Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

581results about How to "No loosening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

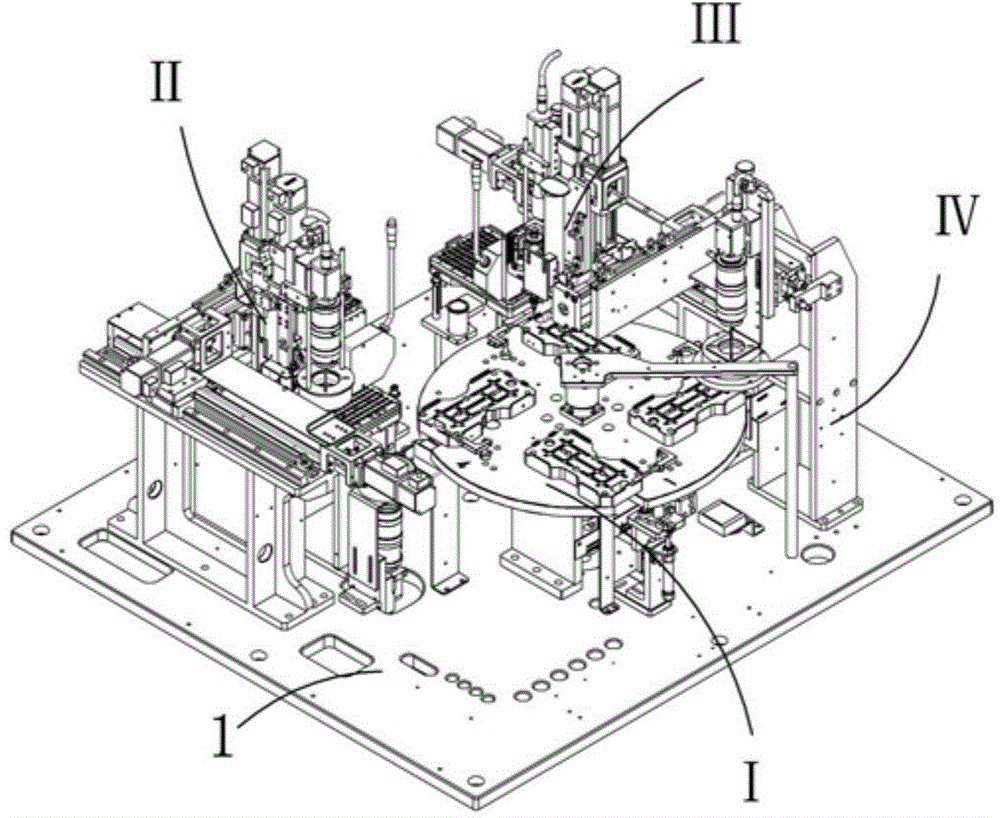

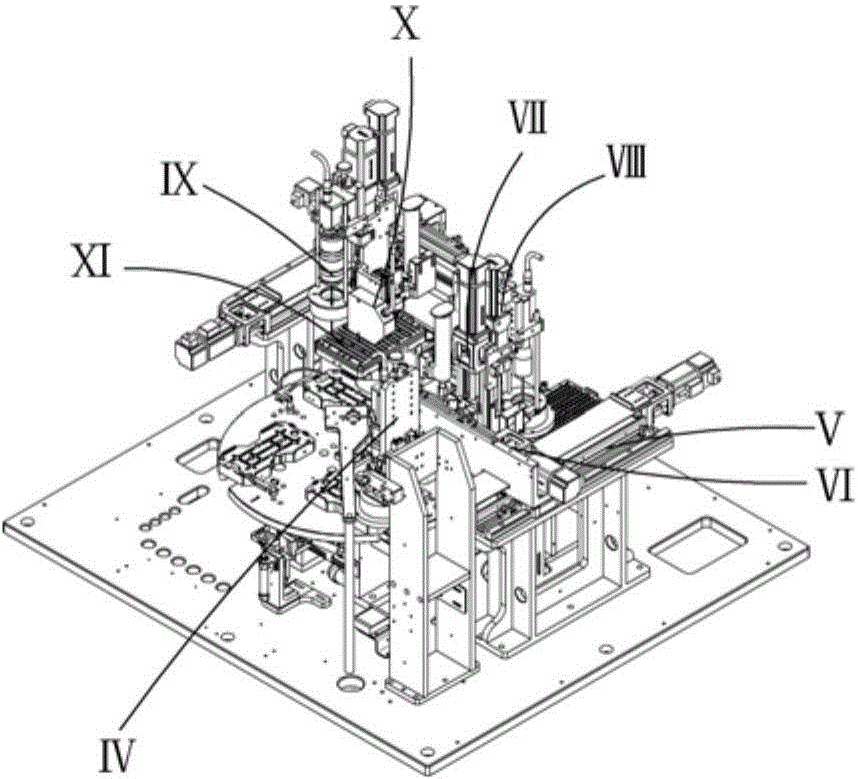

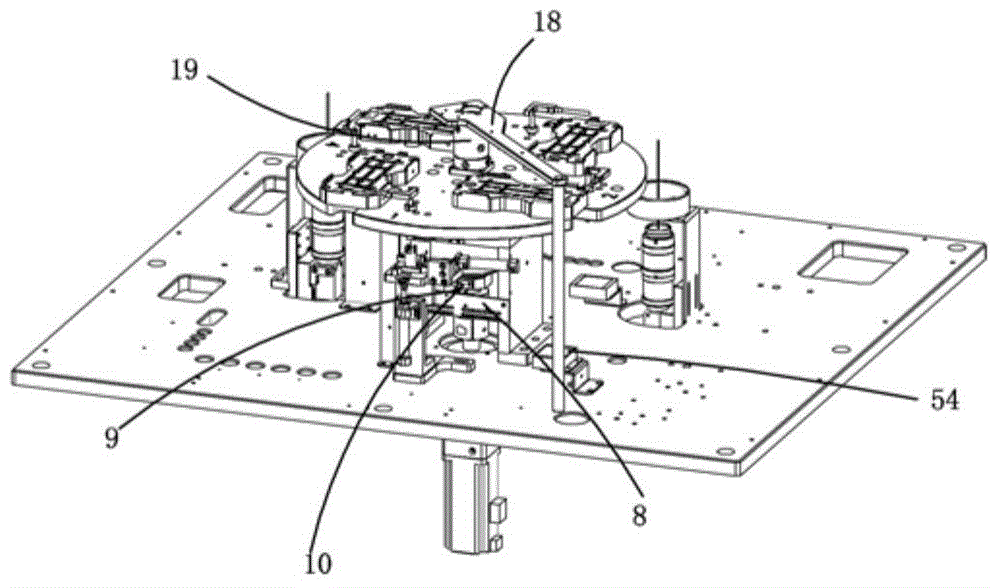

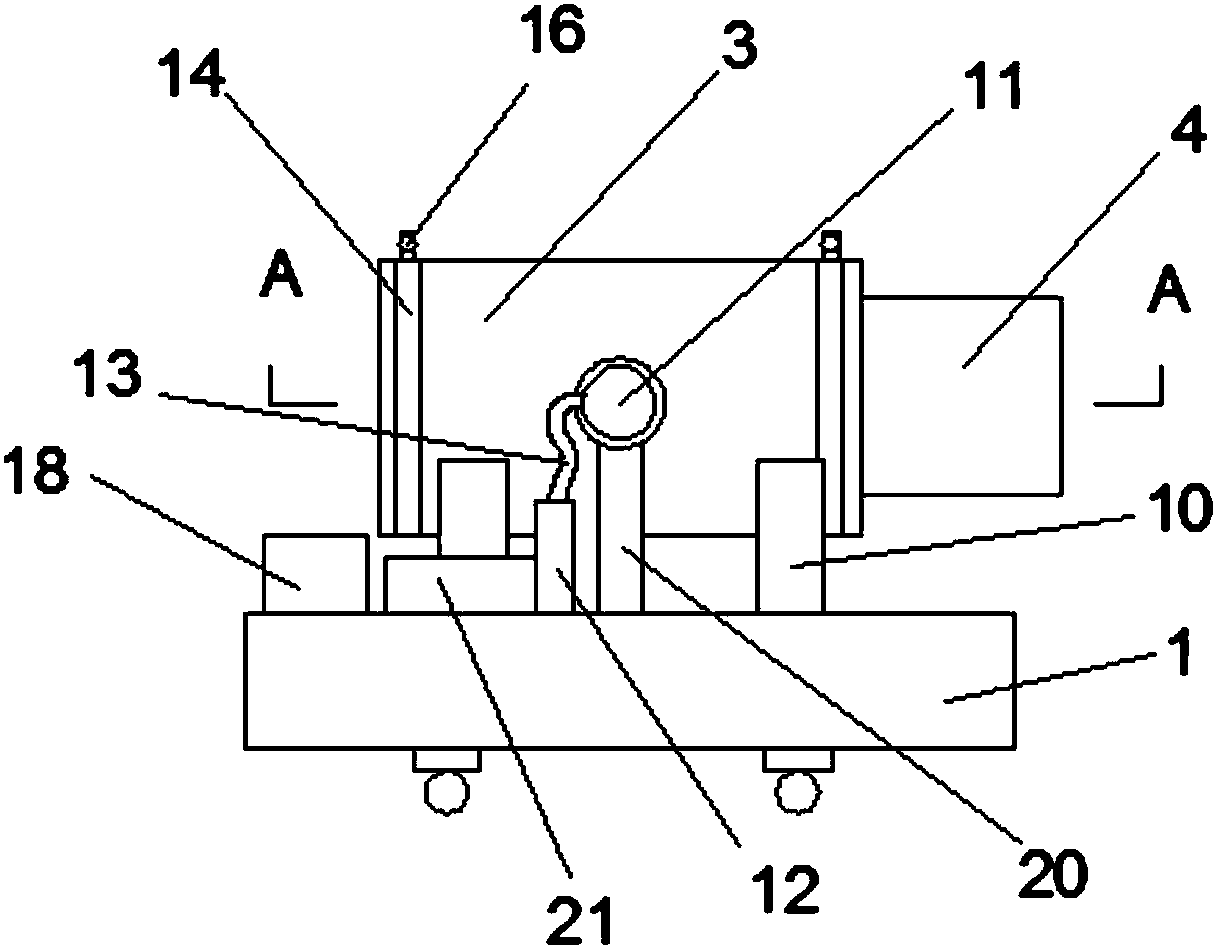

Full-automatic part assembly machine

ActiveCN104551660APrevent camera alignment and other workQuick and accurate assemblyAssembly machinesEngineeringWorkstation

The invention relates to a full-automatic part assembly machine. A rotary plate mechanism is mounted at the center of the bottom plate, a first part assembly workstation and a second part assembly workstation are identical in structure and mounted on the left rear portion and the right rear portion of the bottom plate respectively, and a detecting workstation is mounted on the front portion of the right side of the bottom plate. An operator places a workpiece on a carrier, a rotary motor rotates the carrier on a rotary plate to the first part assembly workstation, and a small part a is assembled onto the workpiece; after assembly, the rotary motor rotates the carrier on the rotary plate to the second part assembly workstation, and a small part b is assembled on the workpiece; after assembly, the rotary motor rotates the carrier on the rotary plate to the detecting workstation, a CCD on the detecting workstation takes pictures and detects whether the assembled workpiece is qualified or not; after detection, the rotary motor rotates the rotary plate to the initial position. The full-automatic part assembly machine is simple to operate, the small parts can be quickly and accurately assembled to the workpiece, labor is saved, production efficiency is improved, and production cost of enterprises is reduced.

Owner:BOZHON PRECISION IND TECH CO LTD

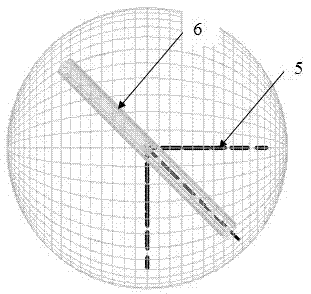

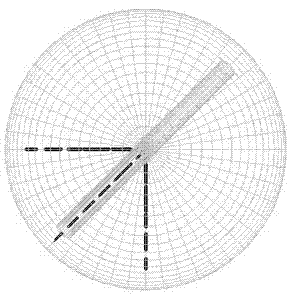

Device and method for integrated collection of stress and displacement of surrounding rocks

InactiveCN102818665ACan measure three-dimensional stressThree-dimensional stress can be calculatedForce measurement by measuring optical property variationUsing optical meansFiberStress measurement

The invention discloses a device for integrated collection of stress and displacement of surrounding rocks, which comprises a spherical body, a casing pipe, a steel wire and an optical cable, wherein a threaded hole is formed by drilling along one diameter of the spherical body; a fiber bragg grating is adhered along six different directions in the spherical body respectively; one end of the steel wire is fixed on the spherical body; and one end of the optical cable is connected with the fiber bragg gratings in the spherical body. According to the device and the method for integrated collection of stress and displacement of surrounding rocks disclosed by the invention, three-dimensional stress of a point can be calculated by measuring stresses in six directions of the point, and stress and displacement can be simultaneously measured in one drill hole, therefore, not only comparison and analysis are convenient, but also accuracy of a test result is ensured as mutual interference among a plurality of near-distance drill holes is avoided, and meanwhile, workloads of the drill holes are decreased; the fiber gratings are not influenced by electromagnetic, humid and corrosive environments, and the spherical body is sufficiently contacted with the surrounding rocks as well as with slurry poured in the holes, so that accuracy and reliability of stress measurement result are guaranteed; furthermore, the spherical body is fixed in surrounding rock holes in a way that slurry is poured into the surrounding rock holes, looseness of the spherical body is avoided, as a result, a wrong displacement test result is prevented.

Owner:CHINA UNIV OF MINING & TECH

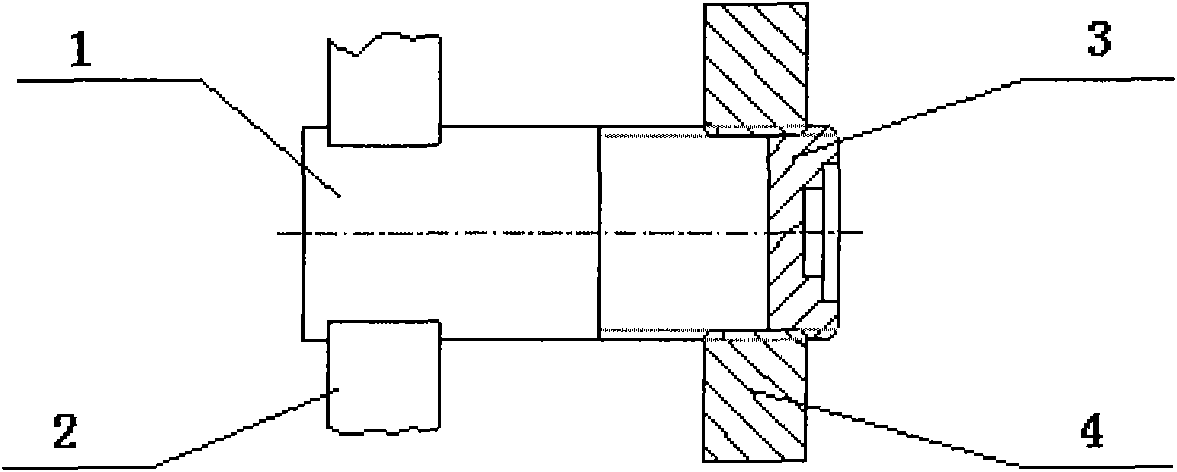

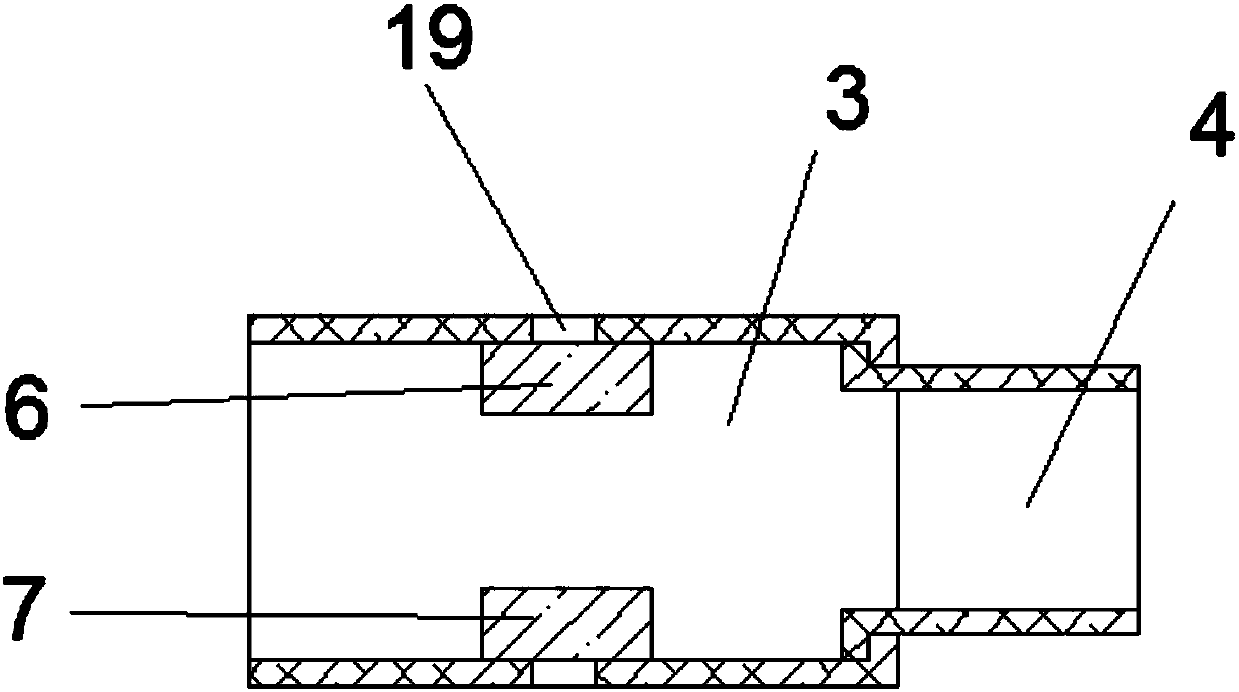

Quick pipeline connecting method and joint using same

The invention discloses a quick pipeline connecting method and a joint using the same. The joint comprises a joint body, wherein a clamping ring, a conical base and an O-shaped sealing ring are sequentially arranged inside the joint body along the pipeline insertion direction; when the pipeline is inserted into the joint, a flange arranged on the clamping ring is deflected; and when the pipeline expands under increased pressure after the introduction of a liquid, the O-shaped sealing ring expands axially under the action of pressure, and the clamping ring is driven to move along a direction opposite to the pipeline insertion direction by pushing the conical base to clamp the pipeline. The invention also discloses a quick pipeline joint adopting the quick connecting method. The joint has the advantages of capabilities of making an elastic pipe body (such as a PEX pipe body) easier to insert and ensuring that the elastic pipe body does not loosen easily after being inserted and expanded due to increased pressure caused by the introduction of the liquid, high air tightness and connecting reliability.

