A kind of tial-based laser cladding superalloy coating and preparation method thereof

A laser cladding and base alloy technology, which is applied in the coating process and coating of metal materials, can solve the problems of room temperature brittleness and high temperature oxidation resistance, hinder the application and promotion of TiAl base alloys, and achieve good high temperature oxidation resistance , Saving cladding efficiency and reducing the effect of crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

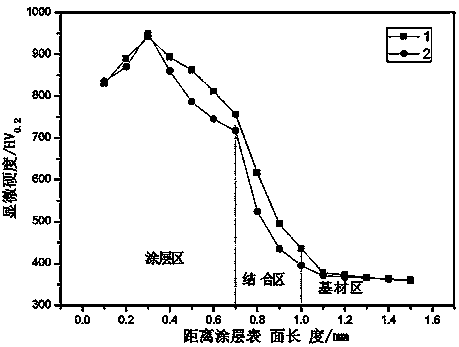

Image

Examples

Embodiment 1

[0024] In this example, the surface modification materials of high-temperature parts are composed of Al, P, Ti, Nb, Zr, Y, and Ce. Specifically, the mass fraction of cladding powder is as follows: Al: 49%, P: 2%, Ti: 33%, Nb : 5%, Zr: 7%, Y: 2%, Ce: 2%.

[0025] The preparation method of the TiAl-based alloy laser cladding coating described in this implementation specifically includes the following steps:

[0026] (1) After mixing the cladding powder, perform ball milling (180 mesh) and dry to obtain a uniformly mixed cladding powder;

[0027] (2) Pretreatment of the TiAl alloy substrate: grinding the surface, decontamination, and drying for later use;

[0028] (3) The cladding powder obtained in step (1) is made into a strip-shaped preset layer (60mm×4mm×3mm in size), and the preset layer is placed on the surface of the TiAl alloy substrate. The surface of the TiAl alloy substrate and the preset layer are melted at the same time to form a coating. The process parameters of ...

Embodiment 2

[0031] In this example, the surface modification materials of high-temperature parts are composed of Al, P, Ti, Nb, Zr, Y, and Ce. Specifically, the mass fraction of cladding powder is as follows: Al: 46%, P: 2%, Ti: 37%, Nb : 5%, Zr: 7%, Y: 2%, Ce: 1%.

[0032] The preparation method of the TiAl-based alloy laser cladding coating described in this implementation specifically includes the following steps:

[0033] (1) After mixing the cladding powders, perform ball milling (160 mesh) and dry to obtain uniformly mixed cladding powders;

[0034] (2) Pretreatment of the TiAl alloy substrate: grinding the surface, decontamination, and drying for later use;

[0035] (3) The cladding powder obtained in step (1) is made into a strip-shaped preset layer (60mm×4mm×3mm in size), and the preset layer is placed on the surface of the TiAl alloy substrate. The surface of the TiAl alloy substrate and the preset layer are melted at the same time to form a coating. The process parameters of ...

Embodiment 3

[0041] In this example, the surface modification materials of high-temperature parts are composed of Al, P, Ti, Nb, Zr, Y, and Ce. Specifically, the mass fraction of cladding powder is as follows: Al: 52%, P: 2%, Ti: 34.2%, Nb : 5%, Zr: 4%, Y: 2%, Ce: 0.8%, the preparation method of the TiAl-based alloy laser cladding coating described in this embodiment is the same as that in Example 2, and the performance of the prepared material coating is the same as that in Example 2. 1 and 2 are similar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com