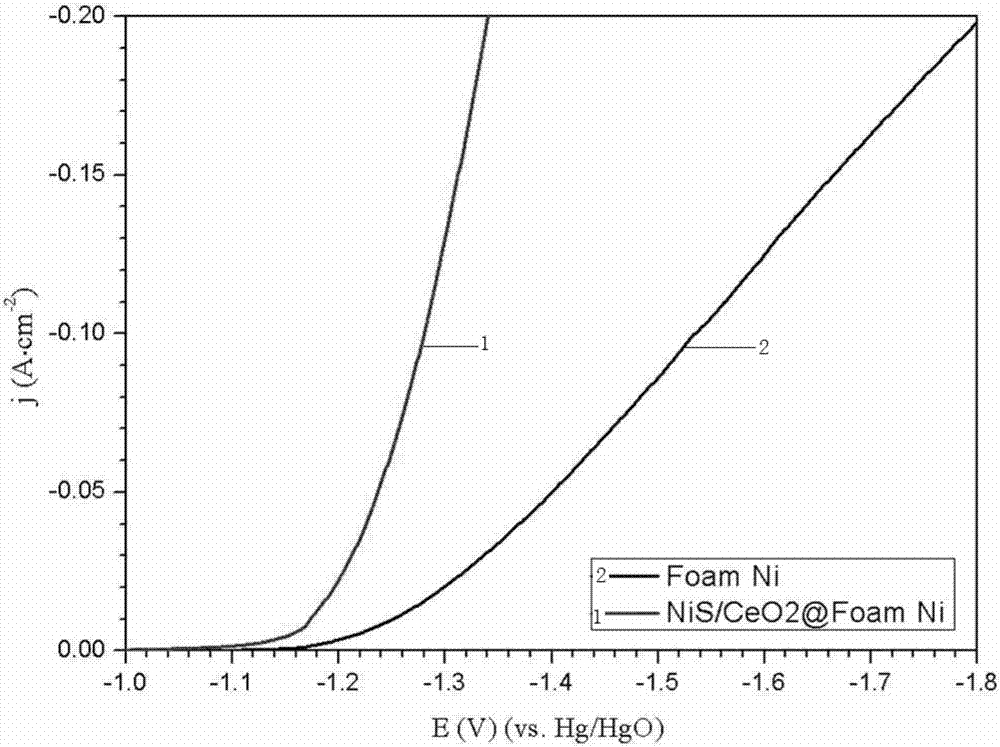

Nickel-sulfur composite hydrogen evolution electrode doped with foamed nickel load CeO2 and preparation method

A hydrogen evolution electrode and composite electrode technology, applied in electrodes, chemical instruments and methods, electrolytic coatings, etc., can solve the problems of low catalytic activity, high cost of hydrogen evolution electrodes, poor stability, etc., and achieve good hydrogen evolution catalytic performance and large price advantage , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