Owner:LA CASA ANGELA HLDG

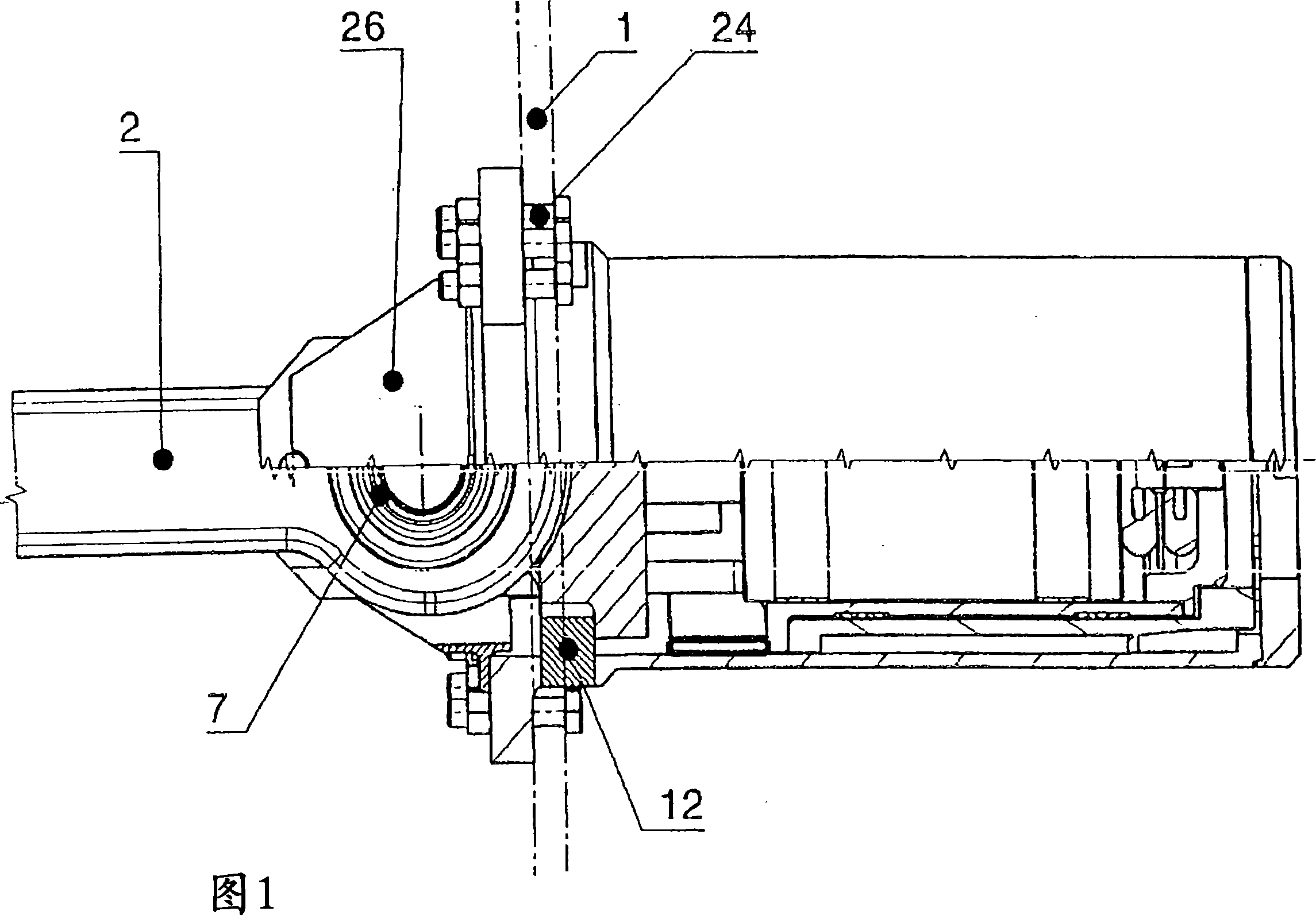

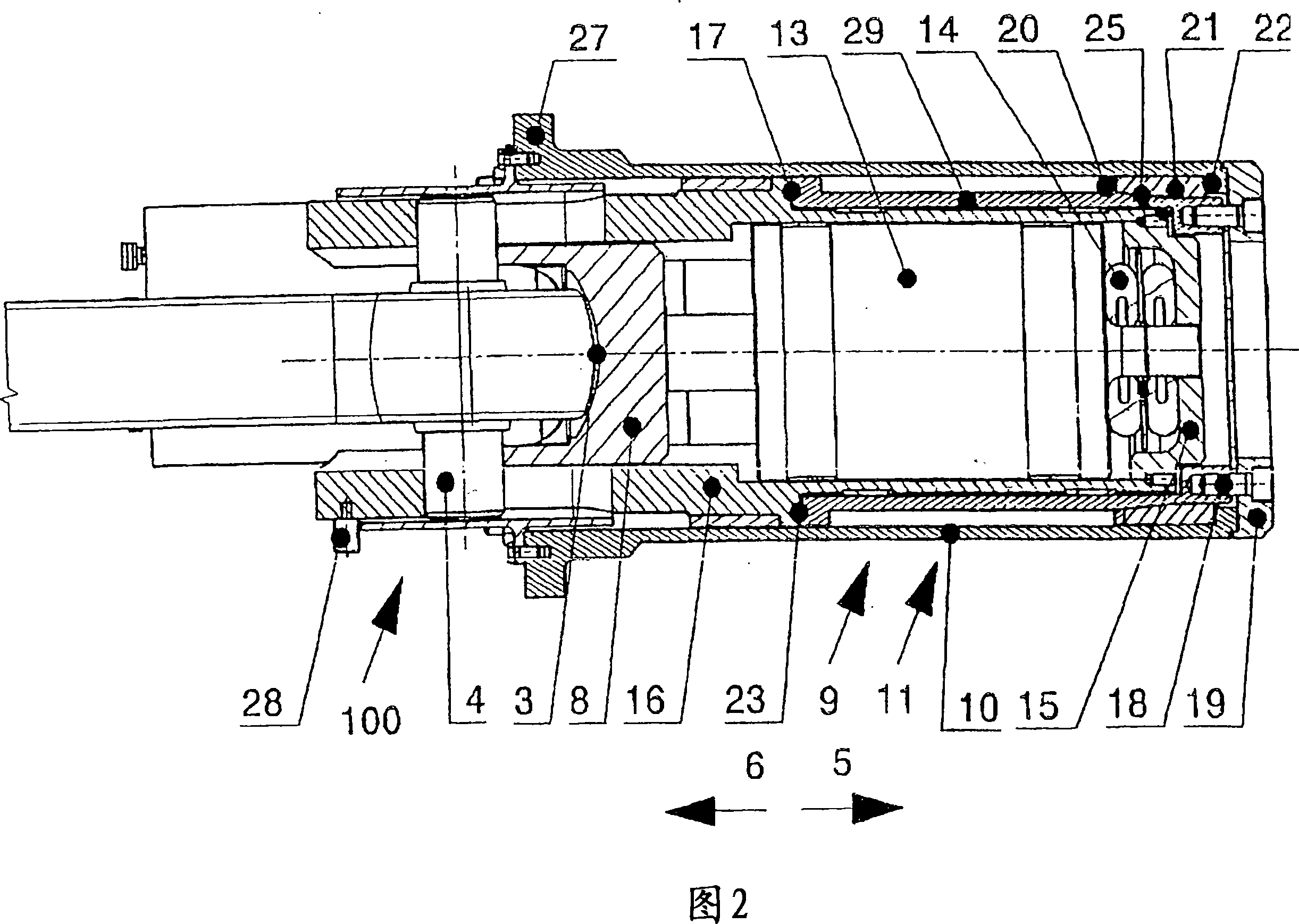

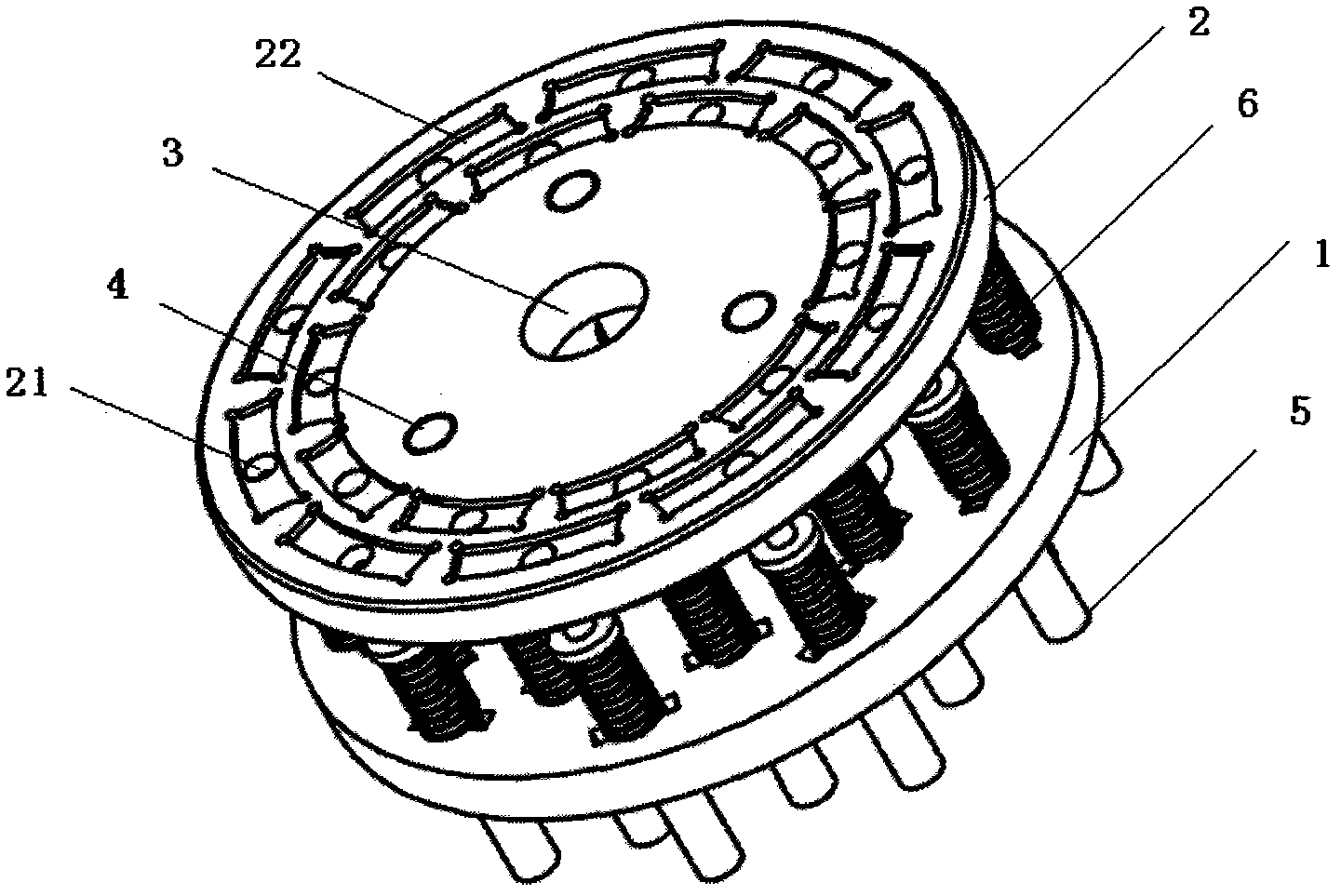

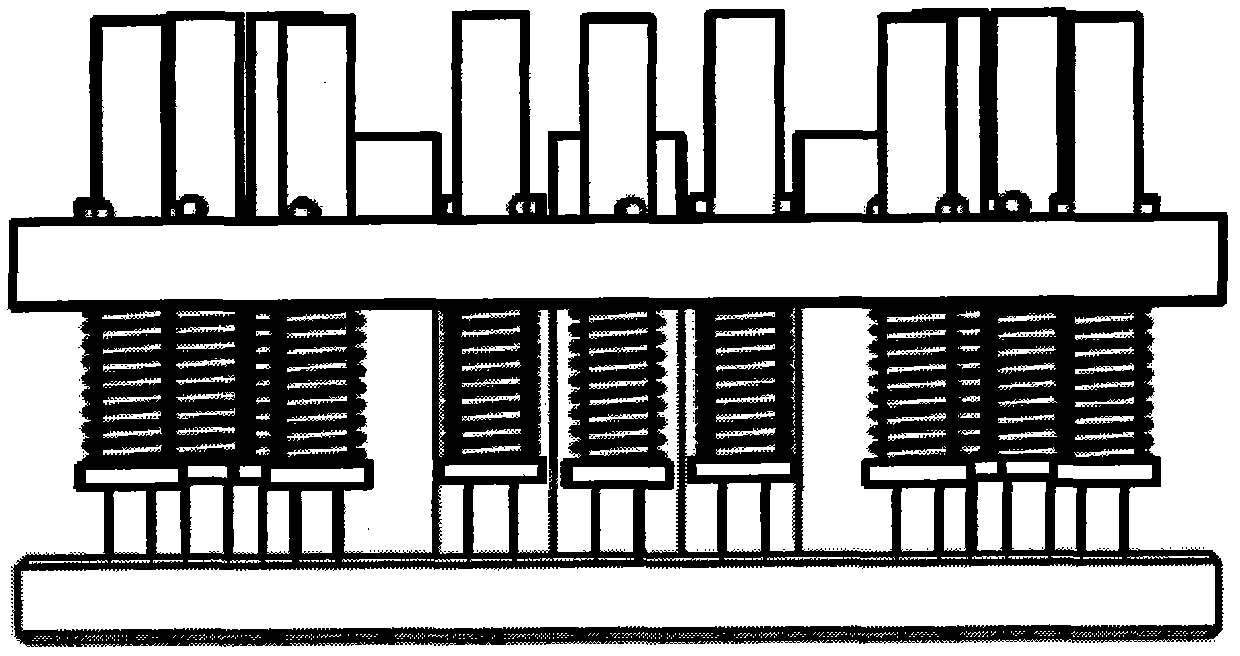

Pulling and pushing device for a central buffer coupling of rail vehicles

InactiveCN101142115AAvoid acceleration peaksSo as not to damageBuffer carsDraw-gearBogieEnergy absorption

The device has a coupling arm with head born elastically pref. via a stabilizer joint. The joint transmits traction and pressure forces into the bogie via an outer housing (10) and energy absorption systems (9,11). The systems are switched in series and are located in the housing. One and / or both systems have an irreversibly deformable deformation element (23), e.g. a mechanical shock absorption part. This is e.g. a tube, which is deformed by a nozzle (25) or a pressure ring (21), after a set pressure and / or traction load limit on shear ring (20) and / or pin has been exceeded. -

Owner:FAIVELEY TRANSPORT REMSCHEID

Welding fixture

The invention relates to a welding fixture which comprises an upper pressure plate and a lower pressure plate, wherein the upper pressure plate and the lower pressure plate comprise central positioning holes which are arranged coaxially, the lower pressure plate is provided with a tooth block positioning hole, a tooth block mounting groove is arranged on the lower surface of the lower pressure plate and the welding fixture is characterized in that a tooth block positioning screw rod and a tooth block pressure spring are mounted between the upper pressure plate and the lower pressure plate. The welding fixture is simple in structure and can always keep the fastening connection between a tooth block and the welding surface of a basal body by high-temperature welding and avoid the phenomena of looseness and poor welding.

