High-air-tightness low-free-oxygen-content nano disperse copper alloy and short-process preparation technology

A technology of preparation process and oxygen content, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of high free oxygen content of nano-dispersed copper alloy, low free oxygen content of nano-dispersed copper alloy, low air tightness, etc., to achieve Low free oxygen content, high dimensional stability, and good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

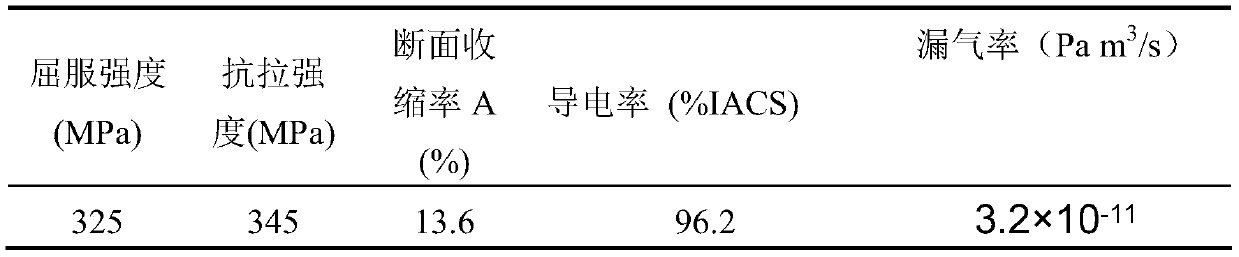

Embodiment 1

[0039] The Cu-0.1wt%Ca-0.1wt%La alloy is smelted under inert gas protection at 1200°C, prepared by high-purity nitrogen atomization, sieved, and subjected to high-energy ball milling to obtain ultrafine powder (average particle size less than or equal to 20 microns). The Al and Cu are smelted at 1218-1230 ℃ to form a Cu-Al alloy with an Al content of 0.04wt%. The high-purity nitrogen atomization is used to prepare and sieve the alloy powder with a particle size of less than 40 meshes, which is mixed with an oxidant. Mix, perform ball milling, conduct internal oxidation with oxidizing agent at 386-395 °C for 2 hours, and then conduct internal oxidation at 892-900 °C for 3 hours, crush the above-mentioned internal oxidation powder, and reduce hydrogen at 885-893 °C For 6 hours, mix with Cu-Ca-La alloy ultrafine powder in a ratio of 15:1, cold isostatic pressing of the above mixed powder, argon chamber pure copper jacket, 900 ℃ water seal hot extrusion, extrusion ratio 15 : 1, sw...

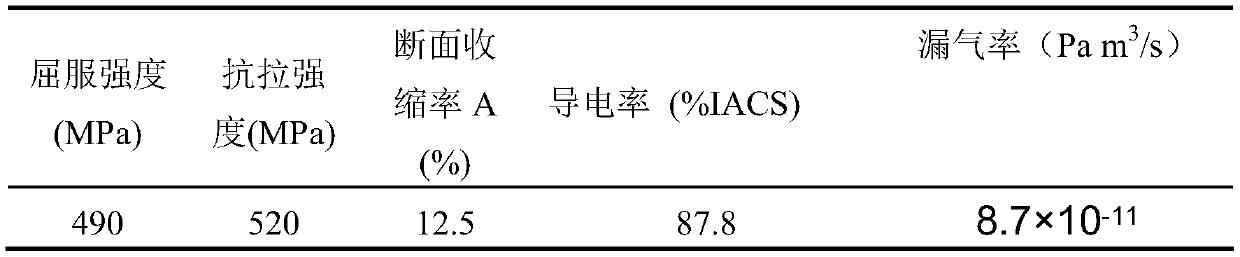

Embodiment 2

[0043] The Cu-0.1wt%Ca-0.1wt%La alloy was smelted under inert gas protection at 1200°C, prepared by high-purity nitrogen atomization, sieved, and subjected to high-energy ball milling to obtain ultrafine powder (average particle size less than or equal to 20 microns). The Al and Cu are smelted at 1200-1222 ℃ to form a Cu-Al alloy with an Al content of 0.12wt%. Mix, perform ball milling, conduct internal oxidation of the mixed powder with an oxidant at 392-400 °C for 2 hours, and then oxidize at 893-898 °C for 3 hours, crush the above-mentioned internal oxidation powder, and reduce it with hydrogen at 895-900 °C for 6 hours, Mixed with Cu-Ca-La alloy ultrafine powder in a ratio of 13:1, cold isostatic pressing of the above powder, argon chamber pure copper jacket, 900 ℃ water sealing hot extrusion, extrusion ratio 15:1, Swaged after extrusion; re-swaged bar in new jacket, evacuated for 10 -3 After Pa, it was sealed and placed in a nitrogen atmosphere with a pressure of 50 MPa ...

Embodiment 3

[0047] The Cu-0.1wt%Ca-0.1wt%La alloy was smelted under inert gas protection at 1200°C, prepared by high-purity nitrogen atomization, sieved, and subjected to high-energy ball milling to obtain ultrafine powder (average particle size less than or equal to 20 microns). The Al and Cu are smelted at 1215-1230 ℃ to form a Cu-Al alloy with an Al content of 0.30wt%. The high-purity nitrogen atomization is used to prepare and sieve the alloy powder with a particle size of less than 40 meshes, which is mixed with an oxidant. Mix, perform ball milling, conduct internal oxidation of the mixed powder with an oxidizing agent at 382-393 °C for 2 hours, and then oxidize at 887-896 °C for 3 hours, crush the above-mentioned internal oxidation powder, and reduce it with hydrogen at 892-898 °C for 6 hours, Mixed with Cu-Ca-La alloy ultrafine powder in a ratio of 10:1, cold isostatic pressing of the above powder, argon chamber pure copper jacket, 900 ℃ water sealing hot extrusion, extrusion ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com