Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Reduce crystallization rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

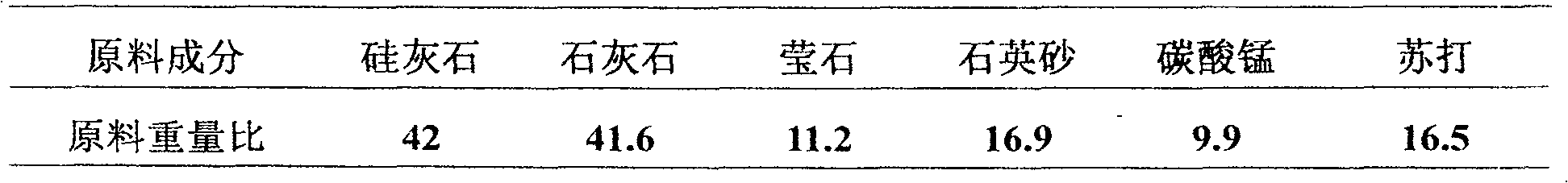

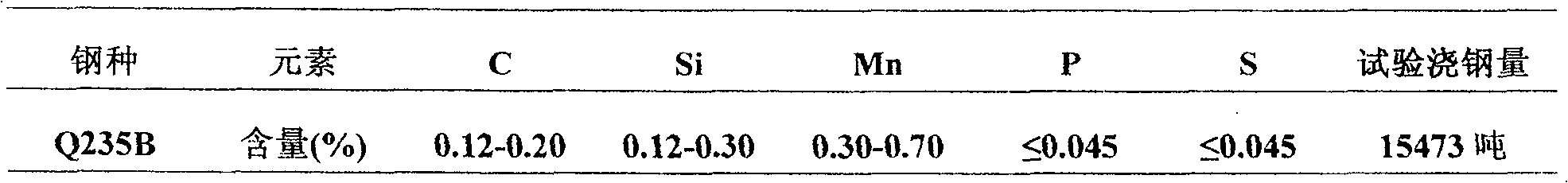

Crystallizer protecting cinder for continuous casting of crack sensitive steel and its prepn process

InactiveCN1974062AReduce crystallization rateLower crystallization temperatureProcess efficiency improvementManganese(II) carbonateWollastonite

The present invention provides one kind of crystallizer protecting cinder for continuous casting of crack sensitive steel and its preparation process. The protecting cinder is compounded with wollastonite, limestone, quartz sand, fluorite, industrial soda, manganese carbonate and carbon material. Chemically, it consists of CaO 28-42 wt%, SiO2 26-40 wt%, CaF2 10-20 wt%, Na2O 4-10 wt%, MnO2 2-8 wt%, Al2O3 0-6 wt%, and C 2-10 wt%, and has the weight ratio between CaO and SiO 2in 1.0-1.2. The crystallizer protecting cinder can reduce the heat transfer, maintain the crystallization rate and the crystallization temperature of protecting cinder, reduce longitudinal cracks in the surface of cast billet, and raise continuous casting efficiency and quality.

Owner:CHONGQING UNIV

Low-fiber-emergence low-warping high-tenacity flame-retardant PET/PETG composite material and preparation method

The invention discloses a low-fiber-emergence low-warping high-tenacity flame-retardant PET / PETG composite material and a preparation method, and relates to the field of high polymer materials. The composite material is prepared by mixing 30-50 parts of PET resin, 5-20 parts of PETG resin, 0.1-1 part of a coupling agent, 2-8 parts of a flexibilizer, 11-15 parts of a fire retardant, 0-1 part of a nucleating agent, 0.1-1 part of an antioxidant and 0.1-1 part of a lubricating agent, adding 15-30 parts of irregular-shaped glass fibers during the extrusion process of a twin-screw extruder, extruding, and pelletizing to obtain. The preparation method of the low-fiber-emergence low-warping high-tenacity flame-retardant PET / PETG composite material disclosed by the invention utilizes the characteristic that the PETG resin is well compatible with the PET resin; the addition of the flame-retardant system PETG, the flexibilizer and the nucleating agent greatly improves the processing performance, the surface performance and the impact performance of the composite material, while influencing the other performances a little; meanwhile, the addition of the PETG and the irregular-shaped glass fibers reduces the crystallization temperature and the crystallization rate of the material, and lowers the warping degree.

Owner:古道尔工程塑胶(深圳)有限公司

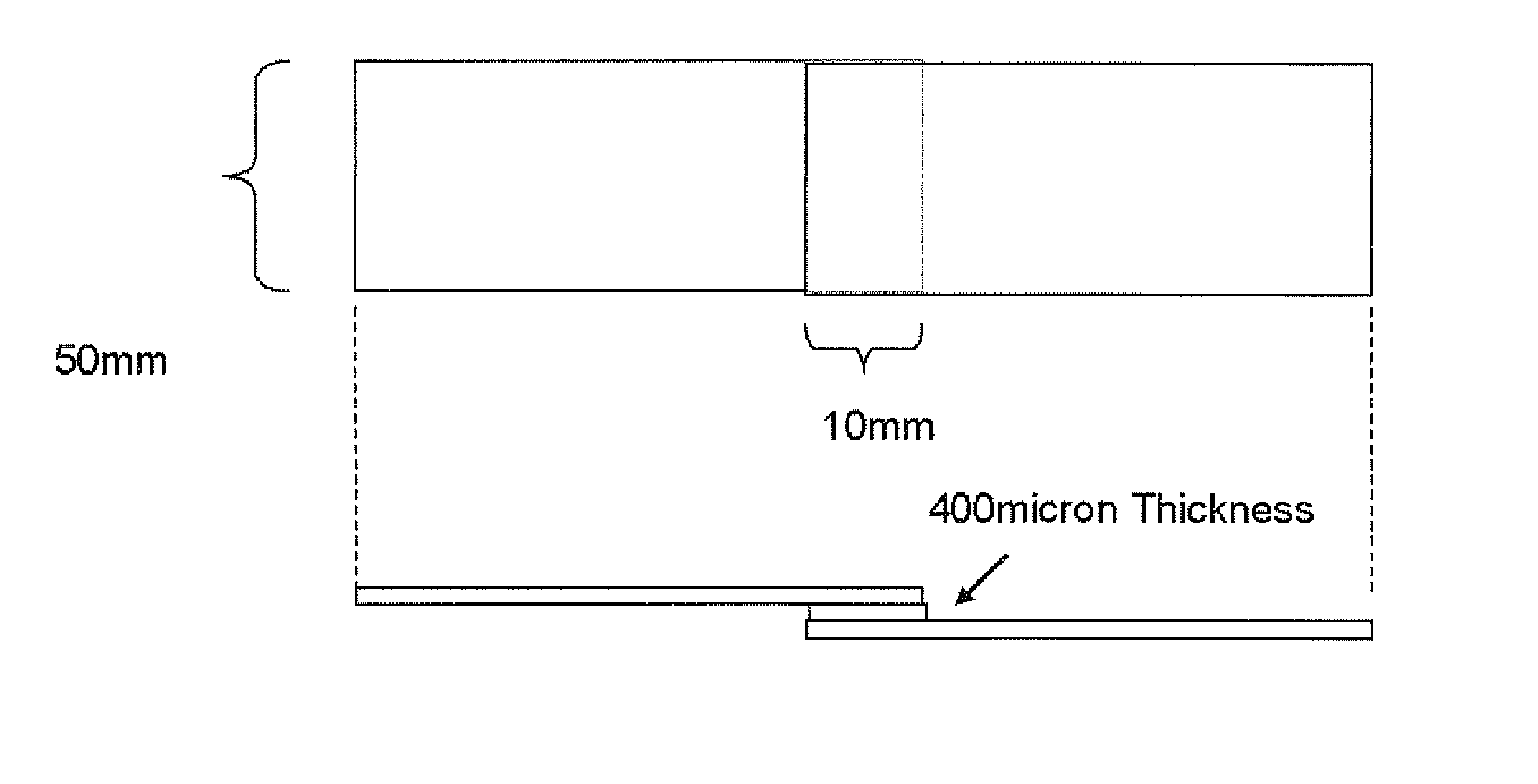

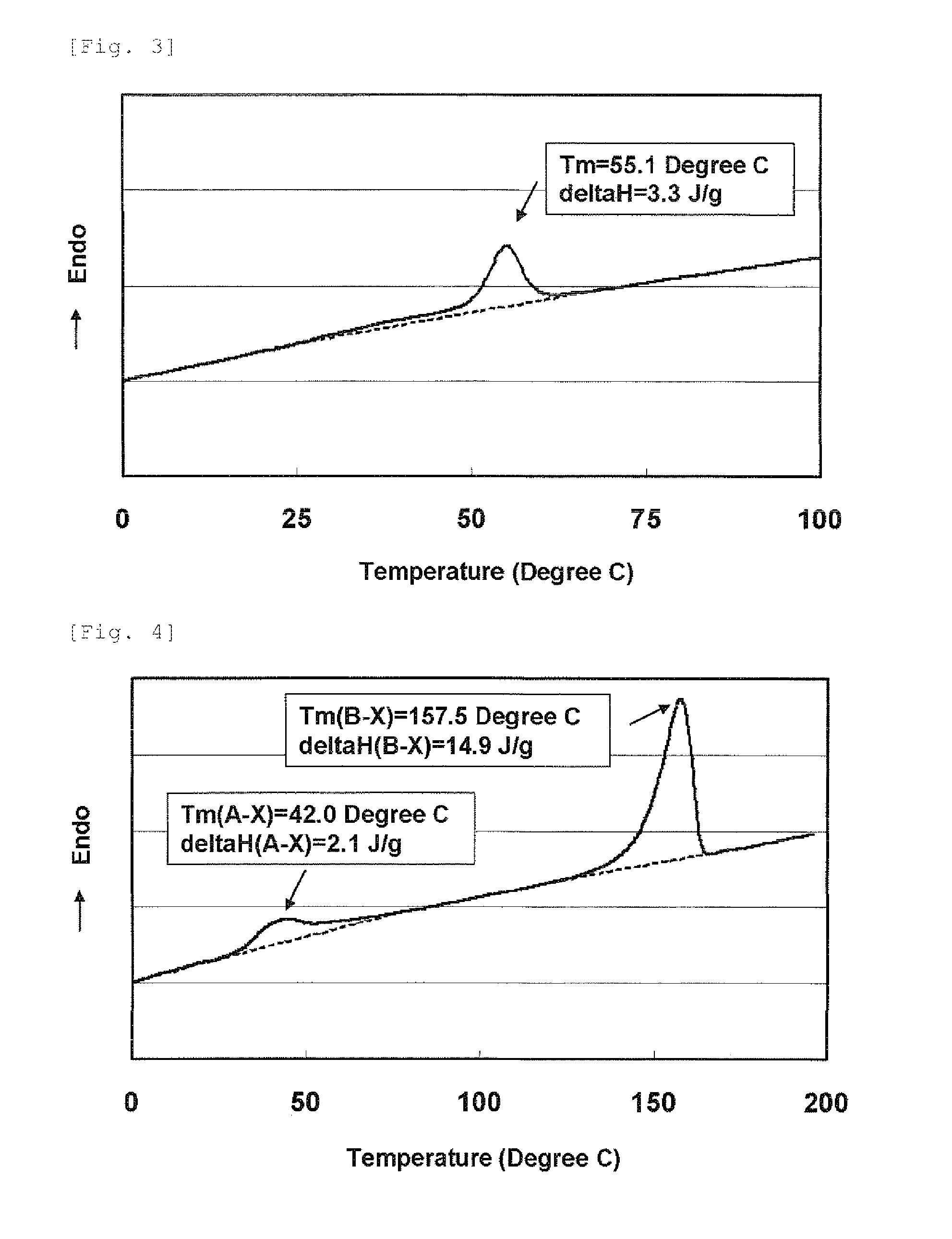

Adhesive composition and adhesive containing the same

ActiveUS20110172348A1Low crystallization rateLong open timeTransportation and packagingMixingPolypropyleneChemistry

It is an object of the present invention to provide adhesive compositions having excellent flexibility, rubber elasticity, mechanical properties, heat resistance and low-temperature properties.An adhesive composition of the invention includes 10 to 70 parts by weight of a soft polypropylene resin composition (X) which includes 40 to 98 wt % of a propylene copolymer (A) satisfying the following requirements (A1) to (A8) and 2 to 60 wt % of a crystalline isotactic polypropylene (B) satisfying the following requirements (B1) to (B3), and 30 to 90 parts by weight of a tackifier (C) (wherein the total of the component (X) and the component (C) is 100 parts by weight), wherein (A1) Shore A hardness: 20 to 90; (A2) the copolymer comprises a copolymer with C3 units at 51 to 90 mol %, C2 units at 7 to 24 mol % and C4-20 α-olefin units at 3 to 25 mol %; (A3) Mw / Mn: 1.2 to 3.5; (A4) mm: 85 to 99.9%; (A5) value B: 0.8 to 1.3; (A6) 2,1-insertion ratio: less than 1%; (A7) Tg: −10° C. to −50° C.; (A8) MFR (230° C.): 0.5 to 500 g / 10 min; (B1) Tm: 100 to 175° C.; (B2) mmmm: 90 to 99.8%; (B3) MFR (230° C.): 0.1 to 100 g / 10 min.