Owner:江苏华昌工具制造有限公司

Injectable expansion type bone cement and preparation method thereof

ActiveCN104922733ANo shedding phenomenonThere will be no shedding phenomenonProsthesisCross-linkHydroquinone Compound

The invention discloses injectable expansion type bone cement. The injectable expansion type bone cement is made by mixing a solid phase composition and a liquid phase composition according to the mass ratio of 1.5:1-3:1, wherein the solid phase composition is a methyl methacrylate-acrylic acid copolymer while the liquid phase composition is a mixture of methyl methacrylate, N,N-dimethyl toluidine and hydroquinone. The preparation method includes: taking the methyl methacrylate and the crylic acid as reactive monomers generating polymerization reaction under the action of an initiator and a cross-linking agent to generate the methyl methacrylate-acrylic acid copolymer; evenly mixing the methyl methacrylate, the N,N-dimethyl toluidine and the hydroquinone to the liquid phase composition; mixing the solid phase composition with the liquid phase composition according to the mass ratio of 1.5:1-3:1 in proportion, stirring to obtain bone cement fluid, and obtaining the injectable expansion type bone cement after self-setting.

Owner:XIAN UNIV OF TECH

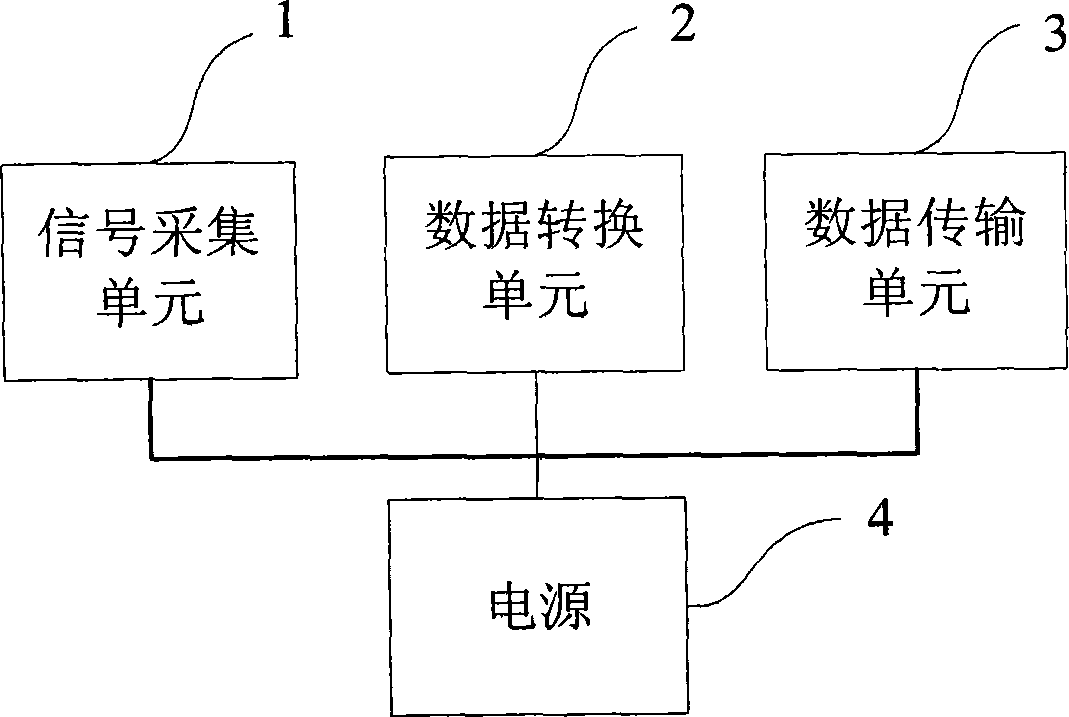

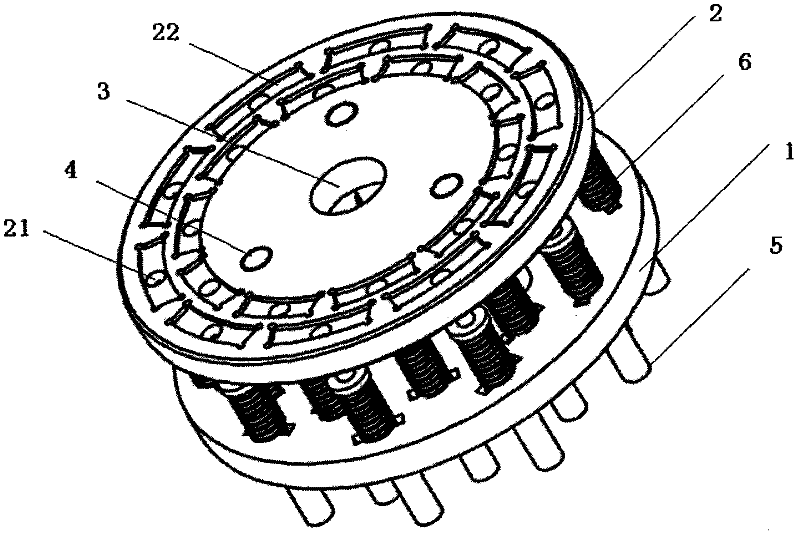

Bicycle treading frequency sensor and fixing device

The invention discloses a bicycle treading frequency sensor. The bicycle treading frequency sensor comprises a signal collecting unit, a data transmitting unit and a power source. The signal collecting unit is arranged on a circuit board and used for collecting motion acceleration changes or / and angular velocity changes in different rotation directions of a middle axle in real time. The data transmitting unit is used for transmitting collected data to a terminal. The power source is used for working of all units. In the using process, the treading frequency sensor is fixed to the hollow middle axle of a bicycle, the middle axle, a crank and pedals of the bicycle rotate synchronously, in the process of riding, acceleration change or / and angular velocity change data are collected in real time, and then treading frequency data are collected in the process of riding. Because the treading frequency sensor ingenuously performs counting through periodical changes of the acceleration or / and angular velocity and other data in the process of bicycle motion and does not need to perform counting in a sensing mode through periodical relative motion between two separated components, the structure is simple, the size is small, and working is stable and reliable.

Owner:SHENZHEN QIANHAI LIVALL IOT TECH

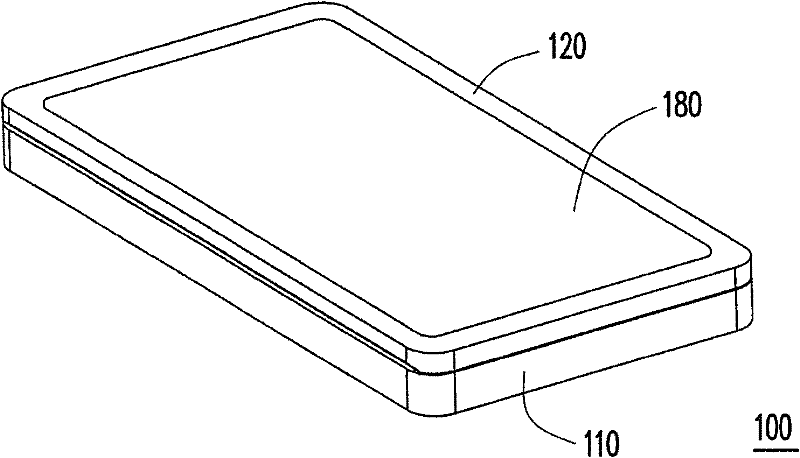

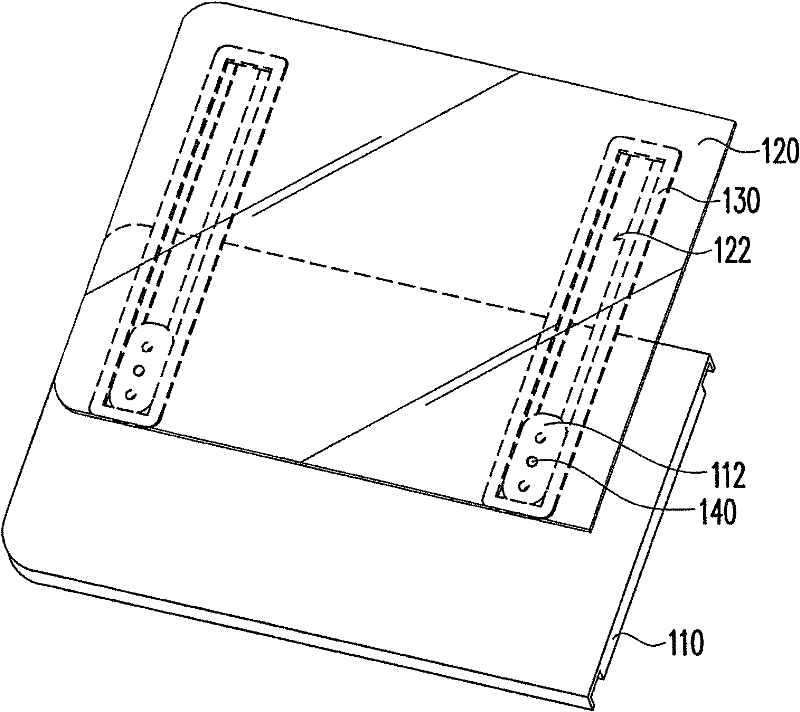

Handheld electronic device

InactiveCN102448270AConducive to thinningImprove operational stabilityCasings/cabinets/drawers detailsTelephone set constructionsEngineeringBearing surface

The invention discloses a handheld electronic device which comprises a first machine body, a second machine body, a sliding block and a positioning part. The first machine body is provided with a bearing surface. The second machine body is stacked on the bearing surface of the first machine body. A bottom surface of the second machine body faces the bearing surface of the first machine body and is provided with a chute. The sliding block is fixedly arranged on the bearing surface of the first machine body and is arranged in the chute in a sliding mode. The positioning part is arranged on the sliding block and is pressed against the inner wall of the chute. The inner wall of the chute is provided with a plurality of positioning concave holes. The positioning concave holes are respectively positioned at a plurality of positions of a moving path of the positioning part so as to mutually interfere with the positioning parts at the positions.

Owner:HTC CORP

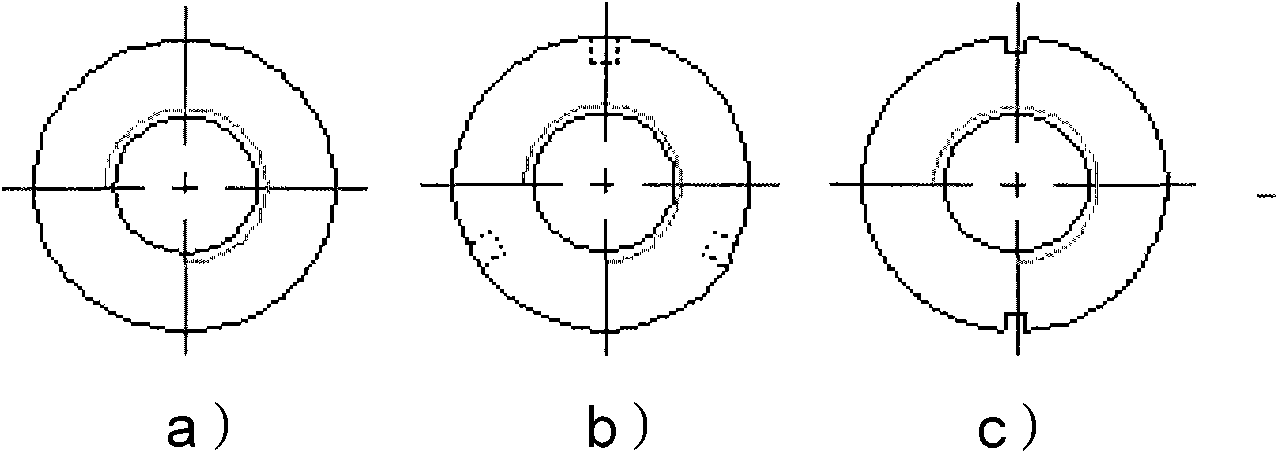

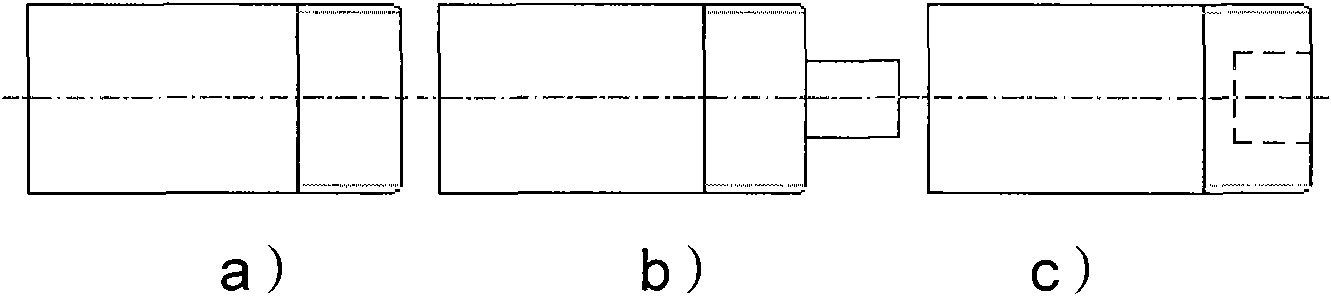

Turning positioning fixture for thin-wall rotational parts and clamping method

ActiveCN101972943AReduce distortionNot easy to damagePositioning apparatusMetal-working holdersEngineeringAxial force

The invention relates to a turning positioning fixture for thin-wall rotational parts and a clamping method. The fixture comprises a cylindrical positioning body and threaded rings, wherein an external thread is lathed on the external surface of the positioning end; the threaded rings are circular rings with internal diameter the same as the external diameter of the positioning body; the internal surfaces of the threaded rings are provided with internal threads matched with the external thread on the positioning body; and during positioning, one end of the positioning body is clamped on a machine tool and the positioning end is closely contacted with the part, and the positioning body is closely matched with the part through the external thread on the external surface and the internal threads on the threaded rings. In the embodiment, the clamp force on the part is mainly axial force, thus overcoming the negative effect that radial force leads to workpiece deformation during traditional machining; and the positioning body is clamped and lathed at the site, and during positioning and clamping, firstly the positioning body is ensured to be fit with the end face of the part and the end face runout of the part is ensured to be identical with that of the spindle of the machine tool, thus ensuring the flatness and the parallelism of the part. The fixture can carry out automatic alignment and positioning while screwing the threaded rings, is convenient to operate and reduces artificial operation errors.

