Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

570results about How to "Improve flex resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

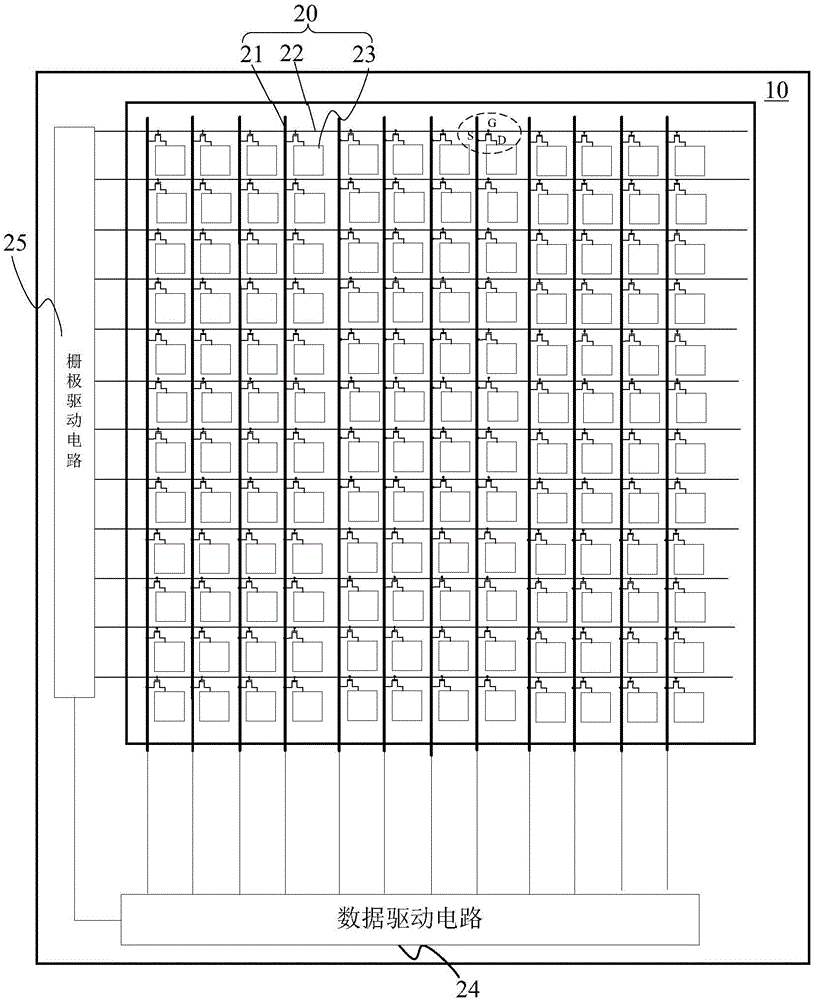

Flat panel display and method for manufacturing the same

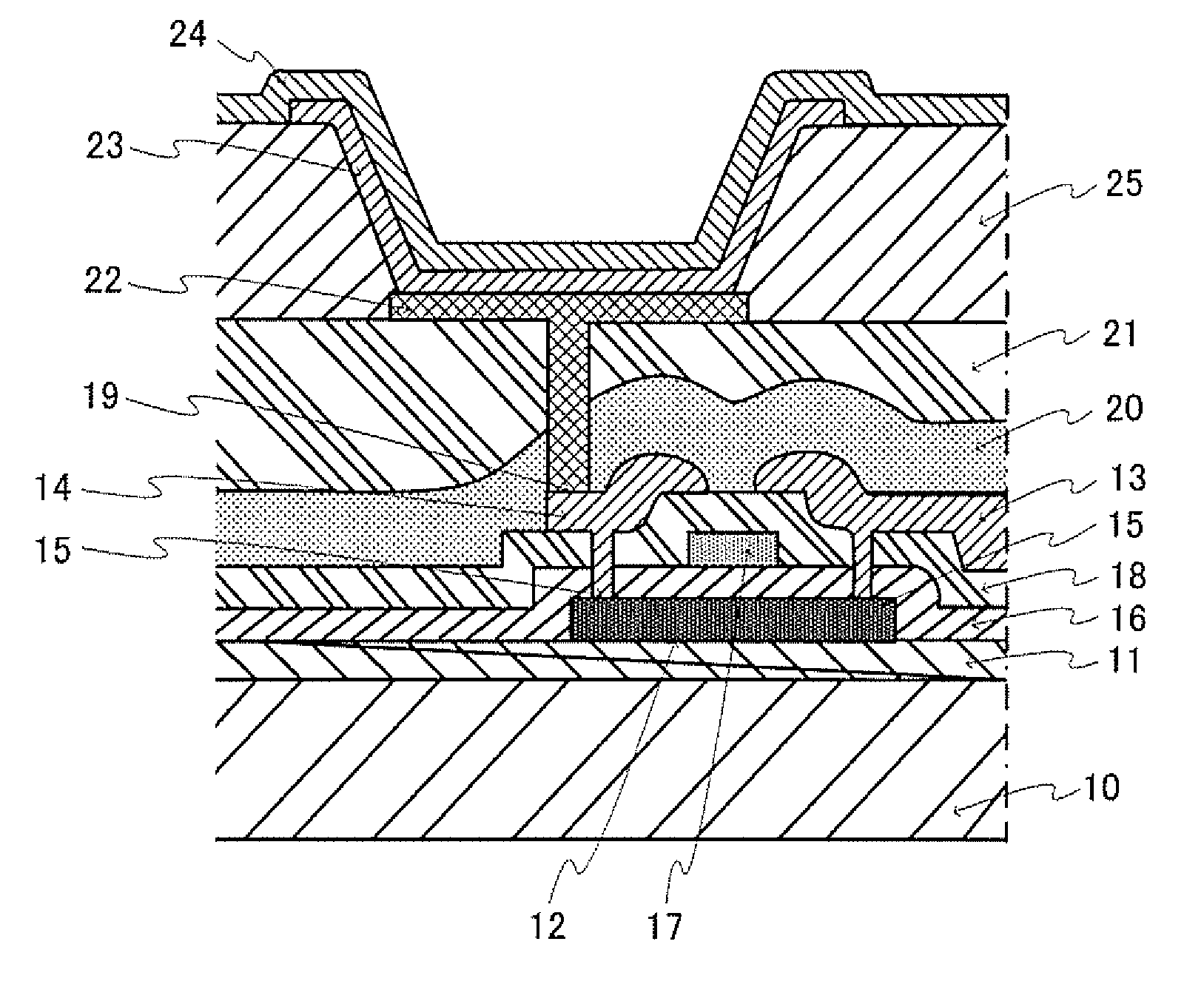

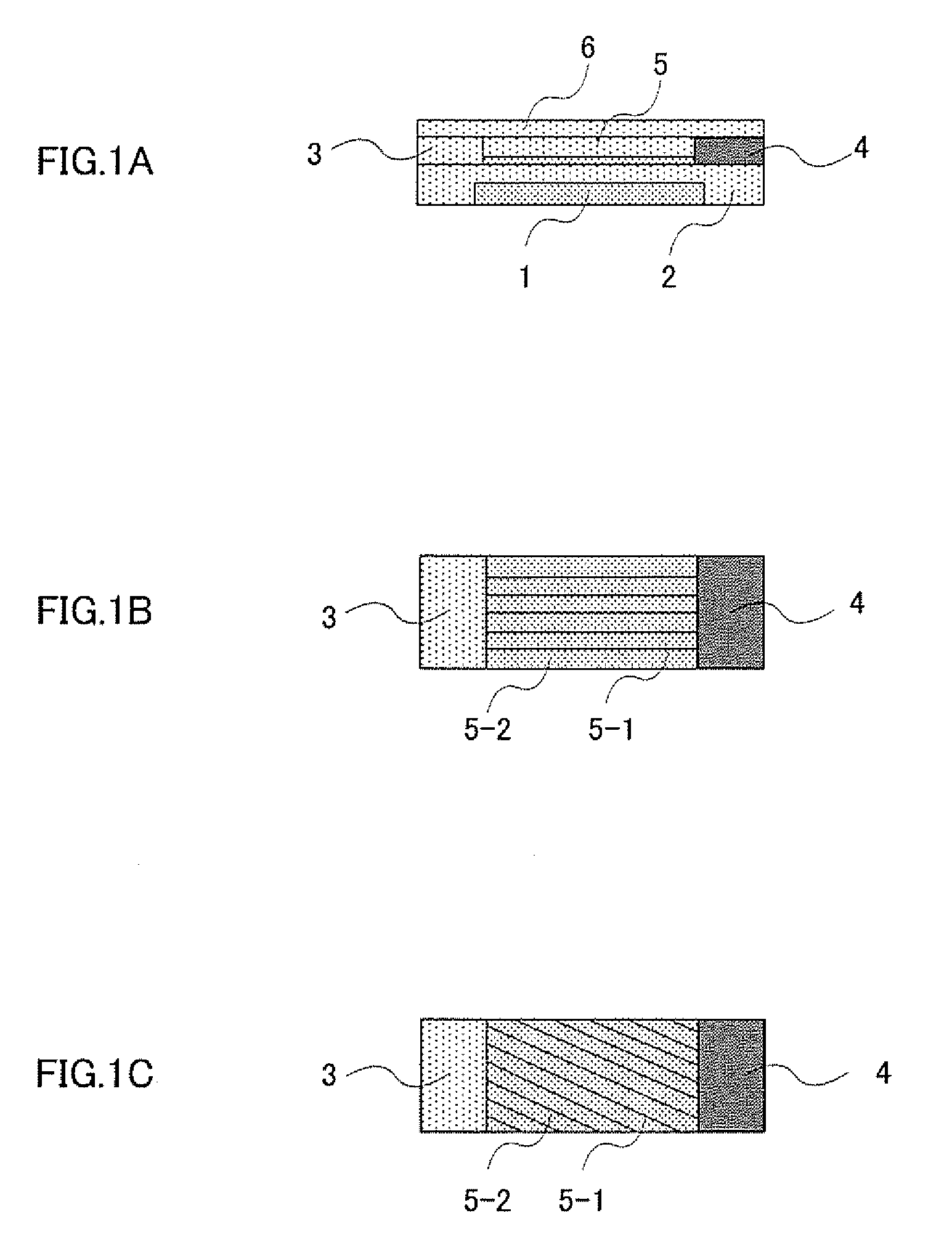

InactiveUS20070069212A1Improve picture qualityIncrease flexibilityNanoinformaticsSolid-state devicesNanowireDisplay device

The present invention relates to a flat panel display having high picture quality, high flexibility and high flex-resistance. Specifically, the present invention provides a flat panel display having a plurality of pixels arranged in a matrix shape on a substrate, each of the plurality of pixels comprising a thin film transistor having a channel region containing nanowire, nanorod, nanoribbon, or nanotube, and a display element driven by the thin film transistor. Here, an axial direction of the nanowire, nanorod, nanoribbon, or nanotube is in the same direction as the source-drain direction of a channel region and the flat panel display can be bent so as to intersect with the source-drain direction.

