A kind of melting flux for welding hsla steel and preparation method thereof

A technology for smelting flux and post-welding, which is applied in the field of smelting flux for welding HSLA steel and its preparation, which can solve the problems of pores in the weld metal, decrease in the mechanical properties of the weld, and increase the brittleness of the weld metal. Uniform texture, good weld formability, and good storability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The smelting flux provided by this embodiment consists of the following components in terms of mass percentage: CaF 2 59%, ZrO 2 20% and SiO 2 twenty one%.

[0065] The preparation method of the molten flux provided in this embodiment comprises the following steps:

[0066] (1), 590gCaF 2 , 200gZrO 2 and 210gSiO 2 Put it into the mixing equipment and stir to make it evenly mixed; then put the evenly mixed mixed material in a graphite crucible and melt it at a temperature of 1600°C for 30 minutes to obtain a smelted product; then water quench the smelted product to obtain a glass state mixture;

[0067] (2) Put the glassy mixture in a muffle furnace and bake it at 850°C for 4 hours to remove impurities such as carbon powder in the smelted flux; then crush and sieve the product obtained after roasting to obtain The particle size is 10~100 mesh melting flux.

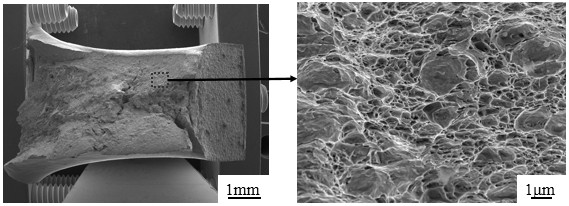

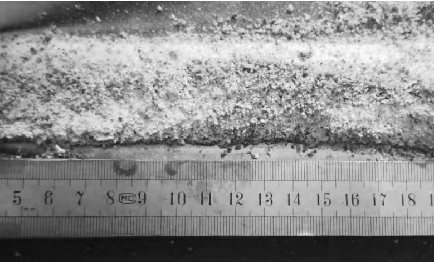

[0068] The smelting flux prepared in Example 1 was dried in a drying oven at a temperature of 300° C. fo...

Embodiment 2

[0070] The smelting flux provided by this embodiment consists of the following components in terms of mass percentage: CaF 2 60%, ZrO 2 20% and SiO 2 20%.

[0071] The preparation method of the molten flux provided in this embodiment comprises the following steps:

[0072] (1), 600gCaF 2 , 200gZrO 2 and 200gSiO 2 Put it into the mixing equipment and stir to make it evenly mixed; then put the evenly mixed mixed material in a graphite crucible and melt it at a temperature of 1630°C for 25 minutes to obtain a smelted product; then water quench the smelted product to obtain a glass state mixture;

[0073] (2) Put the glassy mixture in a muffle furnace and bake it at 800°C for 4 hours to remove impurities such as carbon powder in the melting flux; then crush and sieve the product obtained after roasting to obtain The particle size is 10~100 mesh melting flux.

[0074] The smelting flux prepared in Example 2 was dried in a drying oven at a temperature of 350° C. for 2 hour...

Embodiment 3

[0076] The smelting flux provided by this embodiment consists of the following components in terms of mass percentage: CaF 2 61%, ZrO 2 20% and SiO 2 19%.

[0077] The preparation method of the molten flux provided in this embodiment comprises the following steps:

[0078] (1), 610gCaF 2 , 200gZrO 2 and 190gSiO 2 Put it into the mixing equipment and stir to make it evenly mixed; then put the evenly mixed mixed material in a graphite crucible and melt it at a temperature of 1660°C for 30 minutes to obtain a smelted product; then water quench the smelted product to obtain a glass state mixture;

[0079] (2) Put the glass mixture in a muffle furnace and bake it at 900°C for 3.5 hours to remove impurities such as carbon powder in the melting flux; then crush and sieve the product obtained after roasting, The smelting flux with a particle size of 10-100 mesh is obtained.

[0080]The smelted flux prepared in Example 3 was dried in a drying oven at a temperature of 330° C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com