Method for preparing indoor two-color casual shoes

A casual shoe, two-color technology, applied in the field of indoor two-color casual shoes, can solve the problems of affecting production quality, lowering the vacuuming effect, slow heating speed of the mold, etc., so as to improve the dimensional stability performance, improve the compression deformation performance, and improve the automation. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

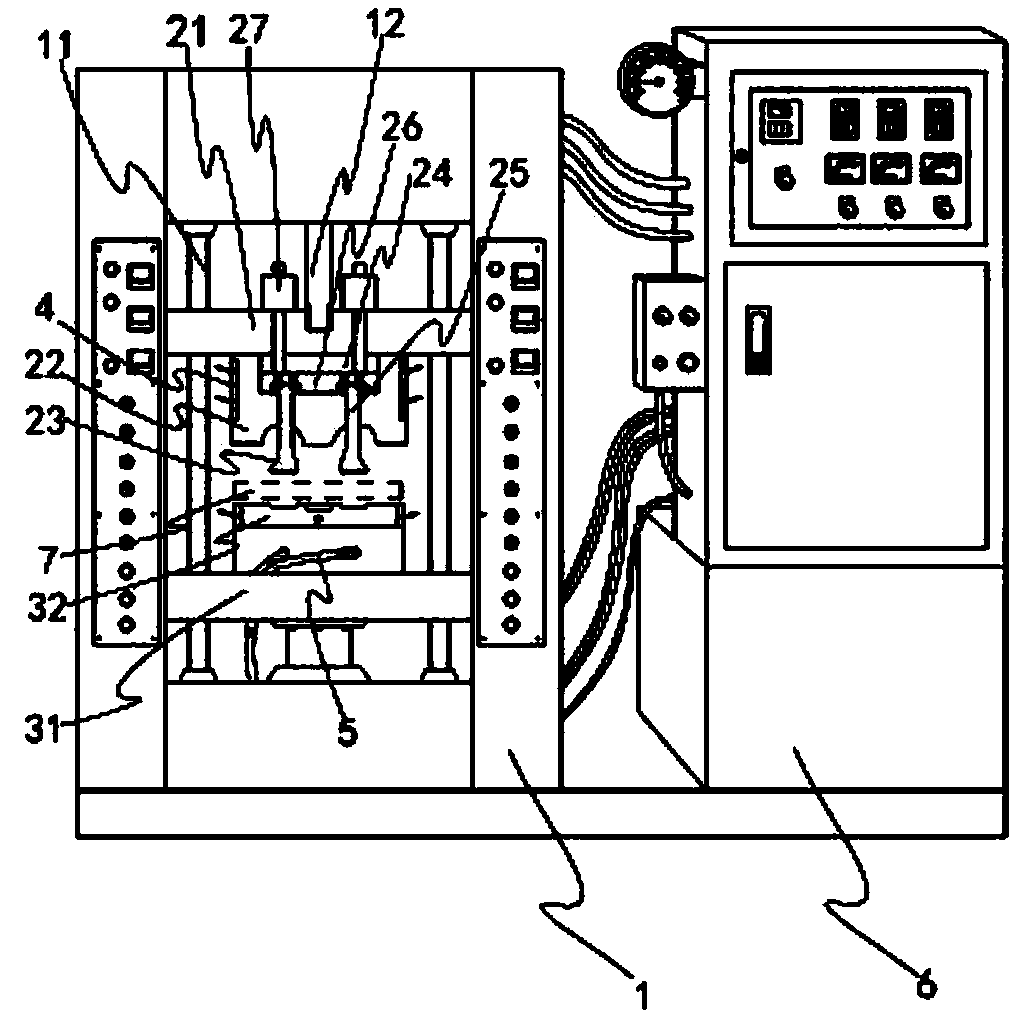

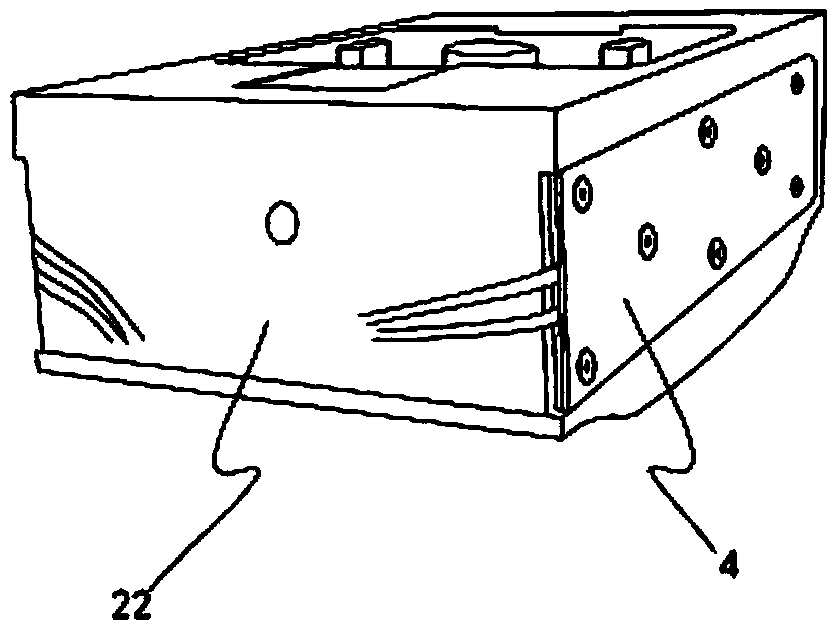

Method used

Image

Examples

Embodiment 1

[0033] A preparation method for indoor two-color casual shoes, comprising the steps of:

[0034] Step 1, preparation of elastomer material A: by weight, 50 parts of SEBS YH503, 15 parts of white mineral oil 4006, 20 parts of EVA 7470, 20 parts of OBC 9107 and 1.5 parts of zinc stearate were pre-prepared in a high-speed mixer Mix for 5 minutes, then pass the premixed material through a twin-screw extruder, melt-extrude at 180°C, cool and granulate to obtain elastomer material A;

[0035] Preparation of elastomer material B: by weight, 50 parts of SEBS YH688, 25 parts of white mineral oil 4006, 10 parts of EVA 74700, 10 parts of EVA 40W, 25 parts of OBC 9077 and 1.5 parts of zinc stearate were mixed in a high-speed mixer Premixed for 5 minutes, then passed the premixed material through a twin-screw extruder, melted and extruded at 180° C., cooled and granulated to obtain elastomer material B.

[0036] Step 2, preparing plastic rice A: the plastic rice A is prepared from the follo...

Embodiment 2

[0055] The preparation method of the two-color indoor leisure shoes described in embodiment 2 is the same as the preparation method in embodiment 1, and the difference is: in embodiment 2

[0056] Elastic material A in step 1: SEBS is YH501, EVA resin is 5110J 10 parts and 7470M 10 parts, OBC is 9500; B (shoe upper): SEBS is YH511, white mineral oil 4006 15 parts.

[0057] In step 2, plastic rice A (: foaming agent AC is 3.1 parts, crosslinking agent 17-40B 2.8 parts, nano-calcium carbonate 10 parts; B (shoe upper): foaming agent AC is 3.0 parts, crosslinking agent 17-40B 2.7 parts of 40B, 10 parts of nano calcium carbonate.

[0058] The two-color indoor casual shoes prepared above have a sole hardness of 38C and a specific gravity of 0.21g / cm 3 , Size shrinkage 1.3%, DIN wear resistance 149mm 3 , compression deformation 45%, anti-slip coefficient (smooth) dry type 0.64 wet type 0.46; vamp hardness 24C, specific gravity 0.21g / cm 3 , Dimensional shrinkage of 1.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com