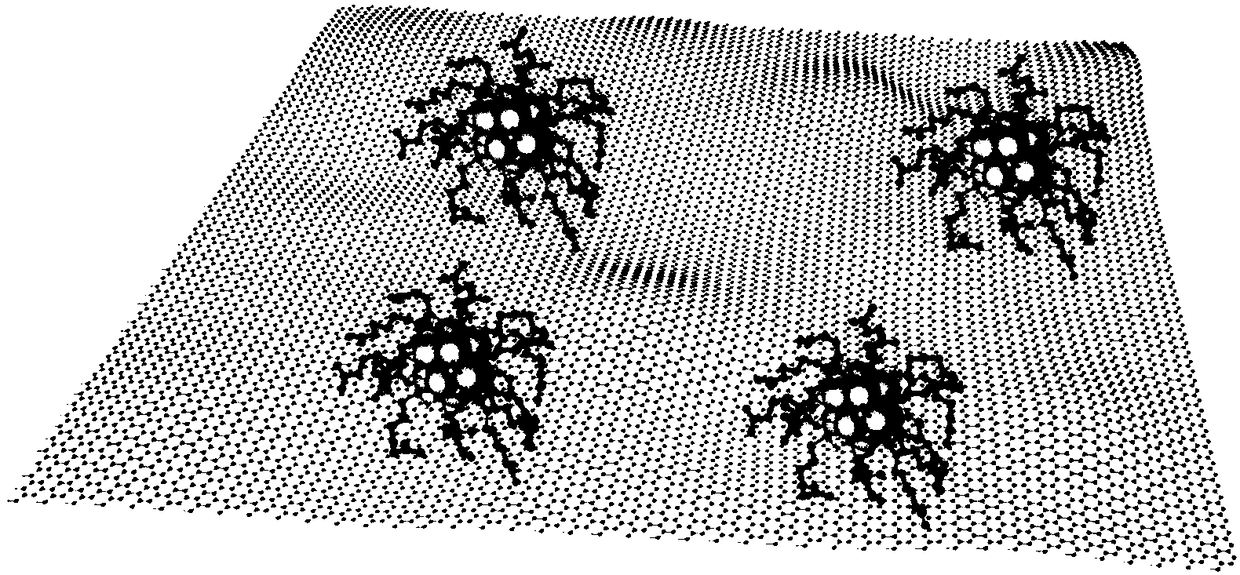

Gold cluster/graphene compound catalytic membrane preparation method

A graphene composite, gold cluster technology, applied in the field of catalytic membrane, can solve the problem of difficult recovery of gold clusters, and achieve the effect of high catalytic activity, large loading, and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 50mg of graphene oxide into a beaker with an analytical balance, add 25mL of deionized water and use a probe to ultrasonically disperse it for 15 minutes to obtain a mixed solution A. Pour A into a polytetrafluoroethylene reactor at 180°C. After heating for 5 hours, the obtained rGO was in the form of rods. After freeze-drying, 5 mg of rGO was added to 10 mL of thiol ligand-protected gold cluster solution (1 mM) and 10 mL of ultrapure water. After ultrasonication for 45 min, a uniformly dispersed mixture B was obtained. After the membrane was washed with 150mL deionized water to form a homogeneous composite catalytic membrane. Use 0.2mM p-nitrophenol (4-NP) solution to pass through the membrane at a flow rate of 1mL / min for 2h to reach adsorption saturation, and then degrade 0.5mM, 1.0mM, and 1.5mM p-nitrophenol (4-NP) in turn. Solution, degradation effect are 100%, 100%, 100% respectively.

Embodiment 2

[0028] Weigh 50mg of graphene oxide into a beaker with an analytical balance, add 25mL of deionized water and use a probe to ultrasonically disperse it for 15 minutes to obtain a mixed solution A. Pour A into a polytetrafluoroethylene reactor at 180°C. After heating for 5 hours, the obtained rGO was in the form of rods. After freeze-drying, take 5 mg of rGO, add 5 mL of thiol ligand-protected gold cluster solution (1 mM) and 15 mL of ultrapure water, and obtain a uniformly dispersed mixture B after ultrasonication for 45 min. After the membrane was washed with 150mL deionized water to form a homogeneous composite catalytic membrane. Use 0.2mM p-nitrophenol (4-NP) solution to pass through the membrane at a flow rate of 1mL / min for 2h to reach adsorption saturation, and then degrade 0.5mM, 1.0mM, and 1.5mM 4-NP solutions in turn, and the degradation effects are respectively 100%, 96.1%, 62.1%.

Embodiment 3

[0030] Weigh 50mg of graphene oxide into a beaker with an analytical balance, add 25mL of deionized water and use a probe to ultrasonically disperse it for 15 minutes to obtain a mixed solution A. Pour A into a polytetrafluoroethylene reactor at 180°C. After heating for 5 hours, the obtained rGO was in the form of a rod. After freeze-drying, take 5 mg of rGO and add 20 mL of thiol ligand-protected gold cluster solution (1 mM). After ultrasonication for 45 min, a uniformly dispersed mixture B was obtained. After pumping B, use 150 mL to remove A homogeneous composite catalytic membrane is formed after washing excess substances with ion water. Use 0.2mM p-nitrophenol (4-NP) solution to pass through the membrane at a flow rate of 1mL / min for 2h to reach adsorption saturation, and then degrade 0.5mM, 1.0mM, and 1.5mM 4-NP in sequence, and the degradation effects are 100 %, 100%, 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com