Owner:PANASONIC CORP

TPU clad net

InactiveCN101225610AExcellent physical mechanism performanceGood mechanical strengthLaminationLamination apparatusCold tolerancePolyester

The invention provides a TPU mesh fabric, which is made by coating a special PU adhesive to a high-strength polyester fiber and then combining with a TPU film. The PU coating steps are: PU-coat arrow dry arrow cool the high-strength polyester fiber; the coating quantity is 180-200g / m2; the coating speed is 20-25m / min; the drying temperature is 110-130 DEG C; the two layers of TPU film (underlayer, face layer) are preheated and fused through the adjustment and change of the heating drum temperature, and then are rolled, cooled and formed with the high-strength polyester mesh fabric after middle-layer preheating through rubber roller and iron roll. The TPU mesh fabric has the advantages of environmental protection, innocuity, high strength, abrasion resistance, high cold tolerance, good color stability, good heat resistance and best PVC-replacing material.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

Preparation method of acrylate modified water-borne polyurethane emulsion for synthetic leather

The invention discloses a preparation method of acrylate modified water-borne polyurethane emulsion for synthetic leather. The preparation method comprises the following steps of: 1) preparing water-borne acrylate emulsion; 2) preparing water-borne polyurethane emulsion; and 3) physically blending the water-borne acrylate emulsion obtained in the step 1) and the water-borne polyurethane emulsion obtained in the step 2) to obtain the acrylate modified water-borne polyurethane emulsion for synthetic leather. The preparation method disclosed by the invention has the advantages that: by introducing a natural reproducible polyhydric alcohol compound namely castor oil, the water resistance of the water-borne polyurethane material can be improved, and good flexibility, cold resistance and warping strength of the coating are obtained at the same time; meanwhile, by adding a silane coupling agent, good air permeability and flexibility of the material can be obtained, and the water-borne polyurethane emulsion can be spread on the surface of a base material (particularly a non-polar base material) better so as to improve the adhesive force and water repellency; and moreover, by modifying with the thermoplastic material namely water-borne acrylate, the embossing stability of the water-borne polyurethane leather can be improved.

Owner:福建宝利特新材料科技有限公司 +1

Double-component organic silicon polyurethane elastomer and preparation method thereof

The invention discloses a double-component organic silicon polyurethane elastomer. The double-component organic silicon polyurethane elastomer consists of a component A and a component B, wherein the mass ratio of isothiocyano in the component A to hydroxyl in the component B is 1:(1.05-1.2); the component A is prepared by reacting the following raw materials in part by mass: 10 to 30 parts of polyisocyanate, 30 to 80 parts of polyalcohol, 0.1 to 10 parts of active hydrogen-containing siloxane and 0 to 10 parts of plasticizing agent; and the component B consists of the following raw materialsin part by mass: 10 to 50 parts of polyalcohol, 1 to 10 parts of reinforcing agent, 20 to 60 parts of inorganic filler, 3 to 10 parts of pigment, 0.1 to 10 parts of aid and 5 to 20 parts of plasticizing agent. The double-component organic silicon polyurethane elastomer has high elasticity, hardness, solvent resistance, wear resistance, flexure resistance, high and low temperature resistance, ultraviolet resistance and oxidative degradation resistance, low surface energy and high hydrophobicity, and can meet the long-term using requirement of the sport field.

Owner:GUANGDONG BOSHENG NEW MATERIAL TECH CO LTD

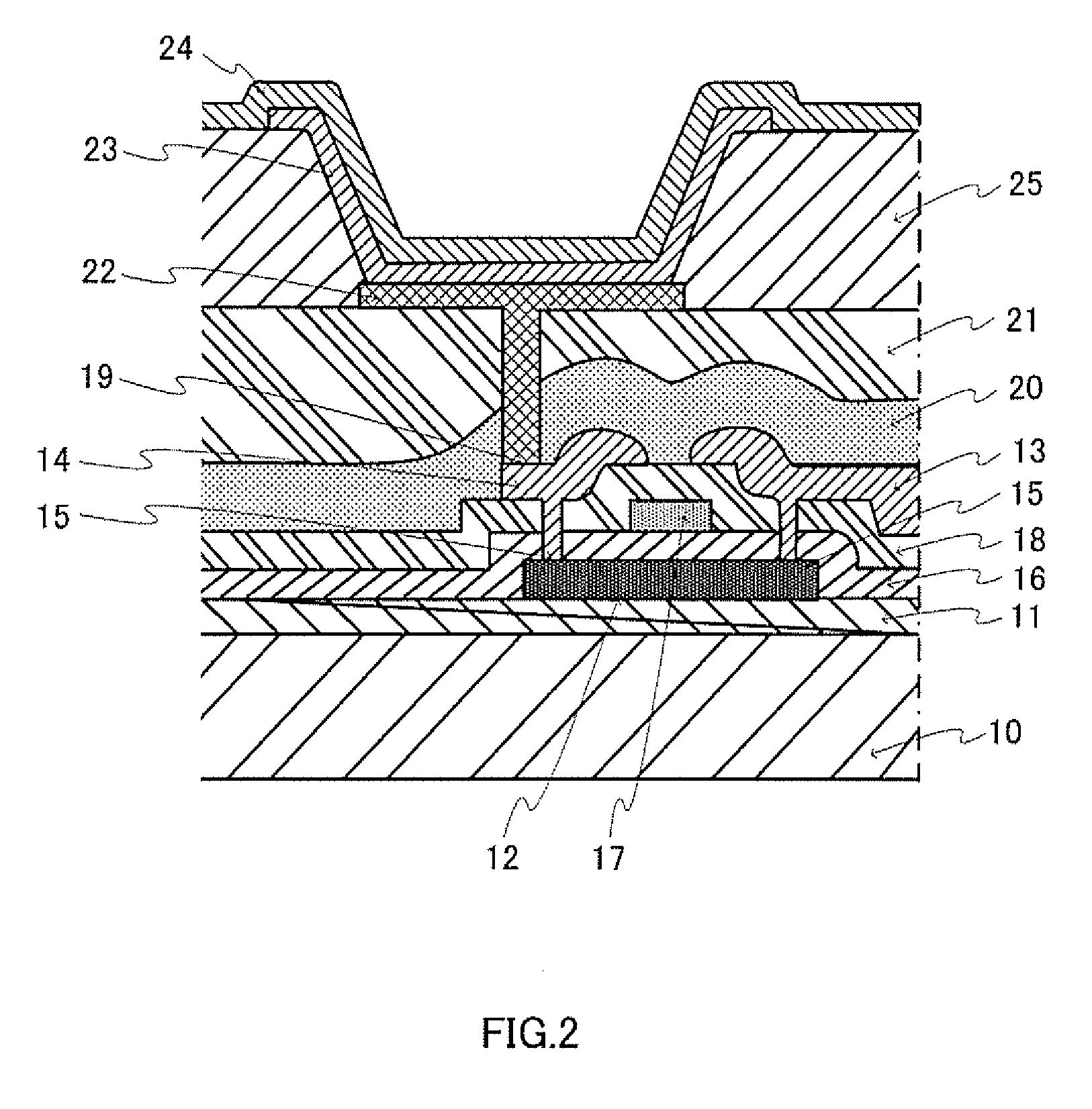

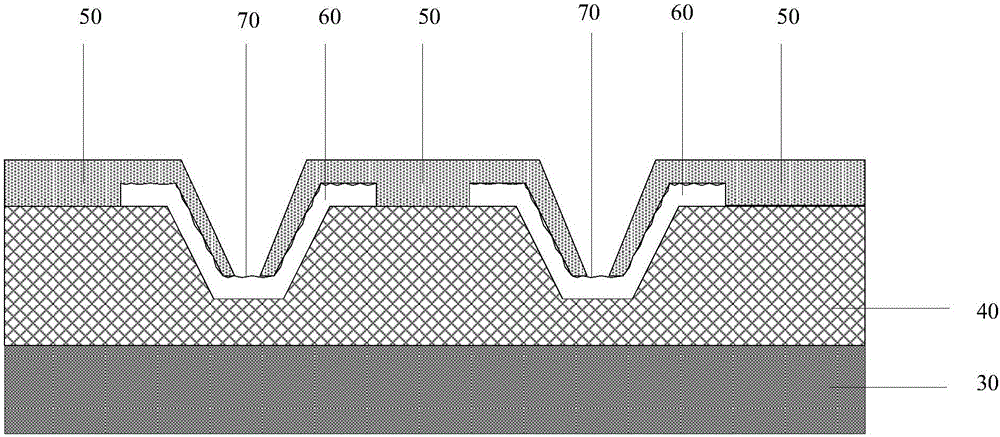

OLED display panel, display device, and array substrate and manufacturing method thereof

ActiveCN106449657AImprove flex resistanceImprove utilization efficiencySolid-state devicesSemiconductor/solid-state device manufacturingRough surfaceDisplay device

The application discloses an OLED display panel, a display device, and an array substrate and a manufacturing method thereof. The array substrate comprises a first substrate, a pixel drive film layer, a flat layer, a first pixel definition layer, a reflective layer, an anode layer and a second pixel definition layer. The first pixel definition layer is provided with a plurality of pixel grooves. The reflective layer is arranged on the surface of the first pixel definition layer and covers the pixel grooves completely, thereby improving the utilization efficiency of emergent light of a display sub pixel. Besides, a rough surface is formed on one side, far away from the first substrate, of the reflective layer and thus incident ambient light does not pass through the reflective layer to form mirror reflection, so that a glaring phenomenon is avoided and a problem of absorption of emergent light of a display sub pixel because of utilization of a linear polarizing film for avoidance of the glaring phenomenon can be solved. Therefore, the luminous efficiency of the display sub pixel of the OLED display panel using the array substrate is improved; and the anti-flexure performance of the OLED display panel is enhanced.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

Polyurethane retanning filler

InactiveCN103030769APromote environmental protectionImprove hydrophobicityTanning treatmentPolymer scienceEmulsion

The invention relates to a polyurethane retanning filler. The preparation method of the polyurethane retanning filler comprises the following steps: preparing a prepolymer from raw materials IPDI (isophorone diisocyanate), PEG (polyethylene glycol), castor oil and DMBA (dimethylbenzanthracene); adding triethylamine to carry out neutralization reaction to generate salt; and adding an ethylenediamine water solution to carry out emulsification and chain extension to prepare the water-based polyurethane emulsion. The coated film of the water-based polyurethane emulsion has favorable water resistance and yellowing resistance.

Owner:QINGDAO WINCHANCE TECH

Self-lubricating high-wear resistance oil seal and production method thereof

InactiveCN102061046AImprove wear resistanceReduce coefficient of frictionEngine sealsDomestic articlesPhysical agingWeather resistance

The invention provides a self-lubricating high-wear resistance oil seal and a production method thereof. The self-lubricating high-wear resistance oil seal is characterized by being prepared from 60-80 parts by weight of fluorous rubber, 20-40 parts by weight of polytetrafluoroethylene, 1.5-2.5 parts by weight of p-phenylenediamine aging resister, 1.5-2.5 parts by weight of dihyaroquinoline aging resister, 3-6 parts by weight of physical aging resister, 5-10 parts by weight of plasticizing agent, 35-48 parts by weight of strengthening agent, 2-6 parts by weight of slipping agent, 2-4 parts of dispersion agent, 1.5-2.5 parts by weight of vulcanizing agent, 5-8 parts by weight of activating agent, 1-2 parts by weight of stearic acid and 1.6-2.0 parts by weight of accelerating agent. The self-lubricating high-wear resistance oil seal obtained by the invention can be adapted to the high speed of an engine and a crankshaft, has the advantages of high wear resistance, small friction coefficient, high-low temperature resistance, weather resistance, favorable heat resistance and long service life and ensures that the oil seal does not leak oil when an automobile is driven for at least 0.3 million kilometer.

