Forging method for large and medium steel ingot

A large and medium-sized steel ingot technology, applied in the field of forging, can solve the problems of low material utilization rate, shrinkage cavity in the center of the clamp, etc., and achieve the effect of improving quality, easy cleaning, quality and yield guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

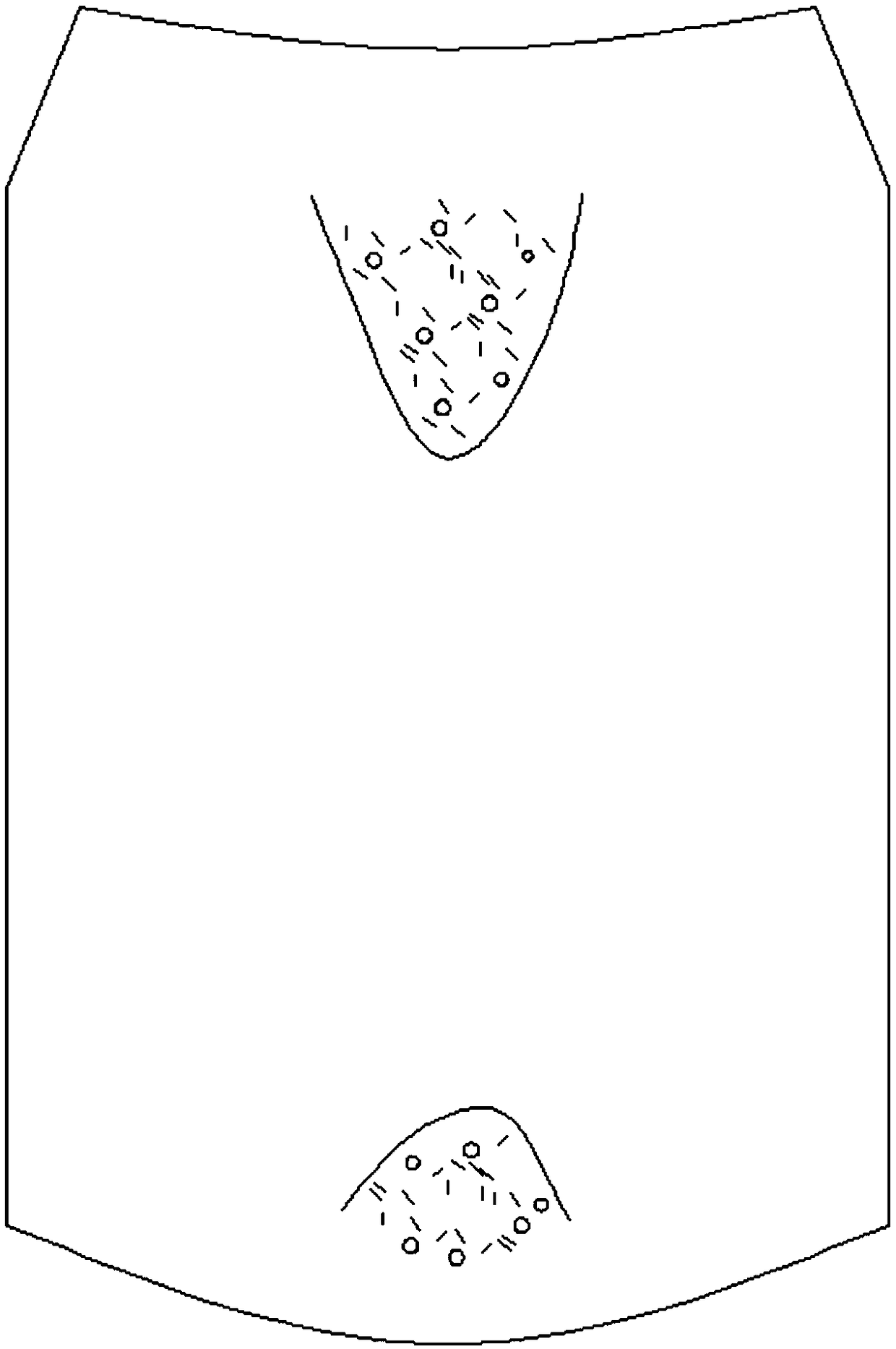

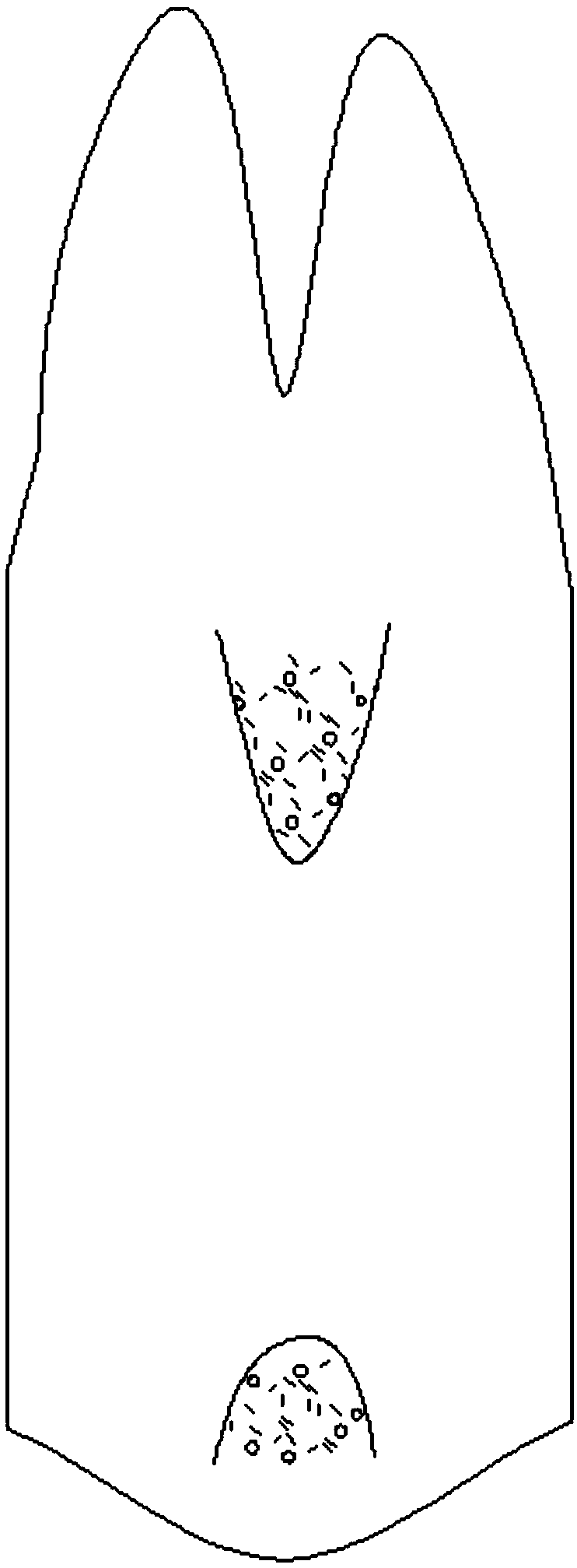

Image

Examples

Embodiment 1

[0036] The forging method of large and medium-sized steel ingot of the present invention comprises the following steps:

[0037] a) Production of steel ingots: cast steel ingots by pouring method. When producing steel ingots, select thermal insulation boards with good thermal insulation and corrosion resistance. The insulation board material around the surface of the steel ingot caps and molten steel should not stick together as much as possible;

[0038] b) Cleaning up residues: Before putting the steel ingot into the heating furnace for heating, clean up the residual material of the heat insulation plate at the mouth of the cap as much as possible, and at the same time clean the connection between the ingot body and the mouth of the cap and the outer surface of the mouth of the cap with flame gas cutting and other methods to deal with the flying skin , interlayer and other irregular residual steel, try to ensure a smooth transition between the ingot body and the cap opening, ...

Embodiment 2

[0045] The forging method of large and medium-sized steel ingot of the present invention comprises the following steps:

