Full-automatic part assembly machine

An assembly machine and fully automatic technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems that small parts are easy to loose, difficult to locate, and time-consuming, etc., to improve production efficiency and save manpower , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

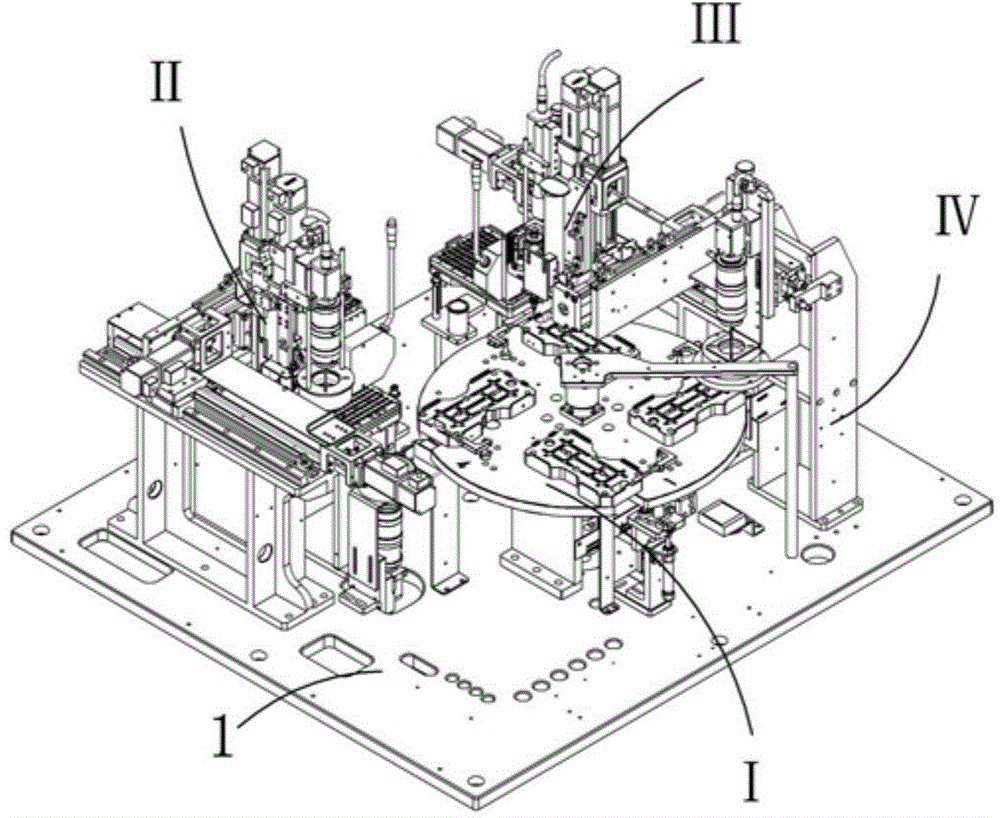

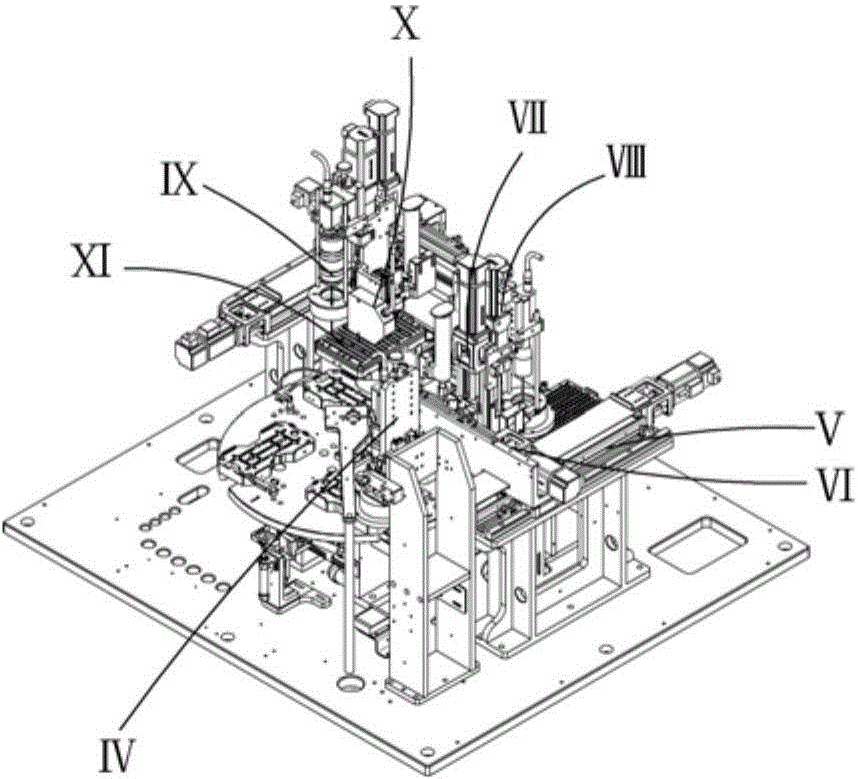

[0054] Examples, see attached Figure 1-26 , a fully automatic parts assembly machine, which includes a bottom plate 1, and also includes a turntable mechanism I, a parts assembly station II, a parts assembly second station III and a testing station IV, the turntable mechanism is installed at the central position of the bottom plate; The