Owner:SHANGHAI ZHONGLI AUTO PARTS

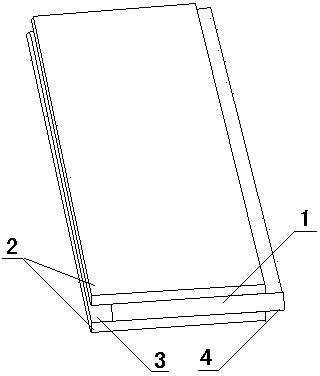

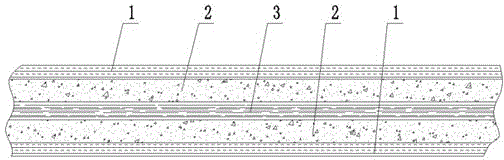

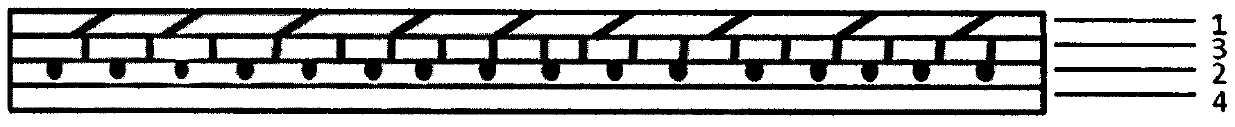

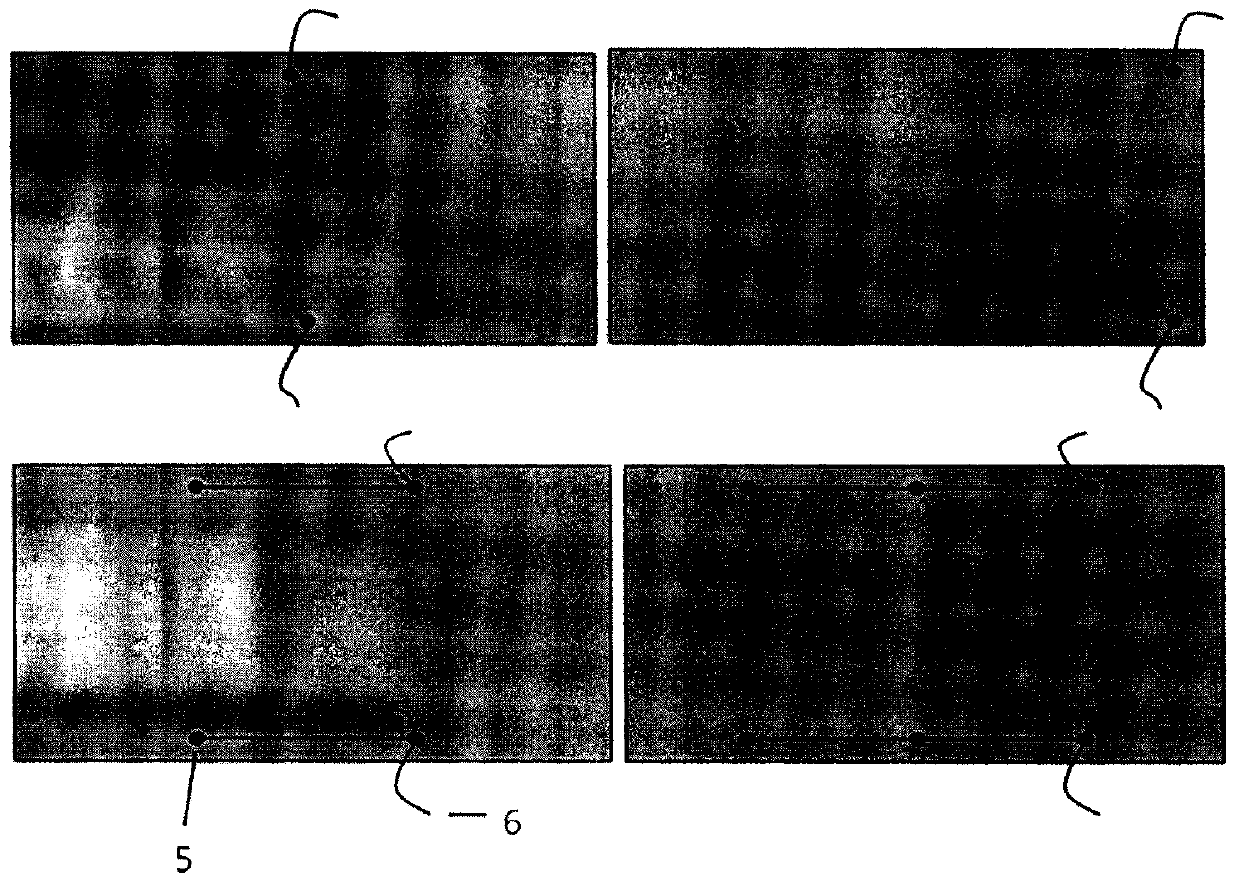

Composite engaging-type thermal-insulation wall plate composed of rigid polyurethane foam and reinforced foamed concrete

InactiveCN104110093AImprove stress resistanceImprove impact resistanceBuilding componentsCompressive resistanceFoam concrete

The invention relates to a composite engaging-type thermal-insulation wall plate composed of rigid polyurethane foam and reinforced foamed concrete. The wall plate includes a rigid polyurethane foam plate (1) and reinforced foamed concrete plates (2). The wall plate is characterized in that the rigid polyurethane foam plate (1) is employed as a middle layer of the thermal-insulation wall plate. Both the two sides of the rigid polyurethane foam plate (1) are provided with the reinforced foamed concrete plates (2). The rigid polyurethane foam plate (1) and the reinforced foamed concrete plates (2) on the two sides of the rigid polyurethane foam plate (1) are integrated completely. An engaging opening (3) is disposed at one side of the wall plate and an engaging tenon (4) is arranged at an opposite side of the wall plate to form the composite thermal-insulation wall plate. A rebar grid (5) is disposed inside each reinforced foamed concrete plate. Two surfaces of each reinforced foamed concrete plate are provided with fiber grids (6). According to the invention, a compressive resistance of the thermal-insulation wall plate is increased; a weight of a building wall is reduced by 50-70%; a shock resistance of the building wall is enhanced; and mechanized assembly in a construction site is achieved.

Owner:山东鲁盾保温材料有限公司

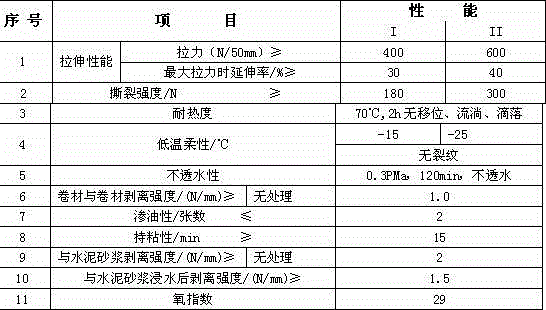

Graphene-modified conductive silver paste and preparation method thereof

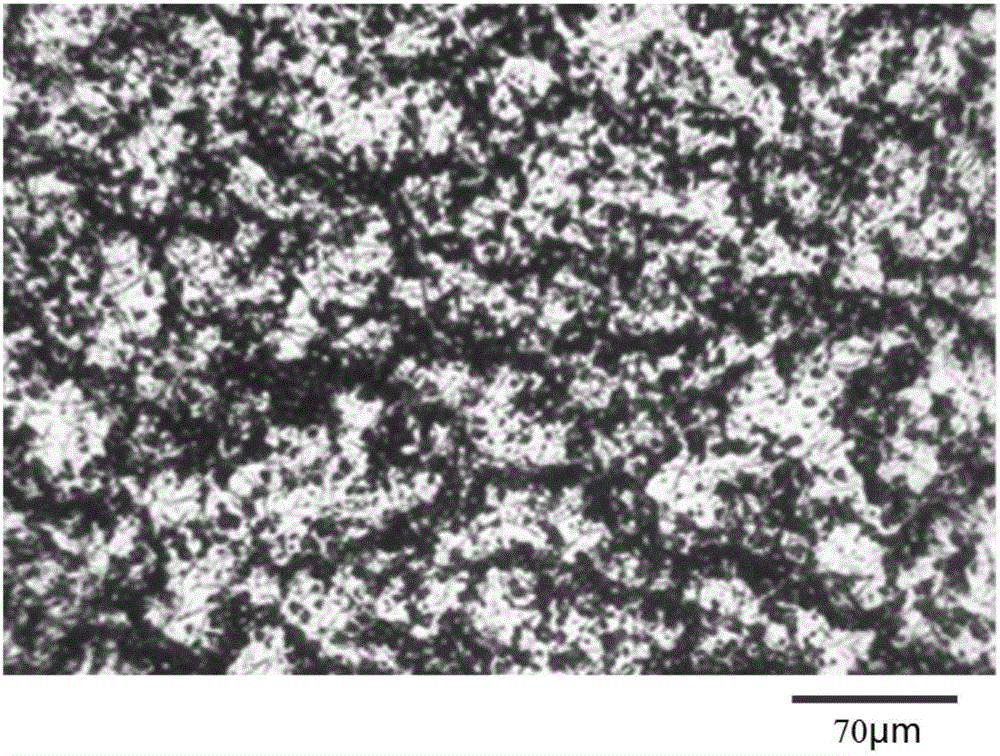

ActiveCN106816202AGood dispersionPrevent oxidationNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteSolvent

The invention provides a graphene-modified conductive silver paste and a preparation method thereof. The graphene-modified conductive silver paste mainly comprises silver nanowires, graphene materials, a binder and a solvent. The graphene materials comprise one or a combination of at least two materials selected from graphene, a graphene nanosheet, biomass graphene or graphene oxide. According to the technical scheme of the invention, the silver nanowires and the graphene materials are adopted together as an electrically conductive agent, and the silver nanowires are filled into gaps among graphene material sheet layers. Therefore, the graphene material sheet layers are connected in series through the silver nanowires, and the above two parts play a synergistic effect to realize the conductive performance. Meanwhile, the graphene materials are covered on the surfaces of the silver nanowires, so that the oxidation of the silver nanowires is avoided. The system stability and the stable exertion of the conductive performance are better ensured. Moreover, by means of the binder and other components, the adhesive force of the system is improved obviously. The printability of the conductive silver paste is improved.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