Owner:MITSUI CHEM INC

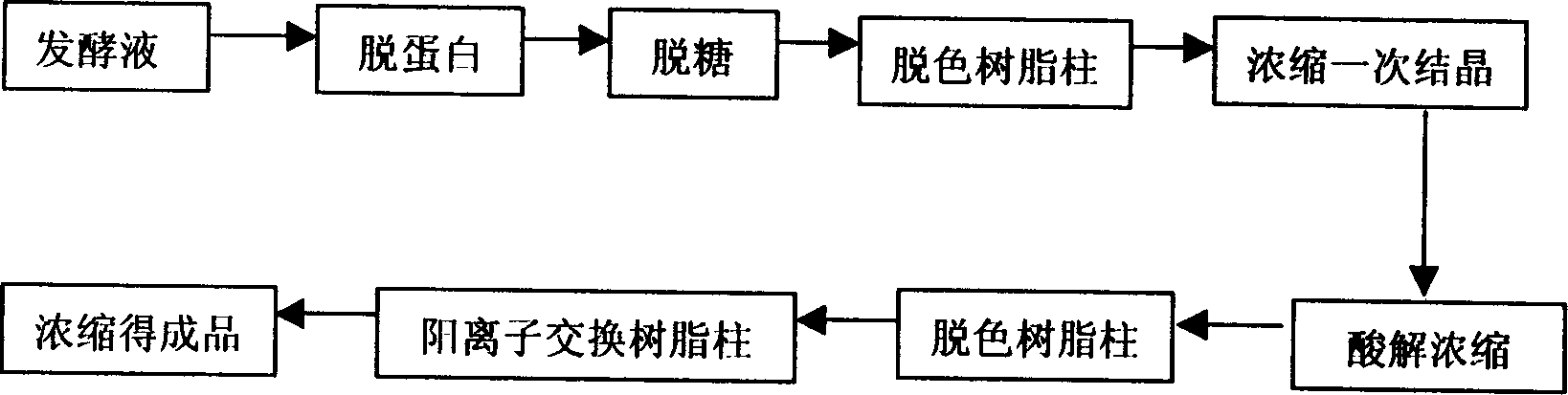

Process for extracting lactic acid from fermentation liquid

InactiveCN1603298AHigh removal rateHigh extraction rateCarboxylic compound separation/purificationCrystallinityFermentation

This invention relates to a technical proposal of producing lactic acid by deep layer fermentation, that is the proposal of extracting lactic acid from fermentation liquor. The features are that desugarization and decoloration are done by using granular active carbon and H-103 resin column. Two times consumption of heat is adopted, that is the temperature reduces from 300C to 15, then from 150C to 40C, and calcium lactate is extracted through once crystallization. The loss of lactic acid is much reduced and the technology continuance is realized by this invention. The extraction rate and purity are raised, the percent crystallinity can reach 80%, purity 97.2%, the extraction rate of lactic acid exceeds 70% and stability of finished product lactic acid is good.

Owner:HEFEI UNIV OF TECH

Resin composition for refrigerant-transporting hose and method of producing the resin composition, and refrigerant-transporting hose

ActiveUS20130056107A1Improve the immunityReduce crystallization rateMaterial nanotechnologyLayered productsElastomerAramides

A resin composition for a refrigerant-transporting hose, including: a semi-aromatic polyamide resin (A) as a main component; an aliphatic polyamide resin (B); and an elastomer (C), in which the aliphatic polyamide resin (B) is dispersed in a phase formed of the semi-aromatic polyamide resin (A) and the elastomer (C), which is not crosslinked, is incorporated in the form of particles into the dispersed aliphatic polyamide resin (B). Thus, excellent refrigerant permeation resistance and acid resistance, and at the same time, for example, extrusion processability and flexibility, are obtained.

Owner:SUMITOMO RIKO CO LTD

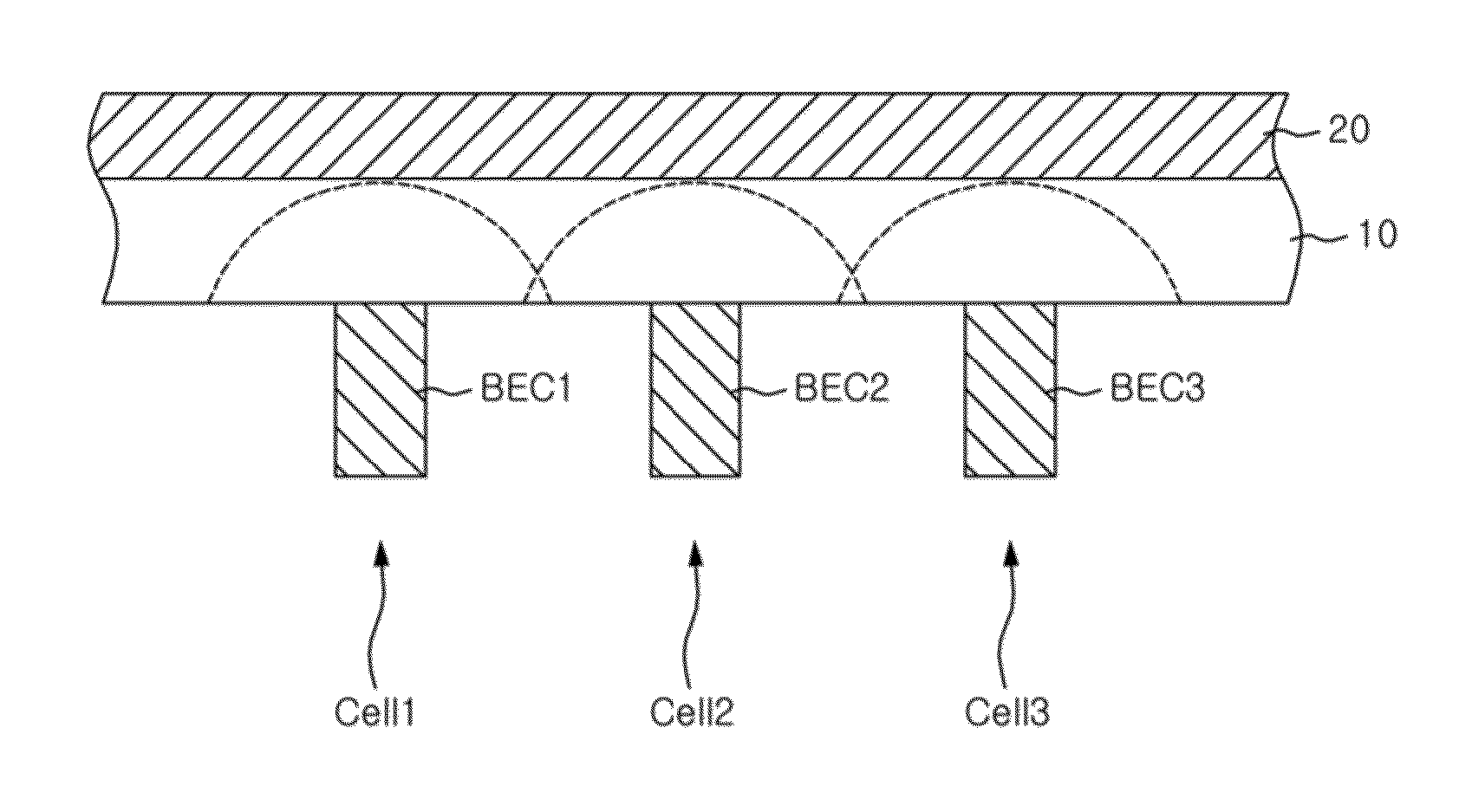

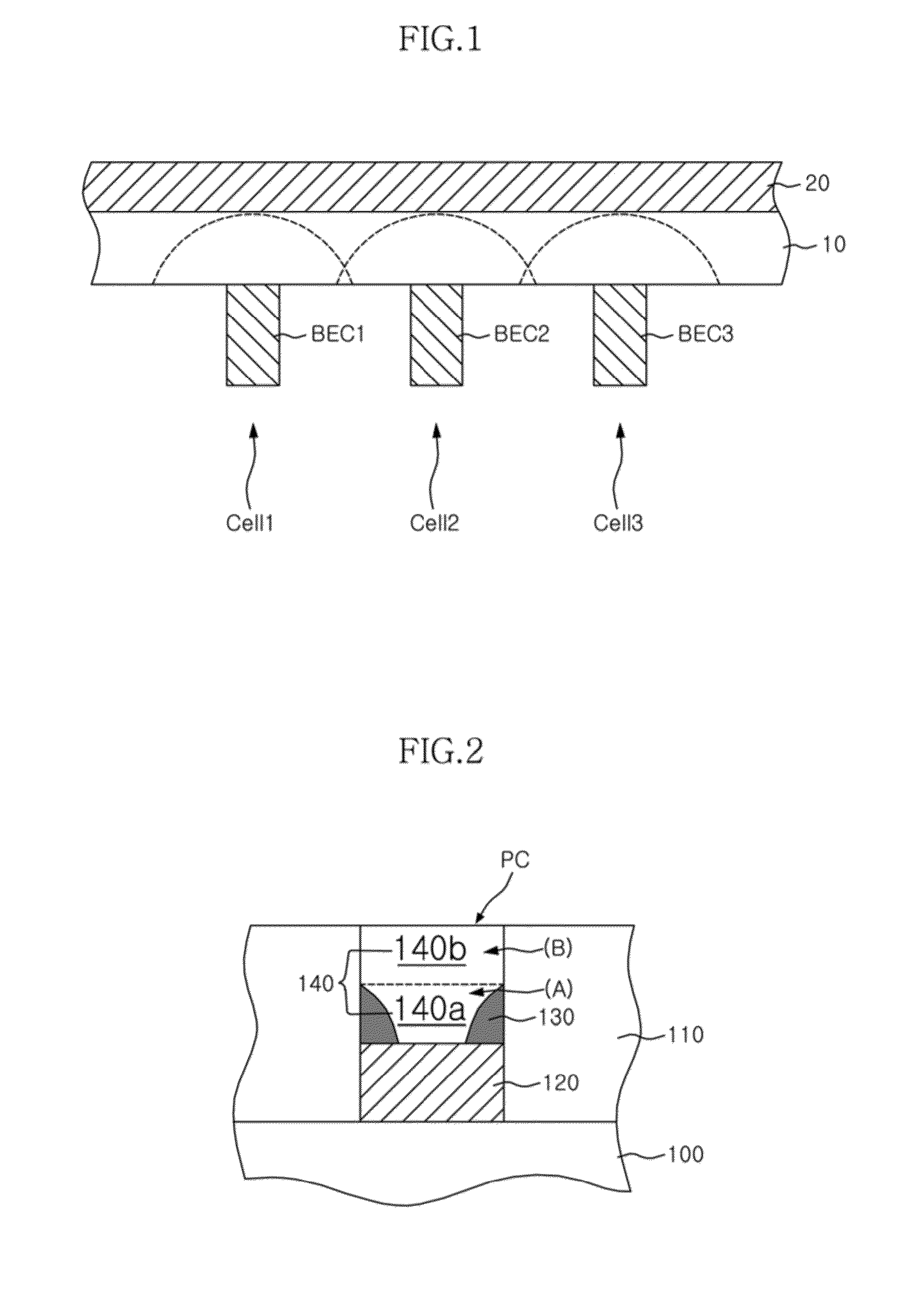

Phase-change memory device having phase-change region divided into multi layers and operating method thereof