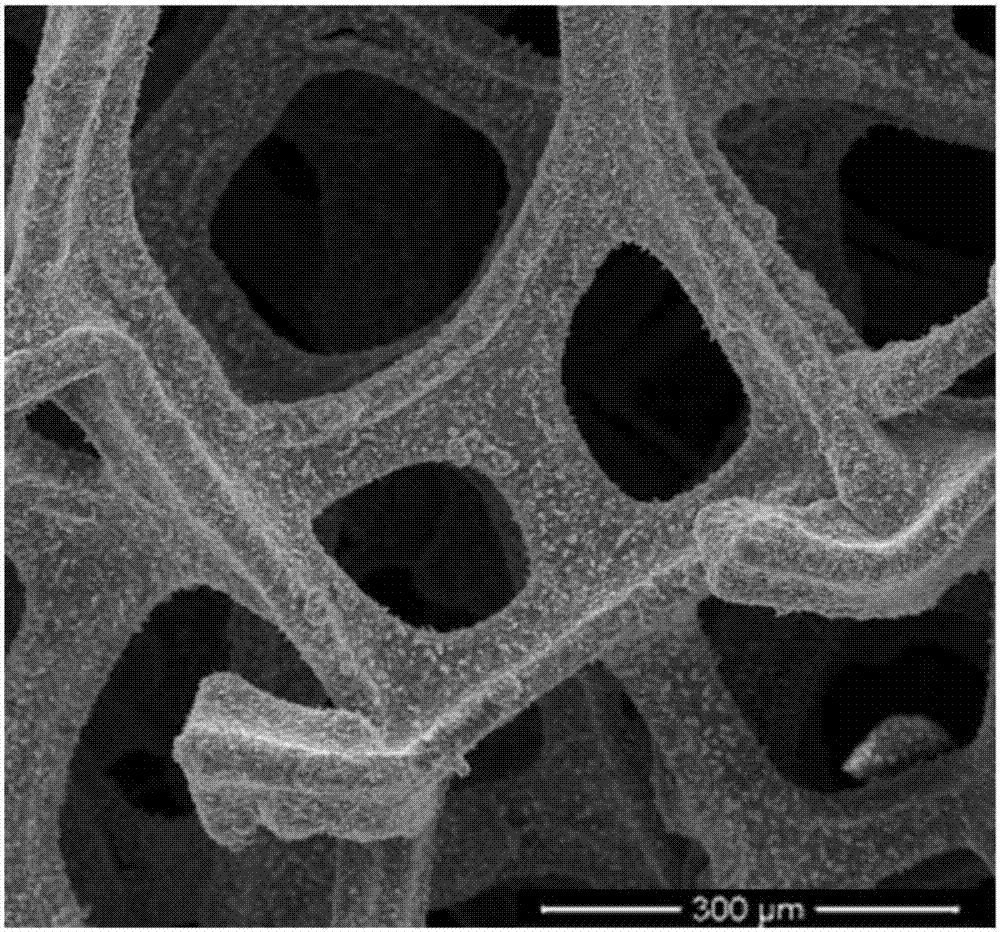

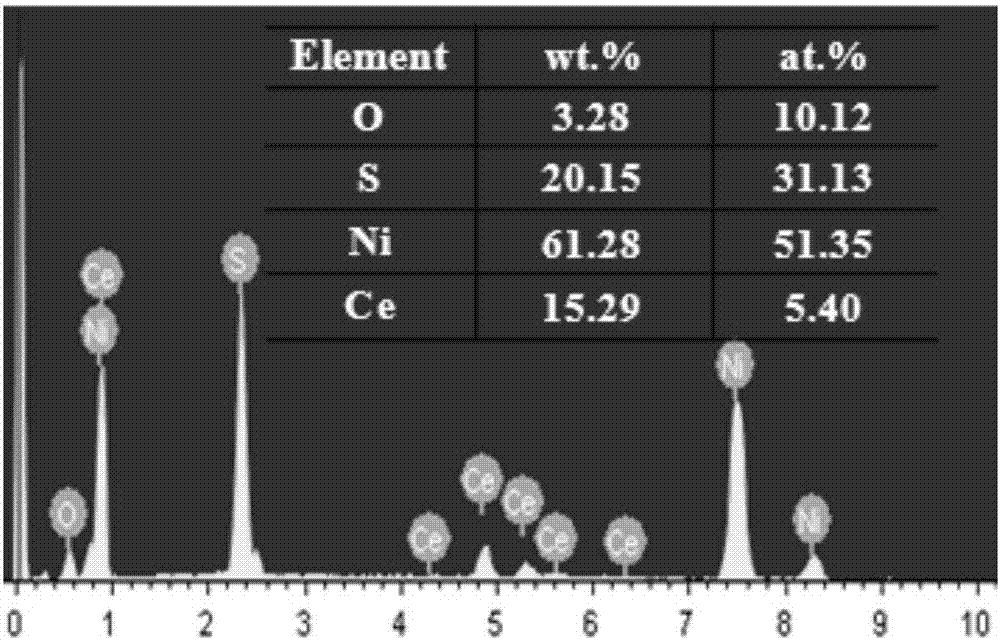

[0024] In this example, foamed nickel-based NiS / CeO 2 The preparation method of the composite electrode adopts a composite electrodeposition method to deposit a nickel-sulfur coating on the surface of the three-dimensional foamed nickel. At the same time, during the electrodeposition process, the nano-scale CeO in the composite plating solution was mixed by magnetic stirring. 2 Doped into the nickel-sulfur coating, the specific steps are as follows:

[0025] (1) Selection and pretreatment of nickel foam

[0026] The purity of the three-dimensional porous nickel foam is 99.9%, and the surface density is 480g / m 2 . At room temperature, degrease and degrease the nickel foam in acetone for 10 minutes, and clean it with ultrapure water; then, put it into 2M (molar concentration) HCl for acidification and activation treatment for 5 minutes; finally, put it into ultrapure water for ultrasonic cleaning for 2 minutes and bake Dry and set aside.

[0027] (2) Preparation of foamed n...

Embodiment 2

[0035] In this example, foamed nickel-based NiS / CeO 2 The preparation method of the composite electrode adopts a composite electrodeposition method to deposit a nickel-sulfur coating on the surface of the three-dimensional foamed nickel. At the same time, during the electrodeposition process, the nano-scale CeO in the composite plating solution was mixed by magnetic stirring. 2 Doped into the nickel-sulfur coating, the specific steps are as follows:

[0036] (1) Selection and pretreatment of nickel foam

[0037] The purity of the three-dimensional porous nickel foam is 99.9%, and the surface density is 550g / m 2 . At room temperature, the nickel foam was degreased and degreased in acetone for 10 minutes, and cleaned with ultrapure water; then, it was acidified and activated in 2M HCl for 5 minutes; finally, it was ultrasonically cleaned in ultrapure water for 2 minutes and dried for use.

[0038] (2) Preparation of foamed nickel-based NiS / CeO 2 Compound electrode

[0039]...

Embodiment 3

[0043] In this example, foamed nickel-based NiS / CeO 2 The preparation method of the composite electrode adopts a composite electrodeposition method to deposit a nickel-sulfur coating on the surface of the three-dimensional foamed nickel. At the same time, during the electrodeposition process, the nano-scale CeO in the composite plating solution was mixed by magnetic stirring. 2 Doped into the nickel-sulfur coating, the specific steps are as follows:

[0044] (1) Selection and pretreatment of nickel foam

[0045] The purity of the three-dimensional porous nickel foam is 99.9%, and the surface density is 500g / m 2 . At room temperature, the nickel foam was degreased and degreased in acetone for 10 minutes, and cleaned with ultrapure water; then, it was acidified and activated in 2M HCl for 5 minutes; finally, it was ultrasonically cleaned in ultrapure water for 2 minutes and dried for use.

[0046] (2) Preparation of foamed nickel-based NiS / CeO 2 Compound electrode

[0047]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com