High-wearability insulating cable material and preparation method thereof

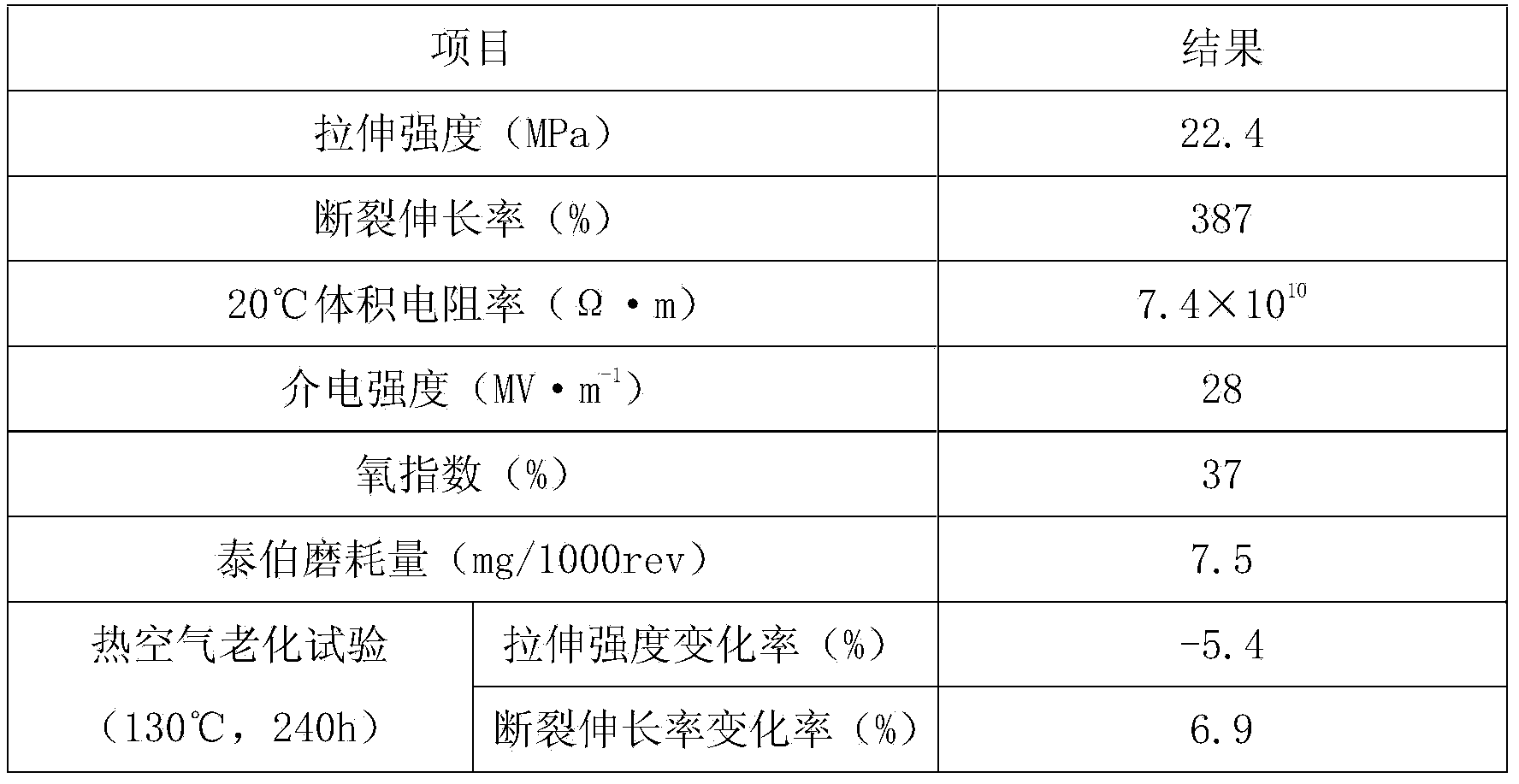

InactiveCN103881359AExcellent wear resistanceGood heat resistancePlastic/resin/waxes insulatorsDiamineChemistry

The invention discloses a high-wearability insulating cable material and a preparation method thereof. The high-wearability insulating cable material is prepared from the following raw materials in parts by weight: 70 to 90 parts of polyurethane rubber, 15 to 20 parts of polytetrafluoroethylene, 10 to 15 parts of nylon 6, 10 to 15 parts of polypropylene glycol adipate, 5 to 10 parts of dipropylene glycol dibenzoate, 5 to 10 parts of trel-butylphenyl diphenyl phosphate, 7 to 13 parts of antimonous oxide, 5 to 10 parts of decabromodiphenylethane, 4 to 8 parts of zinc borate, 2 to 3 parts of tert-butyl peroxybenzoate, 1.5 to 2 parts of zinc oxide, 2 to 3 parts of stearic acid, 3 to 6 parts of chlorcosane, 1 to 2 parts of accelerant ZDMC (Zinc Dimethyldithiocarbamate), 1 to 2 parts of accelerant CZ (N-cyclohexylbenzothiazole-2-sulphenamide), 15 to 20 parts of fumed silica, 10 to 15 parts of attapulgite nanoocomposites, 5 to 10 parts of nano zeolite, 10 to 15 parts of precipitated barium sulphate, 1.5 to 2.5 parts of antioxidant 1010, 2 to 3 parts of anti-aging agent TPPD (N-(p-toluene-sulphonylamido-N'-phenylene diamine)), and 3 to 6 parts of composite filler. The cable material is outstanding in wearability, particularly, the wearability is always several times and even dozen times that of the common electrical material under a terrible working condition in the presence of water, oil and other wetting medias; the cable material is also remarkable in heat resistance, flame resistance, ageing resistance, oil resistance, warping strength, impact resistance and tear resistance.

Owner:ANHUI WANGDA COPPER DEV

Bobbin body paper made of waste paper pulp and production process thereof

InactiveCN103147343AImprove flex resistanceImprove toughnessSpecial paperPaper recyclingAdhesiveSand-paper

The invention relates to a manufacturing process of bobbin body paper, and in particular relates to bobbin body paper made of waste paper pulp and a production process thereof. The production process comprises the following steps of: 1, pulping of waste paper pulp; 2, preparing wear-resisting ingredients which comprises the components in parts by weight as follows: 100 parts of organic macromolecular material, 0.1-0.5 parts of stabilizer, 0-1 parts of lubricant, 0.5-1.5 parts of antioxidant, 1-1.5 parts of adhesive and 1-1.5 parts of mountain flour; 3, doping 1-2.5% of wear-resisting ingredients to the pulp of the waste paper pulp obtained by the step 1 and uniformly mixing through a high speed stirrer to obtain wear-resisting pulp; and 4, mixing the wear-resisting pulp with waste paper pulp treated according to proportion, and manufacturing a sand paper pipe to obtain regenerated bobbin body paper, wherein the proportion of the wear-resisting pulp and the waste paper pulp is (40-60):(60-40). The invention is applied to preparing bobbin body paper by using waste paper pulp, and the wear-resistance is improved.

Owner:FUJIAN YIYUAN WASTE UTILIZATION

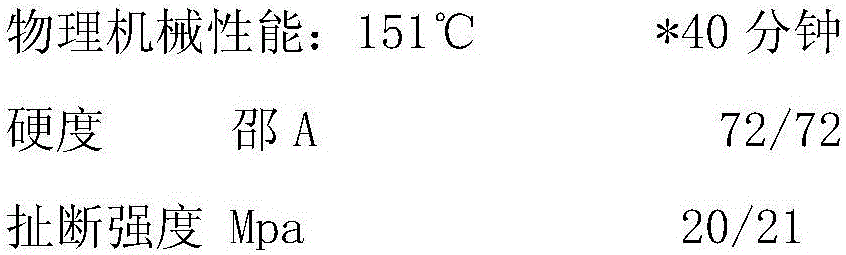

Ultra-wearable rubber formulation for sports shoes sole

The invention discloses a superwear-resisting rubber formulation of sport sole, and is characterized in that the formulation according to parts by weight comprises 80 parts of polybutadiene rubber, 20 parts of natural gum STR-5L, 1 part of uniform tackiness resin, 45-48 parts of white carbon black, 3.5 parts of softening oil, 3-3.2 parts of coupler, 5.2-5.8 parts of activator, 1 part of zinc stearate, 1 part of antifog agent, 1.9-2.1 parts of sulphur, and 1.65-1.95 part of accelerating agent, an ideal raw material functional combination can be obtained after applying the rubber formulation for sports shoes, which makes the sport shoe rubber sole having superwear resistance which is superior to ordinary rubber sole, and has a plurality of excellent properties such as wet-skid resistance, impact resistance and the like.

Owner:ANTA CHINA

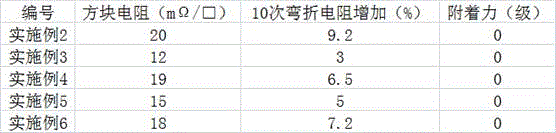

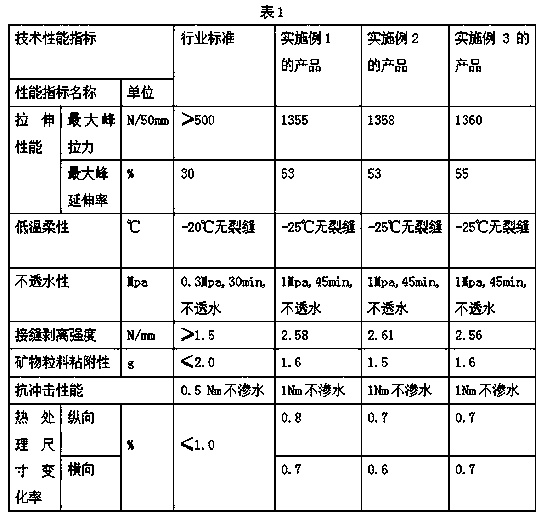

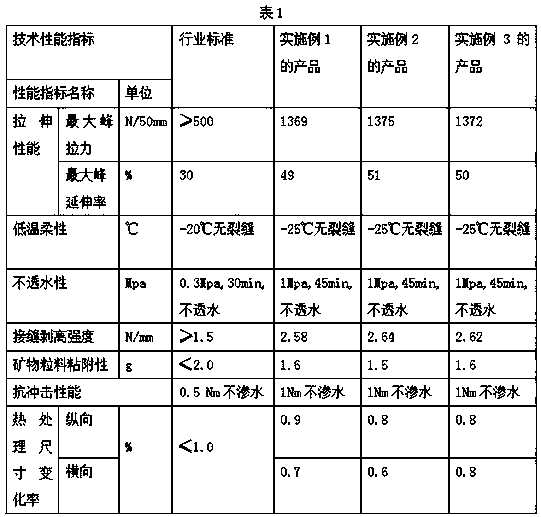

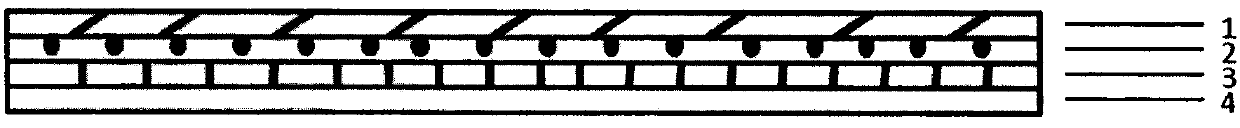

Antiflaming waste rubber powder modified asphalt wet-paving waterproof coiled material and production method thereof

InactiveCN102975465AWon't igniteImprove securityNon-macromolecular adhesive additivesUnderground chambersSurface reactionWaste rubber

The invention discloses an antiflaming waste rubber powder modified asphalt wet-paving waterproof coiled material and a production method thereof. The antiflaming waste rubber powder modified asphalt wet-paving waterproof coiled material comprises an antiflaming modified asphalt sticky layer, an isolation film protection layer and an antiflaming main body material layer which can generate chemical crosslinking reaction and physical mortise-tenon coordinative sticking action together with concrete. According to the interlayer structure of the coiled material, the surface layer is a protection film; the second layer and the fourth layer are waste rubber powder modified asphalt adhesive layers; the third layer is a main body layer; and all the layers are adhered through hot pressing during production. The waterproof coiled material has high waterproof performance; the modified asphalt with reaction activity penetrates into cement gel and concrete capillary holes in a creepage manner when cement and concrete are solidified; and the chemical crosslinking reaction happens at contact interfaces to form a base surface reaction layer; and by addition of the waste rubber powder and the antiflaming agent, the coiled material has a good antiflaming effect.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

Method for improving performances of resin abrasive tools through carbon nano-tubes

InactiveCN101602191AHigh strengthHigh impact strengthAbrasion apparatusGrinding devicesCarbon nanotubeCarbonylation

The invention discloses a method for improving performances of resin abrasive tools through carbon nano-tubes. By adding the carbon nano-tubes of which the surfaces are subjected to organic treatment to resin abrasive tools, the method improves the body strength, anti-impact strength, bending resistance and wear resistance of the resin abrasive tools, and then improves the surface shape stability and machining accuracy of the resin abrasive tools, and prolongs life span. The surfaces of the carbon nano-tubes after organic treatment have carboxyl hydroxyl and other organic functional groups, and the addition amount of the carbon nano-tubes is 1 to 5 percent by weight. When the carbon nano-tubes added are carbonylation carbon nano-tubes, the wear resistance of the abrasive tools can be improved by 10 to 15 percent. When the carbon nano-tubes added are hydroxylation carbon nano-tubes, the wear resistance of the abrasive tools can be improved by 15to 20 percent.