InactiveUS20140301137A1Small resistivityReduce crystallization rateSolid-state devicesDigital storagePhase-change memoryEngineering

A phase-change memory device including a multi-level cell and an operation method thereof are provided. The device includes a first phase-change material layer to which a current is provided from a heating electrode, and a second phase-change material layer formed with continuity to the first phase-change material layer and having a different width from the first phase-change material layer, and to which a current is provided from the heating electrode. The second phase-change material layer includes a material having smaller resistivity and a lower crystallization rate than the first phase-change material layer.

Owner:SK HYNIX INC

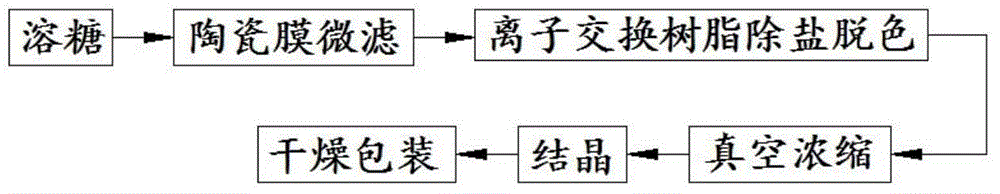

Production process of poly-crystal rocky candy

The invention discloses a production process of poly-crystal rocky candy. The production process comprises the following six steps: by taking first-grade white sugar as a raw material, dissolving the sugar, micro-filtering and clarifying, desalting and decolorizing by using ion exchange resin, concentrating in vacuum, charging seeds for crystallization, drying and packaging to produce the poly-crystal rocky candy. The poly-crystal rocky candy produced by the method disclosed by the invention is sweet and delicious in taste and white and transparent in color and luster; no sodium hydrosulfite is added for color protection during the overall production, so the product is environmental friendly and safe; the crystallization rate of the rocky candy is above 95%; the problem of low crystallization rate during production of the poly-crystal rocky candy for a long time is solved.

Owner:GUANGXI UNIV

Purification technology for trichloroacetone

InactiveCN105130780AReduce exposureReduce pollutionCarbonyl compound separation/purificationSolventCrystallization

The invention provides a purification technology for trichloroacetone, and belongs to the technical field of compound purification. According to the technology, crude trichloroacetone with the purity of 42-53% is adopted as the raw materials, recrystallization is performed on the crude trichloroacetone through mixed solvent of water and petroleum ether in a reaction kettle, filtering and washing are performed, and then the purified trichloroacetone is obtained; washing is directly performed in the reaction kettle by adopting a filtering mode through closed washing, a filter screen is arranged at a discharging opening in the bottom of the reaction kettle, filtrate is drained into a filtrate storage tank through the discharging opening in the bottom of the reaction kettle after recrystallization is completed, filter cake washing is performed by adding the petroleum ether into the reaction kettle after the filtrate is drained completely, washing is performed for once again, the washed filtrate is drained into the filtrate storage tank, the discharging opening in the bottom of the reaction kettle is closed after washing is completed, and the purified trichloroacetone is obtained. According to the purification technology, the purity of the trichloroacetone is high, and compared with the prior art, the yield can be improved by 2% when the purified trichloroacetone is applied to folic acid production.

Owner:JIHENG PHARMA HENGSHUI CITY

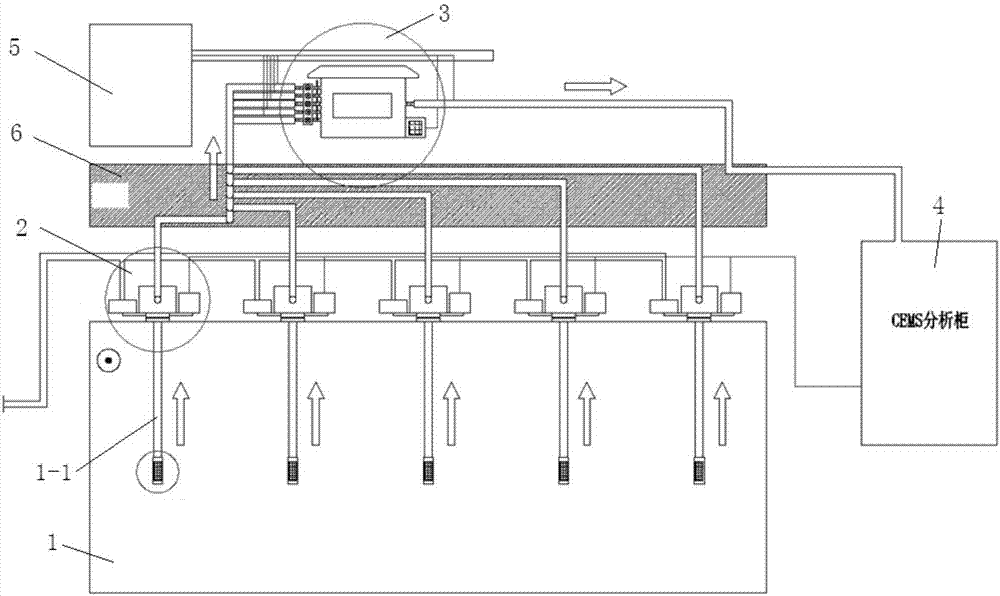

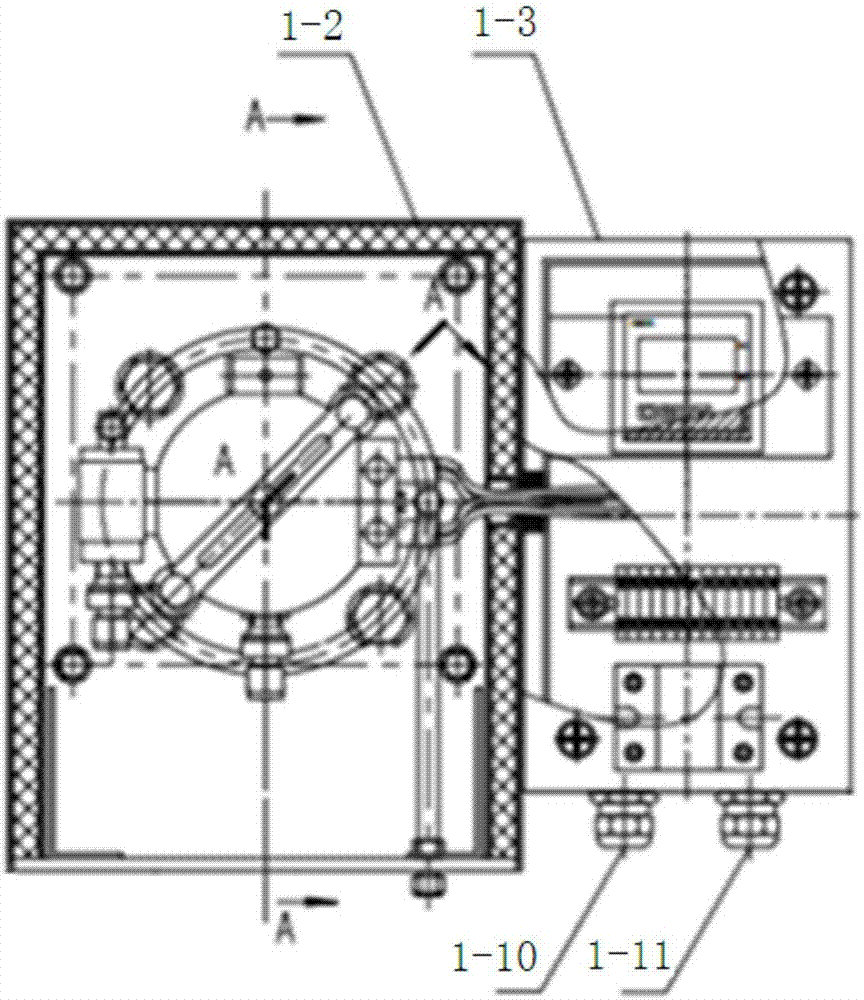

Gaseous pollutant multi-point matrix mixed sampling device, sampling method thereof and reverse blowing maintenance method

ActiveCN107421790ASolve the problem of unrepresentative samplingMixed average concentration is reasonableWithdrawing sample devicesAir quality improvementFlue gasFiltration

The invention discloses a gaseous pollutant multi-point matrix mixed sampling device, a sampling method thereof and a reverse blowing maintenance method. The device comprises a flue gas duct, a plurality of high-temperature sampling probes are uniformly arranged on the outer side of the pipe wall of the flue gas duct along the same section of a pipe, gaseous pollutants are conveyed into a rear-end mixing box by a 180-DEG C high-temperature heat tracing pipe, mixed and then conveyed into an analysis cabinet. The sampling device solves the problems that single-point flue gas sampling is non-representative, a sampling section of an existing sampling device is blocked by dust, and sampling of a sampling end does not meet standards. According to the whole multi-point matrix mixed sampling device, each probe is individually filtered, two-stage filtration is performed, namely, a front feeler lever is provided with a sintered metal filtering screen, middle high-temperature sampling probes are provided with sintered ceramic filter elements, and dust in flue gas is further prevented from entering the pipe.

Owner:NANJING YOUZHI TECH CO LTD

Sleeve molding

InactiveUS7615176B2Cost-effectiveControl over the amounts of materialsOther chemical processesMouldsBlow moldingWhole body

Sleeve molding apparatus and methods for making multi-layer injection molded plastic articles in successive mold cavities. In a first molding step, an inner sleeve is molded on a core in a first mold cavity, which may comprise a full body length sleeve or only a partial sleeve, such as an upper neck finish portion. The sleeve and core are withdrawn from the first mold cavity while the sleeve is still warm, and transferred without substantial delay to a second mold cavity for injection molding an outer layer which bonds to the inner sleeve. By transferring the sleeve at an elevated temperature into the second mold cavity, an improved bond is formed between the inner sleeve and outer layer which resists separation during a later reheat stretch blow molding step, and / or in use of the resulting article. In a preferred embodiment, a pasteurizable beer container is provided having a finish-only sleeve of a PEN polymer. In a second embodiment, a returnable and refillable water container is provided having a full-length body sleeve of a PEN polymer. A multi-station injection molding apparatus is provided having a transfer mechanism, such as a rotatable turret or reciprocating shuttle, for cost-effective manufacture of preforms simultaneously in multiple cavity sets.

