Laser cladding coating powder and preparation method thereof

A laser cladding and powder technology, applied in coatings, metal material coating processes, etc., can solve the problems of easy volatilization and splashing, low powder quality, and difficulty in laser cladding of elemental aluminum, so as to reduce volatilization and splashing, The effect of grain refinement and good macroscopic appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

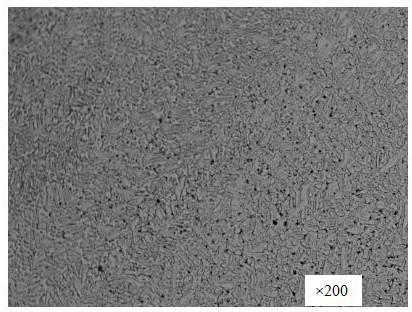

Embodiment 1

[0031] A laser cladding coating powder whose composition and mole fraction are: TiAl powder: 99%, B powder: 1%, the average particle size of TiAl powder is 100 mesh, the average particle size of B powder is 200 mesh, TiAl powder contains Ti and The atomic ratio of Al is 1:1.

[0032] The preparation method of laser cladding coating includes the following steps:

[0033] (1) Pretreatment of the substrate: polish and clean the metal substrate, and the specific steps of polishing and cleaning: the surface of the metal substrate is polished with 200 grit sandpaper and then polished with 400 grit sandpaper, and polished until the surface has no coarse scratches. Make sure the direction of the wear scar is the same and the surface is bright. Then clean with alcohol and acetone to remove the oxide film and oil stain on the surface of the metal substrate. After drying, the metal substrate is TC4 titanium alloy. The chemical composition is shown in Table 1.

[0034] (2) Weigh the laser cladd...

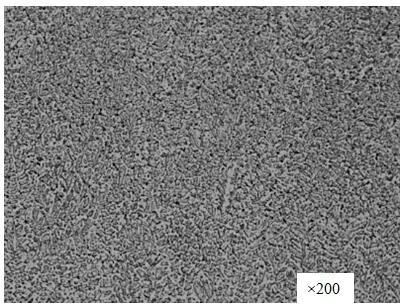

Embodiment 2

[0041] A laser cladding coating powder whose composition and mole fraction are: TiAl powder: 90%, B powder: 10%, the average particle size of TiAl powder is 120 mesh, the average particle size of B powder is 220 mesh, TiAl powder contains Ti and The atomic ratio of Al is 1:1.

[0042] The preparation method of laser cladding coating includes the following steps:

[0043] (1) Pretreatment of the substrate: polish and clean the metal substrate, and the specific steps of polishing and cleaning: the surface of the metal substrate is polished with 200 grit sandpaper and then polished with 400 grit sandpaper, and polished until the surface has no coarse scratches. Make sure the direction of the wear scar is the same, and the surface is bright, and then clean with alcohol and acetone to remove the oxide film and oil on the surface of the metal substrate. After drying, the metal substrate is TC4 titanium alloy, and its chemical composition is the same as that of Example 1.

[0044] (2) Weig...

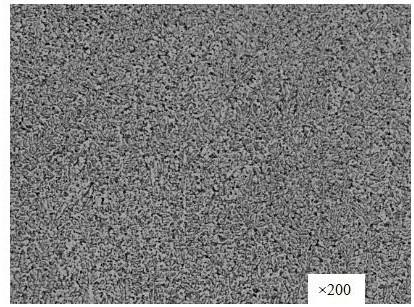

Embodiment 3

[0049] A laser cladding coating powder whose composition and mole fraction are: TiAl powder: 96%, B powder: 4%, the average particle size of TiAl powder is 150 mesh, the average particle size of B powder is 250 mesh, TiAl powder contains Ti and The atomic ratio of Al is 1:1.

[0050] The preparation method of laser cladding coating includes the following steps:

[0051] (1) Pretreatment of the substrate: polish and clean the metal substrate, and the specific steps of polishing and cleaning: the surface of the metal substrate is polished with 200 grit sandpaper and then polished with 400 grit sandpaper, and polished until the surface has no coarse scratches. Make sure the direction of the wear scar is the same, and the surface is bright, and then clean with alcohol and acetone to remove the oxide film and oil on the surface of the metal substrate. After drying, the metal substrate is TC4 titanium alloy, and its chemical composition is the same as that of Example 1.

[0052] (2) Weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com