Owner:云南光电辅料有限公司

Conducting ink and preparation method thereof

The invention discloses conducting ink, which is prepared from the following ingredients in parts by mass: 35 to 55 parts of conducting filling materials, 20 to 30 parts of bonding agents, 9 to 21 parts of solvents and 2 to 5 parts of auxiliary agents, wherein the conducting filling materials comprise grapheme, flaky silver powder and ball-shaped silver powder; the grapheme accounts for 0.2 to 2 parts of the total amount of the conducting filling materials; the flaky silver powder accounts for 30 to 40 parts of the total amount of the conducting filling materials; the ball-shaped silver powder accounts for 5 to 15 parts of the total amount of the conducting filling materials. The invention also discloses a preparation method of the conducting ink. The method comprises the following steps of (1) bonding agent preparation; (2) grapheme precursor preparation; (3) crude pulp preparation; (4) grinding and filtering; (5) finished product obtaining. The preparation method has the advantages that the conducting performance and the anti-bending performance of the ink can be obviously improved; in addition, the characteristics of wide printing applicability, low conducting ink solid content and the like are realized.

Owner:DEYANG CARBONENE TECH

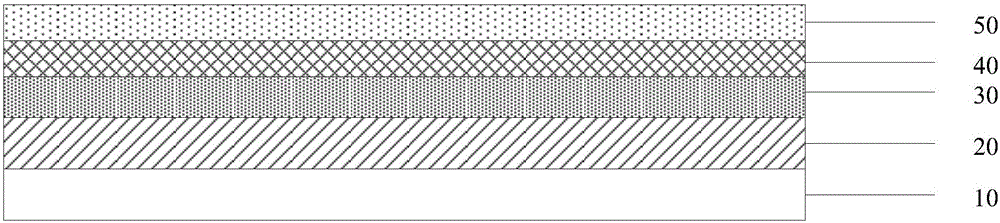

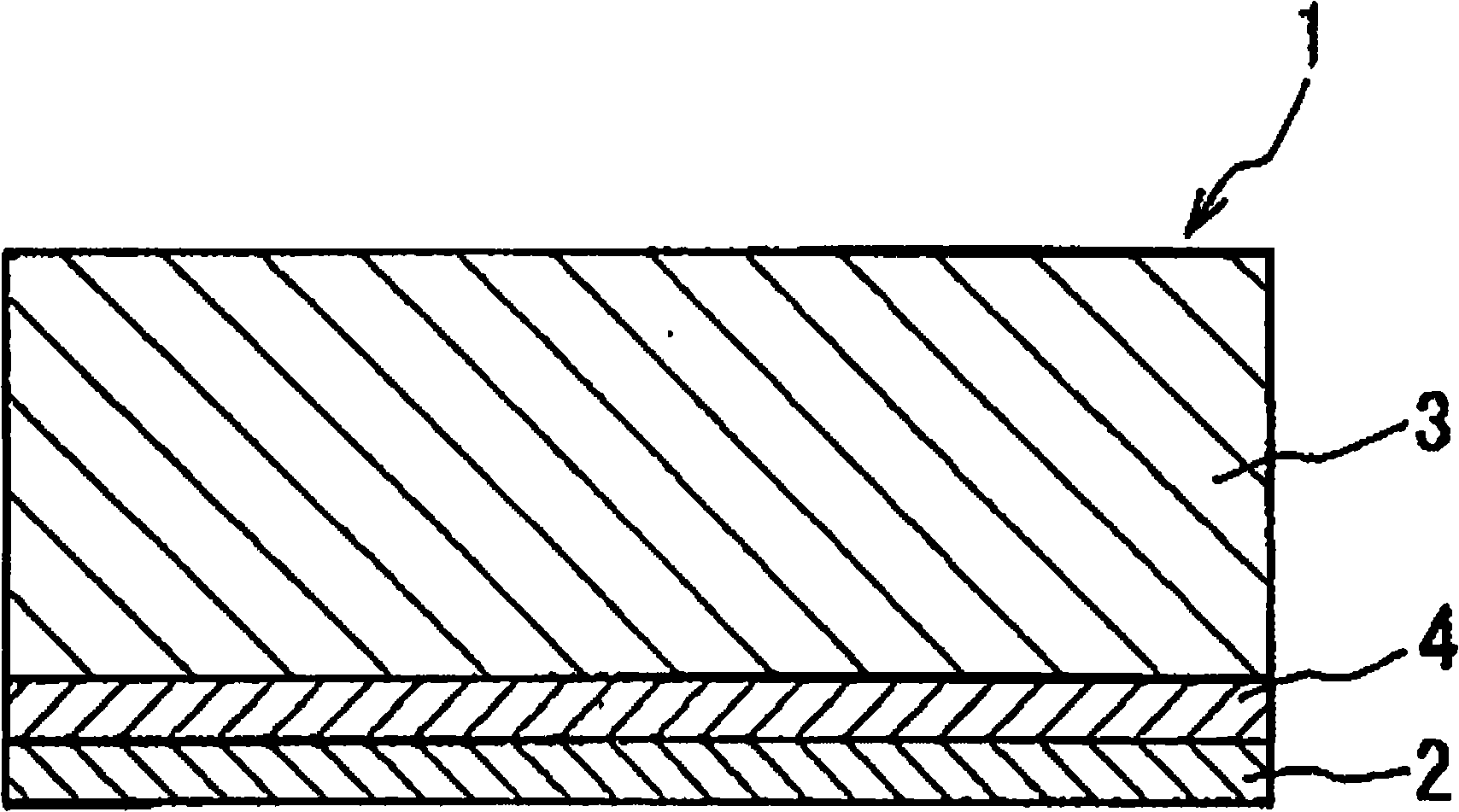

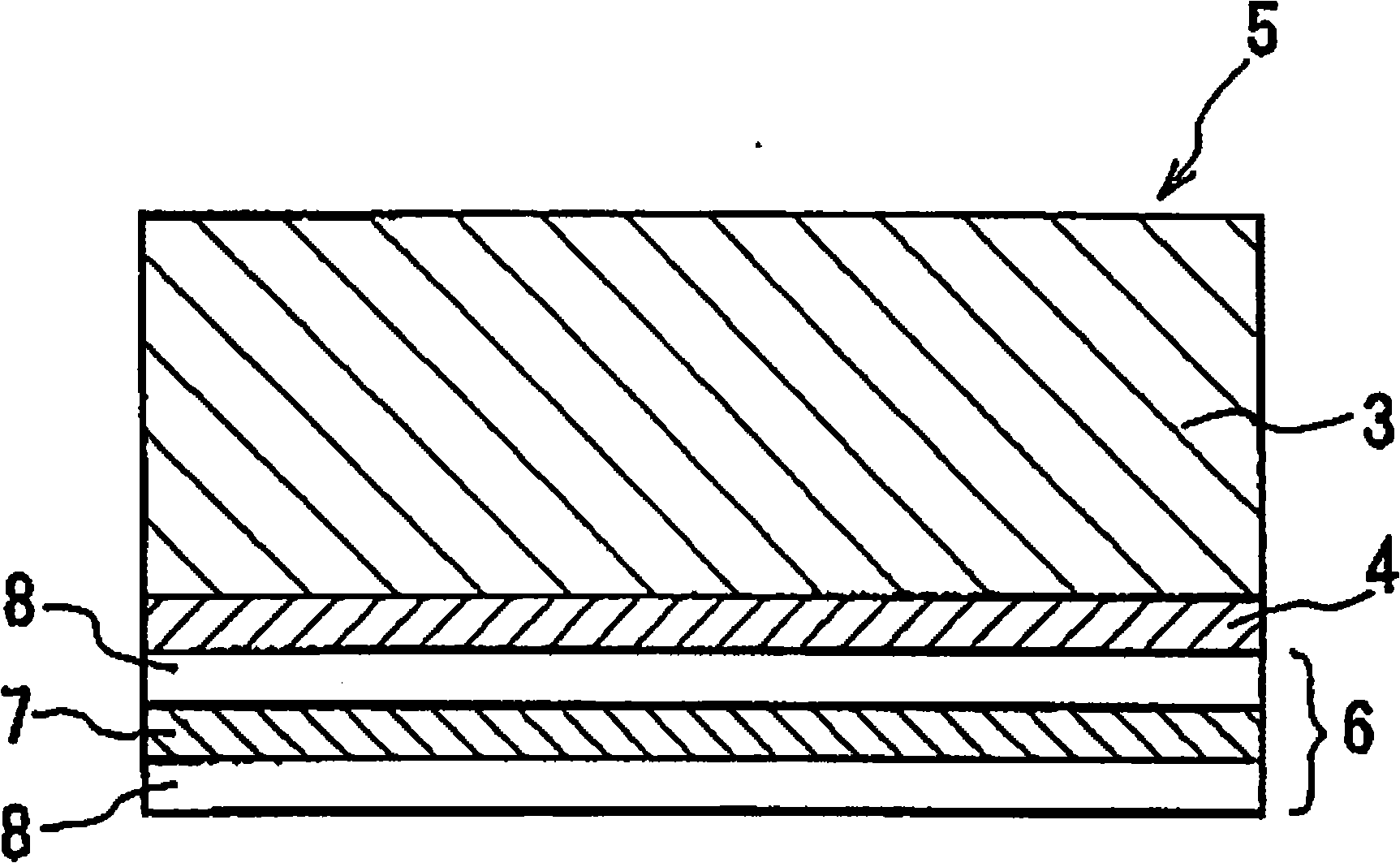

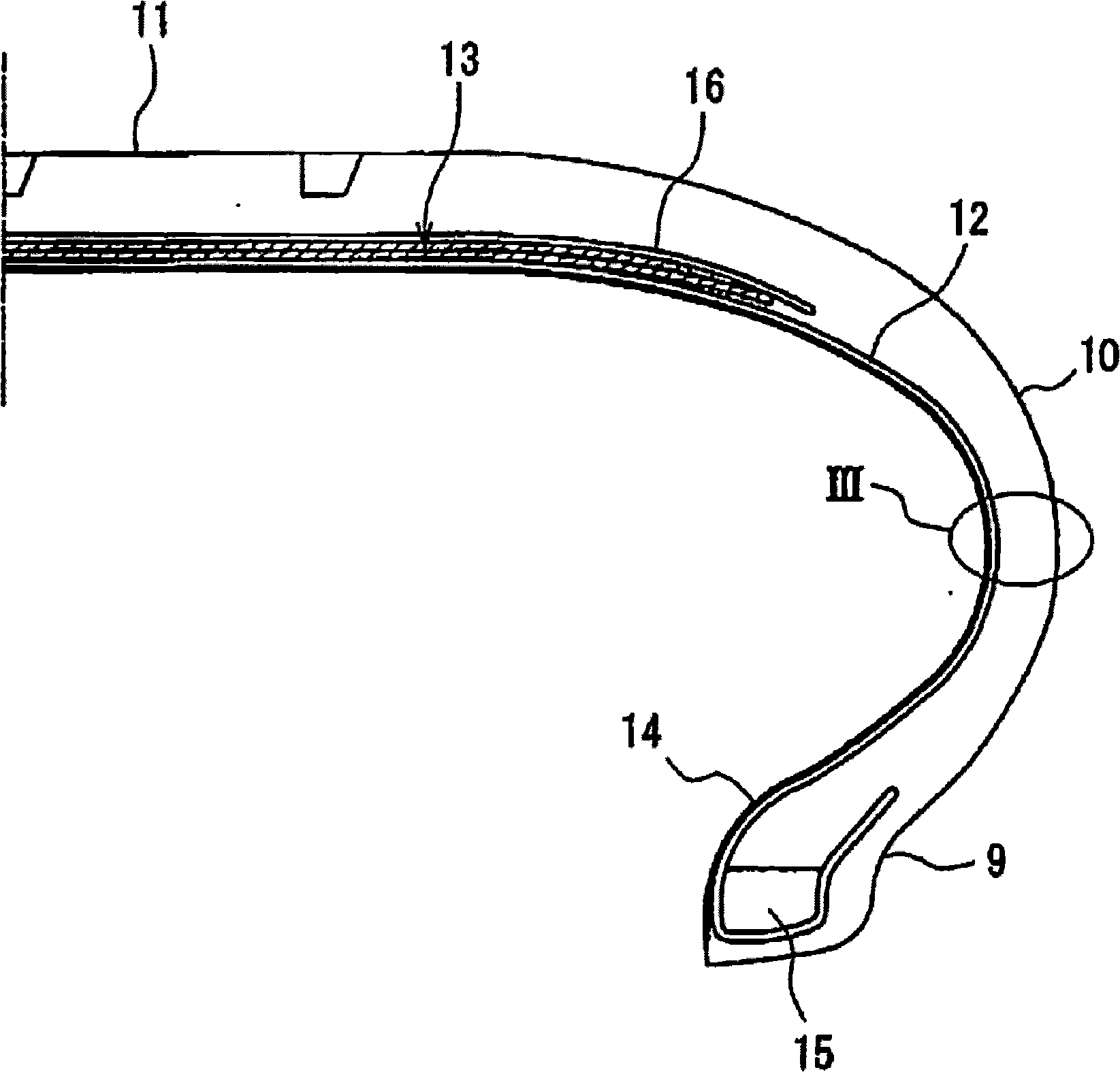

Multilayer body, method for producing the same, inner liner for pneumatic tire and pneumatic tire

InactiveCN101516646AEasy to processEnhanced resistance to peelingWithout separate inflatable insertsSynthetic resin layered productsElastomerImide

Disclosed is a multilayer body (1) which is obtained by joining a resin film layer (D)(2) with a rubber-like elastic layer (E)(3) through an adhesive layer (F)(4). The resin film layer (D)(2) contains at least a layer composed of a resin composition (C) wherein a soft resin (B) having a Young's modulus at 23 DEG C lower than that of a thermoplastic resin (A) is dispersed in a matrix composed of the thermoplastic resin (A). By using, for the adhesive layer (F)(4), an adhesive composition (I) obtained by blending not less than 0.1 part by mass of at least one of a maleimide derivative (H) having two or more reactive moieties in a molecule and poly-p-dinitrobenzene per 100 parts by mass of a rubber component (G), the multilayer body (1) can have good workability during production and excellent separation resistance.

Owner:BRIDGESTONE CORP +1

Modified asphalt waterproof coiled material with root penetration resistance and production method of coiled material

InactiveCN107933035AImprove the interface binding forceImprove adhesionAntifouling/underwater paintsRoof covering using flexible materialsWater leakageIsolation layer

The invention relates to a modified asphalt waterproof coiled material with root penetration resistance. The waterproof coiled material has a five-layer structure, and the waterproof coiled material is sequentially provided with an upper surface isolation layer, an upper modified asphalt layer, a base material layer, a lower modified asphalt layer and a lower surface isolation layer from the top to the bottom; and the upper modified asphalt layer and the lower modified asphalt layer are separately prepared from a modified