Owner:GRAHAM PACKAGING PET TECH

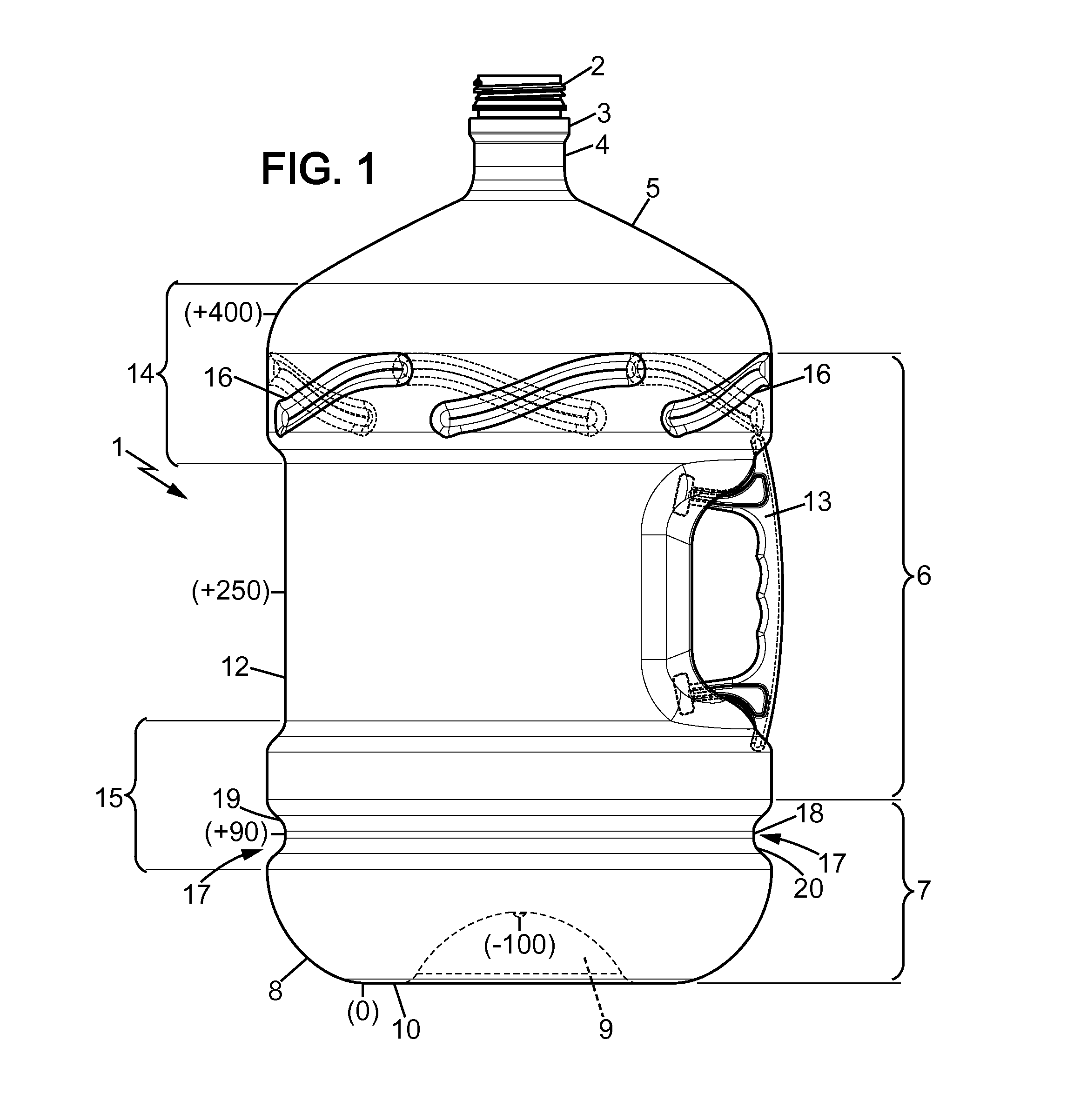

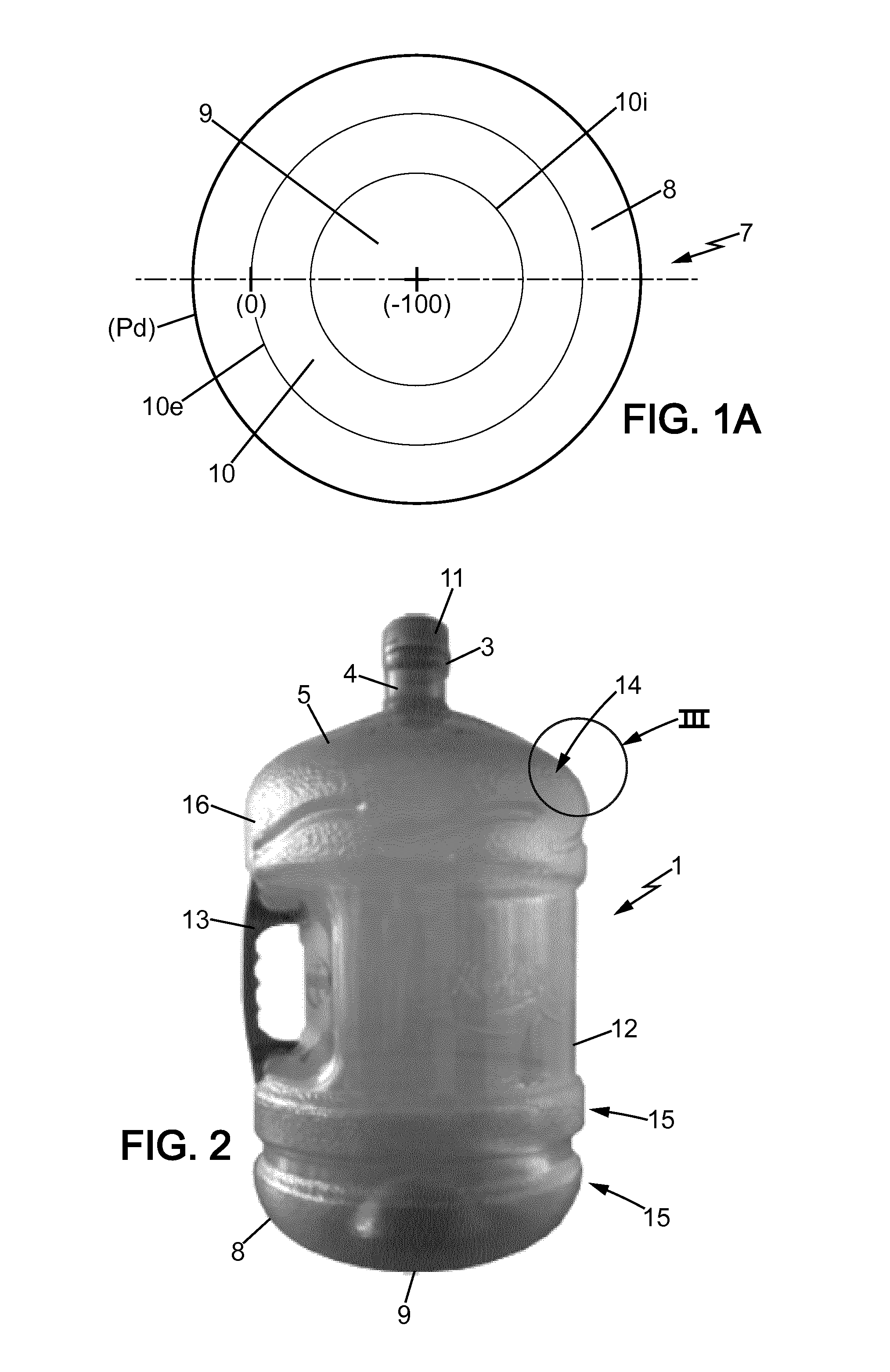

Blow Moulded Bottle, Method of Manufacturing and Mould

InactiveUS20150151869A1Increase crystallization rateGood mechanical resistanceBottlesContainer/bottle contructionEngineeringMedian plane

A blow moulded plastic bottle includes a neck, a shoulder, a tubular body portion, and an integral bottom structure including: a terminal curved portion, an internal axially inwardly directed dome, and an (annular) base joining the terminal curved portion to the dome; wherein: a spline comprises a flat part in the base plane (Pb) onto the bottle rests when it stands up; the height (h1) between (Pb) and the apex of the dome, the height (h2) between (Pb) and the spline diametral median plane (Pd) which is in the middle of the spline (17) and which is parallel to (Pb), and the maximum external diameter (Dm) of the tubular body portion, being so that [(h1) / (Dm)]*100 is comprised between 14.0 and 16.0% and (h1)<(h2)≦3.5(h1).

Owner:DES EAUX MINERALES DEVIAN

Glass fiber, composition for producing the same, and composite material comprising the same

A composition for producing a glass fiber, including the following components with corresponding percentage amounts by weight: SiO2: 57.1-61.4%; Al2O3: 17.1-21%; MgO: 10.1-14.5%; Y2O3: 1.1-4.3%; CaO: <6.5%; Li2O+Na2O+K2O: ≤1%; Li2O: ≤0.75%; TiO2: <1.8%; and Fe2O3: 0.05-1.2%. The total weight percentage of the above components in the composition is greater than or equal to 98%. The weight percentage ratio of Al2O3 to SiO2 is greater than or equal to 0.285. The invention also provides a glass fiber produced using the composition and a composite material including the glass fiber.

Owner:JUSHI GRP CO

Low-shrinkage silane cable material and preparation method thereof

The invention discloses a low-shrinkage silane cable material and a preparation method thereof. The cable material comprises the following components in parts by weight: 100 parts of polyethylene resin, 3-10 parts of ethylene-propylene copolymer resin, 1-5 parts of ethylene-octene copolymer resin, 1-5 parts of silane cross-linking agent, 0.02-0.05 part of initiating agent and 4-10 parts of catalytic masterbatch, wherein the catalytic masterbatch further comprises the following components in parts by weight: 100 parts of polyethylene resin, 0.5-1 part of low temperature catalyst, 1-2.5 parts ofantioxidant, and 0.5-1 part of lubricant. The cable material can effectively solve the problems of an existing cable material that in the production of the cable, the shrinkage rate is large, the production efficiency is low, the rejection rate is high, and the energy consumption is large.

