ceramic particles comprises the following steps of: mixing nano-ceramic particleswith amino groups, an acetylating agent and a catalyst according to a formula ratio, and performing a reaction to obtain the modified nano-ceramic particles. The ceramic diaphragm slurry provided by the invention is non-toxic and harmless to the environment; and the diaphragm prepared by using the ceramic diaphragm slurry provided by the invention can greatly improve the cycle performance and ratecapability of a battery.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

Oxidation-resistant strong-acid-resistant organosilicon compound, and synthesis method and application thereof

The invention discloses an oxidation-resistant strong-acid-resistant organosilicon compound and a synthesis method and application thereof. The structural formula of the organosilicon compound is shown in the specification: -[Si(CH<3>)<2>-O-]<m>[Si(CH<3>)R-O-]<n>[Si(CH<3>)<2>-O-]<o>-, R is [-CH<2>]-(Ph)<q>SO<3>X, [-CH<2>]-(Ph)<q>PO<3>X,-(CH<2>)-naphthenic group-Ph-COOX or [-CH<2>]-(CO)<q>-CH<3>. According to the invention, polydimethylsiloxane containing silicon-hydrogen bonds is used as a grafting raw material, and acid-resistant and oxidation-resistant hydrophilic groups are grafted on the side chains of polydimethylsiloxane, so that the product achieves the purposes of acid resistance and oxidation resistance, has surface activity, and plays a role in effectively inhibitingacid mist dissipation. Moreover, the organosilicon compound disclosed by the invention belongs to an environment-friendly product, fluorine compounds are not used in synthesis raw materials of the organosilicon compound, forbidden perfluorooctylsulfonic acid compounds are not contained, and degradation products of the organosilicon compound do not contain fluorine elements or highly toxic perfluorooctylsulfonic acid surfactants, so that the organosilicon compound is safe and non-toxic.

Owner:GUANGZHOU HKS SURFACE TREATMENT CO LTD

Modified polyurethane coating and preparation method thereof

InactiveCN110776823AImprove performanceStrong temperature insulationPolyurea/polyurethane coatingsPolymer scienceThermal insulation

The invention belongs to the technical field of coatings, and particularly relates to a modified polyurethane coating and a preparation method thereof. The modified polyurethane coating comprises thefollowing raw materials: a polyester resin component, an amino resin component, an isocyanate component, a thermal insulation agent component and an auxiliary agent component, wherein the thermal insulation agent component is composed of organic sepiolite, styrene, butyl acrylate, deionized water and oleic acid. According to the invention, styrene and butyl acrylate monomers generate styrene-butylacrylate under the action of an initiator, and styrene and butyl acrylate enter the space between organic sepiolite layers, so the thermal insulation agent component is obtained; oleic acid is unsaturated fatty acid and is environmentally friendly and harmless, and the addition of oleic acid is beneficial for polymerization between the styrene and butyl acrylate monomers, enables the styrene andbutyl acrylate monomers to react under lower preset conditions and functions as a surfactant for the styrene and butyl acrylate monomers, thereby realizing more thorough polymerization of the styreneand butyl acrylate monomers; and due to the addition of the thermal insulation agent component, the original performance of the polyurethane coating is improved, and the polyurethane coating has relatively strong thermal insulation performance.

Owner:斯博锐精细化学品(广东)有限公司

Microparticle enhanced special high temperature wear-resisting brazing bar and manufacturing method thereof

InactiveCN109702370AHigh tensile strengthImprove wear resistanceWelding/cutting media/materialsSoldering mediaMicrometerMicroparticle

The invention provides a microparticle enhanced special high temperature wear-resisting brazing bar. The brazing bar comprises a microparticle enhanced hollow copper brazing filler metal inner core, Co-coated Cr2O3 composite particles filled into the microparticle enhanced hollow copper brazing filler metal inner core, and a copper brazing flux coating adhering to the outer surface of the microparticle enhanced hollow copper brazing filler metal inner core. The microparticle enhanced hollow copper brazing filler metal inner core comprises a metal phase and micrometer SiC particles. The metal phase is composed of metal elements including, by mass percent, 1.1-1.4% of Ag, 0.6-0.9% of Mn, 0.4-0.5% of La, 1.3-2.93% of Sn, 1.6-1.8% of Nd and the balance Cu. The invention further provides a method for manufacturing the microparticle enhanced special high temperature wear-resisting brazing bar. The microparticle enhanced special high temperature wear-resisting brazing bar can improve wear-resisting performance and tensile strength of the brazing layer.