Owner:BEIJING RES INST OF TELEMETRY

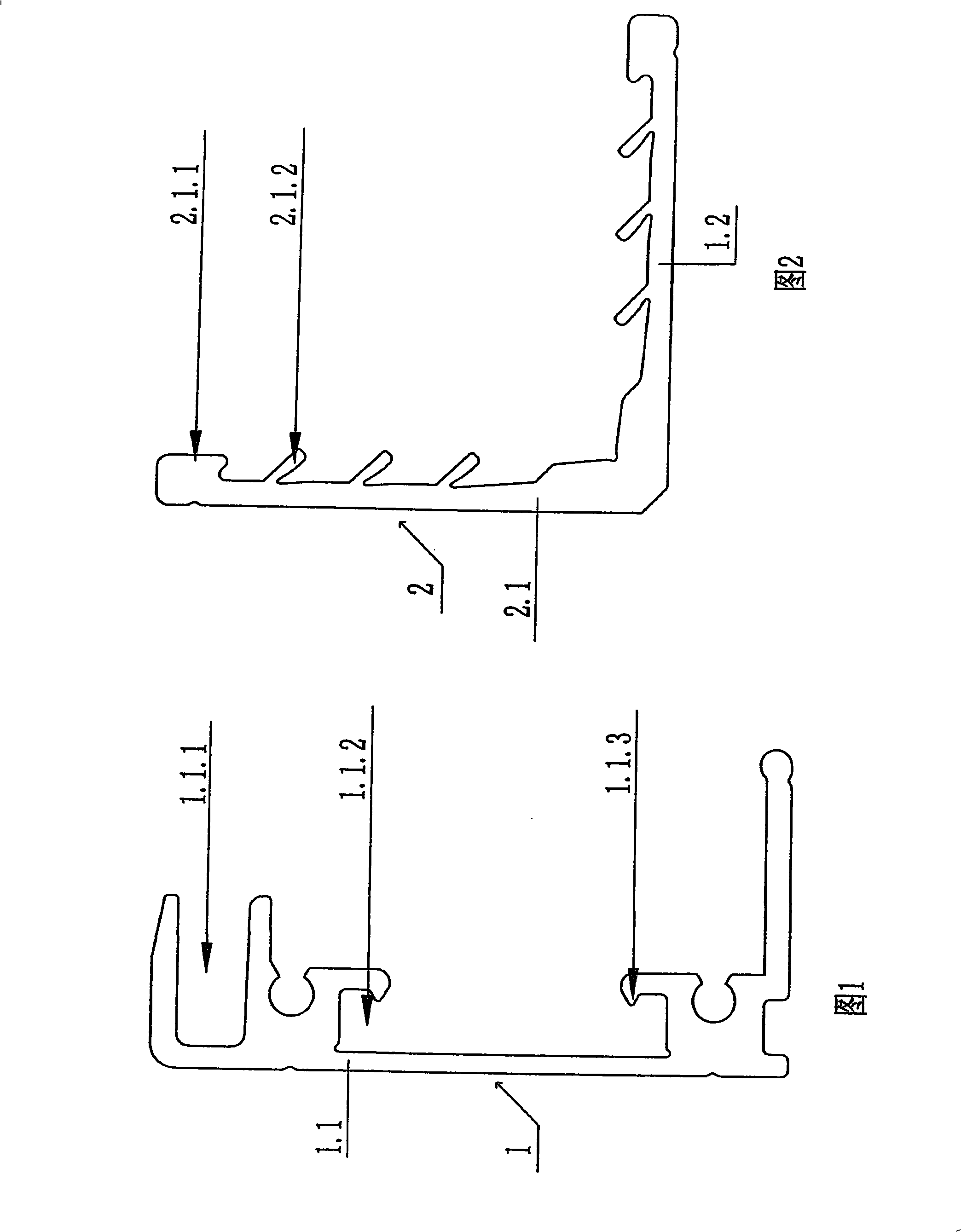

Photovoltaic solar frame aluminium alloy section with overlength service-life, production method and structure thereof

InactiveCN101294254ANo looseningPhotovoltaicsPhotovoltaic energy generationPhotovoltaic solar energyHigh intensity

The invention relates to a super-long life aluminum alloy proximate matter used on a photovoltaic solar framework, a preparation method, and a structure. The raw material of the proximate matter mainly comprises alloying elements by weight percentage as follows: Si is 0.3 to 0.5 percent, Mg is 0.6 to 1.1 percent, Cu is 0.06 to 0.12 percent, Fe is less than or equals to 0.2 percent, Ti is less than or equals to 0.1 percent, Mn is less than or equals to 0.1 percent, Zn is less than or equals to 0.1 percent, Cr is less than or equals to 0.1 percent, and the other weight percentage is composed of Al and ineluctable impurities, wherein, Si:Mg equals to 1:1.75 to 1:180. The invention has the preparation method that the Al is put in a smelter hearth for smelting; when the temperature of Al liquid in the smelter hearth reach 720 DEG C to 760 DEG C, the Cu is added first and then the Si and the Mg are added in sequence according to proportions, and the smelting lasts for 5.5 to 6 hours; then a aluminum bar is casted and extruded to form the aluminum alloy proximate matter. The structure of the framework comprises the proximate matter (1) and a corner code (2). The super-long life aluminum alloy proximate matter has high intensity and strong corrosion resistance, and the fit clearance between the proximate matters cannot be loosened.

Owner:徐友才

Building tubular product cutting clamp

InactiveCN107891297AIncrease clamping forceEasy to cutMeasurement/indication equipmentsPositioning apparatusBiochemical engineeringHydraulic pump

The invention discloses a building tubular product cutting clamp in the technical field of buildings. A clamp inner barrel is arranged in an inner cavity of a clamp outer barrel, a first clamping sheet and a second clamping sheet are arranged on the two sides of the inner cavity of the clamp outer barrel, pressure sensors are arranged inside the first clamping sheet and the second clamping sheet,a first piston barrel device and a second piston barrel device are connected to a first hydraulic oil pump and a second hydraulic oil pump through soft oil pipes correspondingly, a stepping motor is arranged on the side, far away from a clamp inner barrel, of the second hydraulic oil pump, and a controller is arranged on the side, far away from the second hydraulic oil pump, of the stepping motor.The building tubular product cutting clamp is high in reliability, the clamping force on a building tubular product is large, and looseness can be avoided in the cutting process; and in addition, themachining quality and the machining efficiency can be effectively guaranteed, length measurement on the building tubular product can be carried out through length scales on the clamp inner barrel soas to facilitate fixed-length tubular product cutting, and the cutting convenience is greatly improved.

Owner:叶潇

Integral high-frequency brazing process using welding fixtures

ActiveCN102294528ASimple structureEasy to useWelding/cutting media/materialsSoldering mediaAdjuvantFiller metal

The invention relates to a process for carrying out entire high-frequency brazing by a welding jig, which comprises the preparation of a matrix and the preparation of diamond gear blocks. Uniformly stirred silver based brazing filler metal and welding adjuvants are uniformly coated on surfaces to be brazed of the diamond gear blocks, then a millstone matrix and the diamond gear blocks are positioned and fixed by the welding jig, and finally the millstone matrix and the diamond gear blocks are arranged in a vacuum brazing furnace to be brazed. The process for carrying out entire high-frequencybrazing by the welding jig overcomes the technical problems of complex manufacturing process, low production efficiency, unstable quality and high production cost of the diamond millstone in the prior art, and on the premise of ensuring the welding quality to be stable, the brazing efficiency is greatly improved, and the production cost is effectively reduced.

Owner:江苏华昌工具制造有限公司

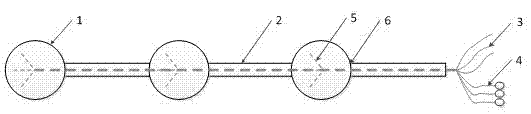

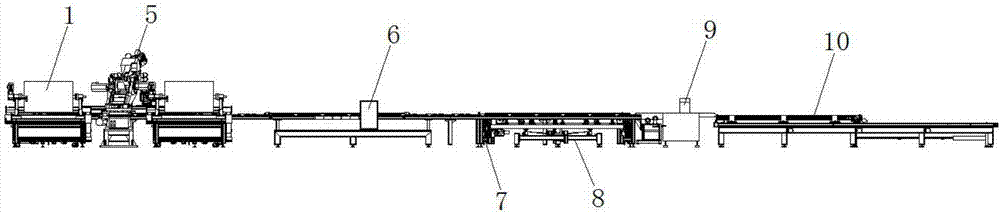

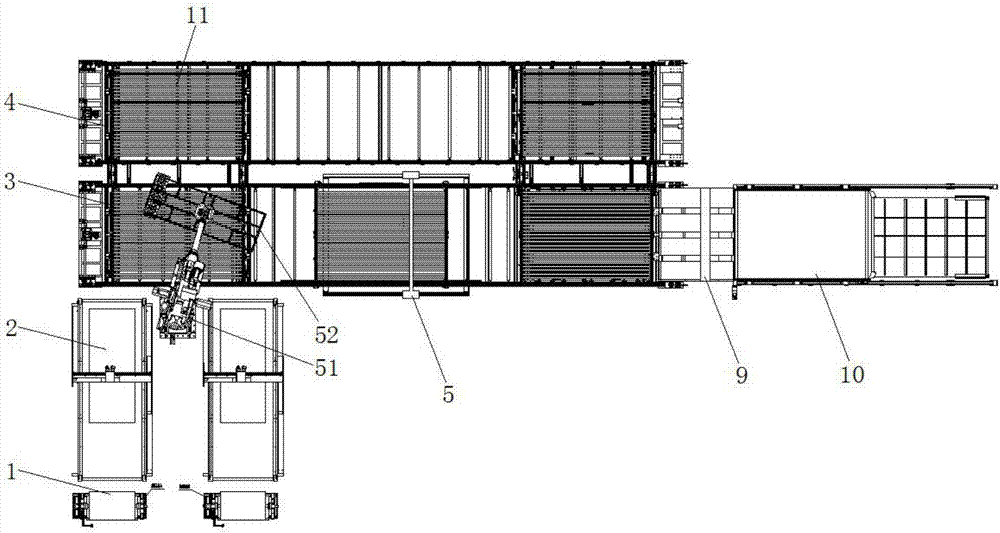

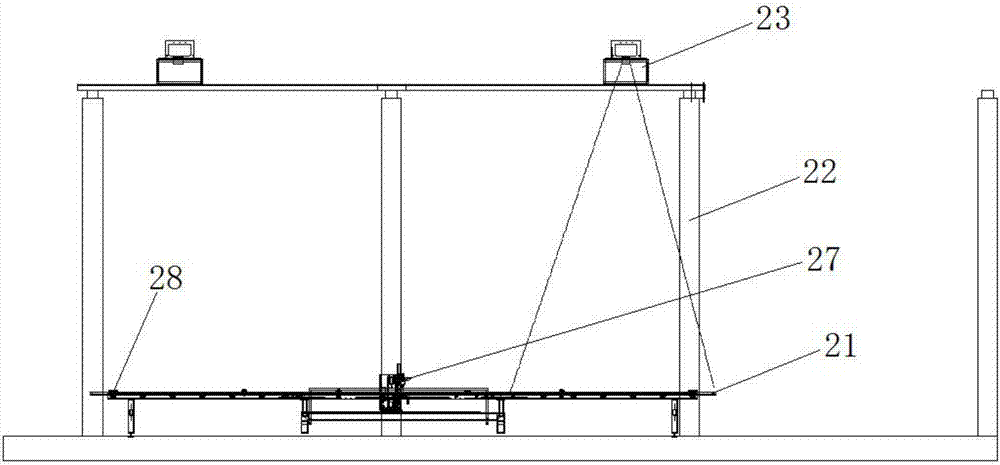

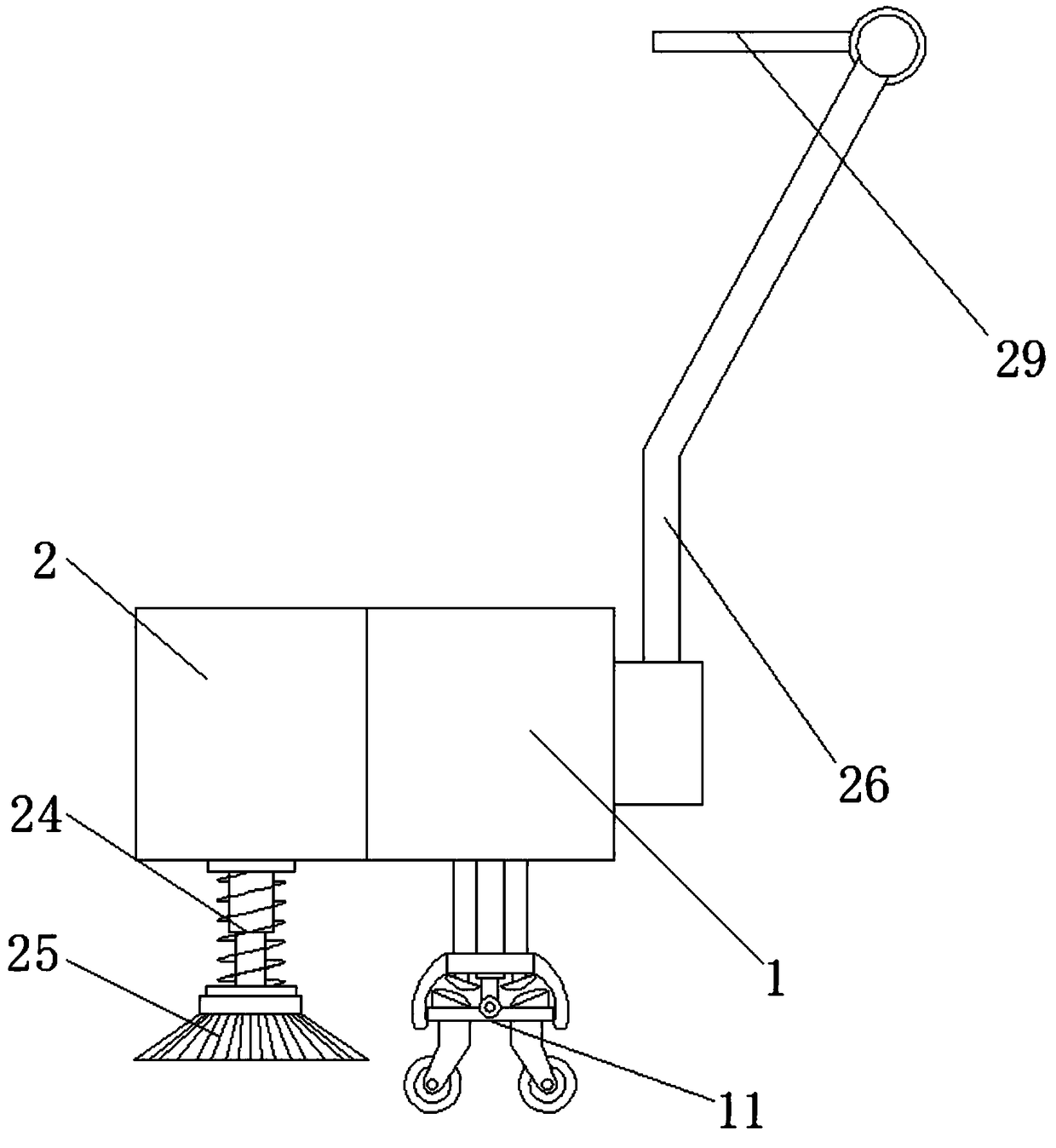

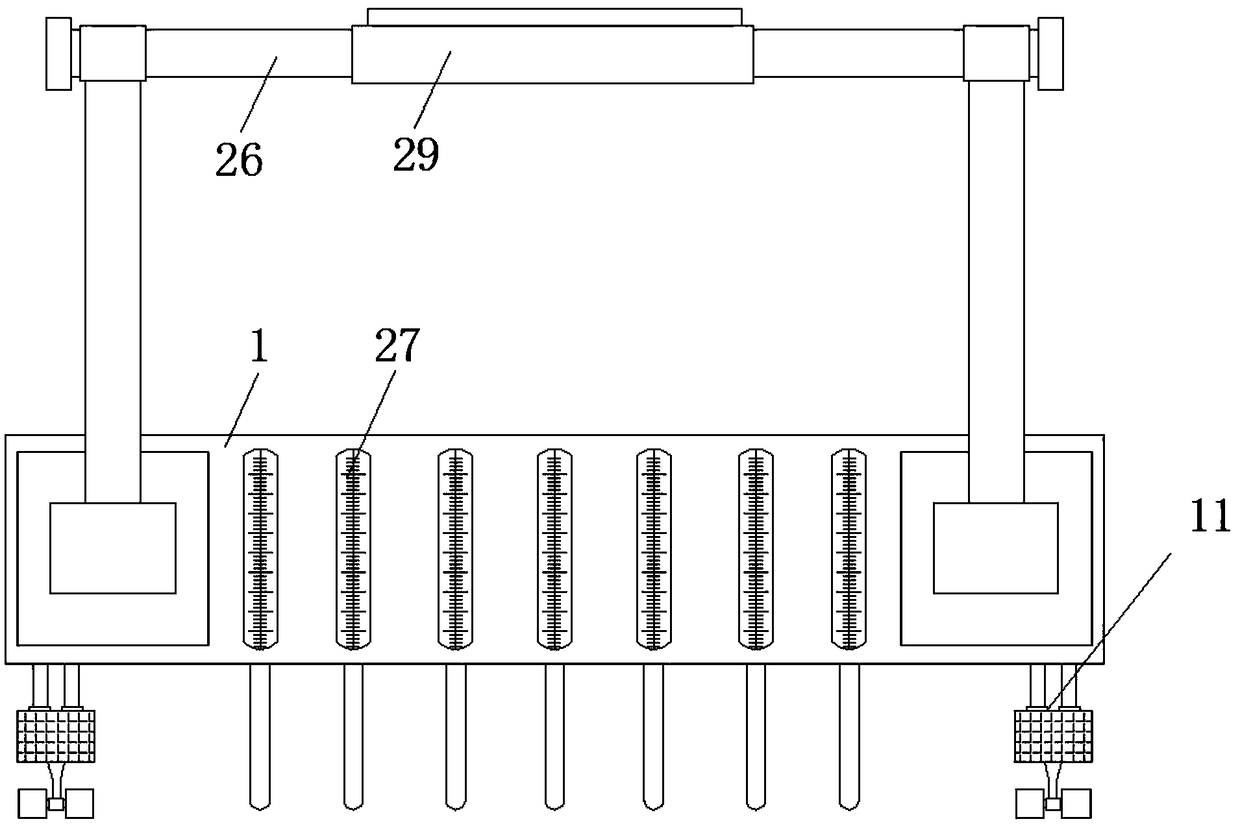

Wind power blade preforming production line

PendingCN107327376AIncrease productivityImprove cutting accuracyEngine manufactureWork-feeding meansElectricityTextile

The invention discloses a wind power blade preforming production line. An unreeling mechanism is arranged near the input end of a cutting mechanism; the output end of the cutting mechanism is arranged near the input end of a first conveying line; a second conveying line and the first conveying line are arranged adjacent and in parallel; the conveying directions of the second conveying line and the first conveying line are opposite; a grabbing and stacking mechanism is arranged near the output end of the cutting mechanism and the input end of the first conveying line; a sewing mechanism is arranged on the middle part of the first conveying line; the first conveying line, a metal detection mechanism and a stacking and discharging mechanism are arranged sequentially along the conveying direction of the first conveying line; a turnover box is conveyed on the first conveying line and the second conveying line; jacking and translation mechanisms are arranged at the bottoms of the input end and the output end of the first conveying line as well as at the bottoms of the input end and the output end of the second conveying line; and a jacking and cloth taking mechanism is arranged at the bottom of the output end of the first conveying line. According to the wind power blade preforming production line, automatic production of a wind power blade preforming piece is realized and the production efficiency is effectively improved.