Owner:成都鑫成鹏高分子科技股份有限公司

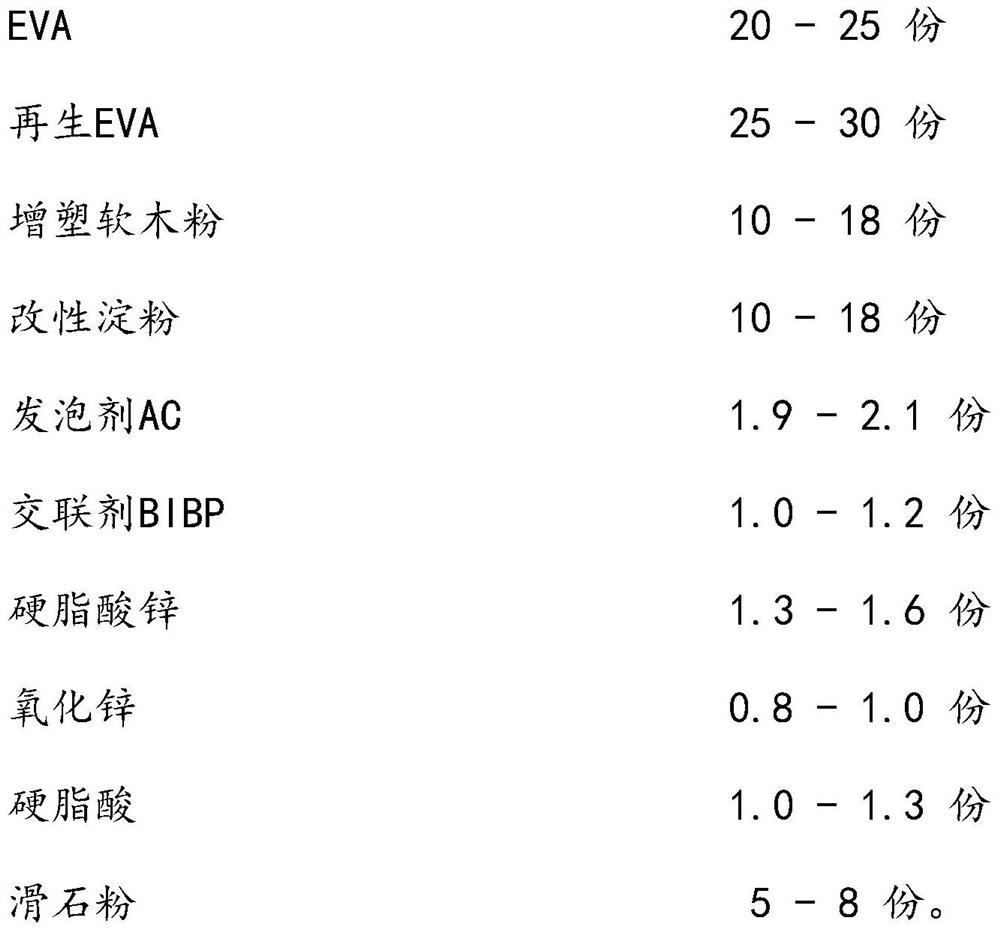

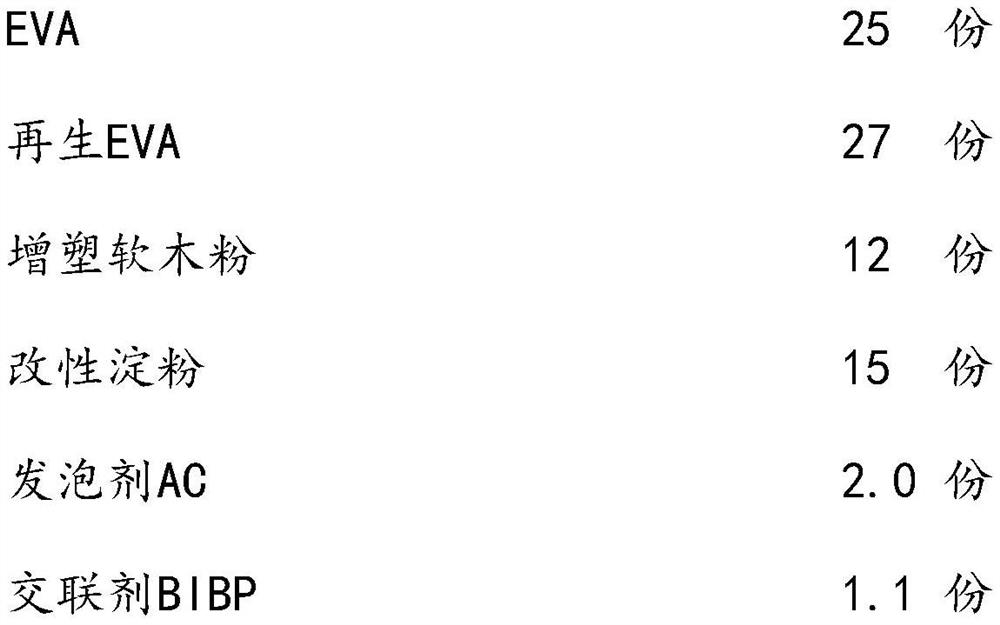

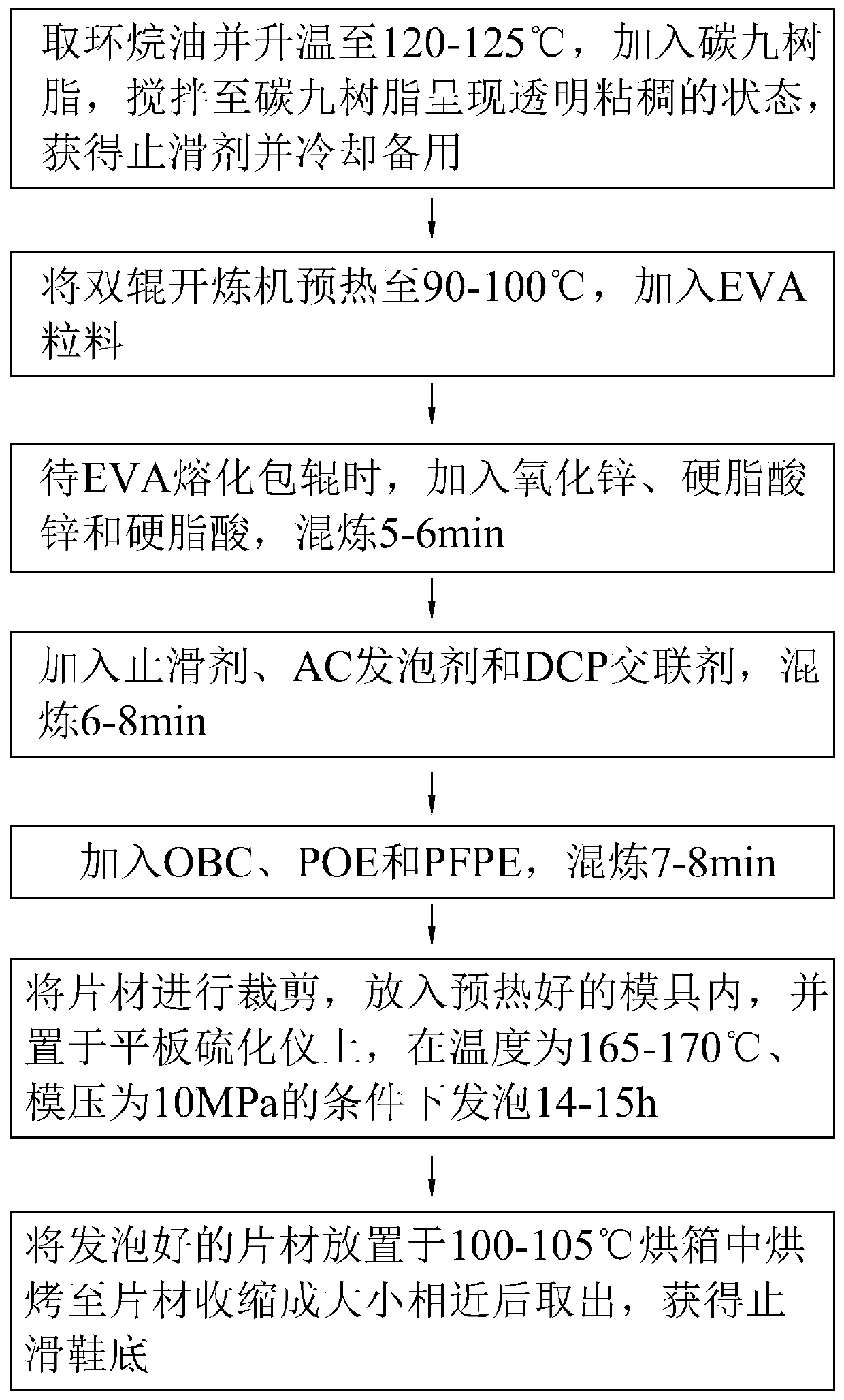

Preparation method of secondary mold pressing foaming sole

ActiveCN112157861ASolve the cooling effectResolution timeDomestic articlesPolymer scienceMolding machine

The invention discloses a preparation method of a secondary mold pressing foaming sole. The preparation method comprises the following steps: a) preparing EVA (Ethylene Vinyl Acetate) foam granules; b) conducting mold pressing foaming on the EVA foam granules obtained in the step a), wherein the first foaming ratio is 140%-185%, the foaming temperature is 172 DEG C-182 DEG C, conducting automaticmold opening after foaming is completed, and obtaining a foaming primary blank with the surface temperature not lower than 130 DEG C; an c) putting the foaming primary blank with the surface temperature not lower than 130 DEG C into an oil pressure mold, closing the mold, pushing the mold into a heating station of a secondary foaming forming machine, and conducting pressurizing and heating, wherein the ratio of the oil pressure mold is 135%-180%, the temperature is 170 DEG C-180 DEG C, and the time is 20 seconds-100 seconds; and then transferring the oil pressure mold to a cooling station, conducting pressurizing, spraying water to cool the mold, setting the mold for 150 seconds-400 seconds, pulling out the mold, taking out a finished product, and obtaining the foaming sole, wherein the first foaming ratio is greater than the foaming ratio of the oil pressure mold. According to the preparation method, after primary foaming, the product is immediately transferred to the oil pressure mold, the oil pressure heating foaming time is shortened, the energy consumption is reduced, and embossing is easy.

Owner:MAOTAI FUJIAN SOLES CO LTD

Glass ceramic material and preparation method thereof

InactiveCN104386917AImprove reflectivityReduce crystallization rateOxide ceramicAlkaline earth oxides

The invention relates to a glass ceramic material and a preparation method thereof. The preparation method comprises the following steps: (1) preparing raw materials according to the following mass ratio: 30-40% of a glass material, 30-50% of oxide ceramic powders and 10-30% of alkaline earth metal oxide; (2) carrying out a first heat treatment on the raw materials at 650-700 DEG C, carrying out a second heat treatment at 680-750 DEG C and carrying out a third heat treatment at 700-750 DEG C to obtain the glass ceramic material. The glass ceramic baseplate prepared by adopting the preparation method is high in reflectivity and low in crystallization rate of the glass phase, and has the excellent luminescence property.

Owner:华文蔚

EVA sole and preparation method thereof

ActiveCN111154170AImprove heat resistanceEasy to processSolesTextile/flexible product manufacturePolymer scienceEngineering

The invention discloses an EVA shoe sole and a preparation method thereof. The EVA shoe sole is prepared from, by weight, 60-70 parts of EVA, 8-10 parts of OBC, 12-15 parts of POE, 1-2 parts of an ACfoaming agent, 1-2 parts of a cross-linking agent and 2-3 parts of an activator. The OBC has good heat resistance, high elasticity and good processability, and can provide excellent resilience for anEVA foaming system, so that the EVA sole has high elasticity and is not prone to being compacted. By adding the POE, the resilience of the EVA sole can be further improved, the surface crystallizationrate of the material can be reduced, the problem that the surface of a traditional EVA foamed shoe material is prone to wrinkling is solved, and the attractiveness of the product is improved. Besides, OBC molecules and POE molecules inevitably form entanglement in a three-dimensional space, and the entanglement can limit movement of macromolecular chain segments like chemical crosslinking, so that the EVA sole is further not prone to being compacted, the surface of the EVA sole is not prone to wrinkling, and the use performance and the attractive performance are guaranteed.

