Headless continuous casting and rolling ferrite rolling method and device of low/micro-carbon steel coil for deep drawing

A continuous casting, continuous rolling, and ferrite technology, applied in the field of metallurgical steel rolling, can solve the problems of poor performance stability, complex process flow, low production efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

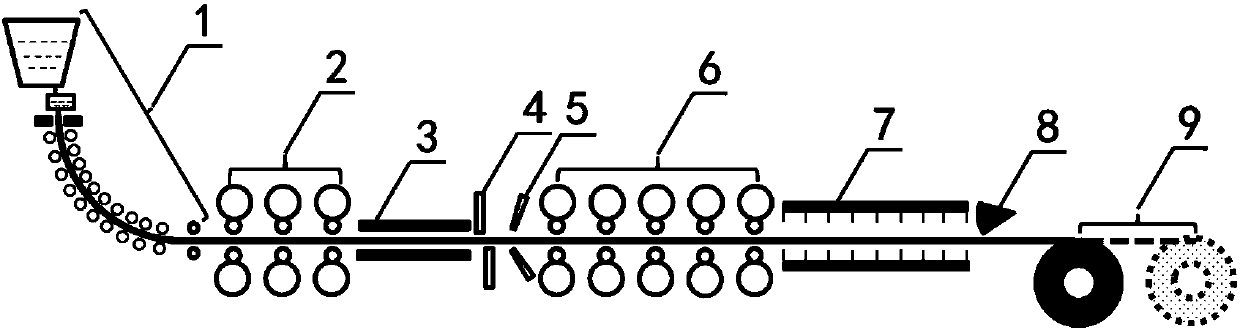

Method used

Image

Examples

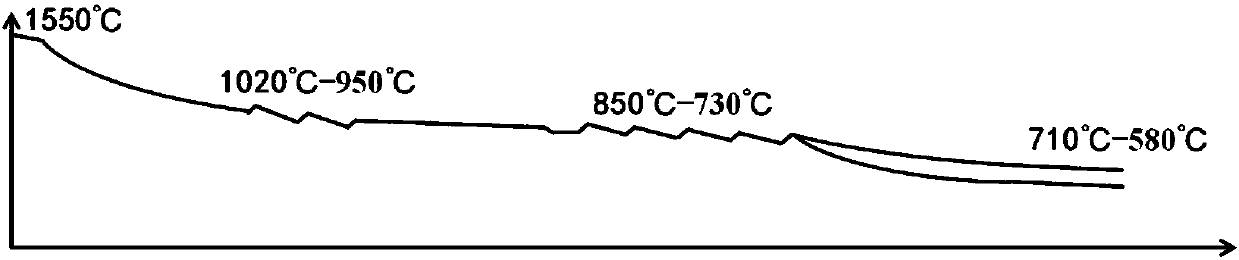

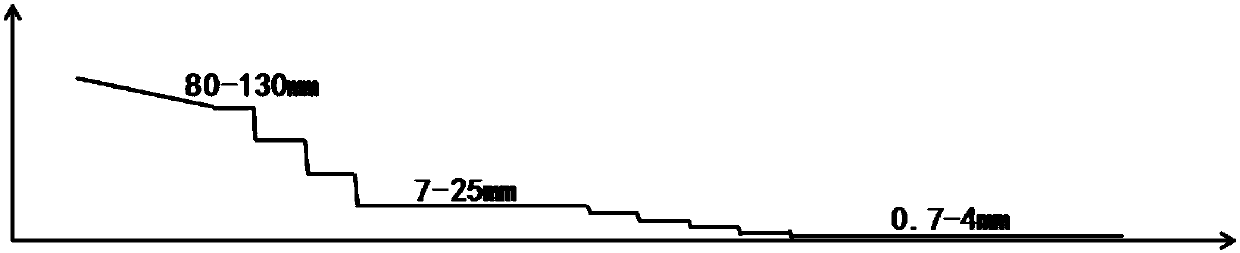

Embodiment 1

[0041] According to the chemical composition and mass percentage of low carbon steel: C: 0.06%, Si: 0.10%, Mn: 0.25%, B: 0.0003%, Ti: 0.005%, Cr: 0.01%, Als: 0.060%, P: 0.019%, S: 0.006%, N: 0.0049%, the rest is Fe and unavoidable impurities for smelting. The slab is cast in a continuous casting machine, the temperature of the continuous casting ladle is 1545°C, the casting speed is 4m / min, and the thickness of the slab is 80mm. It is directly sent to the rough rolling unit for rough rolling. The rough rolling temperature is 990°C-950°C. After rough rolling, the thickness of the intermediate billet is 7mm. The intermediate billet enters the cooling channel to control the temperature, the cooling speed is 0.3°C / s, the rolling shear head is descaled by high-pressure water, the pressure of the descaling water is 35MPa, the finishing rolling unit is finished rolling, and the finishing rolling temperature is controlled at 800°C-730°C. Lubricated rolling can be used in 3 passes, an...

Embodiment 2

[0043] According to the chemical composition and mass percentage of low carbon steel: C: 0.04%, Si: 0.06%, Mn: 0.20%, B: 0.0008%, Ti: 0.030%, Cr: 0.10%, Als: 0.042%, P: 0.013%, S: 0.014%, N: 0.0040%, and the rest is Fe and unavoidable impurities for smelting. The slab is cast in a continuous casting machine, the temperature of the continuous casting ladle is 1547°C, the casting speed is 5m / min, and the thickness of the slab is 95mm. It is directly sent to the rough rolling unit for rough rolling. The rough rolling temperature is 1000°C-960°C. After rough rolling, the thickness of the intermediate billet is 13mm. The intermediate billet enters the cooling channel to control the temperature, the cooling speed is 2°C / s, the rolling shear head is descaled by high-pressure water, the pressure of the descaling water is 33MPa, the finishing rolling unit is finished rolling, and the finishing rolling temperature is controlled at 810°C-740°C. Lubricated rolling can be used in 2 passes...

Embodiment 3

[0045] According to the chemical composition and mass percentage of micro-carbon steel: C: 0.018%, Si: 0.03%, Mn: 0.15%, B: 0.0015%, Ti: 0.012%, Cr: 0.25%, Als: 0.025%, P: 0.010%, S: 0.009%, N: 0.0031%, and the rest is Fe and unavoidable impurities for smelting. The slab is cast in a continuous casting machine, the temperature of the continuous casting ladle is 1550°C, the casting speed is 6m / min, and the thickness of the slab is 110mm. It is directly sent to the rough rolling unit for rough rolling. The rough rolling temperature is 1100°C-970°C. After rough rolling, the thickness of the intermediate billet is 20mm. The intermediate billet enters the cooling channel to control the temperature, the cooling speed is 4°C / s, the rolling shear head is descaled by high-pressure water, the descaling water pressure is 33MPa, the finishing rolling unit is finished rolling, the finishing rolling temperature is controlled at 825°C-755°C, and finally 1 pass can be lubricated and rolled, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com