[0046] a) Production of steel ingots: cast steel ingots by pouring method. When producing steel ingots, select thermal insulation boards with good thermal insulation and corrosion resistance. The insulation board material around the surface of the steel ingot caps and molten steel should not stick together as much as possible;

[0047] b) Cleaning up residues: Before putting the steel ingot into the heating furnace for heating, clean up the residual material of the heat insulation plate at the mouth of the cap as much as possible, and at the same time clean the connection between the ingot body and the mouth of the cap and the outer surface of the mouth of the cap with flame gas cutting and other methods to deal with the flying skin , interlayer and other irregular residual steel, try to ensure a smooth transition between the ingot body and the cap opening, ...

Embodiment 3

[0054] The forging method of large and medium-sized steel ingot of the present invention comprises the following steps:

[0055] a) Production of steel ingots: cast steel ingots by pouring method. When producing steel ingots, select thermal insulation boards with good thermal insulation and corrosion resistance. The insulation board material around the surface of the steel ingot caps and molten steel should not stick together as much as possible;

[0056] b) Cleaning up residues: Before putting the steel ingot into the heating furnace for heating, clean up the residual material of the heat insulation plate at the mouth of the cap as much as possible, and at the same time clean the connection between the ingot body and the mouth of the cap and the outer surface of the mouth of the cap with flame gas cutting and other methods to deal with the flying skin , interlayer and other irregular residual steel, try to ensure a smooth transition between the ingot body and the cap opening, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com