Owner:HENAN ZHILIAN HUANYU INTPROP OPERATION CO LTD

Polyaniline/halloysite/barium ferrite electromagnetic composite material and preparation method thereof

The invention relates to a polyaniline / halloysite / barium ferrite electromagnetic composite material and a preparation method thereof. Purified halloysite is used as a carrier, barium ferrite nanoparticles are loaded on the surface of the halloysite, and polyaniline is used as a coating layer. Through two steps of halloysite purification treatment and preparation of an electromagnetic composite material coated with a polyaniline layer and taking halloysite as a matrix, the polyaniline / halloysite / barium ferrite nano electromagnetic composite material is prepared by adopting a one-step in-situ polymerization method. The organic conductive polymer polyaniline, barium ferrite and halloysite are organically compounded, the advantages of the three components can be maintained, the composite material has dielectric loss and magnetic loss, the halloysite is introduced as the carrier, and the prepared nano composite material with the core-shell structure has an interface effect and a quantum effect. The microwave absorbing performance of the material is greatly improved, the absorbing frequency band of the microwave material is widened, the absorbing efficiency is improved, and the defects that a single wave absorbing product is poor in wave absorbing performance and narrow in absorbing frequency are overcome.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

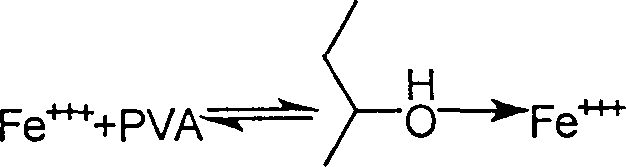

Fe3O4 magnetofluid and its preparation

InactiveCN1233419CImprove preparation efficiencyUniform particle size distributionInorganic non-active ingredientsAntineoplastic agentsPolyvinyl alcoholMacromolecule

The present invention relates to a kind of Fe that is used for targeting anticancer drug 3 o 4 A magnetic fluid and a preparation method thereof belong to the technical field of compounds and their preparation. The present invention adopts in-situ reduction coordination conversion method, first makes Fe 3+ It coordinates with polyvinyl alcohol to form a polymer-metal complex, and then uses a reducing agent, such as oxalic acid, to convert a part of the Fe in the coordination state 3+ reduced to Fe 2+ , and finally converted with alkali to directly obtain Fe 3 o 4 ferrofluid. Adopt the Fe prepared by the inventive method 3 o 4 Ferrofluid is based on Fe 3 o 4 It is a magnetic material, polyvinyl alcohol is used as a coating layer, and water is used as a carrier. The preparation process does not need to isolate oxygen, and the obtained Fe 3 o 4 Fe with very small particle size 3 o 4 Ferrofluid, and Fe 3 o 4 The particle size can be adjusted, and the ferrofluid can be directly obtained without adding surfactants and post-treatment procedures. In addition, the preparation method of the magnetic fluid has the characteristics of readily available and cheap raw materials, simple and easy method, and easy wide application.

Owner:SHANGHAI UNIV

Polybutadiene rubber modified waterborne polyurethane adhesive and preparation method thereof

ActiveCN103409101BIncrease elasticityImprove low temperature resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePolyurethane adhesive

The invention discloses a polybutadiene rubber modified waterborne polyurethane adhesive and a preparation method thereof, which belong to the field of waterborne polyurethane adhesives and are used for solving the problems that an existing polybutadiene rubber modified waterborne polyurethane adhesive is high in thermal activation temperature, low in solid content and poor in primary viscosity and peeling strength. In order to solve the problems, the adhesive disclosed by the invention comprises the following components in parts by weight: 75-100 parts of polybutadiene rubber modified waterborne polyurethane, 3-5 parts of white carbon black, 0.2-0.5 part of 3-amino propyl triethoxysilane, 0.15-0.3 part of waterborne thickening agent, 8-15 parts of plasticizer and 3-7 parts of waterborne curing agent. The invention further provides a preparation method of the polybutadiene rubber modified waterborne polyurethane adhesive. After the adhesive disclosed by the invention is adhered with a sample and impacted for 5 cycles at a high-low temperature between -65 DEG C and 120 DEG C, the peeling strength is reduced by not more than 5%, the elongation at break is as high as 380%-510%, and the tensile strength is as high as 2.8 MPa-4.2MPa.

