Aluminum welding ring and flux core in use for welding joint of tubes made from aluminum and aluminum alloy, and preparation method

A technology of aluminum alloy tubes and aluminum welding rings, which is applied in welding equipment, metal processing equipment, welding media, etc., can solve the problems of difficult cleaning of residues and waste of flux, so as to avoid excessive addition of flux, save flux, The effect of lowering the melting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

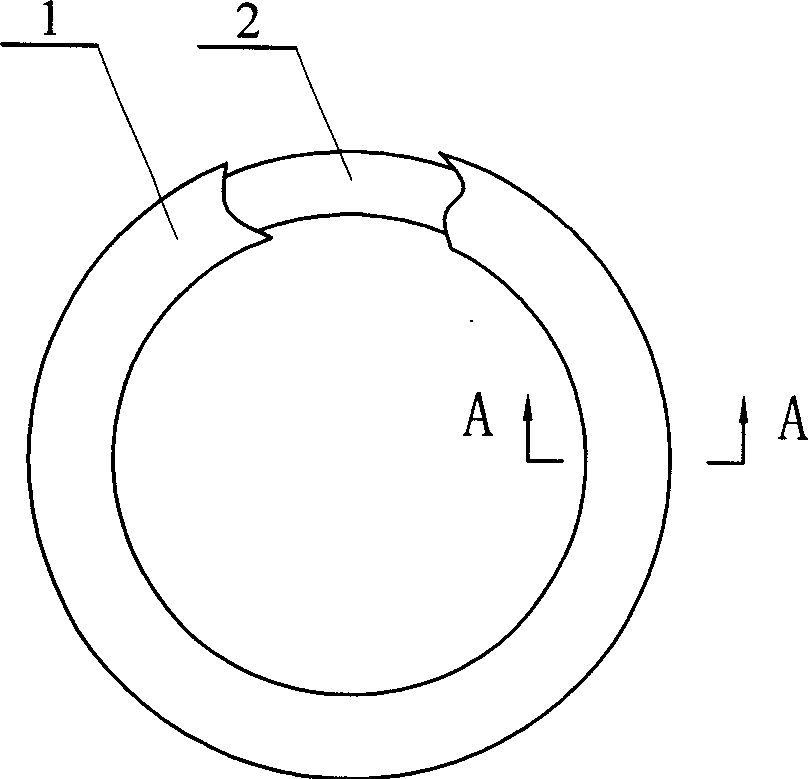

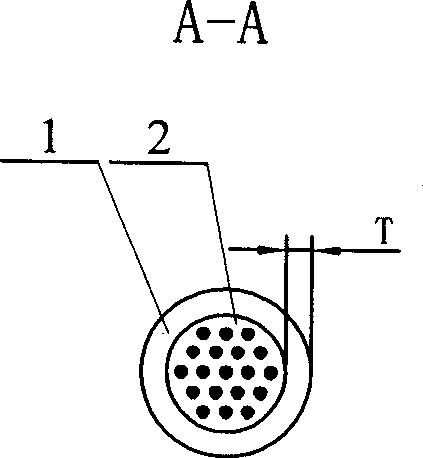

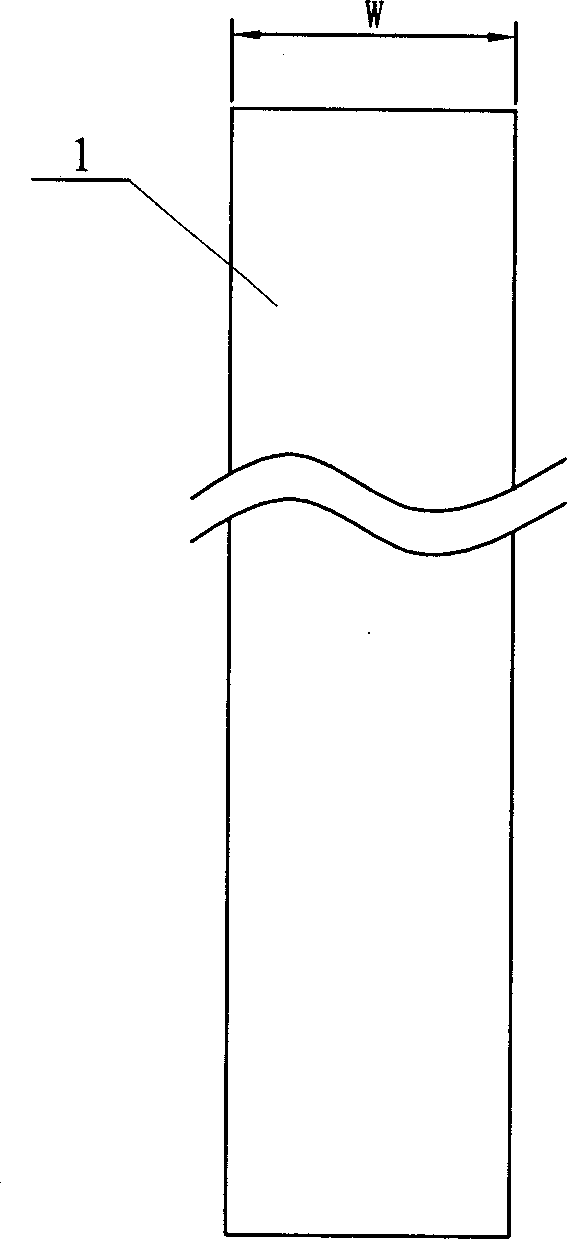

[0006] Specific implementation mode one: (see Figure 1-Figure 3 ) The flux-cored aluminum welding ring used for brazing aluminum and aluminum alloy pipe joints in this embodiment is annular, and it is composed of a skin 1 and a core 2. The skin 1 is made of aluminum-silicon alloy foil, and the thickness of the aluminum-silicon alloy foil is T 0.1-0.5mm, width W is 5-20mm, the core 2 is composed of aluminum-silicon alloy wire and alloy powder, the diameter of the aluminum-silicon alloy wire is 0.6-1.5mm; The weight percentage of the components is: Al: 86.5-97%, Si: 3-13%, Sr: 0.01-0.3%, La: 0.01-0.2%, and the above alloy powder is KAlF 4 and K 3 AlF 6 The eutectic or by KAlF 4 and K 3 AlF 6 Composed of eutectic and silica fume, KAlF 4 and K 3 AlF 