Binary leadless soldering plaster

A lead-free solder paste, solder paste technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of lead poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The binary lead-free solder paste of this embodiment is composed of eutectic micron lead-free solder paste Sn-Bi and nano powder Sn-Ag-Cu, the size of nano powder is ≤100nm, the total weight is 25g, and its composition is calculated by weight fraction: :

[0016] Micron lead-free solder paste 97 parts

[0017] Nano powder 3 parts

[0018] a. The nanopowder stored in the paraffin liquid is separated, and chloroform is selected as the separation solvent.

[0019] b. Mix the separated nano-powder with micron lead-free solder paste evenly.

[0020] c. Screen print the prepared solder paste, and then reflow at 180°C for 6 minutes to form good solder joints.

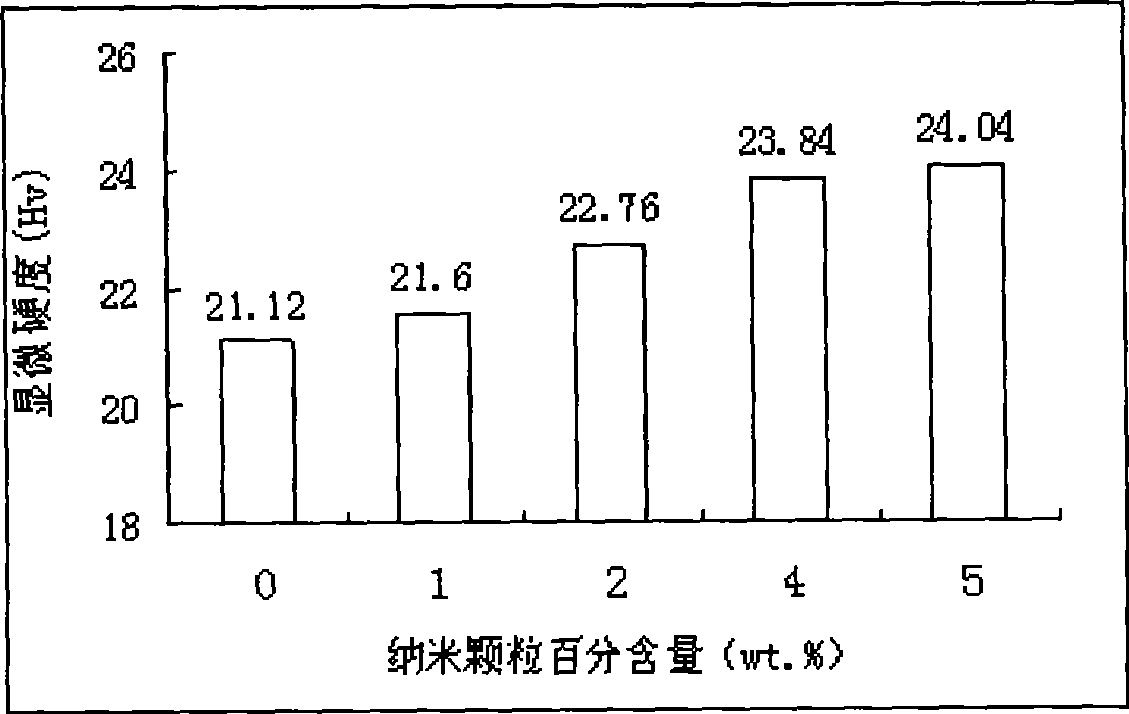

[0021] d. If figure 1 As shown, the microhardness of the solder joint formed by the binary lead-free solder paste is higher than that of the pure eutectic micron lead-free solder paste Sn-Bi; as figure 2 As shown, the shear strength of the solder joints formed by the binary lead-free solder paste is higher than th...

Embodiment 2

[0023] The binary lead-free solder paste of this embodiment is composed of eutectic micron lead-free solder paste Sn-Bi and nano powder Sn-Ag-Cu, the size of nano powder is ≤100nm, the total weight is 25g, and its composition is calculated by weight fraction: :

[0024] Micron lead-free solder paste 99 parts

[0025] Nano powder 1 part

[0026] Mix the above evenly, then perform screen printing, and reflow at 180°C for 6 minutes to form good solder joints. Performance is improved, as in figure 1 , 2 shown.

Embodiment 3

[0028] The binary lead-free solder paste of this embodiment is composed of micron lead-free solder paste Sn-Bi and nano-powder Sn-Co-Cu, the size of the nano-powder is ≤100nm, the total weight is 25g, and its composition is calculated by weight fraction:

[0029] Micron lead-free solder paste 99 parts

[0030] Nano powder 1 part

[0031] Mix the above evenly, then perform screen printing, and reflow at 180°C for 6 minutes to form good solder joints.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com