asphalt. The modified asphalt waterproof coiled material with root penetration resistance produced by the invention has greatly improved performance such as root penetration resistance, tear resistant strength, binding performance, water resistance and aging resistance, higher elongation at break, and a simple production process, and overcomes the disadvantages of tedious production, poor binding performance and the like of a traditional waterproof coiled material. According to the invention, the waterproof coiled material produced by the method is used in building, the binding strength of the waterproof coiled material and the base surface of a building is large,the waterproof and root penetration resistant effects are good, the phenomena of water seepage and water leakage of a waterproof coiled material are effectively prevented, and the product has dual functions of waterproofing and preventing plant root penetration.

Owner:GUANGXI WUXUAN JINPAI WATERPROOF MATERIAL SCI & TECH CO LTD

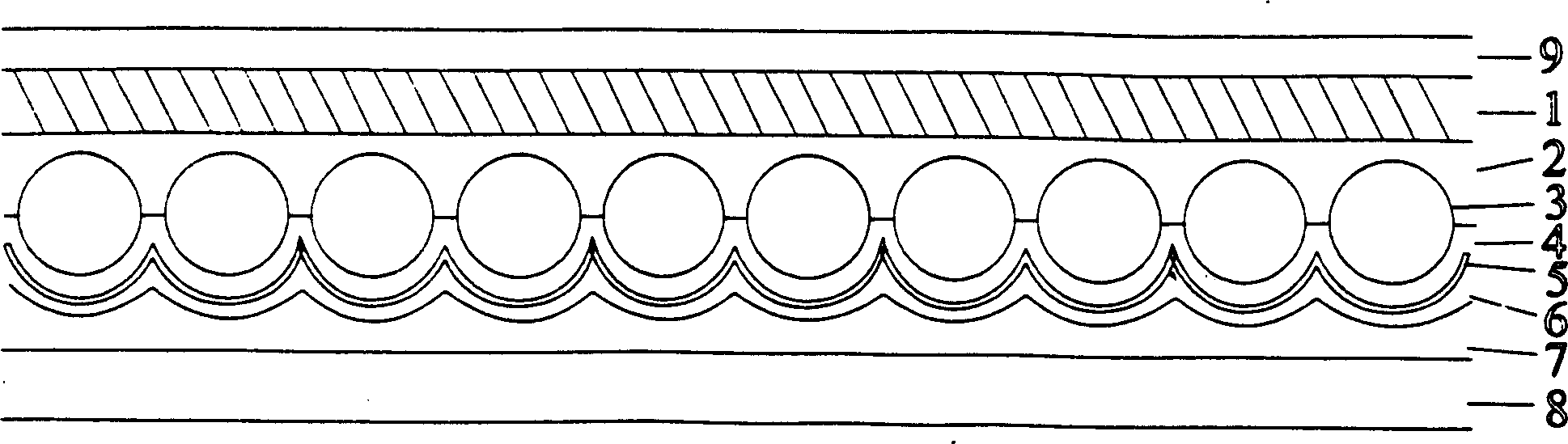

High-toughness Yakeli light-reflecting film and production thereof

InactiveCN1853923AGood flexibilityImprove controllabilitySynthetic resin layered productsPressure sensitivePliability

A reflecting high-flexibility acrylic film is composed of surficial resin layer with protective liner layer, adhesive layer, closely arranged glass microbead layer, focusing paint layer, metallic reflecting layer, metallic protecting layer, pressure sensitive adhesive layer and antisticking layer. Its preparing process is to adhere said layers sequentially.

Owner:陆亚建

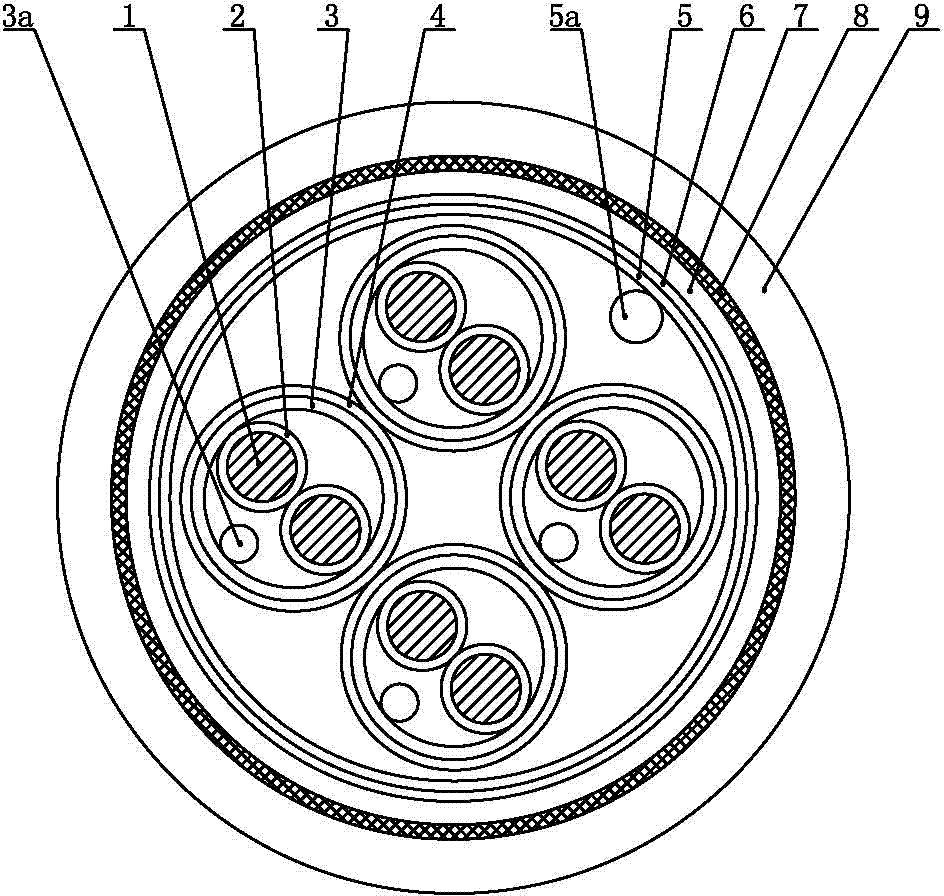

Whitening ultraviolet-proof double-shield instrument cable for ships and manufacturing method thereof

InactiveCN102969046AColor whiteGood physical and mechanical propertiesClimate change adaptationInsulated cablesCopper foilInsulation layer

The invention relates to a whitening ultraviolet-proof double-shield instrument cable for ships and a manufacturing method thereof. The cable is characterized in that a whitening ultraviolet-proof ethylene-propylene rubber insulation layer is extruded at the periphery of a tin-plated annealed stranded copper conductor to form an insulation wire core; every two insulation wire cores are twisted to form twisted wire pairs; each twisted wire pair is wrapped with a wire core copper foil polyester composite tape shielding layer at the periphery; the wire core copper foil polyester composite tape shielding layers are each wrapped with a wire core polyester tape at the periphery to form a pair-twist group; all the pair-twist groups are stranded to the right at 16-24 times of stranding lay ratio to form a cable core; the cable core is wrapped with a cable core copper foil polyester composite tape shielding layer at the periphery; the cable core copper foil polyester composite tape shielding layer is wrapped with a cable core polyester tape at the periphery; an inner sheath is extruded at the periphery of the cable core polyester tape; the inner sheath is coated with a copper alloy wire weaving armor layer at the periphery; and an outer sheath is extruded at the periphery of the copper alloy wire weaving armor layer. The insulation layer of the double-shield cable is white in color, good in mechanical property, excellent in anti-ultraviolet irradiation and anti-aging performance, and long in service life.