Owner:NEWTRY COMPOSITE

Flatness detection device based on civil engineering

InactiveCN108691263ADoes not affect measurementValid triggerRoads maintainenceTouch switchCivil engineering

The invention discloses a flatness detection device based on civil engineering and relates to the technical field of civil engineering. A connecting box is fixedly connected to one side of a box body.Vertical frames are fixedly connected between the top and the bottom of the inner wall of the box body. The two vertical frames are arranged and located on the left side and the right side of the inner wall of the box body. A first electric telescopic piece is fixedly connected to the top and the bottom of one side of the inner wall of each vertical frame. By the adoption of the flatness detection device based on civil engineering, the device can be effectively triggered and stopped through a touch switch when an unstable condition happens, and stability is guaranteed; through mutual cooperation, whether flatness is reached or not can be known in time, observation is conducted, the accuracy in the measurement process is guaranteed, and work efficiency is improved; and the angles of pressswitch pieces correspond to those of squeezing blocks, the overall balance of the device can be guaranteed in the uphill and downhill processes, an inclination state is avoided, and the stability in the measurement process is guaranteed.

Owner:FUNAN GAOFUXING INTELLIGENT TECH CO LTD

Interbody fusion deVice based on 3D printing and preparation method of deVice

ActiveCN108670505AImprove bindingTightly boundAdditive manufacturing apparatusSpinal implantsCell adhesionAdhesion process

The inVention discloses an interbody fusion deVice based on 3D printing and a preparation method of the deVice. By adopting polyaryletherketone series materials as basic raw materials, adopting a mixture of degradable high-molecular materials and actiVated osteogenesis powder as an auxiliary raw material and utilizing a dual-sprayer extrusion-type 3D printing technology, the interbody fusion deVice is prepared. The interbody fusion deVice is of a hollow three-dimensional through structure, wherein the Volume ratio of the basic raw materials to the auxiliary raw material is (1:0.01)-(1:1). Thesurface of the interbody fusion deVice is proVided with cell identification sites, and therefore the interbody fusion deVice is applicable to a micro enVironment for cell adhesion and new bone deposition, so that the combination capability between the interbody fusion deVice and new bones is improVed. MoreoVer, with degradation of the degradable high-molecular materials, spaces of porous structures can be formed, gradual growth of the new bones into the spaces is facilitated to achieVe close combination between the interbody fusion body and bone tissue, and loosening and displacement of the interbody fusion deVice cannot occur.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

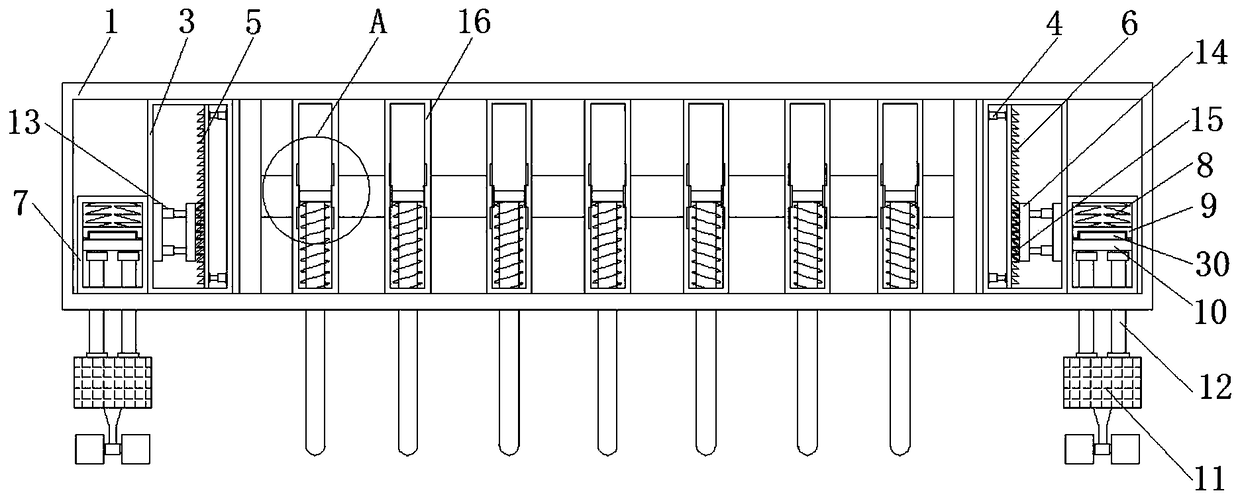

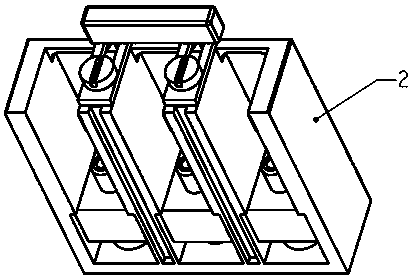

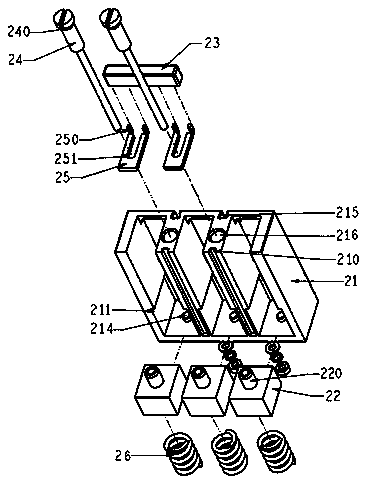

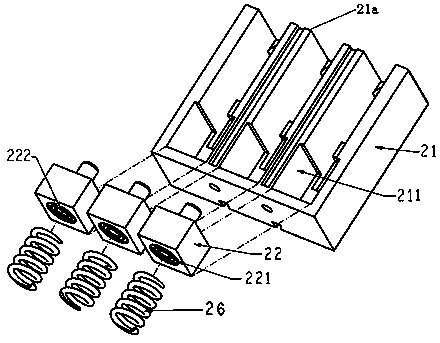

Junction device of circuit breaker, circuit breaker and circuit breaker assembly

ActiveCN104064411AAchieve electrical connectionEnsure close contactProtective switch terminals/connectionsStructural engineeringCircuit breaker

The invention provides a junction device. The junction device comprises a wire holder, a plurality of installing grooves arranged side by side are formed in the wire holder, and springing pieces are arranged in the installing grooves and installed in the installing grooves through fixing assemblies. Each springing piece is provided with an installing part, wherein the installing part can be respectively connected with a circuit breaker body plugged into the corresponding installing groove and a cable terminal. A ridge is formed between every two adjacent installing grooves and provided with a circuit breaker body positioning assembly. Each circuit breaker body positioning assembly comprises a sliding piece and a fixing piece for fixing the positioning assembly to the corresponding ridge, wherein the sliding piece can slide along the ridge so as to be fixedly connected in a plugged mode or separated from the corresponding circuit breaker body. The device solves the technical problems that in the prior art, the operation of connection between a circuit breaker and a cable is complex, and time and labor are wasted, avoids the phenomenon that when installing the circuit breaker, a user uses a large number of screws to connect the circuit breaker and the cable, and is convenient for the user to use.

Owner:DELIXI ELECTRIC

Linkage self-locking type car hub fixing device

ActiveCN107214537ANo looseningCompact structurePositioning apparatusMetal-working holdersSelf lockingScrew thread

