Modified nano ceramic particles, preparation method thereof, ceramic diaphragm slurry, preparation method thereof, diaphragm and lithium ion battery

A technology of nano-ceramic particles and ceramic separators, applied in secondary batteries, battery pack parts, circuits, etc., to achieve the effects of improved cycle performance and rate performance, good air permeability, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

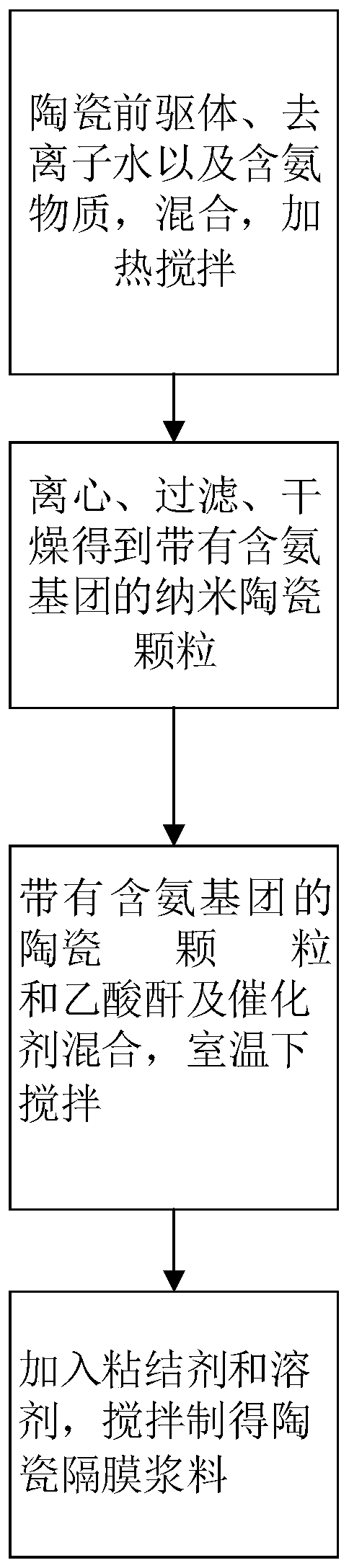

[0075] In this example, modified nano-ceramic particles and ceramic diaphragm slurry were prepared according to the following method:

[0076] (1) Mix the ceramic precursor (tetraethyl orthosilicate TEOS), water, and ammonia-containing substance (glucosamine) in the prescribed amount, and react at a temperature of 60°C under stirring conditions for a reaction time of 8 hours, centrifuge, filter, Dry to obtain nano-ceramic particles with amino groups;

[0077] In this step, by weight:

[0078] Ceramic precursor 5 parts

[0079] 120 parts of water

[0080] Ammonia-containing substance 55 parts.

[0081] (2) Mix the amount of nano-ceramic particles with amino groups, acetylating agent (acetic anhydride) and catalyst (pyridine), and react at a temperature of 20°C under stirring conditions for 12 hours to obtain The modified nano-ceramic particles of the polar group are mixed with the binder (water-based epoxy resin) and solvent (water) in the formula to obtain the ceramic diap...

Embodiment 2

[0088] In this example, modified nano-ceramic particles and ceramic diaphragm slurry were prepared according to the following method:

[0089] (1) Mix the ceramic precursor (titanium tetrachloride), water, and ammonia-containing substance (N-acetylglucosamine) in the prescribed amount, and react at a temperature of 40°C under stirring conditions. The reaction time is 12h, centrifuged, Filter and dry to obtain nano-ceramic particles with amino groups;

[0090] In this step, by weight:

[0091] Ceramic precursor 1 part

[0092] 40 parts of water

[0093] Ammonia-containing substance 1 part.

[0094] (2) Mix the nano-ceramic particles with amino groups, the acetylating agent (acetyl chloride) and the catalyst (perchloric acid) in the formulation amount, and react at a temperature of 15° C. under stirring conditions for a reaction time of 14 hours to obtain The modified nano-ceramic particles containing polar groups are mixed with the binder (nitrile-polyvinyl chloride blend) ...

Embodiment 3

[0100] In this example, modified nano-ceramic particles and ceramic diaphragm slurry were prepared according to the following method:

[0101] (1) Mix the ceramic precursor (3-aminopropyltriethoxysilane APTES), water, and ammonia-containing substance (2-amino-2-deoxysugar) in the formula amount, and mix them at a temperature of 80°C under stirring conditions. Carry out the reaction, the reaction time is 4h, centrifuge, filter, and dry to obtain nano-ceramic particles with amino groups;

[0102] In this step, by weight:

[0103] Ceramic precursor 10 parts

[0104] 200 parts of water

[0105] Ammonia-containing substance 100 parts.

[0106] (2) Mix the nano-ceramic particles with amino groups, the acetylating agent (acetic anhydride) and the catalyst (sodium acetate) in the formula amount, and react at a temperature of 35° C. under stirring conditions, and the reaction time is 10 hours to obtain The modified nano-ceramic particles of the polar group are mixed with a formulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com