Owner:JIANGSU YUANYANG DONGZE CABLE

Polyamide elastomer thermal shrinkable material, polyamide elastomer double-layer material and preparation methods

ActiveCN101629015AGood resistance to oil and chemical solventsHigh strengthFilm/foil adhesivesPolyamideSoft segment

The invention relates to a polyamide (commonly called nylon) elastomer thermal shrinkable material which comprises the following components by weight part: 100 parts of polyamide elastomer, 0.5-6 parts of antioxidant, 0-50 parts of halogenated flame retardant, 0-20 parts of flame-retardant synergist, 0-3 parts of polyfunctional acrylic ester reaction monomer, 0-3 parts of light stabilizer and 0-5 parts of color master batch, wherein the polyamide material is a segmental type segmented copolymer which uses polyamide as hard segments and polyether as soft segments; and the antioxidant is one or a compound of more of an amine antioxidant, a phenol antioxidant and an ester antioxidant. The polyamide elastomer thermal shrinkable material has good thermal ageing resistance, high temperature resistance and oil resistivity and also has the characteristics of excellent mechanical property, strong toughness, good wear-resisting property and simple preparation method. The invention also provides a polyamide elastomer double-layer material made of the thermal shrinkable material and preparation methods of the two materials.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +3

Wear-resisting tire

InactiveCN105384979AImprove carrying capacityImprove traction performanceRolling resistance optimizationRolling resistanceEPDM rubber

The invention discloses a wear-resisting tire. The wear-resisting tire is prepared from, by weight, 16-18 parts of natural rubber, 15-18 parts of EPDM rubber, 10-15 parts of isoprene rubber, 1-3 parts of butadiene rubber, 5-10 parts of butadiene styrene rubber, 3-5 parts of nano-silica, 1-3 parts of nano-zirconia, 1-3 parts of polyether polyol, 2-5 parts of dibutyl phthalate, 1-3 parts of 2-ethylhexyl epoxystearate, 3-6 parts of zinc oxide, 2-5 parts of zinc borate, 3-6 parts of stearic acid, 2-5 parts of fortifier and 0.5-1 part of alkoxy type titanate coupling agent. The wear-resisting tire has high bearing performance, traction performance and buffer performance, and has high wear resistance and surrendering resistance and low rolling resistance and heat generation.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

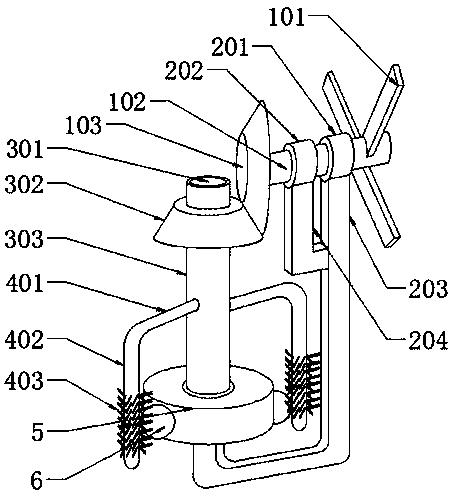

Self-cleaning dedusting monitor

The invention discloses a self-cleaning dedusting monitor, and relates to the technical field of monitoring equipment. The self-cleaning dedusting monitor comprises a mounting seat, a brush, a power mechanism and a transmission mechanism. The power mechanism comprises a support arm. The lower end of the support arm is connected to the mounting seat, the upper end of the support arm is rotatably connected with a rotating shaft, one end of the rotating shaft is connected with a plurality of air wings, and the other end of the rotating shaft is fixedly connected with a driving bevel wheel. The transmission mechanism includes a ball bearing, a transmission shaft and a driven bevel wheel; the lower end of the transmission shaft is rotatably connected to the center of the mounting seat through the ball bearing, and the upper end of the transmission shaft and the driven bevel wheel are fixedly connected, and the driven bevel wheel meshes with the driving bevel wheel. The brush comprises a brush bar, the brush bar is provided with bristles, the brush bar is connected to the transmission shaft, and the bristles can be in contact with a camera. According to the scheme, the self-cleaning dedusting monitor utilizes the wind power existing in the outdoor natural environment as a power source for cleaning the camera, and solves the problem of resource consumption caused by the need of a power supply in the prior art.

Owner:贵州创世科技有限公司

Rubber composition and application thereof

ActiveCN105778179AGood physical and mechanical propertiesGood workmanshipBuilding insulationsPolymer scienceAdjuvant

The invention relates to a rubber composition. The rubber composition is prepared from the ingredients in parts by mass: 80-120 parts of crude rubber, 1-5 parts of peroxide initiator, 2-15 parts of bridging agent, 0.1-1 part of free-radical absorption and release regulator and reinforcing and anti-aging agents, wherein the crude rubber comprises any one to any three of polybutadiene rubber, natural rubber and styrene-butadiene rubber and accounts for 70 percent or more of mass of the crude rubber. According to the rubber composition and the application thereof, a formula of the rubber composition and adjuvants for product cross-linking and the like is provided, so that the requirements of a technical scheme for representatives, i.e., tires, shoe materials and wear resisting plates on good properties and good industrial adaptability effect can be met; cost and environmentally-friendliness can be taken into account simultaneously.

Owner:NANJING SIKAI RUBBER & PLASTIC PROD CO LTD

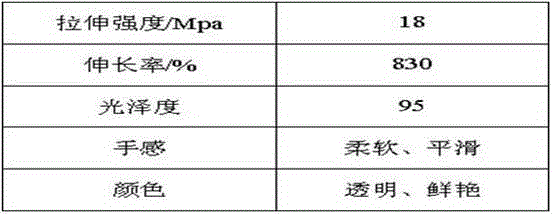

Preparation method of high-gloss PET film transfer mirror-surface polyurethane synthetic leather

The invention provides a preparation method of high-gloss PET film transfer mirror-surface polyurethane synthetic leather. The preparation method comprises the following steps: firstly ironing wet polyurethane synthetic leather by a post-treatment calender at a temperature of 120-140 DEG C, and cooling to obtain a wet polyurethane synthetic leather semi-finished product; using a high-gloss PET mirror-surface film as a release film, and uniformly coating the front surface of the high-gloss PET mirror-surface film with a layer of polyurethane slurry to form a surface layer, and drying to obtain a high-gloss PET film; and finally heat-conglutinating a bonding layer of the high-gloss PET film and the front surface of the wet polyurethane synthetic leather semi-finished product, drying, cooling, and stripping the high-gloss PET mirror-surface film so as to obtain the high-gloss PET mirror-surface polyurethane synthetic leather. The mirror-surface effect of the leather is similar to the mirror-surface effect of patent leather. In addition, the leather provided by the invention has high gloss, high transparency, high flex resistance, resistance to yellowing and fogging resistance.