Owner:DONGGUAN CHENGGUAN SPORT PROD TECH CO LTD

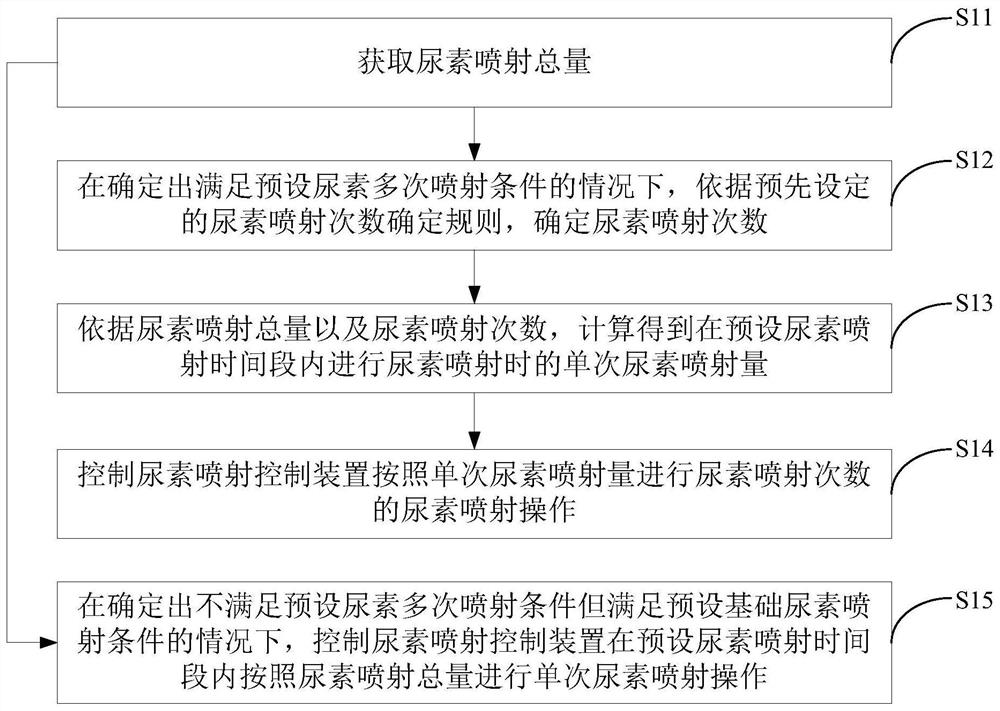

Urea injection control method and device and electronic device

ActiveCN111677579AReduce the probability of hitting a wallThe probability of hitting a wall is reducedInternal combustion piston enginesExhaust apparatusSingle injectionEngineering

The invention provides a urea injection control method and device and an electronic device. When urea injection is carried out and the preset condition of multiple urea injections is met, urea corresponding to the total urea injection amount is injected according to the determined urea injection frequency, the injection amount of each time is the single urea injection amount obtained through calculation according to the total urea injection amount and the urea injection frequency, and the injection frequency is the urea injection frequency. According to the urea injection control method and device and the electronic device, the urea can be injected in a multiple urea injection manner under the low-speed and low-load working condition, compared with the manner that urea injection is completed at a time, the injection amount of single injection is reduced, and the probability that the injected urea collides with a wall in an SCR system can be reduced; and meanwhile, the injection amountof single urea is reduced, heat needed by urea evaporation can be reduced, then the probability of urea crystallization can be reduced, and therefore the tail gas treatment efficiency of the SCR system is improved, the service life of the SCR system is prolonged, and the performance of the SCR system is improved.

Owner:WEICHAI POWER CO LTD

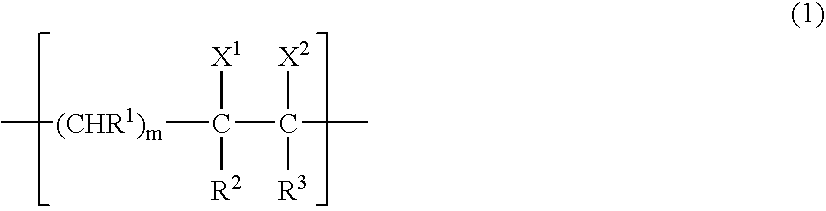

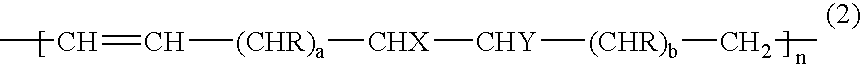

Gas-barrier resin composition

ActiveUS20070093599A1Reduce crystallization rateExcellent gas barrier performanceNon-fibrous pulp additionArylHydrogen atom

A resin composition includes a polymer (A) mainly containing a structural unit represented by following Formula (1): wherein m represents an integer of 2 to 10; X1 and X2 are each hydrogen atom, hydroxyl group or a functional group that can be converted into a hydroxyl group, wherein at least one of X1 and X2 is hydroxyl group or a functional group that can be converted into hydroxyl group; R1, R2 and R3 are each hydrogen atom, hydroxyl group, a functional group that can be converted into hydroxyl group, an alkyl group, an aryl group, an aralkyl group or a heteroaryl group, wherein the plural R1s may be the same as or different from each other; and a vinyl alcohol polymer (B).

Owner:CRYOVAC ILLC +1

Gas-barrier resin composition

InactiveUS20070021556A1Excellent gas barrier performanceReduce crystallization rateArylHydrogen atom

A resin composition includes a polymer (A) mainly containing a structural unit represented by following Formula (1): wherein m represents an integer of 2 to 10; X1 and X2 are each hydrogen atom, hydroxyl group or a functional group that can be converted into a hydroxyl group, wherein at least one of X1 and X2 is hydroxyl group or a functional group that can be converted into hydroxyl group; R1, R2 and R3 are each hydrogen atom, hydroxyl group, a functional group that can be converted into hydroxyl group, an alkyl group, an aryl group, an aralkyl group or a heteroaryl group, wherein the plural R1s may be the same as or different from each other; and a vinyl alcohol polymer (B).

Owner:CRYOVAC ILLC +1

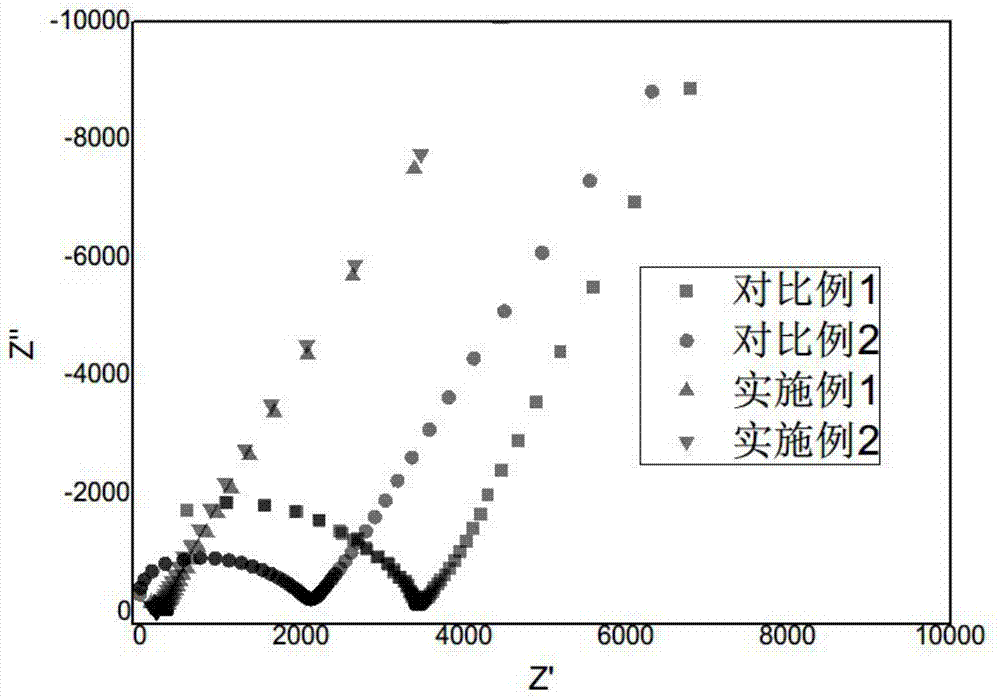

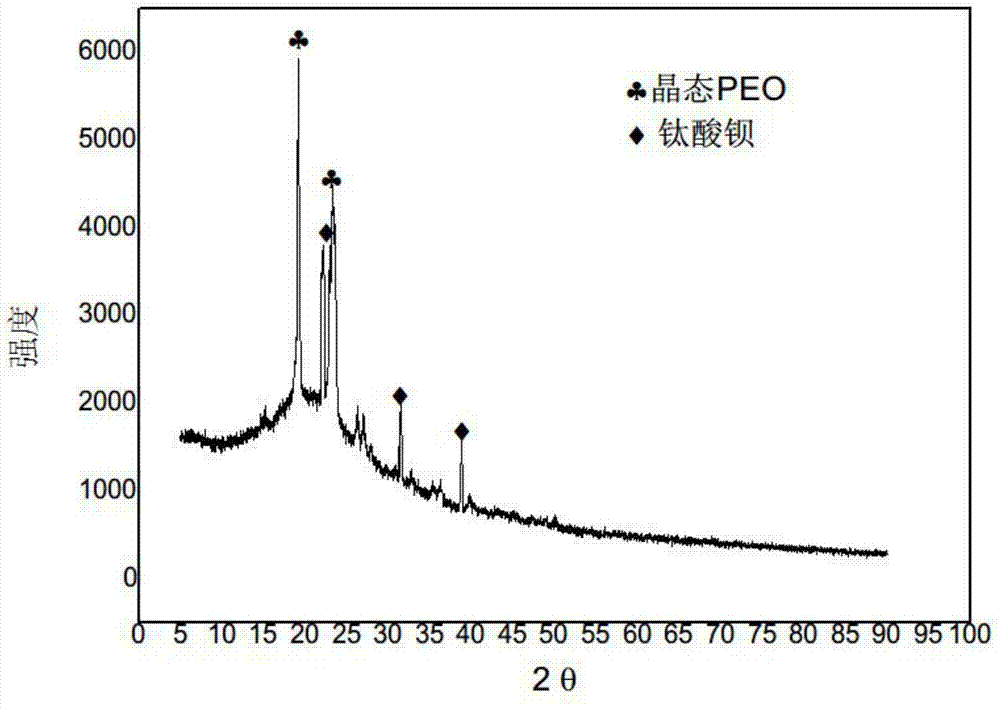

A kind of all-solid polymer electrolyte, its preparation method and application

InactiveCN104538670BImprove conductivityHigh mechanical strengthSolid electrolytesFinal product manufacturePolyethylene oxideNano al2o3

Owner:HUAZHONG UNIV OF SCI & TECH RES INST SHENZHEN

Process for extracting lactic acid from fermentation liquid

InactiveCN1241894CReduce lossesGood effectCarboxylic compound separation/purificationCrystallinityFermentation

This invention relates to a technical proposal of producing lactic acid by deep layer fermentation, that is the proposal of extracting lactic acid from fermentation liquor. The features are that desugarization and decoloration are done by using granular active carbon and H-103 resin column. Two times consumption of heat is adopted, that is the temperature reduces from 300C to 15, then from 150C to 40C, and calcium lactate is extracted through once crystallization. The loss of lactic acid is much reduced and the technology continuance is realized by this invention. The extraction rate and purity are raised, the percent crystallinity can reach 80%, purity 97.2%, the extraction rate of lactic acid exceeds 70% and stability of finished product lactic acid is good.

Owner:HEFEI UNIV OF TECH

Polyester resin composition and formed article including resin composition

Provided is a resin composition excellent in processability and productivity, which improves low crystallization rate and improves processability in forming such as injection molding or sheet forming. Provided is a polyester resin composition including a polyester resin (A), a crystallization promoter (B), and pentaerythritol (C).

