Method for restraining generation of A7N01 aluminum alloy surface coarse grain ring

A technology of A7N01 and aluminum alloy surface, which is applied in the production field of aluminum alloy, can solve the problems of increasing quenching sensitivity, reducing the quenching aging state of extruded products, the influence of alloy mechanical properties and fatigue properties, etc. Effect of coarse-grained ring defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this example, the preparation process of the A7N01 aluminum alloy extruded product containing 0.06wt% scandium:

[0024] 1) The industrial pure Al, pure Zn, pure Mg, Al-Mn master alloy, Al-Cr master alloy, Al-Zr master alloy, Al-Ti master alloy are prepared according to the design composition, and the design composition meets the relevant standards of A7N01 aluminum alloy Regulations: In terms of element mass percentage, zinc: 4.13%, magnesium: 1.31%, manganese: 0.30%, chromium: 0.21%, zirconium: 0.10%, titanium: 0.06%, and the balance is aluminum and unavoidable impurities. And, a trace rare earth element scandium with a mass fraction of 0.06% is introduced by adding an Al-Sc master alloy to the raw material. The above raw materials are vacuum smelted in a graphite crucible furnace. First, pure Al and Al-Cr intermediate alloys are refined in a graphite crucible furnace for 15-20 minutes, and then the rest of the raw materials are added to melt at 720°C, followed by ...

Embodiment 2

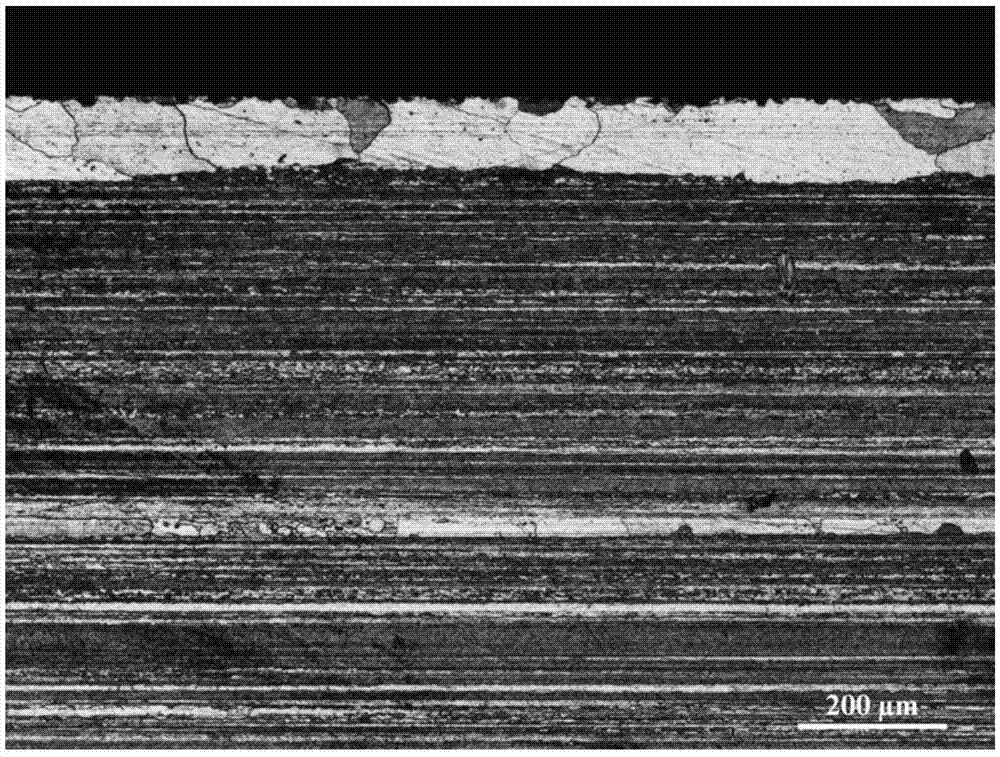

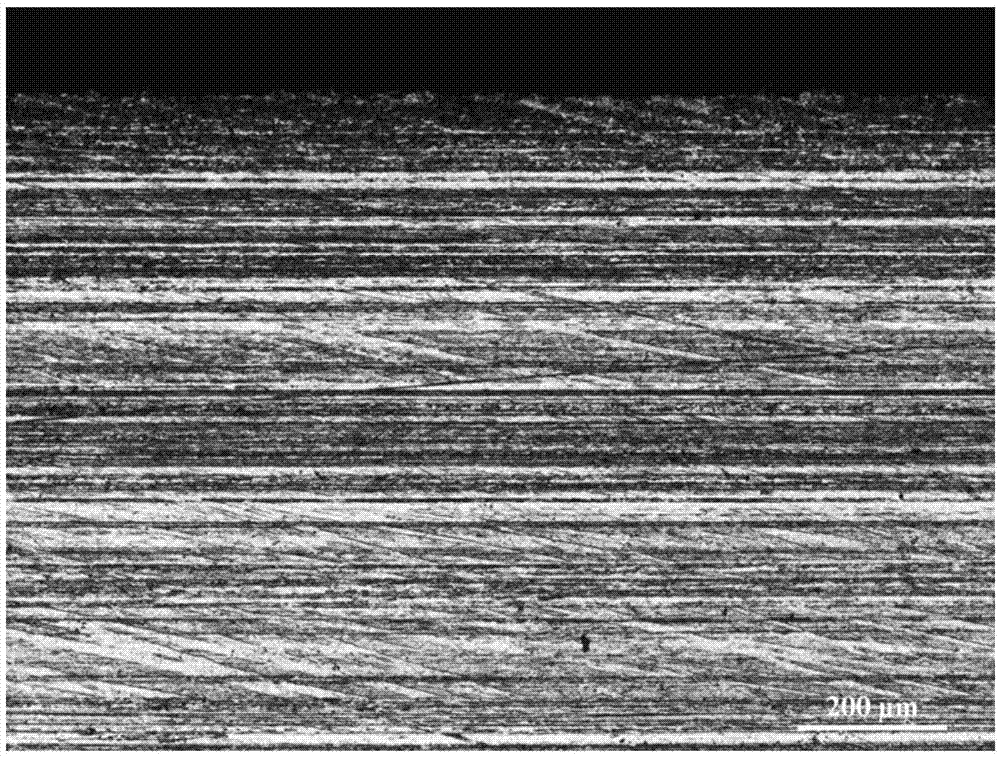

[0030] In this embodiment, the preparation process of the A7N01 aluminum alloy extruded product containing 0.13wt% scandium: is consistent with the above method, the difference is that 0.13wt% scandium is added to the A7N01 aluminum alloy matrix. Its longitudinal microstructure is as image 3 shown, from image 3 It can be seen from the figure that there is still no coarse-grained ring defect at the edge of the extruded product, which is mainly due to the Al 3 The (Sc,Zr) dispersed phase strongly inhibits the effect of recrystallization. Compared with the A7N01 aluminum alloy containing 0.06wt% scandium, the microstructure of A7N01 aluminum alloy containing 0.13wt% scandium is further refined.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com