Manual and automatic integrated clamping and turning-over forging machine

A forging machine, an integrated technology, applied in forging/pressing/hammering machinery, manufacturing tools, forging/pressing/hammer devices, etc., can solve problems such as low forging efficiency, improve forging quality, expand application scope, and facilitate operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

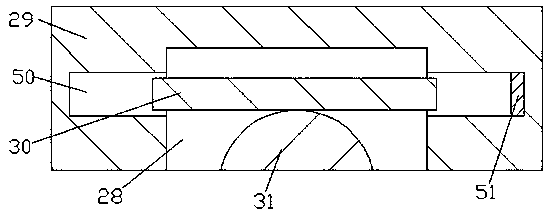

[0018] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0019] combined with Figure 1-5 The described one-manually integrated picking and turning forging machine includes a beating box 10, the right end of the beating box 10 is fixedly connected with a fixed table 19, and the right end of the fixed table 19 is also fixed with an operation table 29, and the beating box 10 is provided with a beating mechanism 67 that can forge the material placed on the upper end of the fixed table 19, and the transmission chamber 28 is provided with a moving chamber 24 whose left and right end walls pass through the transmission chamber 28, and the moving chamber 24 There is a clamping mechanism 69 that can clamp the material or drive the material to rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com