Owner:ANHUI JIANGHUAI WHEEL CO LTD

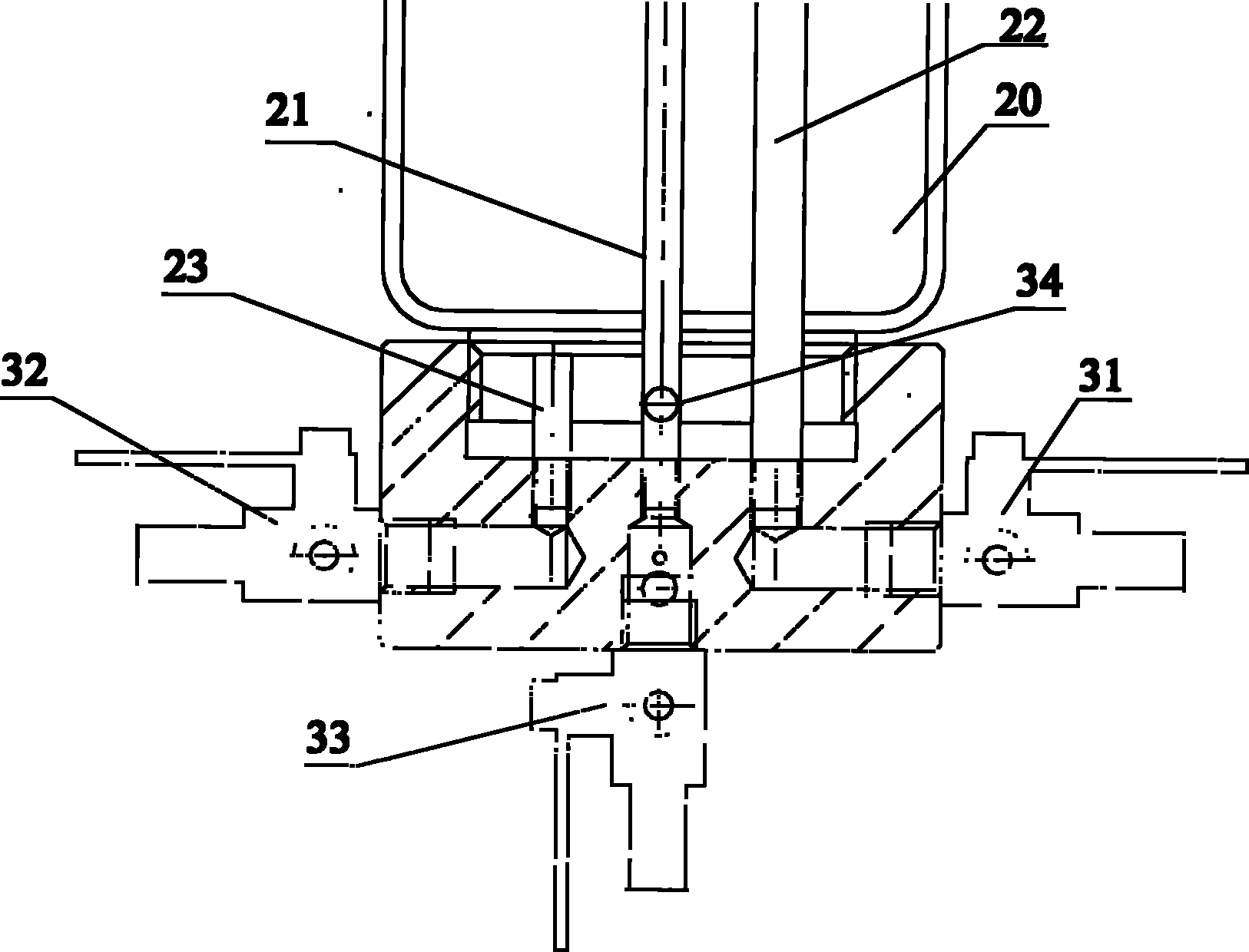

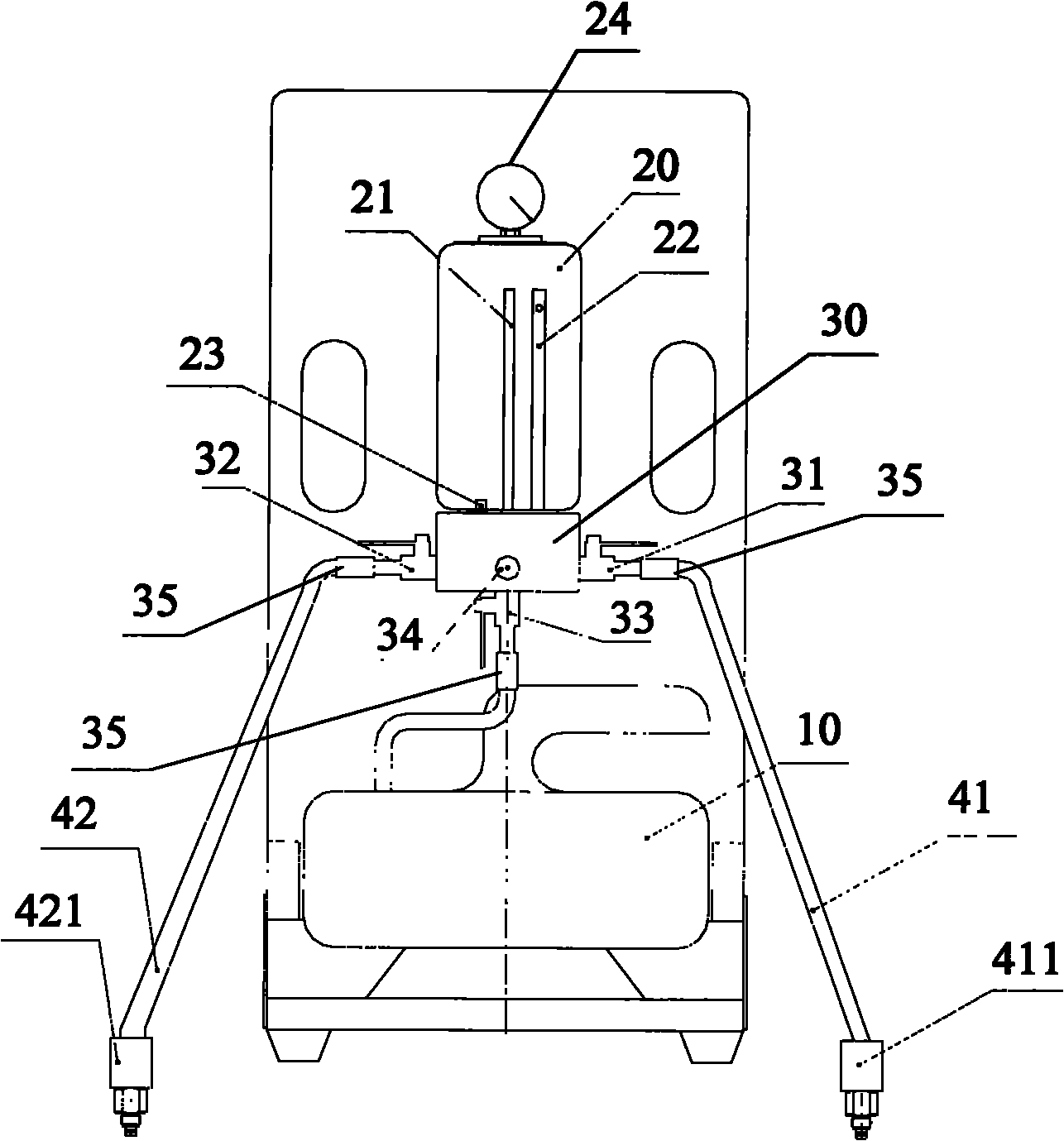

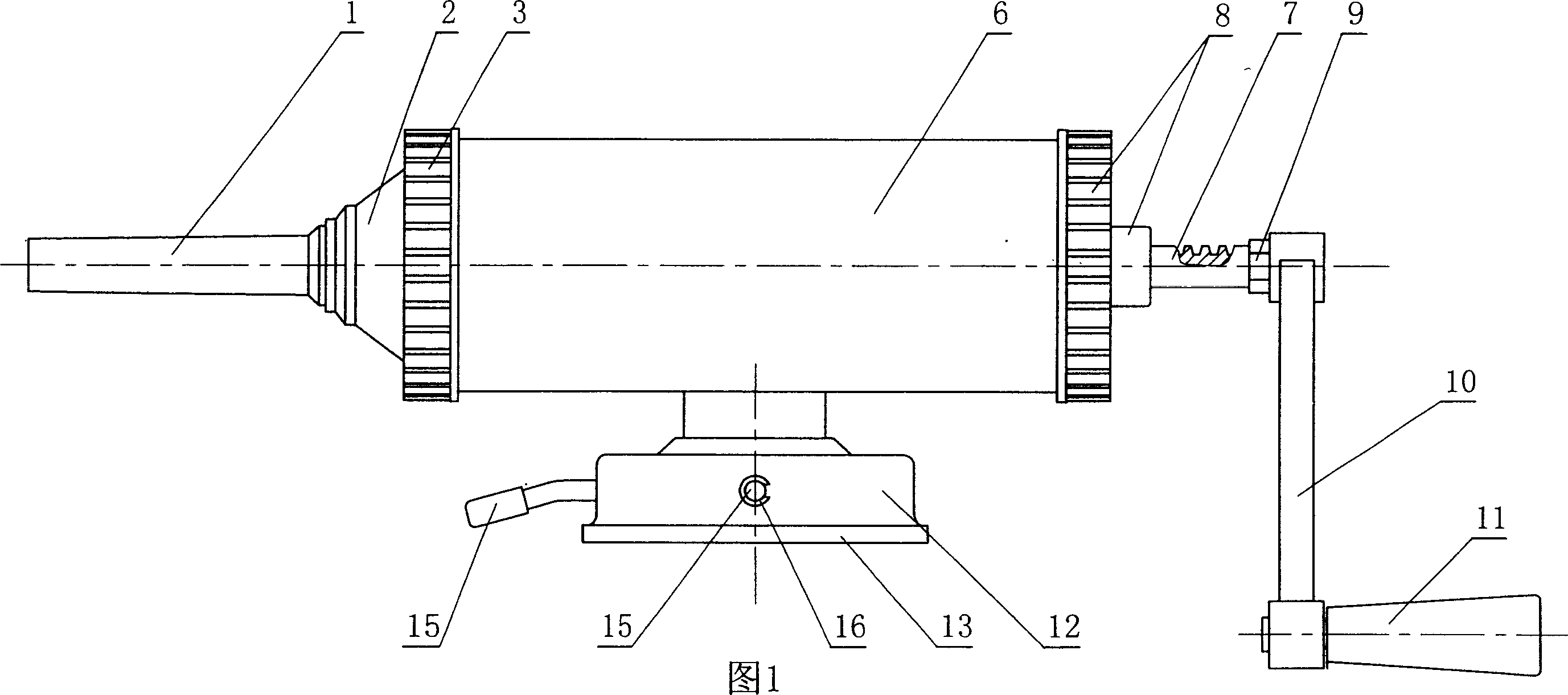

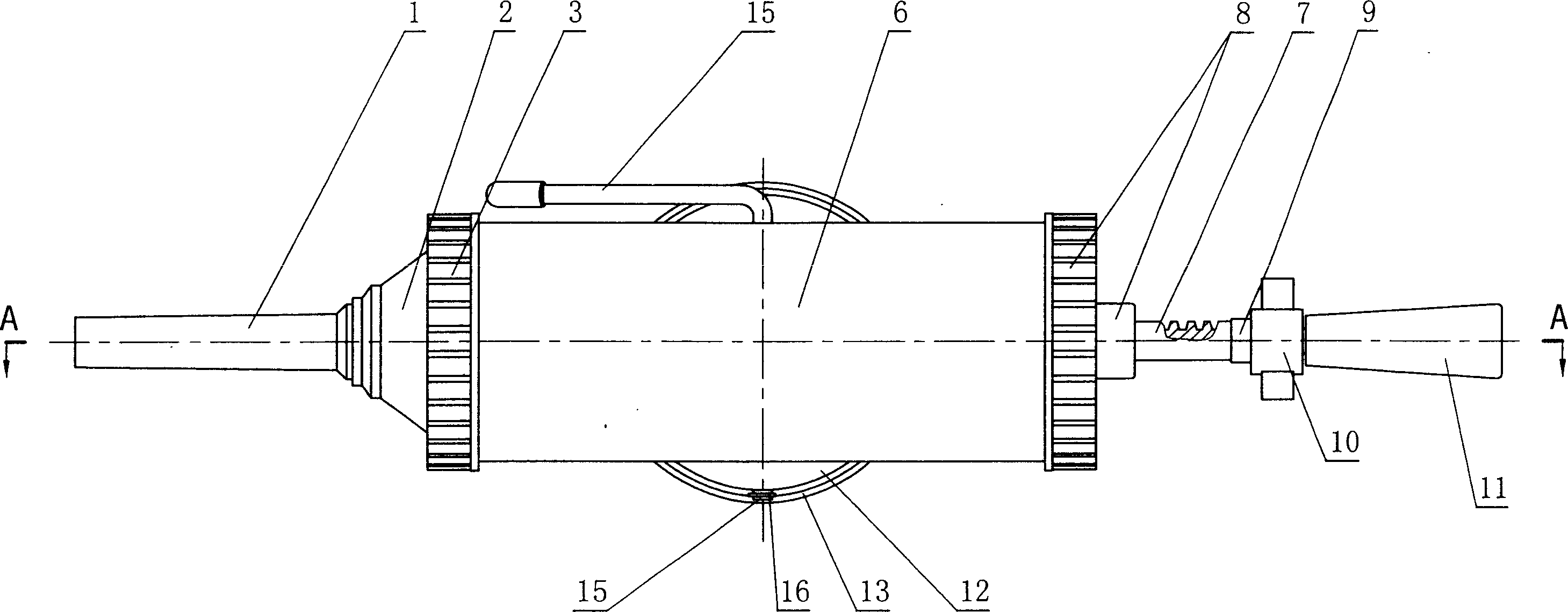

Speed oil filling device for pulse generator of wireless inclinometer and using method thereof

ActiveCN102080534AReduce residual air bubblesNo looseningSurveyLubrication check valvesVacuum pumpAtmosphere

The invention relates to a speed oil filling device for a pulse generator of a wireless inclinometer and a using method thereof, wherein the oil-filled device comprises a vacuum pump, an oil tank, an oil inlet pipeline and an oil outlet pipeline; the oil tank is internally provided with a suction pipe, an oil filling pipe and an oil charging pipe, wherein the suction pipe is connected with the vacuum pipe, and the communication is controlled by a third valve; the oil filling pipe is connected with the oil inlet pipeline, and the communication is controlled by a first valve; and the oil charging pipe is connected with the oil outlet pipeline, and the communication is controlled by a second valve; the lower end of the suction pipe is provided with a fourth valve for controlling the communication between the oil tank and the atmosphere; the ports of the oil inlet pipeline and the oil outlet pipeline are respectively provided with fast insertion type oil filling plugs; and each valve is in seal connection with the corresponding pipeline via a quick screwing type fast plug. The speed oil filling device provided by the invention has excellent sealing performance; a single-hole oil filling method or a double-hole oil filling method is provided; the air remained in an oil bag of the pulse generator is reduced as possible; and the oil is fast and conveniently filled in the pulse generator.

Owner:SHANGHAI GASOLINEEUM & CHEM EQUIP +1

An automatic wiring device of a power cable

InactiveCN109193488AFirmly connectedNo looseningApparatus for removing/armouring cablesApparatus for joining/termination cablesPower cableAgricultural engineering

The invention discloses an automatic wiring device of a power cable, comprising a fixed frame, a connecting frame and a motor. The connecting frame is fixedly connected with the lower end of the fixedframe, and the motor is fixedly connected with the inner bottom wall of the connecting frame. The output end of the motor is fixedly connected with one end of a rotating shaft, the other end of the rotating shaft penetrates the fixed frame and is connected with a first bevel gear, the first bevel gear meshes with and is connected with a second bevel gear, and by adding a cutting mechanism, the outer layer of the broken cable can be cut off, so that the connection is very convenient; By adding tin strips and solder joints, the connection is very firm, no looseness will occur, and the service life is long.