Owner:KANEKA CORP

Crystallizer protecting cinder for continuous casting of crack sensitive steel and its preparation process

InactiveCN100563871CReduce crystallization rateLower crystallization temperatureProcess efficiency improvementManganese(II) carbonateWollastonite

The present invention provides one kind of crystallizer protecting cinder for continuous casting of crack sensitive steel and its preparation process. The protecting cinder is compounded with wollastonite, limestone, quartz sand, fluorite, industrial soda, manganese carbonate and carbon material. Chemically, it consists of CaO 28-42 wt%, SiO2 26-40 wt%, CaF2 10-20 wt%, Na2O 4-10 wt%, MnO2 2-8 wt%, Al2O3 0-6 wt%, and C 2-10 wt%, and has the weight ratio between CaO and SiO 2in 1.0-1.2. The crystallizer protecting cinder can reduce the heat transfer, maintain the crystallization rate and the crystallization temperature of protecting cinder, reduce longitudinal cracks in the surface of cast billet, and raise continuous casting efficiency and quality.

Owner:CHONGQING UNIV

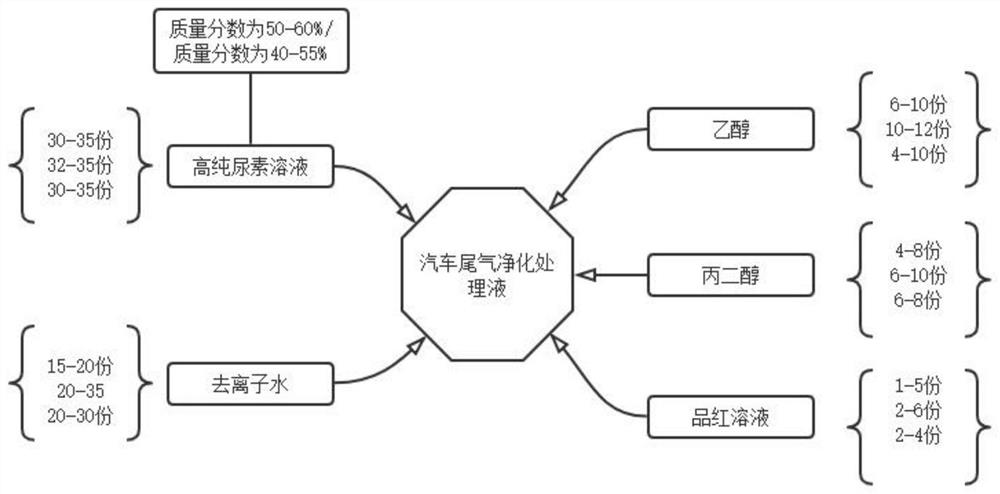

Novel automobile exhaust purification treating fluid and preparation method thereof

PendingCN112879130ARaise vigilanceTimely maintenanceInternal combustion piston enginesExhaust apparatusProcess engineeringPropanediol

The invention discloses novel automobile exhaust purification treating fluid and a preparation method thereof, and belongs to the field of automobiles. According to the novel automobile exhaust purification treating fluid and the preparation method, the novel automobile exhaust purification treating fluid comprises the following components including a high-purity urea solution, ethanol, propanediol, a magenta solution and deionized water; the magenta solution can be added to perform coloring treatment on the automobile exhaust purification treating fluid, so that urea can be effectively developed, the warning degree of the urea color is improved, when a spraying accessory in an SCR system is blocked, an automobile owner or maintenance personnel can quickly and effectively perceive a blocked point, the SCR system can be timely maintained, and the damage degree of the SCR system is reduced; and all solutions are pretreated in a classified mixing manner, so that the urea, magenta and propanediol solution efficiency and dissolving quality are effectively improved, the preparation time is effectively shortened, the urea can be effectively colored through the magenta, and the coloring degree is improved.

Owner:长春盛恒环保科技有限公司

Polyester resin composition and formed article including resin composition

ActiveUS20160090466A1Increase production capacityReduce crystallization rateFireproof paintsPentaerythritolPolyester resin

Provided is a resin composition excellent in processability and productivity, which improves low crystallization rate and improves processability in forming such as injection molding or sheet forming. Provided is a polyester resin composition including a polyester resin (A), a crystallization promoter (B), and pentaerythritol (C).

Owner:KANEKA CORP

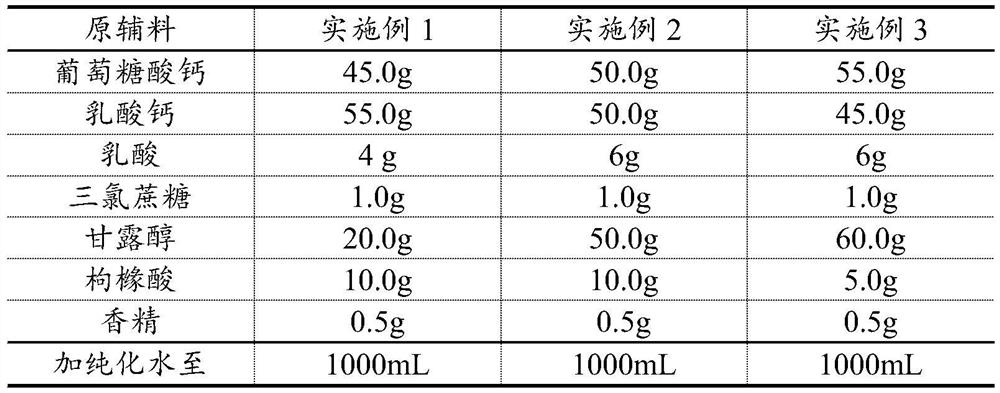

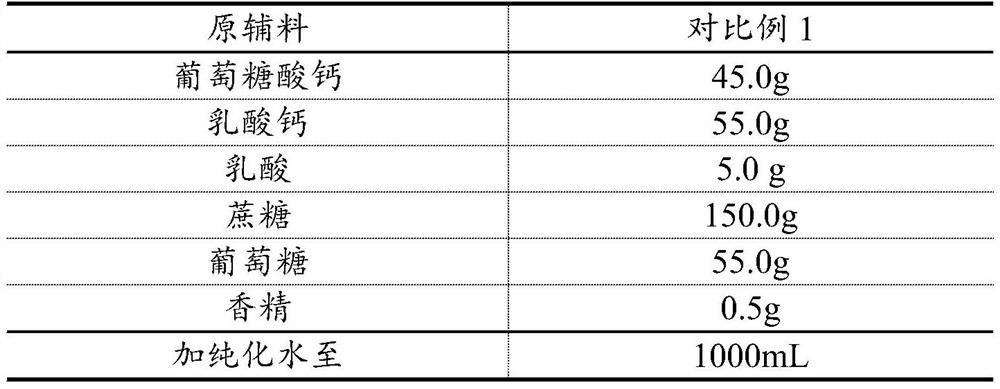

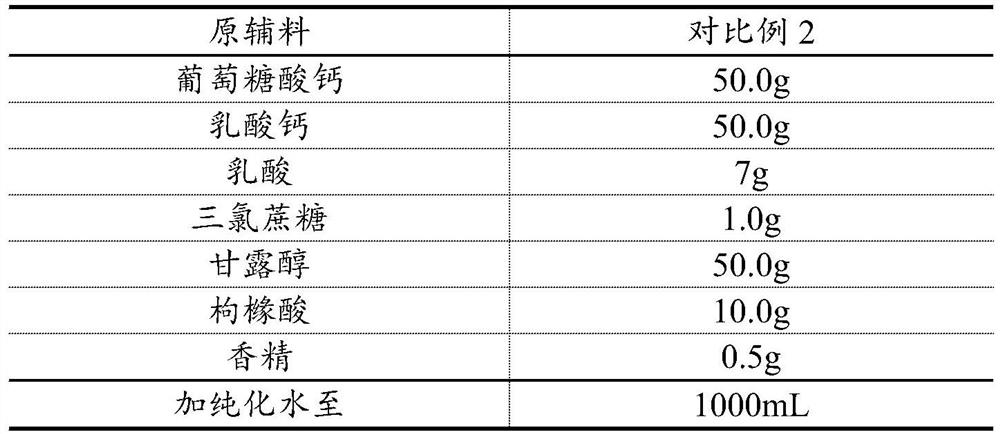

Compound calcium gluconate oral solution and preparation method thereof

PendingCN113876700ALowering the freezing pointImprove stabilityDispersion deliveryMetabolism disorderMannitolGlucobiogen

The invention provides a compound calcium gluconate oral solution and a preparation method thereof, and belongs to the technical field of medicines. The compound calcium gluconate oral solution contains the mannitol and the citric acid, the freezing point of the oral solution is reduced by adding the mannitol, a good effect of delaying low-temperature precipitation is achieved, the lactic acid serves as a pH regulator, the stability of the oral solution can be effectively improved, the crystallization rate is reduced, however, after the lactic acid is excessive, the lactate content and the pH value can exceed the quality control range, and the lactic acid is not suitable for practical application, the citric acid in the invention increases the acidity of the solution on the premise of not increasing the lactate content, makes up for the deficiency of the lactic acid, and further promotes the dissolution of calcium ions. Data of the embodiment shows that the compound calcium gluconate oral solution provided by the invention can be stably stored at 2-8 DEG C.

Owner:KUNMING YUANRUI PHARMA

Preparation method of low-tyrosine and low-salt flavored soybean paste

ActiveCN112515110ANourish the bodyProvides a natural freshening effectFungiSynthetic fibresBiotechnologyFiber

The invention relates to a preparation method of low-tyrosine and low-salt flavored soybean paste. The method comprises the following steps of (1) soy sauce residue pretreatment; (2) functional raw material compound formulation; (3) soybean pretreatment; (4) sterilization treatment; (5) flour stir-frying; and (6) preparation of a loofah sponge casein-removed fiber material, wherein the fiber material contains tyrosine aminotransferase; (7) preparation of yeast for making hard liquor; (8) preparation of potassium ion saline water, wherein edible salt, KCl and water are mixed uniformly in a massratio of (1.2-1.5): 0.5: 10; (9) preparation of a W1 / O / W2 emulsified bacteria solution; and (10) soybean paste fermentation. Added hericium erinaceus powder, pleurotus eryngii powder, hypsizygus marmoreus powder, cantharellus flocclsus schw powder and tremella powder are rich in polysaccharide, peptide and bioactive substance, and have the effects of helping digestion, benefiting five internal organs, resisting cardiovascular diseases, nourishing the body and the like. In addition, composite mushroom powder is rich in glutamic acid, aspartic acid, pleurotus eryngii polypeptide and the like, and can achieve a natural freshness improving effect.

Owner:TIANJIN UNIV OF SCI & TECH

Preparation method of glass ceramic

The invention relates to a preparation method of glass ceramic. The method comprises the following steps: (1) preparing the following raw materials by mass percent: 30%-40% of magnesia borosilicate glass powder, 30%-50% of aluminum oxide filler powder, 10%-30% of Y2O3 and 10%-15% of rare earth ions, wherein the magnesia borosilicate glass powder contains 40%-70% of SiO2, 8%-25% of B2O3, 5%-30% of Al2O3 and 20%-30% of MgO; (2) performing heat treatment for the first time at 650-750 DEG C and performing heat treatment for the second time at 700-750 DEG C. A glass ceramic substrate prepared by the method is high in reflection rate, low in glass phase crystallization rate and excellent in luminous performance.

