Preparation method of high-strength high-conductivity high-softening-temperature copper-clad dispersion copper conductive rod

A technology of softening temperature and dispersed copper, which is applied in the direction of conductive materials, conductive materials, cable/conductor manufacturing, etc., can solve the problems of affecting the mechanical life of vacuum switches, the change of vacuum switch contact opening distance, and the hardness reduction of oxygen-free copper materials. Achieve good electrical conductivity, increase softening temperature, and good brazing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

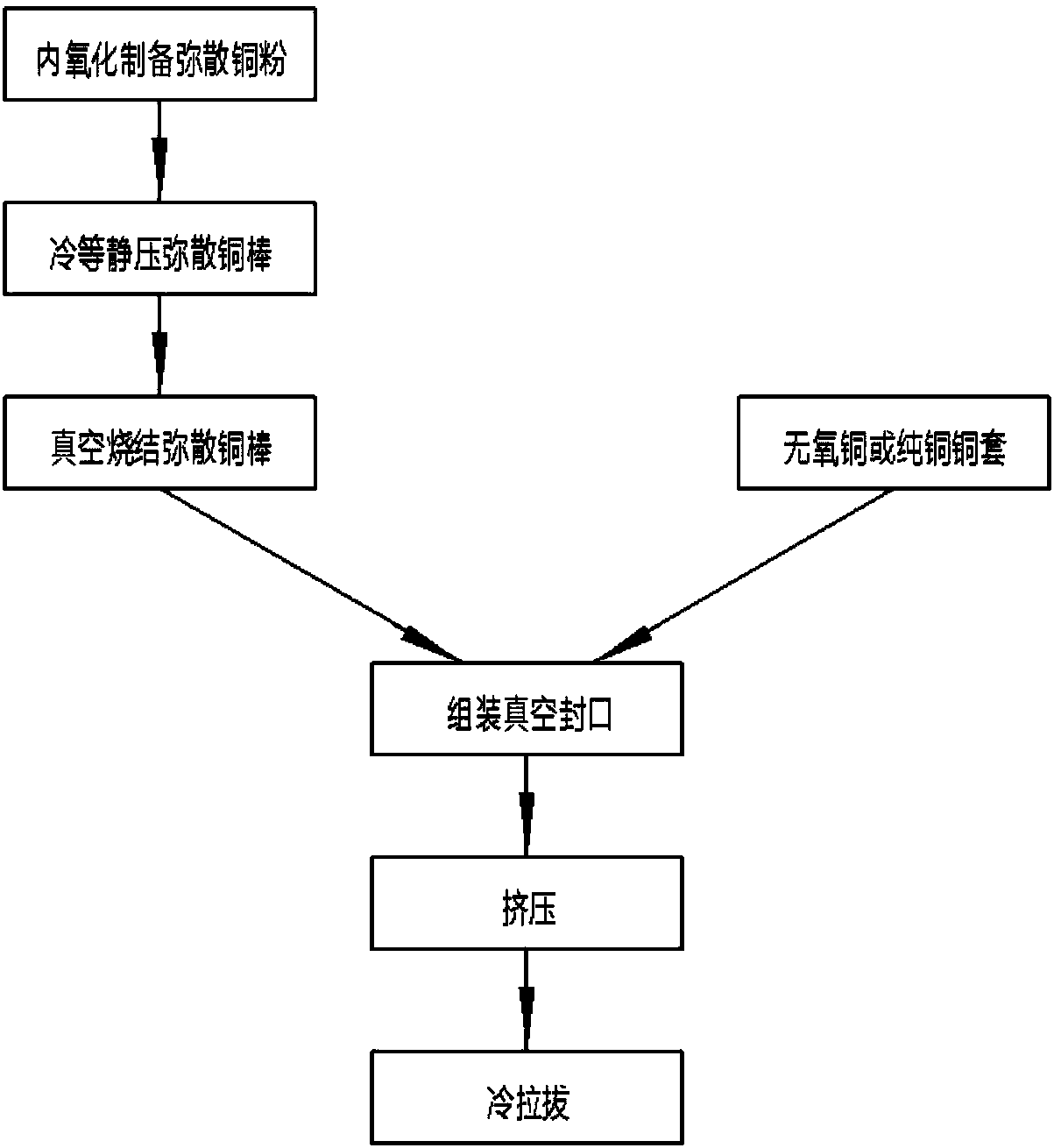

[0027] Such as figure 1 Shown, a kind of preparation method of the copper-clad dispersed copper conducting rod of high strength, high conductance and high softening temperature comprises the following steps:

[0028] (1) Preparation of dispersed copper alloy powder: preparation of ceramic reinforcement phase Al by internal oxidation method 2 o 3 For dispersed copper alloy powder with a content of 0.2%, the content of the ceramic reinforcement phase is too low, and the reinforcement effect is not obvious; the content is too high, and the electrical conductivity is seriously affected;

[0029] (2) Cold isostatic pressing method to prepare the dispersed copper rod in the heart: put the dispersed copper alloy powder prepared in step (1) into the rubber sleeve and vibrate, the vibration time is 35s, then put the rubber sleeve into Inside the steel hoop, put them into an isostatic press together for pressing, the pressing pressure is 150MPa, and the holding time is 3min to obtain ...

Embodiment 2

[0037] Such as figure 1 Shown, a kind of preparation method of the copper-clad dispersed copper conducting rod of high strength, high conductance and high softening temperature comprises the following steps:

[0038] (1) Preparation of dispersed copper alloy powder: preparation of ceramic reinforcement phase Al by internal oxidation method 2 o 3 For the dispersed copper alloy powder with a content of 0.3%, the content of the ceramic reinforcement phase is too low, and the reinforcement effect is not obvious; the content is too high, and the electrical conductivity is seriously affected;

[0039] (2) Cold isostatic pressing method to prepare the dispersed copper rod in the heart: put the dispersed copper alloy powder prepared in step (1) into the rubber sleeve and vibrate, the vibration time is 45s, then put the rubber sleeve into Inside the steel hoop, put them into an isostatic press together for pressing, the pressing pressure is 220MPa, and the holding time is 6min to obt...

Embodiment 3

[0047] Such as figure 1 Shown, a kind of preparation method of the copper-clad dispersed copper conducting rod of high strength, high conductance and high softening temperature comprises the following steps:

[0048] (1) Preparation of dispersed copper alloy powder: preparation of ceramic reinforcement phase Al by internal oxidation method 2 o 3 For dispersed copper alloy powder with a content of 0.4%, the content of the ceramic reinforcement phase is too low, and the reinforcement effect is not obvious; the content is too high, and the electrical conductivity is seriously affected;

[0049] (2) Cold isostatic pressing method to prepare the core dispersed copper rod: put the dispersed copper alloy powder prepared in step (1) into the rubber sleeve and vibrate for 60s, then put the rubber sleeve into Inside the steel hoop, put them together in an isostatic press for pressing, the pressing pressure is 300MPa, and the holding time is 10min to obtain dispersed copper rods;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com