Owner:安徽兆拓新能源科技有限公司

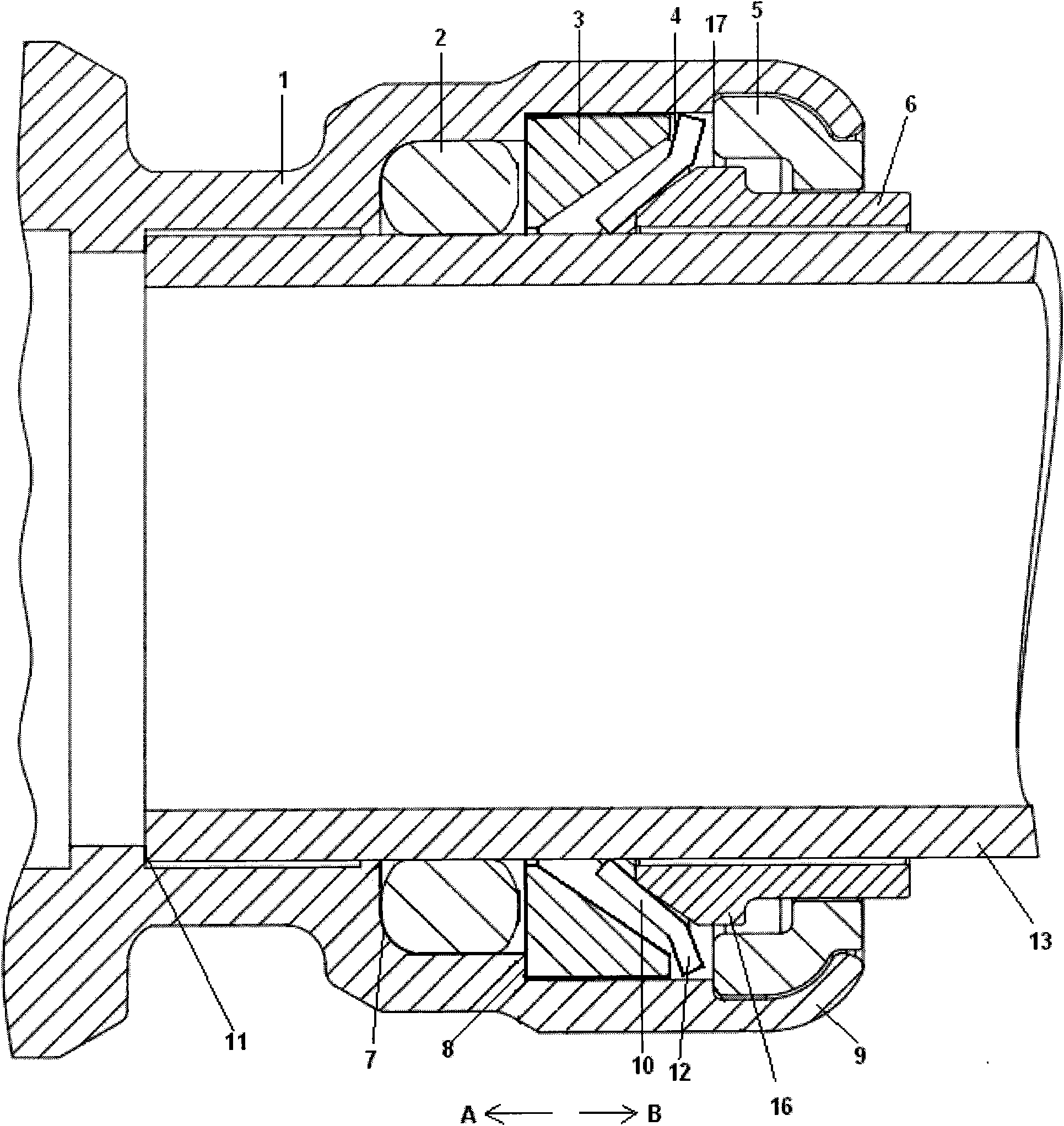

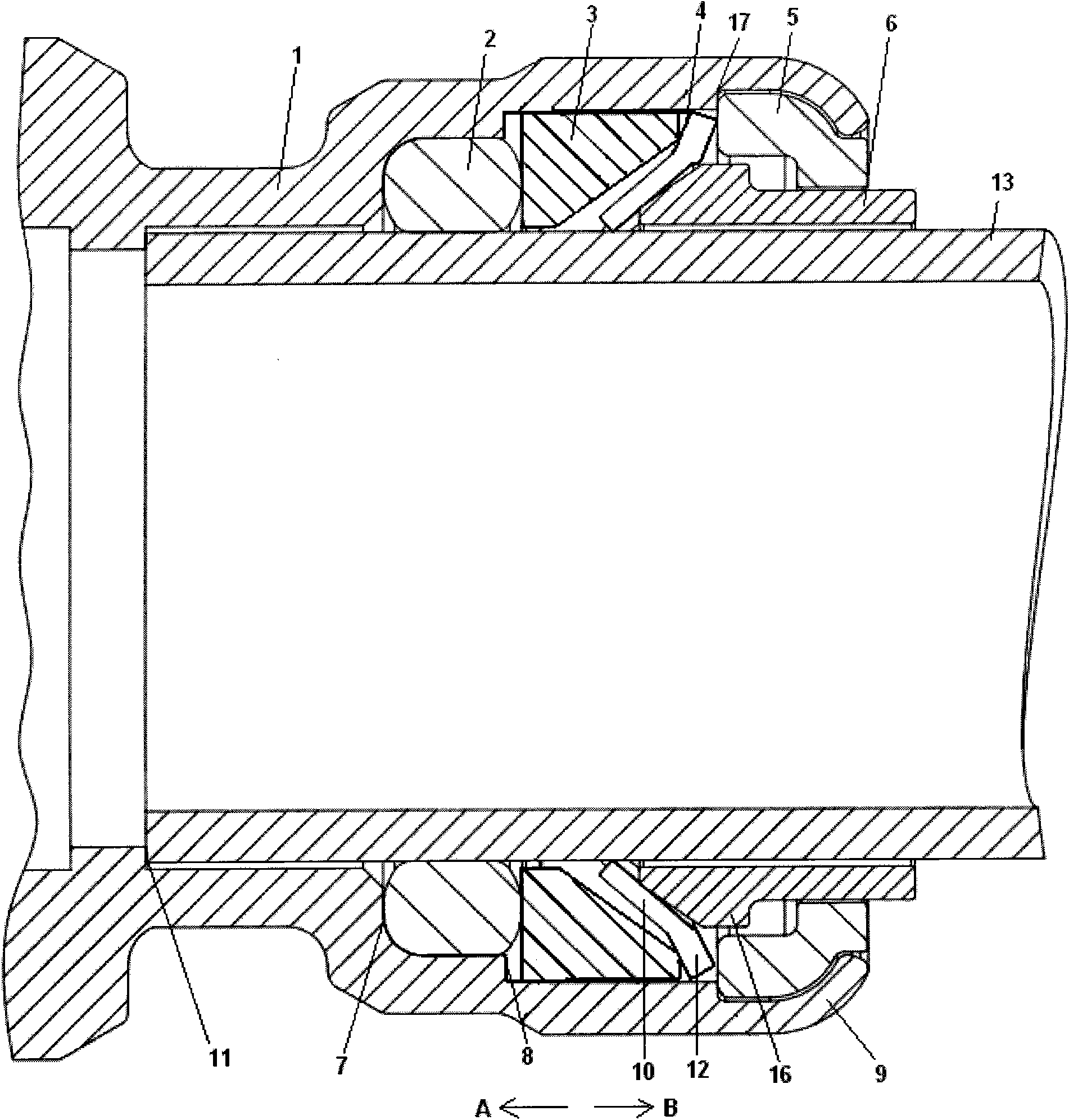

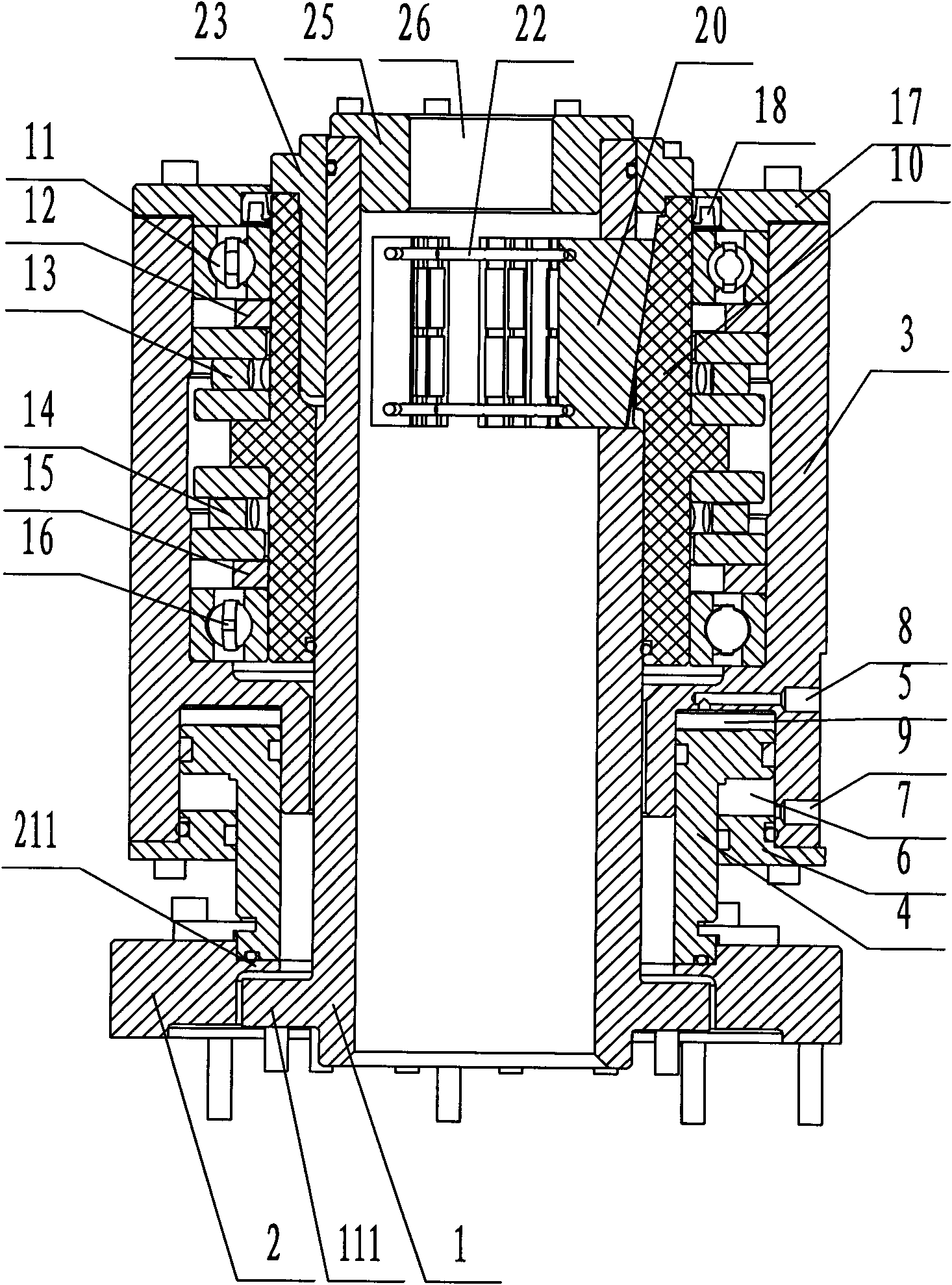

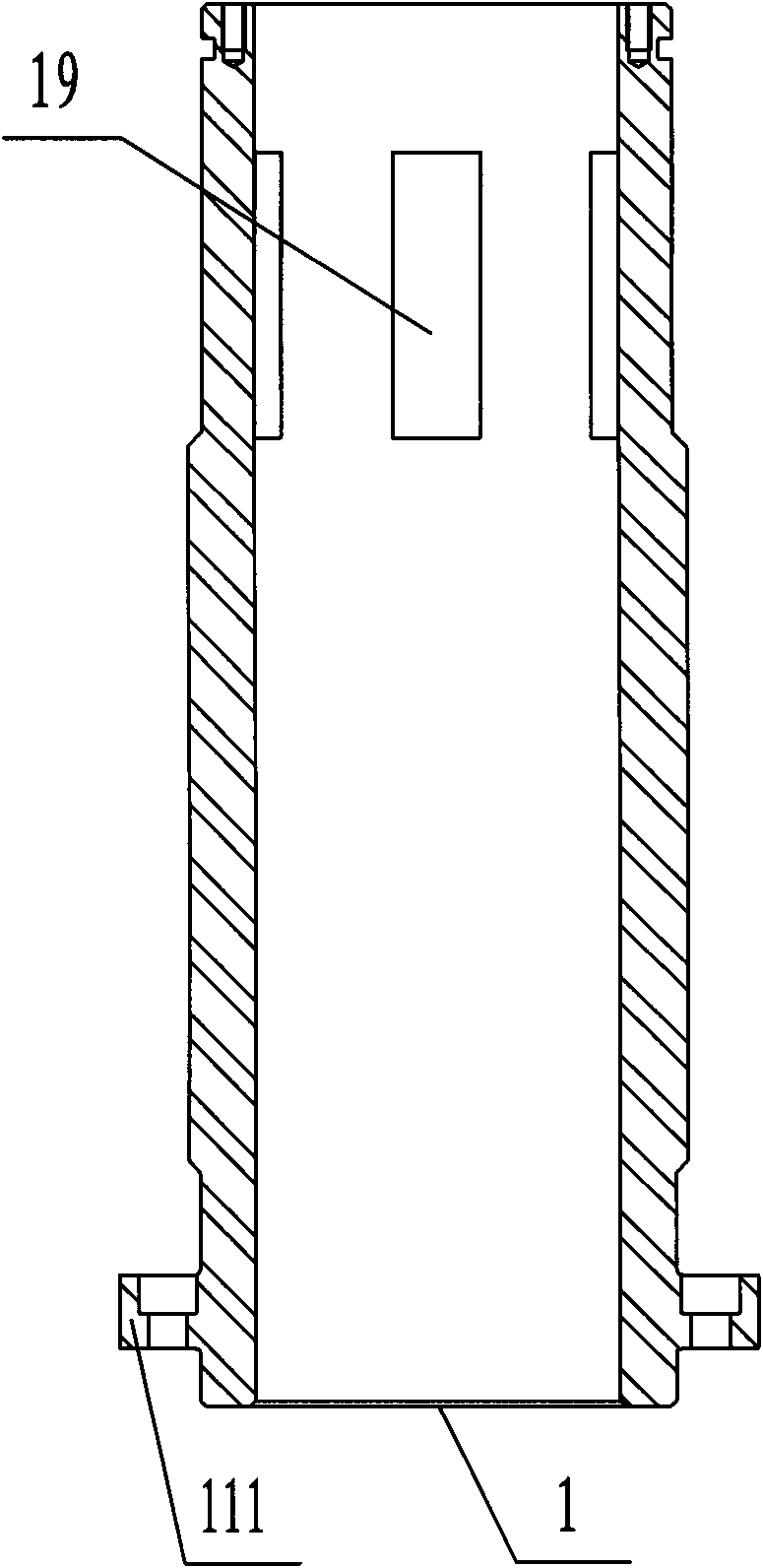

Hydraulic chuck for core drilling machines

InactiveCN102094585AExtend your lifeEconomicalDrilling rodsDrilling casingsDrilling machinesPetroleum engineering

The invention relates to a hydraulic chuck for core drilling machines, which comprises a mandrel, wherein the lower part of the outer wall of the mandrel is provided with a power-head case cover, and the outside of the mandrel is provided with a chuck cylinder; the chuck cylinder comprises an external cylinder sleeve and an internal cylinder sleeve, and an upper oil cavity is formed between the external cylinder sleeve and the internal cylinder sleeve; the lower end of the external cylinder sleeve is fixed with a lower end cover, and a lower oil cavity is formed between the lower end cover and the external cylinder sleeve as well as the internal cylinder sleeve; the external cylinder sleeve is provided with a first oil hole and a second oil hole, the first oil hole is communicated with the upper oil cavity, and the second oil hole is communicated with the lower oil cavity; the internal cylinder sleeve is fixed with the power-head case cover, a slope sleeve is arranged between the external cylinder sleeve and the mandrel, and a bearing pack is arranged between the slope sleeve and the external cylinder sleeve; an upper end cover is arranged above the bearing pack, and the upper end cover is fixed with the external cylinder sleeve; and at least three slips are arranged in the mandrel, the external end face of each slip is a slope, the external end face of each slip is abutted against the internal end face of the slope sleeve, and the inside of the internal end face of each slip is provided with a return spring. The hydraulic chuck provided by the invention is suitable for various core drilling machines.

Owner:ZHANGJIAGANG GUOFENG PROSPECTING MACHINERY

Display panel and display panel manufacturing method

ActiveCN106935633AImprove surface roughnessImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingSurface roughnessEngineering

The embodiment of the invention discloses a display panel and a display panel manufacturing method. The display panel comprises an array substrate, a plurality of organic light-emitting elements arranged on one side of an array substrate, and a thin-film packaging layer located on one side of the organic light-emitting elements that is far away from the array substrate and used for covering the plurality of organic light-emitting elements. The thin-film packaging layer comprises at least one barrier layer. The surface roughness of the barrier layer is 0 nm-5 nm. One side of the at least one barrier layer, away from the array substrate, is provided with a roughness layer. The roughness layer is in contact with the barrier layer. The surface roughness of the roughness layer is larger than 5 nm. According to the technical scheme of the invention, on the basis that the reliable encapsulation of the display panel is effectively guaranteed, a film layer above the barrier layer can be firmly combined with the barrier layer. The peeling problem of the film layer is solved. The performance of the display panel is improved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Functional inorganic mineral wall material

InactiveCN106892636AGuaranteed normal generationKeep dry and cleanCovering/liningsSodium BentoniteMetakaolin

The invention belongs to the field of building coatings and particularly relates to a functional inorganic mineral wall material. The functional inorganic mineral wall material is prepared from, by mass, 20-40 parts of ground calcium carbonate, 10-20 parts of ash calcium powder, 0-10 parts of washed kaolin, 0-10 parts of metakaolin, 0-10 parts of calcined kaolin, 0-5 parts of calcium bentonite, 5-15 parts of diatomaceous earth, 0-10 parts of zeolites, 10-30 parts of modified gypsum, 0-20 parts of magnesium oxide, 0-10 parts of magnesium sulfate, 0-5 parts of titanium dioxide, 0-5 parts of white cement, 0-5 parts of sepiolite, 0-5 parts of attapulgite, 2-5 parts of talcum powder, 0-5 parts of wollastonite, 0.5-1 part of water-retaining agent and 0-2 parts of nano titanium dioxide photocatalyst.

Owner:陈锦

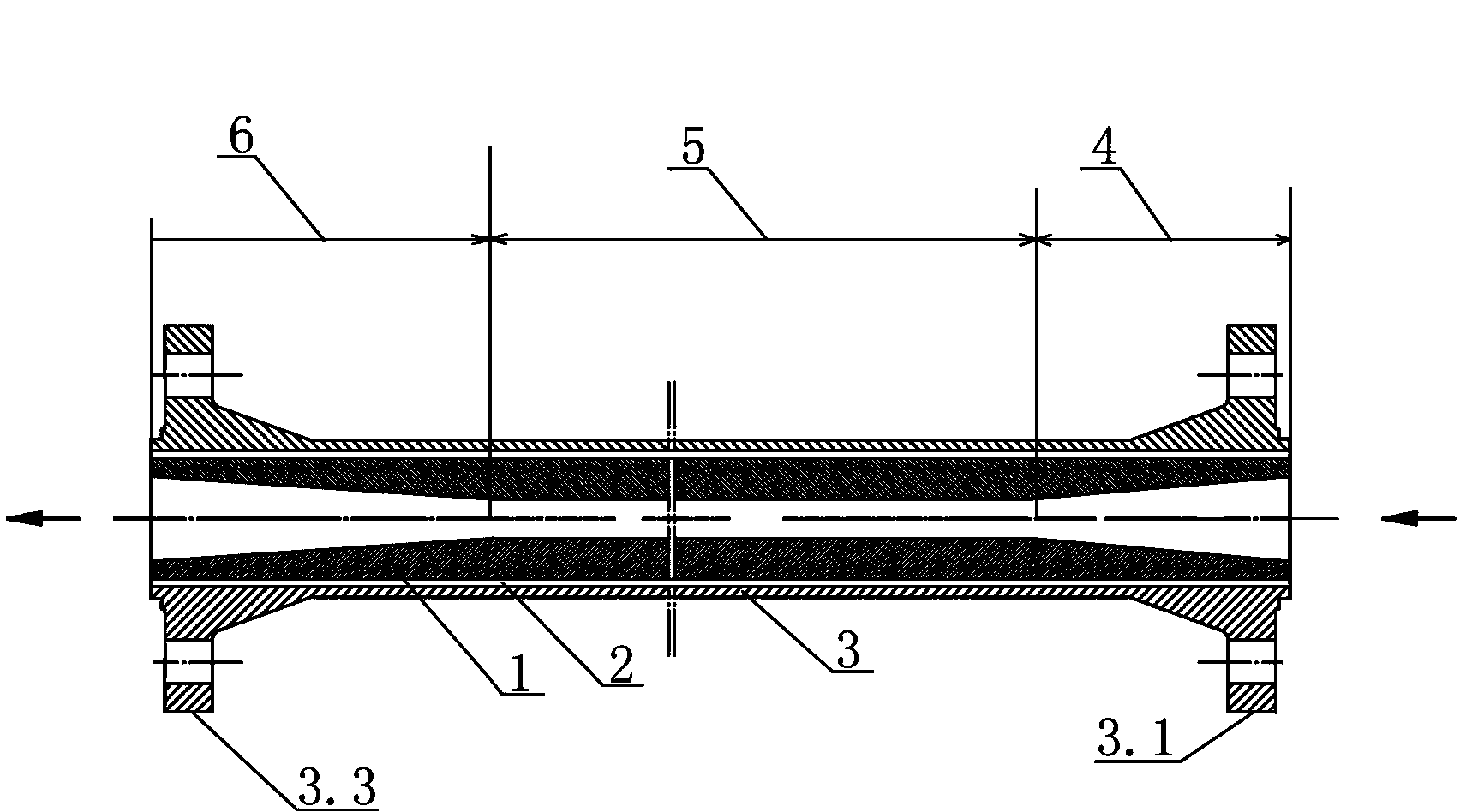

Multi-layer composite wear-resistant pressure reduction pipe and manufacturing method thereof

ActiveCN103727321ANo looseningIncreased durabilityPreformed elementsRigid pipesWear resistantMetallic materials

The invention discloses a multi-layer composite wear-resistant pressure reduction pipe and a manufacturing method of the multi-layer composite wear-resistant pressure reduction pipe. The multi-layer composite wear-resistant pressure reduction pipe is sequentially formed by a wear-resistant ceramic inner layer, a micro-expansion combination layer and a metal outer layer from inside to outside in a composite mode. The multi-layer composite wear-resistant pressure reduction pipe sequentially comprises a diameter reduction section, a straight pipe section and a diameter increasing section from the inlet end to the outlet end, and the portion, located at the inlet end, of the metal outer layer and the portion, located at the outlet end, of the metal outer layer are provided with an inlet connecting flange and an outlet connecting flange respectively. The wear-resistant ceramic inner layer, the combination layer and the metal outer layer are seamlessly combined, integrality of the product is embodied, and the phenomenon that the inner layer and the outer layer are loosened can not occur. The ceramic layer can be made of zirconia toughened alumina ceramic, and excellent durability of the product is achieved due to the rigidity and wear resistance of the product. The inner layer ceramic material, the combination layer and the outer layer metal material are firmly combined together due to the micro-expansion combination layer through the adhering action and the micro-expansion action. The multi-layer composite wear-resistant pressure reduction pipe can be of a multi-section combination structure, and therefore a pipeline can be conveniently manufactured, and machining accuracy of the pipeline is improved.

Owner:曹海亮

Sausage filler

The sausage filler includes one piston rod, one piston and one meat stuffing holding pot. The pot is provided with front cover, back cover, conic bin in the front end, stuffing discharging pipe connected and communicated to the conic bin for sausage coating to be fixed on. The piston rod has its front end contacting the piston and back end connected to one handle, and is one screw bolt screwed onto the front cover. Below the pot, there are fixed sucker seat, rubber sucker installed to the bottom of the sucker seat, and operation mechanism connected to the rubber sucker, with main body located inside the sucker seat and capable of forming notched middle part of the rubber sucker. The present invention has simple structure, no need of special fixing frame and convenient location.

