Preparation method of secondary mold pressing foaming sole

A secondary molding and molding technology, which is applied in the field of foam materials, can solve the problems of low hardness and long production time, and achieve the effects of short production time, long production time and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for preparing a secondary molded foam material, comprising the following steps:

[0044] a) Prepare modified starch:

[0045] 1) Put 1000g of cornstarch in a four-hole reaction kettle, add distilled water under stirring conditions to prepare 40% (mass ratio) starch milk, add 30g of solid sodium chloride, heat up to 50°C, and use 0.5mol / L The NaOH solution was adjusted to a pH value of 11.0, and 20 g of sodium hexametaphosphate solid was added to keep the pH constant during the reaction, and the reaction time was 4 hours;

[0046] 2) Adjust the pH value to 8.5 with 0.5mol / L HCl solution, and add 75g of acetic anhydride dropwise. During the dropwise addition process, continuously neutralize the reaction system with 0.5mol / L NaOH solution to keep the pH value of the system basically unchanged. After the completion of acetic anhydride, the reaction was continued for 3.0h;

[0047] 3) After the reaction, adjust the pH to neutral with 0.5mol / L HCl solution, filter ...

Embodiment 2

[0060] A method for preparing a secondary molded foam material, comprising the following steps:

[0061] a) Prepare EVA material rice:

[0062] Mix 25 parts of EVA7350M, 39 parts of EVA7470M, 15 parts of POE81501, 1.7 parts of foaming agent AC, 1.0 parts of crosslinking agent BIBP, 1.5 parts of zinc stearate, 1.0 parts of zinc oxide, 1.0 parts of stearic acid, and 7 parts of talcum powder For refining, adjust the banburying temperature to 96°C, keep it for 6 minutes, then turn over the material twice, continue banburying and raise the temperature, and the discharge temperature is 106°C, after the banburying is completed, carry out refining and extrusion granulation to obtain EVA rice;

[0063] b) Foaming:

[0064] Pour the EVA material rice into a small vacuum foaming mold, heat up and foam, the foaming ratio is 164%, the mold temperature is 178°C, the foaming is completed, the mold is automatically opened, and the foaming embryo with a temperature of not lower than 130°C is ...

Embodiment 3

[0068] A method for preparing a secondary molded foam material, comprising the following steps:

[0069] a) Prepare EVA material rice:

