Graphene-modified conductive silver paste and preparation method thereof

A technology of graphene modification and conductive silver paste, which is applied in the direction of cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., and can solve the problem that the conductive properties of conductive inks need to be further improved, and the conductive properties need to be further improved , Low addition of graphene, etc., to achieve excellent charge conductivity, improved adhesion, and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] (1) Mix 100 parts by weight of silver nanowires, 100 parts by weight of biomass graphene and 110 parts by weight of n-butanol, grind to a particle size of less than 10 microns, and obtain mixture a;

[0067] (2) 200 parts by weight of epoxy resin and 110 parts by weight of n-butanol are mixed uniformly to obtain mixture b;

[0068] (3) Mix mixture a and mixture b evenly, and then grind to a particle size of less than 10 microns with a three-roll mill to obtain the graphene-modified conductive silver paste 1#.

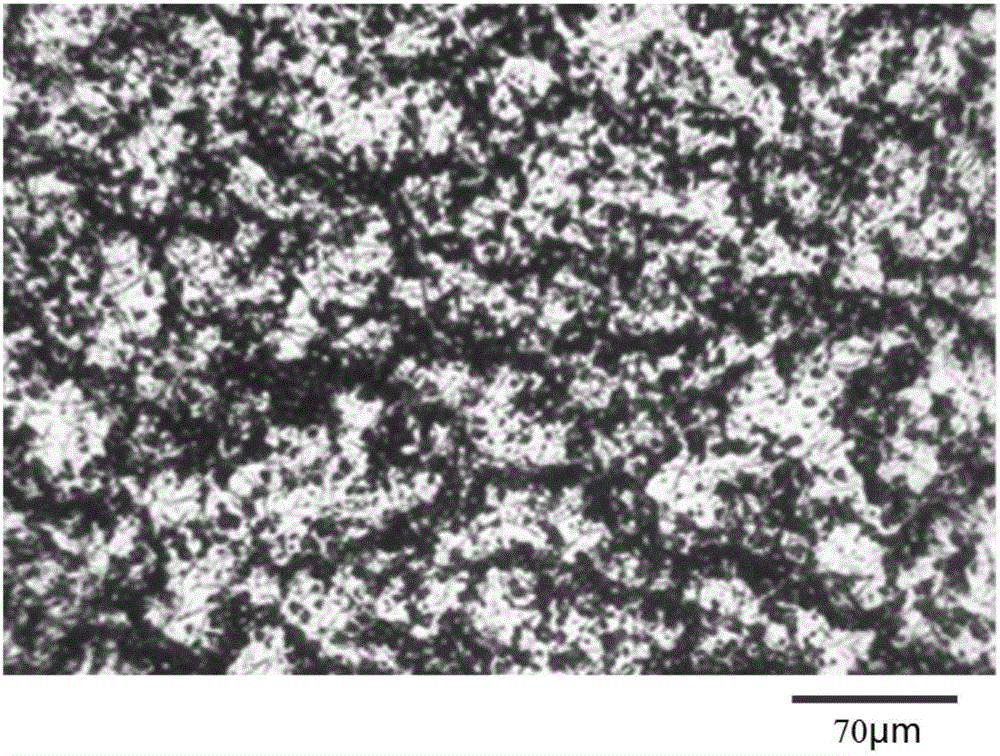

[0069] Using a microscope to characterize the prepared graphene-based conductive silver paste, the results are as follows figure 1 As shown, it can be seen from the figure that the silver nanowires are criss-crossed and filled between the graphene, connecting the isolated graphene sheets like wires to build a conductive network.

Embodiment 2

[0071](1) 80 parts by weight of silver nanowires, 120 parts by weight of biomass graphene and 120 parts by weight of isophorone are mixed uniformly, and ground to a particle size of less than 10 microns to obtain mixture a;

[0072] (2) 180 parts by weight of acrylic resin and 120 parts by weight of isophorone are uniformly mixed to obtain mixture b;

[0073] (3) Mix mixture a and mixture b uniformly, and then grind to a particle size of less than 10 microns with a three-roll mill to obtain the graphene-modified conductive silver paste 2#.

Embodiment 3

[0075] (1) Mix 90 parts by weight of silver nanowires, 100 parts by weight of biomass graphene and 110 parts by weight of butyl acetate, and grind to a particle size of less than 10 microns to obtain mixture a;

[0076] (2) 200 parts by weight of alkyd resin and 110 parts by weight of butyl acetate are uniformly mixed to obtain mixture b;

[0077] (3) Mix mixture a and mixture b evenly, and then grind to a particle size of less than 10 microns with a three-roll mill to obtain the graphene-modified conductive silver paste 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com