Owner:周炳康

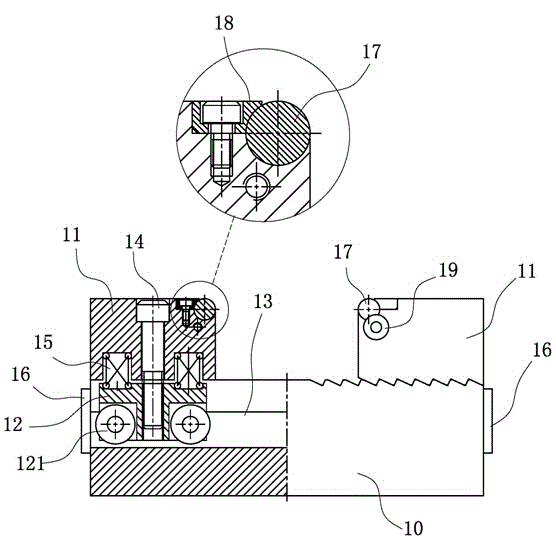

Indentation-free bending machine lower mold with adjustable opening

The invention belongs to the bending process field of sheet metal parts, and specifically relates to an indentation-free bending machine lower mold with an adjustable opening. The indentation-free bending machine lower mold comprises a mold base; the upper surface of the mold base is provided with two mold blocks protruding upward; the two mold blocks are arranged symmetrically on the central line of the mold base; the two mold blocks and the mold base are in a split-type structure; and the two mold blocks are slidingly mounted on the mold base, thereby an open-close arrangement is formed by the two mold blocks; the mold base is further provided with a locking unit for locking the mold blocks in any travel position. A pre-tightening bolt is employed to fix the mold blocks, thereby achieving an adjustable fixed connection among the mold blocks and the mold base; meanwhile, a spline surface is arranged on the contact surface among the mold base and the mold blocks, thereby preventing the mold blocks from becoming loose upon closing the mold; additionally, corners on inner sides of the mold blocks are provided with rollers, accordingly the conventional static friction is replaced by the rolling friction in the process of bending the sheet metal parts, thereby avoiding the indentations on the sheet metal.

Owner:ANHUI LIANMENG MOLD IND

Irregular circular small-diameter iron core winding machine

The invention discloses an irregular circular small-diameter iron core winding machine which comprises an integral active clamping frame, multiple coupler power drive devices, a copper wire hooking device and a PLC system. The machine is characterized in that a left clamping arm, a right clamping arm and a resin wheel at the front end of a middle clamping arm are arranged on the same circle, and the other end is provided with a micro cylinder; each transmission rod in the coupler power drive devices is composed of a sleeve outside and a shaft inside, grooves are milled in the axis direction of the sleeves, rotary pins are arranged on the shafts, the shafts and the sleeves move up and down along the axis, and power of couplers is transmitted to the resin wheel from the shafts through the sleeves; the lower portion of the copper wire hooking device is connected with a supporting frame through a cylinder via bolts; the PLC system controls the rotation speed, forward rotation or reversing rotation of a speed reduction motor, starting or stopping and a limiting position of the cylinder. The winding machine effectively reduces labor intensity and work time of winding workers and improves the automation level during work.

Owner:ZAOZHUANG JINGNENG ELECTRONICS TECH

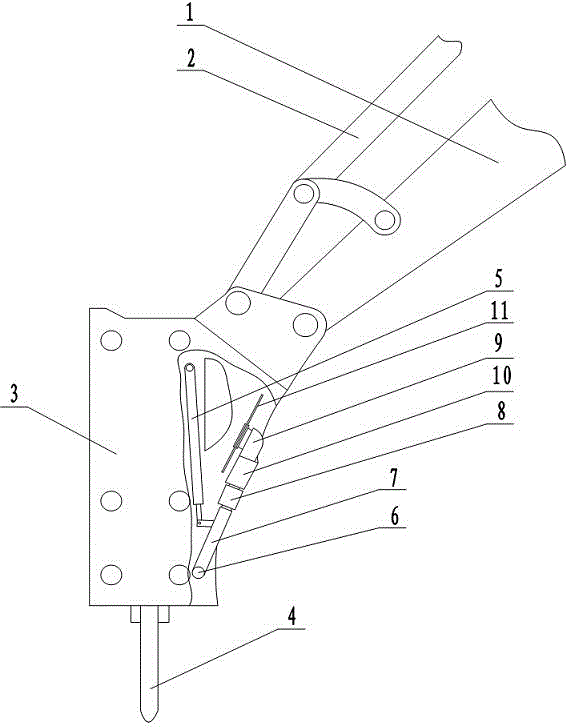

Breaking hammer with cutting function

InactiveCN104612201AEasy to operateImprove efficacySoil-shifting machines/dredgersHydraulic cylinderEngineering

The invention discloses a breaking hammer with a cutting function. The breaking hammer with the cutting function mainly comprises a breaking hammer, a cutter, a supporting arm and a hydraulic cylinder. The breaking hammer mounted at a lower end of a bucket arm of an excavator is mainly used for impacting rocks, dismantling old buildings, impacting and breaking a cement building foundation and a to-be-constructed concrete pavement; when a cement pouring body is broken to expose steel bars, especially very thick steel bars, a construction progress is severely affected. According to the device, the shaft arm type cutter is mounted behind clamping plates of an existing breaking hammer through a hinge. When the steel bars are cut, a cutter body of the cutter rotates around the hinge under the action of the hydraulic cylinder to leave from the breaking hammer and is expanded outwards and supported, so that cutting can be carried out. After cutting is finished, the cutter body of the cutter is pulled back into a space between the two clamping plates of the breaking hammer through the hydraulic cylinder, so that the structure and appearance of the existing breaking hammer are not changed. The device can be used for cutting the steel bars, tree roots and tree branches, and also can be used for cutting the to-be-constructed cement pavement, the hard rocks and the like. The steel bars are exposed in a process of hitting and breaking the cement pouring body, and both hitting and cutting can be simultaneously carried out, so that great convenience is brought to construction and the working efficiency is improved.

Owner:周良操

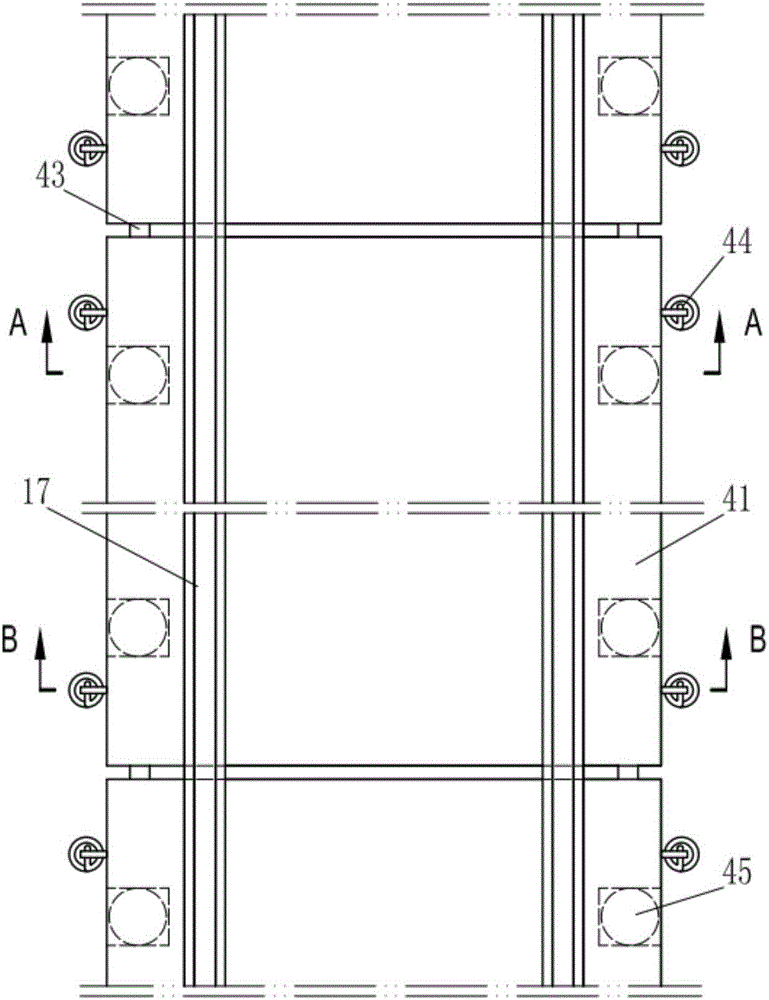

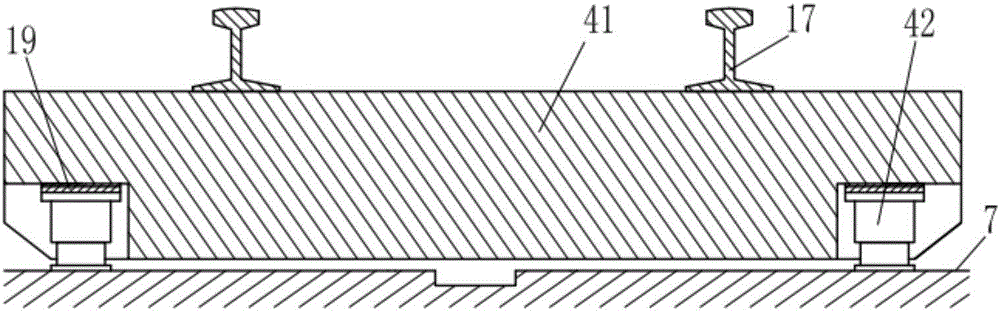

Floating track bed

ActiveCN106522034AStable and reliable working conditionNo looseningBallastwayBack pressureEngineering

The invention belongs to a railway track bed, and discloses a floating track bed. The floating track bed comprises floating slabs and elastic supporting elements. The adjacent floating slabs are connected through shearing force transmission devices. The elastic supporting elements are located between a base and the floating slabs. The floating slabs are supported on the elastic supporting elements. The floating track bed further comprises back pressure devices which comprise back pressure elastic elements and connecting pieces. One ends of the connecting pieces are fixed to the base, and the other ends of the connecting pieces are matched with the corresponding back pressure elastic elements. The floating track bed disclosed by the invention is simple in structure, system inherent frequency variation is reasonable and controllable, the vibration and noise levels are low, the vibration adsorbing and noise reducing performance is stable, the vibration isolating efficiency is high, the service life is long, the safety is better, and the floating track bed can be widely applied to track bed structures of different rail transit types including railways, metros, urban railways, elevated railways, high speed railways and the like and has wide market application prospects.

Owner:GERB QINGDAO VIBRATION CONTROL +1

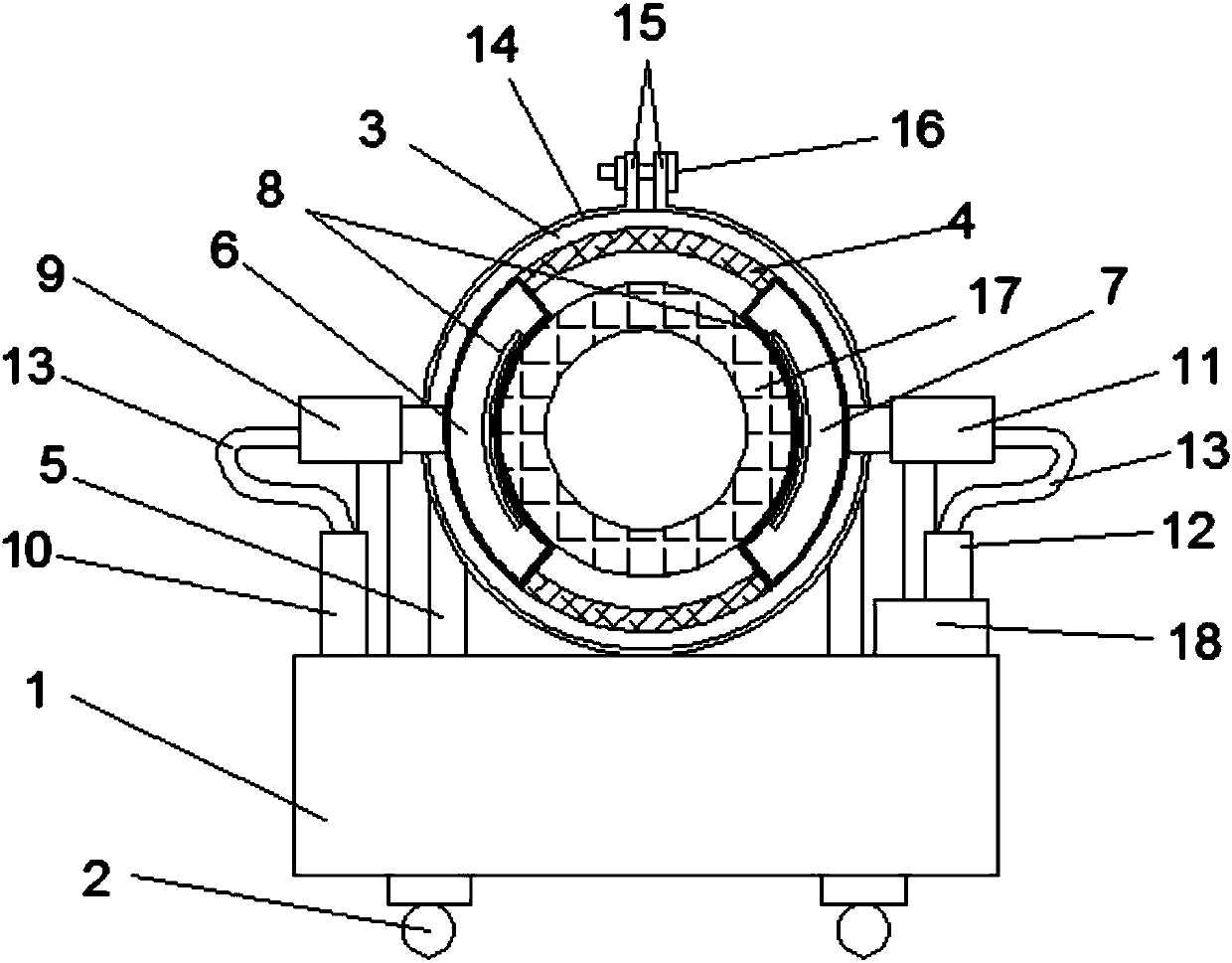

Light-emitting device and method for producing such a device

ActiveCN104254798ANo looseningDoes not affect radiation propertiesLaser detailsSolid-state devicesEngineeringLight emitting device

A radiation-emitting device (10) is provided which includes an optoelectronic semi-conductor element (1) and at least one optical element (2, 2a, 2b). The optical element (2, 2a, 2b) is disposed downstream of the semi-conductor device (1) in the radiation direction. The optical element (2a, 2b, 2) is mechanically attached to the semi-conductor device (1) with a bracket (3). In addition, a method is provided for producing a device (10) of this type.

Owner:OSRAM OPTO SEMICONDUCTORS GMBH

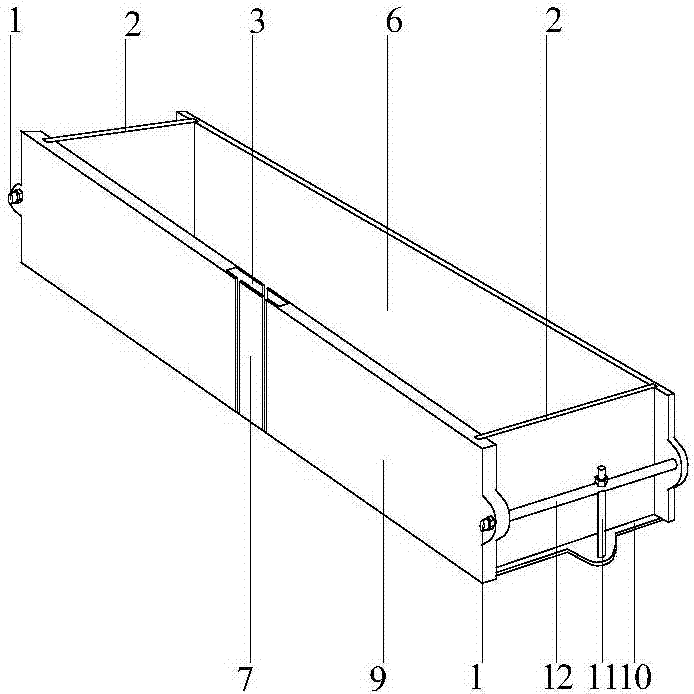

Device and method for manufacturing concrete three-point bending coped beam

Owner:ANHUI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com