first part assembly station and the second part assembly station have the same structure, and are respectively installed at the left and right rear parts of the bottom plate; the inspection station is installed at the right front part of the bottom plate.

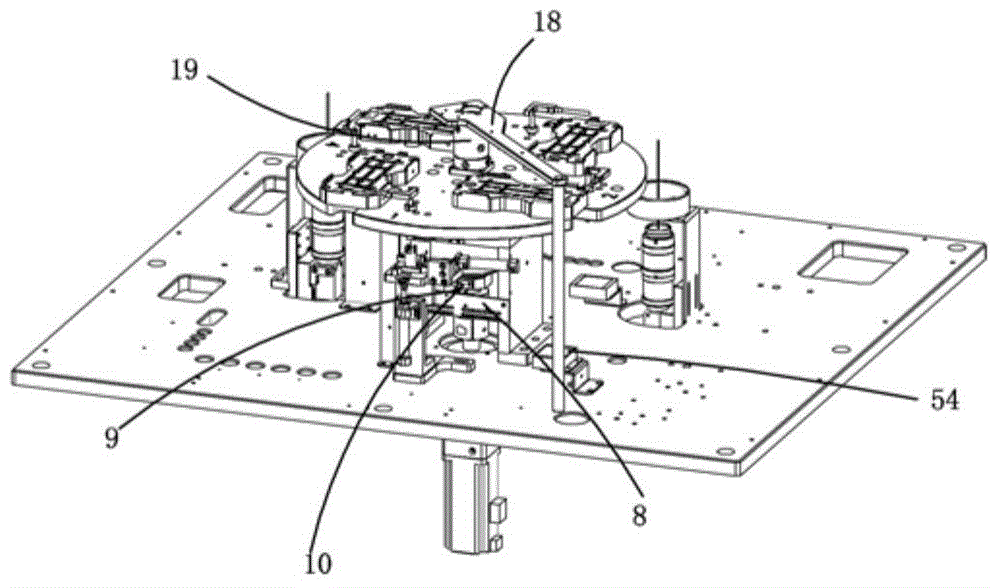

[0055] The turntable mechanism I includes a rotating motor mounting seat 2, a rotating motor 3, a rotating coupling 4, a rotating bearing seat 5, a rotating shaft 6 and a rotating disk 7, and there are two rotating motor mounting seats, which are mounted symmetrically on the bottom plate. The seat is mounted on two rotating motor mounts, and the rotating motor is installed between the two r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com