Owner:CHANGCHUN SANHUA IND

An environmentally friendly phosphorus-free pretreatment solution suitable for water-based paints and its preparation and application

ActiveCN109385213BGood film formingImprove corrosion resistanceAnti-corrosive paintsLacquerHazardous substance

The invention relates to an environmentally friendly phosphorus-free pretreatment solution suitable for water-based paints and its preparation and application. The treatment solution is prepared from the following components and raw materials in mass percentage: modified water-based resin grafted with nano-cellulose 16-25%, compound complexing agent 0.8-1.8%, corrosion inhibitor 0.1-0.3%, sodium nitrate 0.4-0.6%, and the balance is deionized water. Compared with the prior art, the preparation of the pretreatment solution of the present invention is simple, and the substances used do not contain harmful substances such as phosphorus and chromium, and the environmental protection and economy are good, the film forming stability is good, and the bonding force with the water-based paint film is strong. And it has excellent corrosion protection performance, can effectively solve the technical problems such as poor film-forming property and poor bonding force with water-based paint film existing in the existing pretreatment liquid, and has a good application prospect.

Owner:金华市鸿新新材料科技有限公司

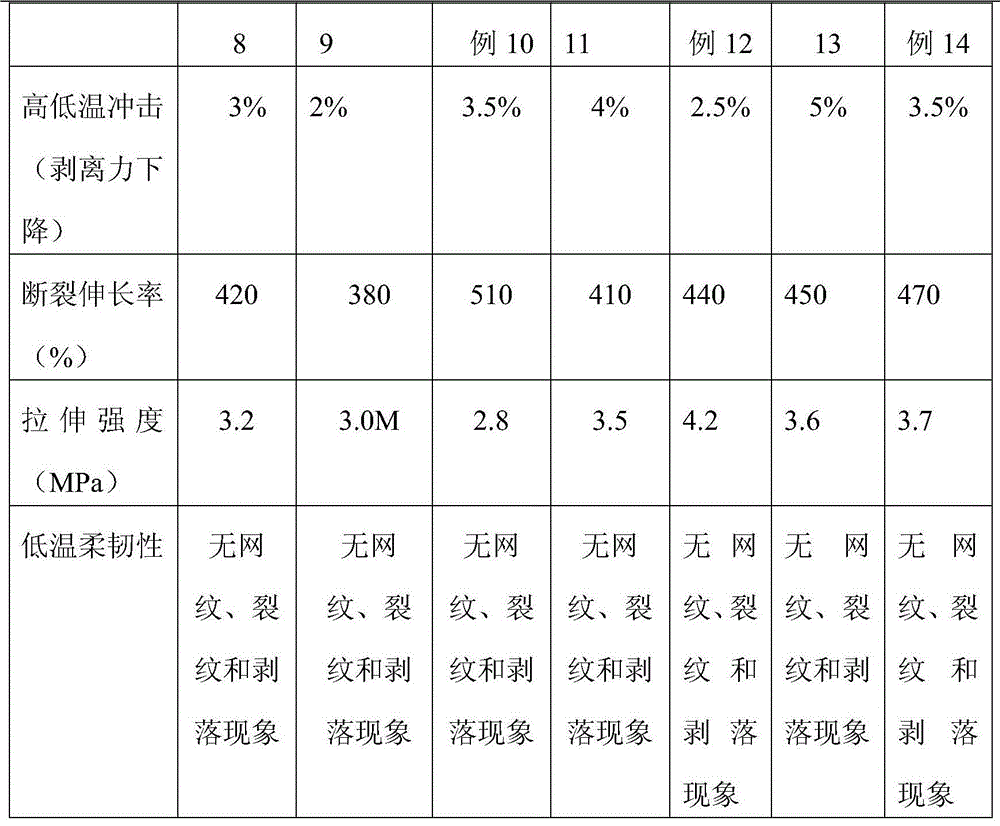

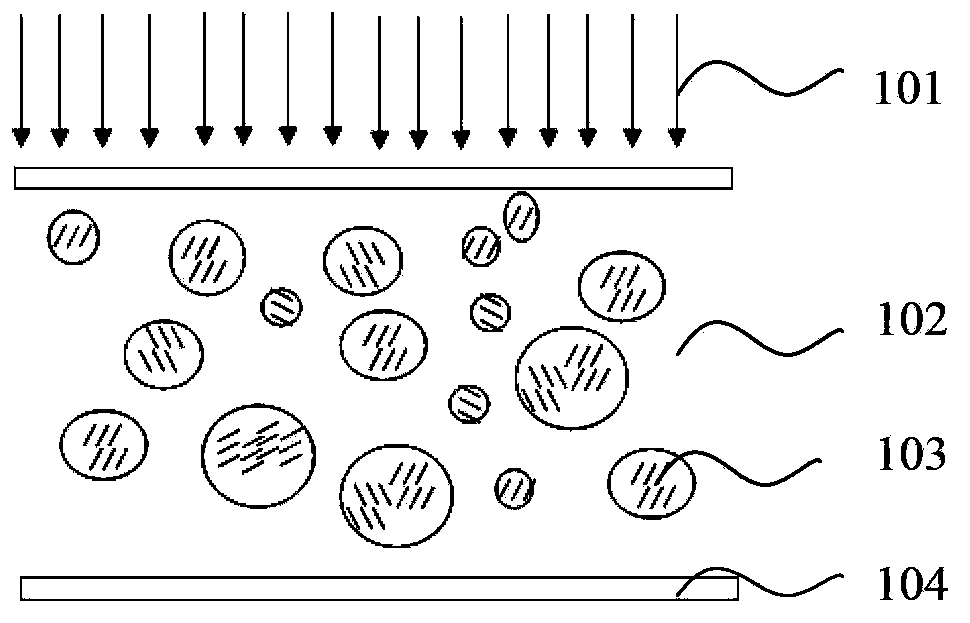

Polymer-dispersed liquid crystal as well as preparation method and application

InactiveCN103013534BHigh transparencySmall sizeLiquid crystal compositionsNon-linear opticsCrystallographyLiquid-crystal display

The invention relates to the technical field of liquid crystal display and discloses a polymer-dispersed liquid crystal as well as a preparation method and application thereof. The polymer-dispersed liquid crystal comprises liquid crystal and polyacrylate and further comprises sodium polyacrylate. The