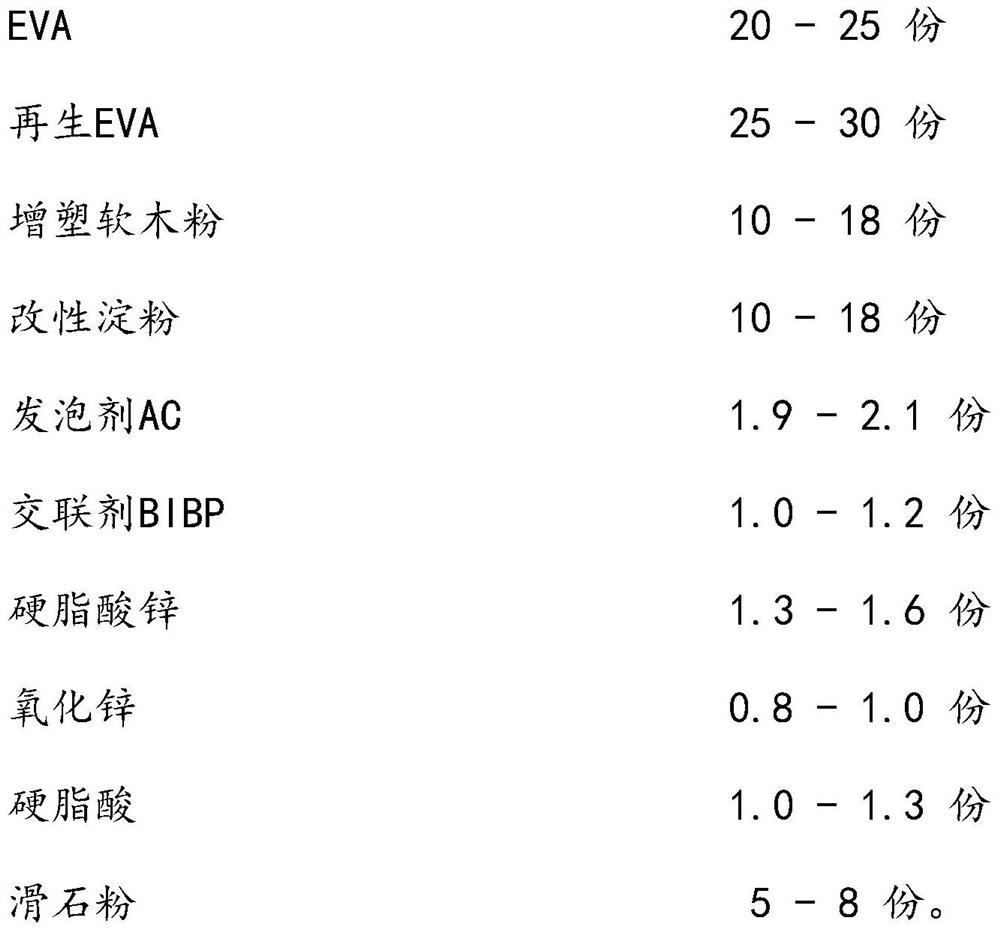

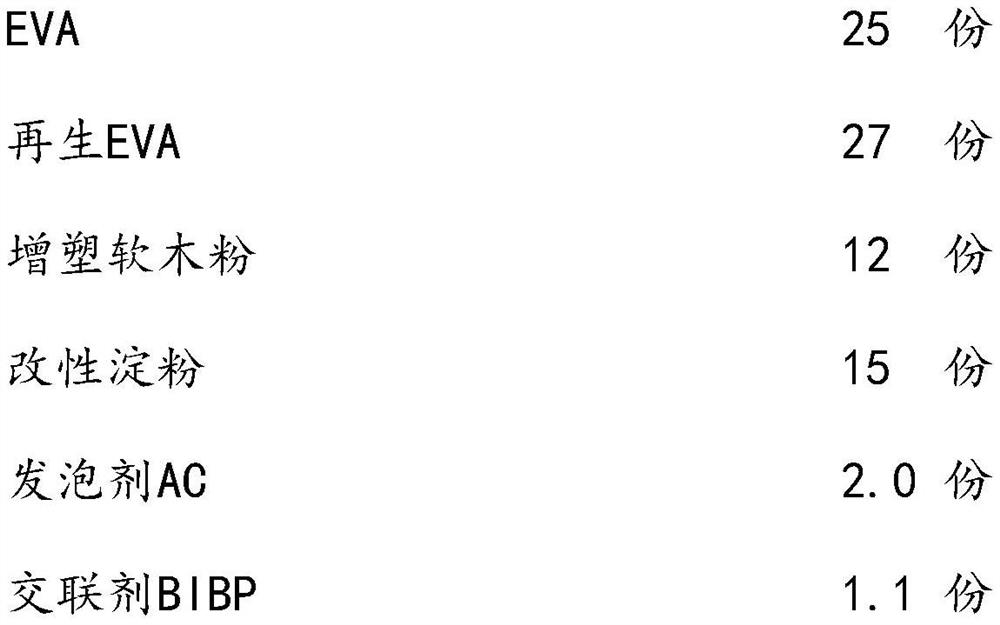

[0070] 20 parts of EVA7470M, 25 parts of regenerated EVA, 18 parts of plasticized cork powder, 18 parts of modified starch, 2.1 parts of foaming agent AC, 1.2 parts of crosslinking agent BIBP, 1.6 parts of zinc stearate, 1.0 parts of zinc oxide, hard Mix 1.3 parts of fatty acid and 8 parts of talcum powder for banburying, adjust the banburying temperature to 95°C, keep it for 6 minutes, then turn over the material twice, continue banburying and heat up, the output temperature is 106°C, and start the banburying, Extrude and granulate to obtain EVA material rice;

[0071] b) Foaming:

[0072] Pour the EVA material rice into the suction barrel, automatically absorb the material, and inject and form it. The foaming ratio is 167%, the mold temperature is 182°C, and the foaming is completed, and the mold is automatically opened to obtain a foamed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com