Processing method for crossed forged piece for supporting ITER magnet

A processing method and technology supported by magnets, applied in the field of forging, can solve the problems of cracking, processing deformation, large forging allowance, etc., and achieve the effects of increasing equivalent compressive stress, sufficient section deformation, and small processing allowance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will combine the attached drawing , to clearly and completely describe the technical solutions in the embodiments of the present invention.

[0029] The present invention provides a processing method for an ITER magnet supporting cross-shaped forging, comprising the following steps:

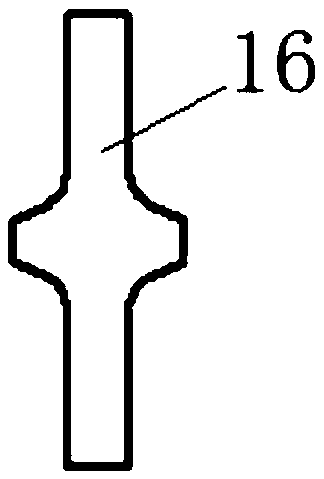

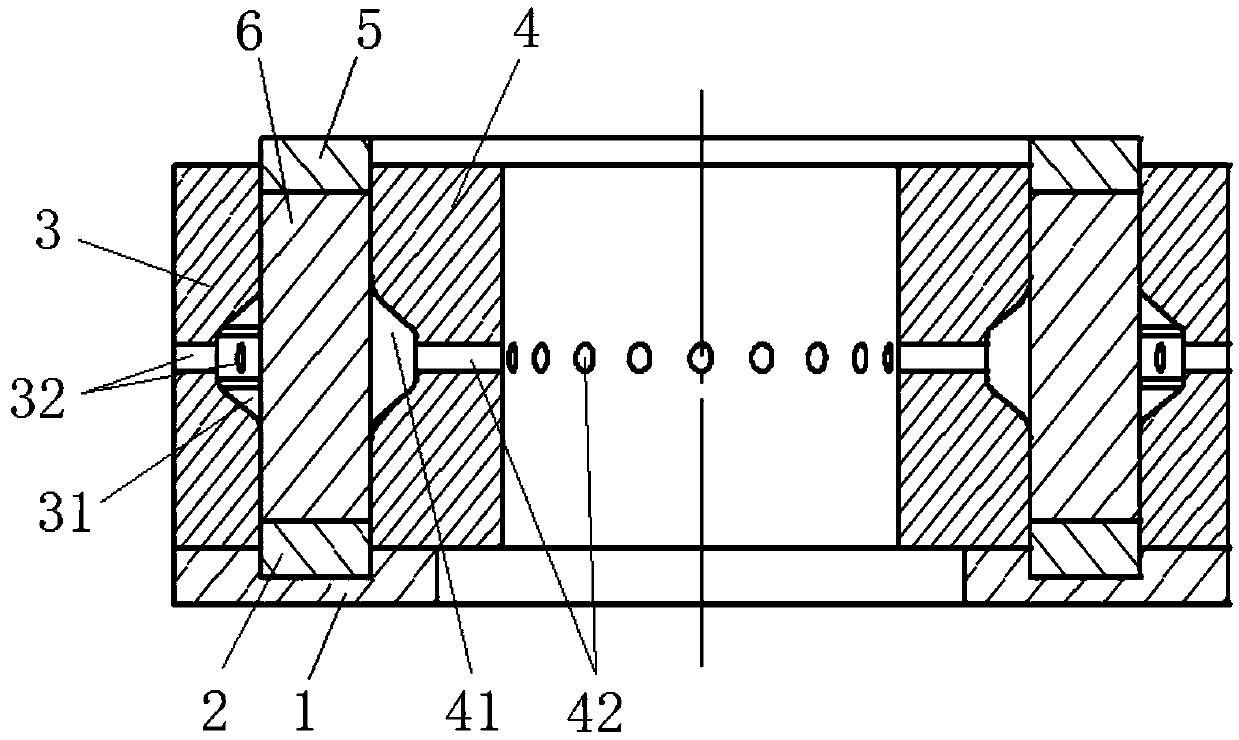

[0030] 1) like image 3 As shown, a set of molds for upsetting extrusion including a lower sealing ring 1, a lower gasket 2, an outer mold 3, a mold core 4 and an upper gasket 5 are manufactured, wherein the outer mold 3 and the mold core 4 are both annular, and the outer mold 3 and the mold core 4 are annular. The inner wall of the mold 3 and the outer wall of the mold core 4 are provided with a ring of grooves 31 and 41 with trapezoidal cross-sections, and an annular groove is provided on the top of the lower sealing ring 1 .

[0031] 2) Take an alloy ingot and process it into a ring-shaped billet 6, which is then heated in a heating furnace.

[0032] 3) Preheat the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com