High-entropy alloy coating resistant to high-temperature abrasion and preparation process and application thereof

A high-entropy alloy and coating technology, applied in the field of high-entropy alloy wear-resistant coating and titanium alloy parts, to achieve the effect of improving hardness and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

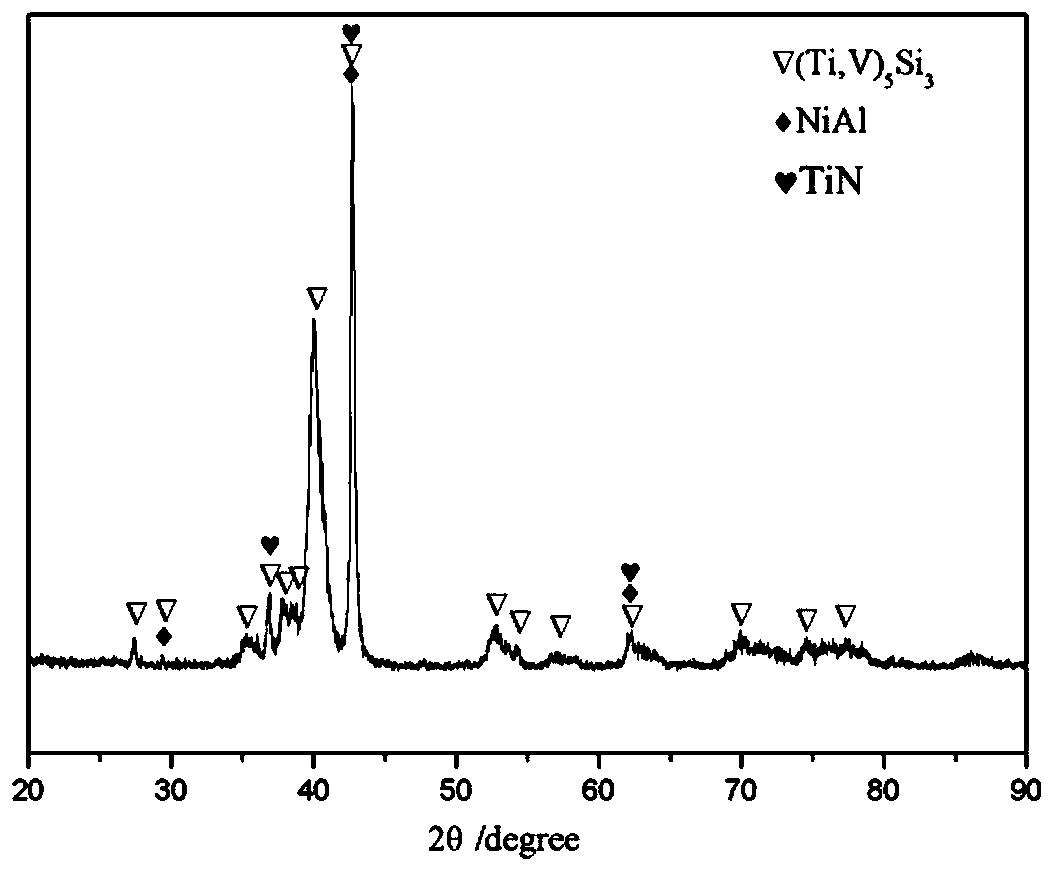

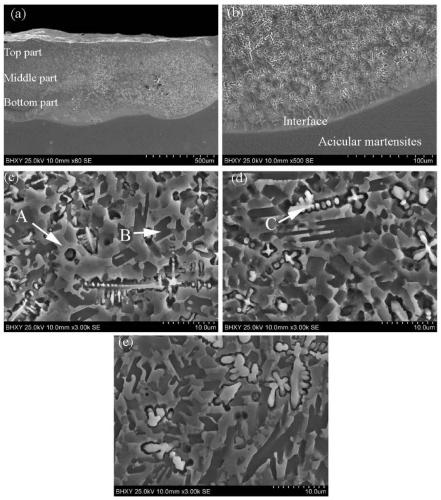

[0054] A multi-principal element high-entropy alloy coating, the composition of which is a mixed powder of 22% Ti, 13% Ni, 28% Al, 13% Si and 24% V (hereinafter referred to as: TiAlNiSiV), prepared by laser cladding technology , the specific steps are as follows:

[0055] (1) Cut the titanium plate to the required size by wire electric discharge cutting, then polish, clean and dry it for use;

[0056] (2) weigh the metal powder according to a certain molar ratio, and use a vortex powder mixer to mix the powder evenly;

[0057] (3) Evenly spread the mixed powder of the cladding material on the surface of the titanium alloy substrate, the thickness is controlled at 0.6-1 mm, and the thickness is kept uniform;

[0058] (4) For the laser cladding of the mixed powder on the surface of the titanium alloy, the laser power is selected as 2kW, the scanning speed of the laser is 300mm / min, the argon gas is blown for protection, the gas flow rate is 10-15L / min, and the laser spot diamet...

Embodiment 2

[0062] A multi-principal element high-entropy alloy coating, whose composition is 22% Ti, 13% Ni, 28% Al, 13% Si and 24% V, is prepared by laser cladding technology, and the specific steps are as follows:

[0063] (1) Cut the titanium plate to the required size by wire electric discharge cutting, then polish, clean and dry it for use;

[0064] (2) Weigh the metal powder and B according to a certain molar ratio 4 C powder mixing, its ratio is 95% (TiNiAlSiV) + 5% B 4 C and use a vortex mixer to mix the powder evenly;

[0065] (3) Evenly spread the mixed powder of the cladding material on the surface of the titanium alloy substrate, the thickness is controlled at 0.6-1 mm, and the thickness is kept uniform;

[0066] (4) For the laser cladding of the mixed powder on the surface of the titanium alloy, the laser power is selected as 1kW, the scanning speed of the laser is 300mm / min, the argon gas is blown for protection, the gas flow rate is 10-15L / min, and the laser spot diamete...

Embodiment 3

[0070] A multi-principal high-entropy alloy coating whose composition is metal powder Ti, Ni, Al, Si and V, and the ceramic phase is B 4 The mixed powder of C is prepared by laser cladding technology, and the specific steps are as follows:

[0071] (1) Cut the titanium plate to the required size by wire electric discharge cutting, then polish, clean and dry it for use;

[0072] (2) Weigh the metal powder and B according to a certain molar ratio 4 C powder mixing, and use a vortex mixer to mix the powder evenly;

[0073] (3) Evenly spread the mixed powder of the cladding material on the surface of the titanium alloy substrate, the thickness is controlled at 0.6-1 mm, and the thickness is kept uniform;

[0074] (4) For the laser cladding of the mixed powder on the surface of the titanium alloy, the laser power is selected as 2kW, the scanning speed of the laser is 300mm / min, the argon gas is blown for protection, the gas flow rate is 10-15L / min, and the laser spot diameter is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com