Fe3O4 magnetofluid and its preparation

A magnetic fluid and aqueous solution technology, which is applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, inorganic non-effective ingredients, etc., can solve the problems of continuous particle size change, difficulty in controlling particle size, wide particle size distribution, etc. , to achieve the effect of easy industrial application, simple method and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

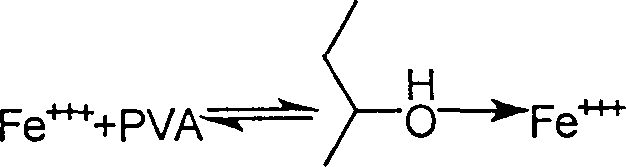

Method used

Image

Examples

Embodiment 1

[0025] Embodiment one: the FeCl of 5L 2.35mol / L 3 The aqueous solution was mixed with 128L weight concentration of 2% polyvinyl alcohol aqueous solution, and stirred for 2 hours at a temperature of 80°C to make the Fe 3+ Coordinate with polyvinyl alcohol to obtain a polymer metal complex; then add 4L of 0.5mol / L oxalic acid aqueous solution to the above polymer metal complex at room temperature, stir evenly, and leave it open at room temperature for 3 days , the resulting Fe 3+ and Fe 2+ The aqueous solution of polyvinyl alcohol; then heat the aqueous solution to 60 ° C, and add 22L of 2mol / L NaOH aqueous solution under stirring, and continue to stir for 15 minutes, and then centrifuge to remove large particles of Fe 3 o 4 After the precipitate, black Fe was obtained 3 o 4 ferrofluid. The Fe 3 o 4 The particle size of the magnetic fluid is: 1.22nm.

Embodiment 2

[0026] Embodiment two: the processing step of the present embodiment is identical with embodiment one, and difference is that the add-on of 2% polyvinyl alcohol aqueous solution is 32L, and the black Fe that obtains 3 o 4 ferrofluid. The Fe 3 o 4 The particle size of the magnetic fluid is: 1.31nm. After sedimentation, drying and grinding of the magnetic fluid, the molar magnetic susceptibility of the obtained powder was measured with a Gouy magnetic balance to be 7.35×10 -3 / mol.

Embodiment 3

[0027] Embodiment three: the process step of this embodiment is the same as embodiment one, the difference is that the FeCl of 5L 2.35mol / L 3 The aqueous solution was mixed with 32L weight concentration of 2% polyvinyl alcohol aqueous solution, and stirred at 80°C for 1 hour to make Fe 3+ Coordination with polyvinyl alcohol; the resulting black Fe 3 o 4 ferrofluid. After the magnetic fluid is precipitated, dried, and ground, the molar magnetic susceptibility of the obtained powder is measured with a Gouy magnetic balance to be 20×10 -3 / mol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com