Preparation method of low-tyrosine and low-salt flavored soybean paste

A technology of tyrosine and soybean paste, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, and the functions of food ingredients, can solve problems affecting the flavor of soybean paste, trouble enterprises, increase the use of soy sauce residue, etc., and achieve Eliminate the taste of crude fiber, facilitate destruction, and reduce space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

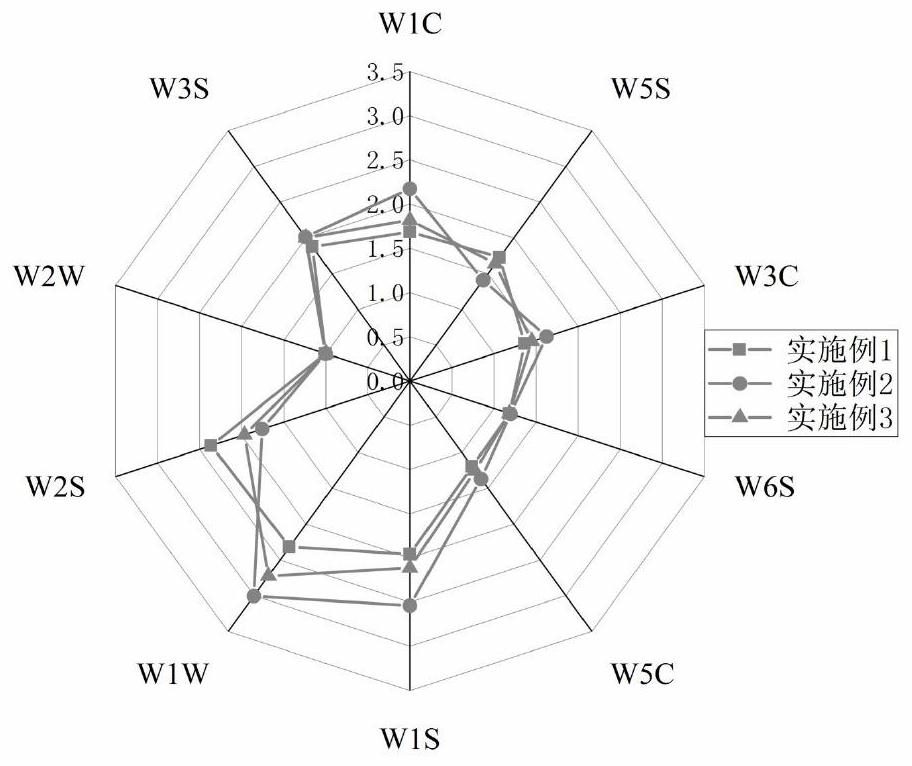

Embodiment 1

[0038] Embodiment 1 (best embodiment)

[0039] The preparation method of low-tyrosine and low-salt flavor soybean paste, the steps are as follows:

[0040] (1) Pretreatment of soy sauce residue: take the soy sauce residue squeezed by cloth bag, grind it into powder, pass it through a 20-mesh sieve, send it into a steam explosion device, perform steam explosion treatment at 0.8MPa for 3 minutes, and dry it for later use. Soy sauce residue: the main components of soy sauce residue after soybean flour fermentation are: 20% crude protein, 8% crude fat, and 11% reducing sugar.

[0041] (2) Functional raw material compound formula: 50 parts of soy sauce residue powder after steam explosion, 5 parts of Hericium erinaceus powder, 5 parts of Pleurotus eryngii powder, 6 parts of seafood mushroom powder, 15 parts of trumpet fungus powder, and 10 parts of white fungus powder .

[0042] (3) Soybean pretreatment: Soak soybeans in water with 5 times the mass, 30°C, and low-frequency ultrason...

Embodiment 2

[0056] The preparation method of low-tyrosine and low-salt flavored soy sauce, without adding soy sauce residue and mushrooms, the steps are as follows:

[0057] (1) Soybean pretreatment: Soak soybeans in water with 5 times the mass, 30°C, and low-frequency ultrasonic treatment for 10 hours.

[0058] (2) Sterilization treatment: Treat the pretreated soybeans at 121° C. for 10 minutes, release the pressure while it is hot and exhaust, continue the treatment for 10 minutes, and release the pressure and exhaust while it is hot again.

[0059] (3) Flour frying: Put the flour into a hot pot and fry for 20-30s. Mix the mixture of functional raw materials and soybeans with the fried flour at a mass ratio of 3:1.

[0060] (4) preparation of loofah antibacterial fiber composite material:

[0061] Preparation of loofah grafted acrylic acid: benzophenone: absolute ethanol = 1:10 (w / v) mix and dissolve completely, add acrylic acid, stir evenly. The loofah is cleaned and soaked in the mi...

Embodiment 3

[0079] The preparation method of low-tyrosine and low-salt flavored soy sauce does not add loofah antibacterial fiber composite material, and the steps are as follows:

[0080] (1) Pretreatment of soy sauce residue: take the soy sauce residue squeezed by cloth bag, grind it into powder, pass it through a 20-mesh sieve, send it into a steam explosion device, perform steam explosion treatment at 0.8MPa for 3 minutes, and dry it for later use.

[0081](2) Functional raw material compound formula: 50 parts of soy sauce residue powder after steam explosion, 5 parts of Hericium erinaceus powder, 5 parts of Pleurotus eryngii powder, 6 parts of seafood mushroom powder, 15 parts of trumpet fungus powder, and 10 parts of white fungus powder .

[0082] (3) Soybean pretreatment: Soak soybeans in water with 5 times the mass, 30°C, and low-frequency ultrasonic treatment for 10 hours.

[0083] (4) Sterilization treatment: mix the raw material compound in step (2) and the pretreated soybeans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com