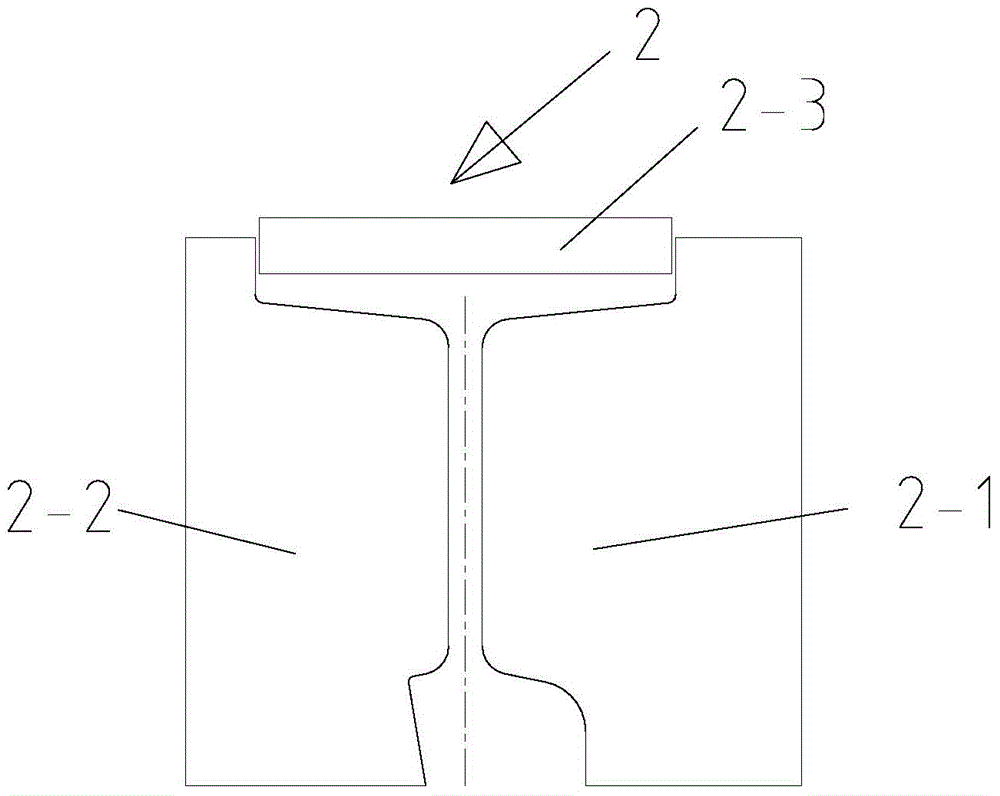

59R2 special-shaped rail and forming method thereof

A special-shaped rail and forming section technology, which is applied in the field of 59R2 special-shaped rail and its forming, can solve the problems of difficult mold blank metal, poor process precision, and low forging quality, and achieve the effects of weakening wear and tear, improving quality, and improving forging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Attached below Figure 1-7 An embodiment of the present invention is described.

[0022] A 59R2 special-shaped rail is composed of a raw material section a, a profiled transition section b, and a forming section c. The forming section c has an offset from the center line of the rail waist of the original material section a, and the offset is 20mm; the forming section The length of section c is 450mm, and the length of profiled transition section b is 150mm. The width of the rail bottom 1-3 of the forming section c is 150mm, and the cross-section of the forming section c removes the existing standard 59R2 rail head II difficult-to-form flange groove 4, which solves the problem of easy folding and The problem of forgings that are not easy to be filled makes the metal flow and distribute better, greatly improves the quality of forgings, and also provides convenience for subsequent machining; Compared with the existing 59R2 special-shaped rail, it is revised based on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com