preparation method of the polymer-dispersed liquid crystal comprises the following steps: preferentially taking distilled water, sodium polyacrylate and a mixed solution at the weight ratio of 40:10:50, wherein the weight ratio of the liquid crystal and the acrylate in the mixed solution is 60:40; mixing the distilled water, the sodium polyacrylate and the mixed solution; and irradiating the mixture with ultraviolet light to solidify to form the polymer-dispersed liquid crystal. The invention also relates to the application of the polymer-dispersed liquid crystal to a liquid crystal display. The preparation method of the polymer-dispersed liquid crystal is easy to operate, the adopted raw materials are easily available, the preparation process is simple, and the prepared polymer-dispersed liquid crystal has high contrast.

Owner:BOE TECH GRP CO LTD

A kind of preparation method and application of medicinal compound plant fatty acid calcium

ActiveCN111646891BEasy extractionGood for healthMetabolism disorderOrganic compound preparationBiotechnologyCalcium biphosphate

The invention discloses a preparation method and an application of medicinal composite plant fatty acid calcium, and belongs to the technical field of biological medicine preparation. The medicinal composite plant fatty acid calcium comprises the following raw materials: linseed oil, mulberry oil, coconut oil, citric acid, water-soluble starch and micron-sized hydroxyl calcium phosphate, and is formed through steps of saponification, filtration, concentration, acidification and calcification. By adopting the method disclosed by the invention, the content and the yield of the polyunsaturated fatty acid are obviously improved. The composite plant fatty acid calcium prepared by the invention can be applied to pharmaceutical adjuvants or auxiliary materials or pharmaceutical products for supplementing calcium for old people.

Owner:BELIKE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com