High-strength high-ductility CNTs-SiCp enhanced aluminum-based composite material and preparation method thereof

A technology for strengthening aluminum-based and composite materials, which is applied in the preparation of the material, in the field of high-strength and high-ductility CNTs-SiCp reinforced aluminum-based composite materials, which can solve the problems of difficulty in balancing strength, ductility, and conductivity, and achieve weakening adverse reactions and strengthening Effect of interfacial bonding and wettability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of this material is:

[0034] Step 1, prepare mixed powder

[0035] Weigh carbon nanotubes, silicon carbide particles and aluminum powder according to the above volume percentage, add the above powder into the ball mill tank, use Φ10mm and Φ5mm mixed zirconia balls for the grinding balls, and the ball-to-material ratio of Φ10mm balls is 1~10:1 , The ball-to-material ratio of Φ5mm grinding balls is 1-5:1. Then add ethanol accounting for 1-5% of the mass of the mixed powder as a process control agent, and adopt a low-speed planetary ball milling method to disperse under the protection of an inert gas. powder.

[0036] Step 2, Sintering

[0037]The ball-milled mixed powder is loaded into a graphite mold, and then the mixed powder is first pressed into a block at room temperature and a pressure of 5-20 MPa, and then the block is sintered at 450-630 °C and 10-30 MPa with discharge plasma for 0.5 ~3h, and finally put the sintered composite material ...

Embodiment 1

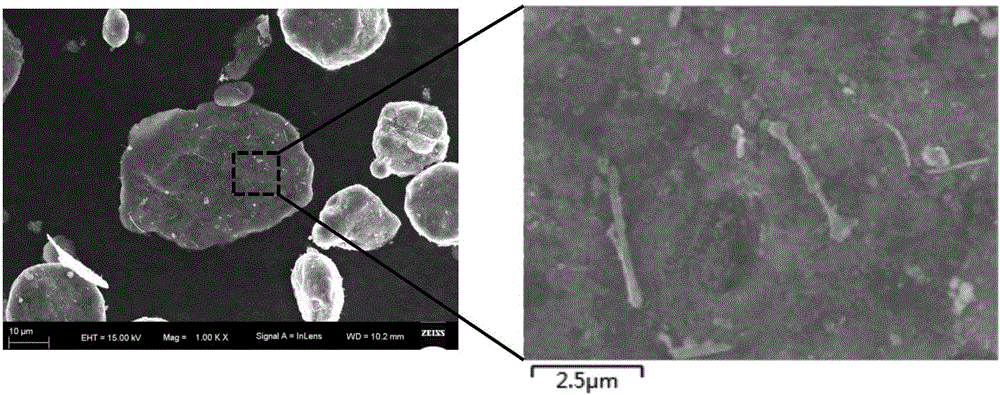

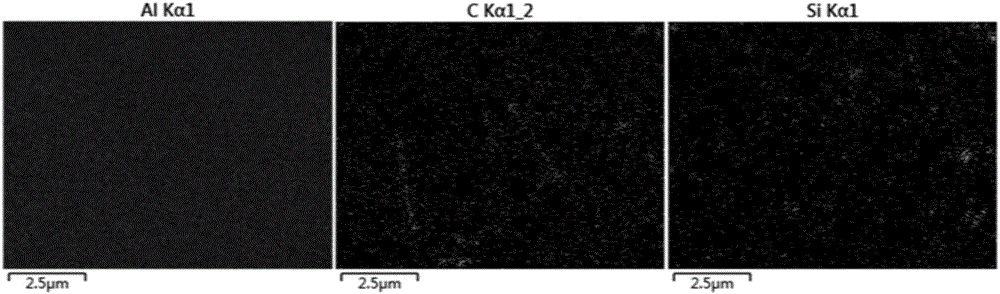

[0040] Preparation of a CNTs-SiC p Enhance AMCs.

[0041] Weigh 0.1110g of single-walled carbon nanotubes with a diameter of 10nm-50nm and a length of 100nm-1cm, 0.1778g of silicon carbide with a particle size in the range of 20nm to 150nm, and 59.7112g of aluminum raw powder with a particle size of 10 to 100μm. The volume percentages are 0.25%, 0.25%, and 99.5%, respectively. Put all the powders into a tungsten carbide ball mill jar, add 240g of 10mm in diameter and 60g of zirconia balls of 5mm in diameter, then add 1ml of absolute ethanol, exhaust with high-purity argon for 5min, and use planetary ball milling under argon atmosphere for 4h at 200rpm, every 10 minutes of ball milling with an interval of 10 minutes. The composite powder was packed in a graphite mold in an argon glove box, pressed into a block with a pressure of 20 MPa, and then sintered in a spark plasma sintering furnace at 630 °C and 30 MPa for 1 hour. In a tube furnace under the protection of inert gas, ...

Embodiment 2

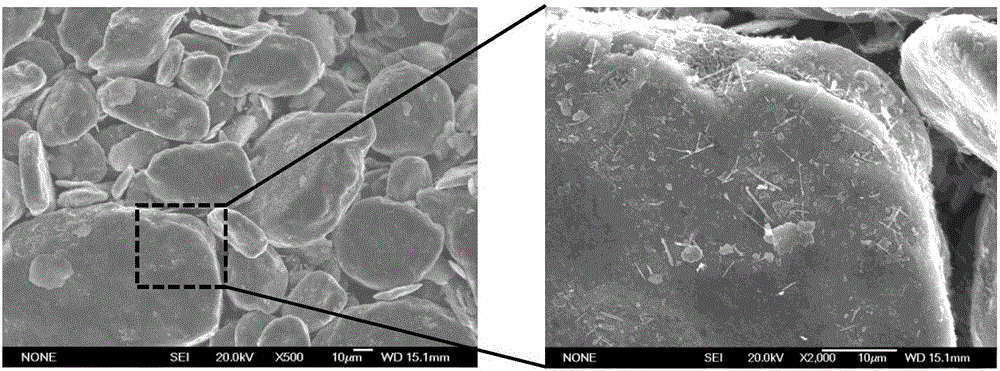

[0043] Preparation of a CNTs-SiC p Enhance AMCs.

[0044] Weigh 0.2223g of multi-walled carbon nanotubes with a diameter of 20nm-200nm and a length of 100nm-1cm, 0.3557g of silicon carbide with a particle size in the range of 20nm-150nm, and 59.4220g of aluminum raw powder with a particle size of 10-100μm. The volume percentages are 0.5%, 0.5%, and 99%, respectively. Put all the powders into a tungsten carbide ball mill jar, add 240g of 10mm in diameter and 60g of zirconia balls of 5mm in diameter, then add 1ml of absolute ethanol, exhaust with high-purity argon for 5min, and use planetary ball milling under argon atmosphere for 4h at 200rpm, every 10 minutes of ball milling with an interval of 10 minutes. The composite powder was packed in a graphite mold in an argon glove box, pressed into a block with a pressure of 10 MPa, and then sintered in a spark plasma sintering furnace at 630°C and 30 MPa for 1 hour. In a tube furnace under the protection of inert gas, the sample ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com