Owner:ANHUI ANLI MATERIAL TECH

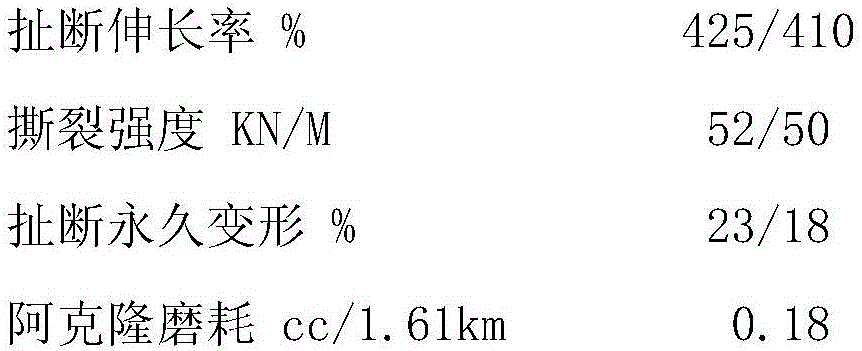

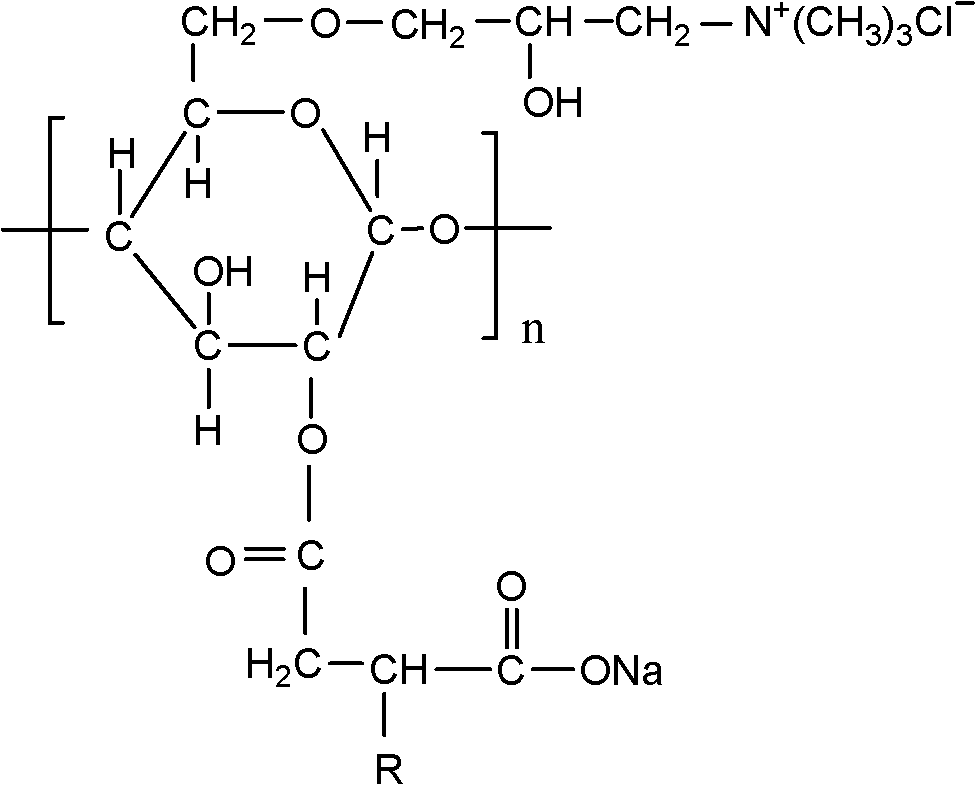

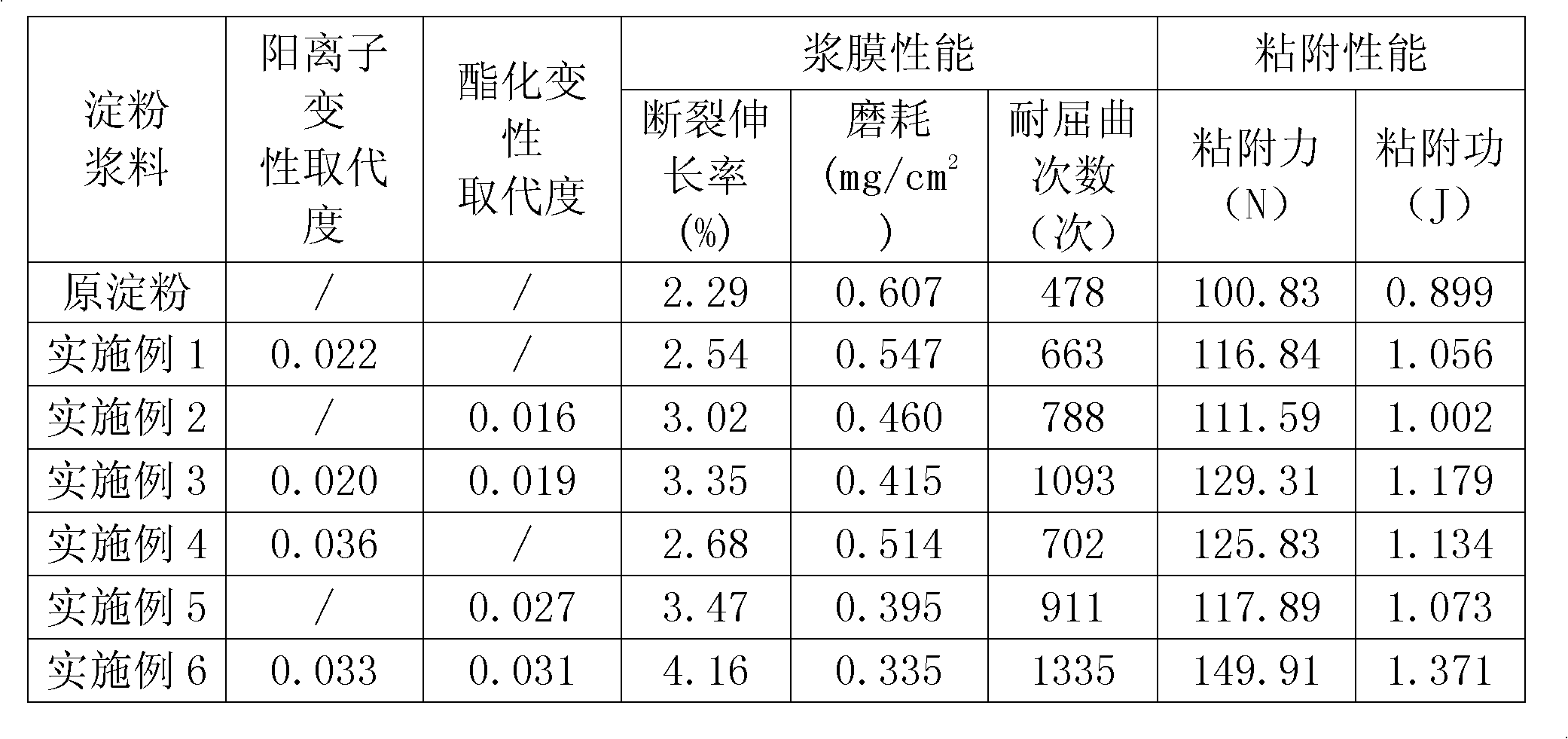

Method for synthesizing composite modified starch slurry

The invention discloses a method for synthesizing composite modified starch slurry, belonging to the technical field of methods for synthesizing the modified starch slurry applied to starching of spinning warps. The method comprises the following steps of: firstly carrying out positive ion modification on starch by utilizing quaternary ammonium type positive ion etherifying agent 3-chlorine-2-hydroxypropyltrimethylammonium chloride to synthesize positive ion starch, and carrying out an esterification reaction between the synthesized positive ion starch and dodecenylsuccinic anhydride so as to synthesize positive ion-dodecenylsuccinate composite modified starch slurry. According to the method for synthesizing the composite modified starch slurry, disclosed by the invention, positive ion groups and ester group which is large in volume and provided with vinyl group are introduced in a starch macromolecular chain so that film performances of the starch slurry is remarkably modified, and adhesion performance of the slurry to synthetic fibers such as terylene can be improved, thus starching requirements of warps, especially the terylene and the like, are better met. The method for synthesizing the composite modified starch slurry, disclosed by the invention, can be used for starching warps of fibers such as cotton, linen, mucilage glue and terylene / cotton, terylene / linen, terylene / mucilage glue through a common sizing machine or a high-speed sizing machine.

Owner:芜湖迅腾新材料有限公司 +1

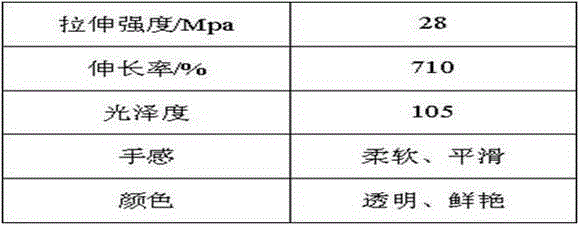

Waterborne polyurethane leather finishing agent and preparation method thereof

ActiveCN104448193AHigh glossImprove picking ratePolyurea/polyurethane coatingsLeather surface finishingPolyurethane dispersionEthylenediamine

The invention discloses a waterborne polyurethane leather finishing agent and a preparation method thereof. The method comprises steps as follows: using diisocyanate, CAB (cellulose acetate butyrate) and a polyether polyol to generate an isocyanate-group-terminated prepolymer, then performing neutralization with triethylamine after extending a chain with a hydrophilic chain extender, and finally, extending a chain with ethylenediamine to form a CAB-modified waterborne polyurethane dispersion so as to obtain the waterborne polyurethane leather finishing agent. According to the waterborne polyurethane leather finishing agent and the preparation method thereof, waterborne polyurethane is modified with the CAB, and the CAB-modified waterborne polyurethane dispersion is obtained. A resin film is bright, firm and good in deflection resistance, leather is endowed with the excellently high gloss, the smooth and soft hand feeling, the good ironing performance and excellent characteristics of light fastness, heat resistance, non-yellowing performance and the like, the selection rate of the leather is greatly increased after top finishing, and the grade of the leather is increased.

Owner:泰兴市华盛银洋新材料科技有限公司

Light-emitting shoe material and preparation method thereof

The invention discloses a light-emitting shoe material and a preparation method thereof. The light-emitting shoe material comprises styrene type thermoplastic elastomer, 1,2-polybutadiene, styrene-butadiene copolymer (K adhesive), white mineral oil, a photo-thermal stabilizer, a lubricant and nano silicon dioxide. The preparation method comprises the following steps: premixing the components in a high-speed mixer, carrying out melt extrusion on the premixture at 120-130 through a double screw extruder, cooling, granulating, and finally, carrying out injection molding at 137-145 DEG C to obtain the light-emitting shoe material. The light-emitting shoe material has the characteristics of uniform light scattering, uniform brightness, soft light rays, favorable toughness, high anti-skid property, stable dimension and the like.

Owner:MAOTAI FUJIAN SOLES CO LTD

Oil-proof antistatic mould-pressing outsole rubber compound and preparation method thereof

The invention discloses oil-proof antistatic mould-pressing outsole rubber compound. The oil-proof antistatic mould-pressing outsole rubber compound is made of, by weight, 70-85 parts of domestic standard rubber 2, 15-30 parts of nitrile butadiene rubber, 2-3 parts of accelerator, 1.6-2.5 parts of sulfur, 2-3 parts of active zinc oxide, 1-1.5 parts of stearic acid, 1.5-2.5 parts of age resister, 50-60 parts of intermediate super abrasion carbon black, 10-20 parts of acetylene black, 6-8 parts of antistatic agent, 20-30 parts of softener, 5-10 parts of tackifier, 0.6 part of release agent and 0.1-0.2 part of peptizer. Further, the invention discloses a preparation method of the oil-proof antistatic mould-pressing outsole rubber compound. Comprehensive performances of the rubber compound are evidently improved, and the average service life of finished products of work shoes made of the rubber compound is longer than 6 months and prolonged by 50% as compared with that of normal products on the market.

Owner:JIHUA 3539 SHOE MAKING

Polyurethane modified asphalt waterproof roll and production method thereof

InactiveCN108099306AStable hydrolysisStable light fadeSynthetic resin layered productsLaminationWater leakageBituminous waterproofing

The invention relates to a polyurethane modified asphalt waterproof roll. The polyurethane modified asphalt waterproof roll is of a five-layer structure which comprises, from top to bottom, a top isolating layer, an upper modified asphalt layer, a padding layer, a lower modified asphalt layer and a bottom isolating layer, wherein the upper modified asphalt layer and the lower modified asphalt layer are prepared from modified asphalt. The polyurethane modified asphalt waterproof roll is greatly improved in tearing strength, adhesion, water resistance, aging resistance and the like, has high elongation at break, and overcomes the disadvantages of tedious preparation, weak adhesion and the like of conventional waterproof rolls. A production method for the polyurethane modified asphalt waterproof roll is simple. As the polyurethane modified asphalt waterproof roll is applied to a building, a contact surface of the polyurethane modified asphalt waterproof roll and the base surface of the building has good bonding strength and waterproof effect, so the waterproof roll is effectively prevented from water seepage and water leakage.

Owner:GUANGXI WUXUAN JINPAI WATERPROOF MATERIAL SCI & TECH CO LTD

Low-voltage flexible electrothermal film and preparation method therefor

InactiveCN107660006AImprove heating effectThere is no safety hazard of electric shockOhmic-resistance electrodesHeating element materialsLow voltageHeat conducting

The invention discloses a low-voltage flexible electrothermal film and a preparation method therefor. The electrothermal film comprises an insulating base material, an electrode layer, a conductive heating layer, a heat conducting and infrared radiation layer and an externally connected wire; each layer is formed by printing, and drying is completed in a drying channel; and the electrothermal filmis applicable to electrothermal clothes. The low-voltage flexible electrothermal film has the advantages as follows: large-area heating at a low voltage (3.7V) can be realized; the heat conducting and radiation layer is adopted to replace an insulation protection layer above the existing heating layer; the layer also has the insulation protection, heat conducting and infrared radiation functions;by adopting the multi-point externally connected wire mode to replace the existing method for improving conductivity of an external electrode, basically same voltages in each point on the external electrode is realized, so that cost is lowered, and meanwhile, electrode flexibility and stability are reinforced; and a mature printing mode is adopted to manufacture the electrothermal film to replacethe existing troublesome, time-consuming and strict working procedure, so that the technical threshold for manufacturing the low-voltage flexible electrothermal film is lowered, thereby facilitatinglarge-scale industrial production of the electrothermal film.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com