Owner:华文蔚

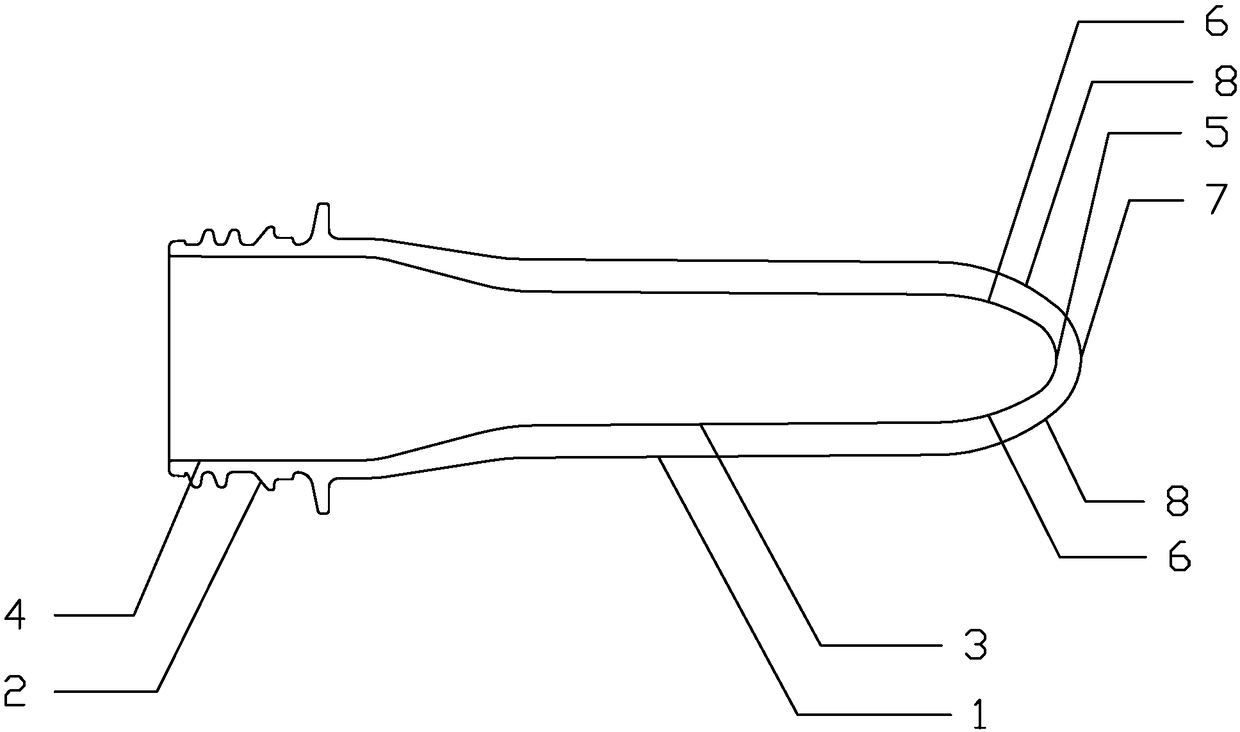

Light preform structure and mold thereof

The invention discloses a light preform structure. The light preform structure comprises a preform with an opening. The cross section, along the center axis of the preform, of the preform is a datum plane. The outer side edge of the datum plane comprises an outer bottleneck segment, an outer bottle body segment and an outer bottle bottom segment which are all sequentially connected, and correspondingly, the inner side edge of the datum plane comprises an inner bottleneck segment, an inner bottle body segment and an inner bottle bottom segment which are all sequentially connected. The outer bottle bottom segment is a structural line or is formed by sequentially connecting multiple structural lines. The inner bottle bottom segment is a structural line or is formed by sequentially connectingmultiple structural lines. Each structural line comprises a straight line and / or a curved line. The distance between the inner bottle bottom segment and the outer bottle bottom segment is gradually increased in the direction from the bottom of the preform to the opening of the preform. After a bottle is blown through the light preform structure, the bottle bottom segment is correspondingly light,production is easy, the flowing speed is higher during injection molding, the shearing stress is small, the crystallization rate is low, and the practicality is high.

Owner:GUANG DONG XING LIAN PRECISE MACHINERY

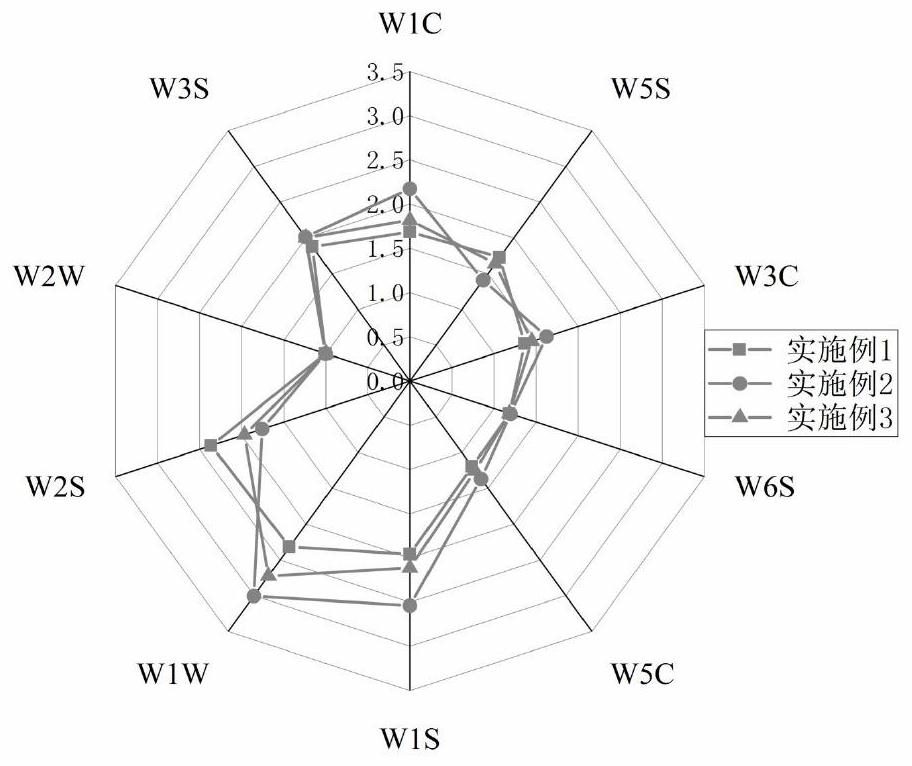

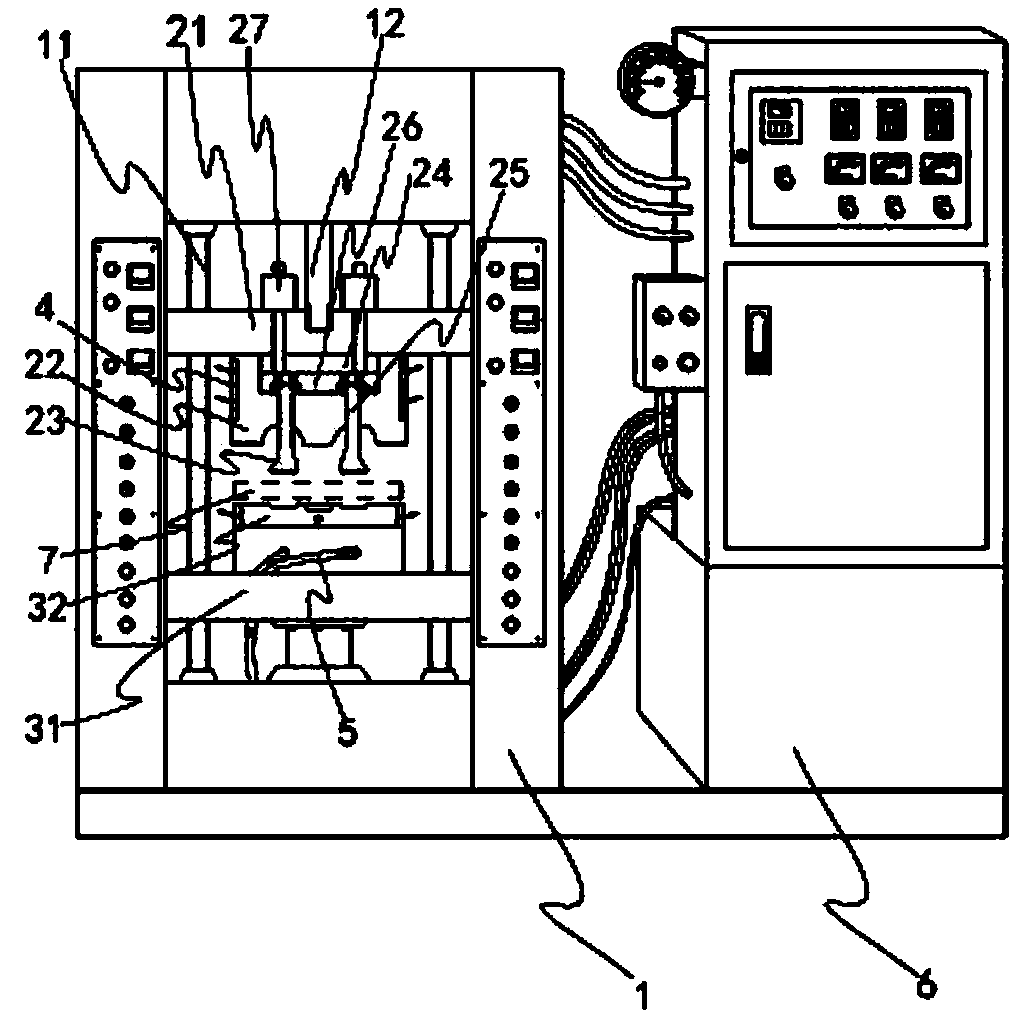

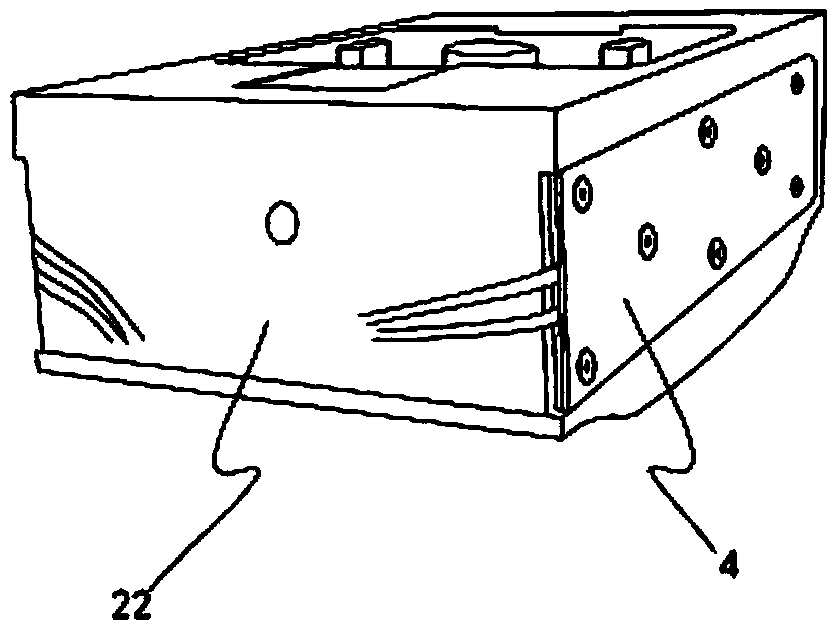

Method for preparing indoor two-color casual shoes

ActiveCN109648902AReduce crystallization rateImproved compression deformation capabilityDomestic footwearEnvironmental resistanceCross-link

The invention relates to the technical field of shoe making, and provides a method for preparing indoor two-color casual shoes. The obtained indoor two-color casual shoes are subjected to SEBS modification, thus, the material crystallization rate is decreased, the compressive deformation property of a material is improved, rubber is good in hand feeling, and comfort is high; the shoes are subjected to OBC modification, the material dimensional stability is improved; an environment-friendly cross-linking agent 17-40B, volatile organic compounds such as acetophenone are not used, and the shoes has the environmental protection characteristic; and a mold device adopted by the method for preparing the indoor two-color casual shoes is rapid in heating, quickly, the duplication precision of solelines is effectively improved, demolding is quick, the injection molding yield and production efficiency are effectively improved, and the method is suitable for mass production and use.

Owner:QUANZHOU JINKE TECH TESTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com