6 The composition weight ratio of the alloy powder composed of eutectic and silicon powder is: KAlF 4 and K 3 AlF 6 Eutectic: silicon powder = 1: (0.1-2), the alloy powder accounts for 5-15% of the total weight of the flux-...

specific Embodiment approach 2

[0007] Specific implementation mode two: (see Figure 1-Figure 3 ) The difference between this embodiment and the first embodiment is that the weight percentages of the chemical components in the aluminum-silicon alloy foil and the aluminum-silicon alloy wire are: Al 88.9%, Si 11%, Sr 0.05%, La 0.05%. Alloy powder is KAlF 4 and K 3 AlF 6 Eutectic, alloy powder accounts for 10% of the total weight of the flux-cored aluminum welding ring. Other compositions are the same as in Embodiment 1.

specific Embodiment approach 3

[0008] Specific implementation mode three: (see Figure 1-Figure 3 ) The difference between this embodiment and the first embodiment is that the weight percentages of the chemical components in the aluminum-silicon alloy foil and aluminum-silicon alloy wire are: Al 96.6%, Si 2.9%, Sr 0.3%, La 0.2%, so The weight ratio of each chemical composition in the alloy powder is: KAlF 4 and K 3 AlF 6 Eutectic: silicon powder = 10:1, the alloy powder accounts for 10% of the total weight of the flux-cored aluminum welding ring. Other compositions are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com