Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

137results about "Buffer cars" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

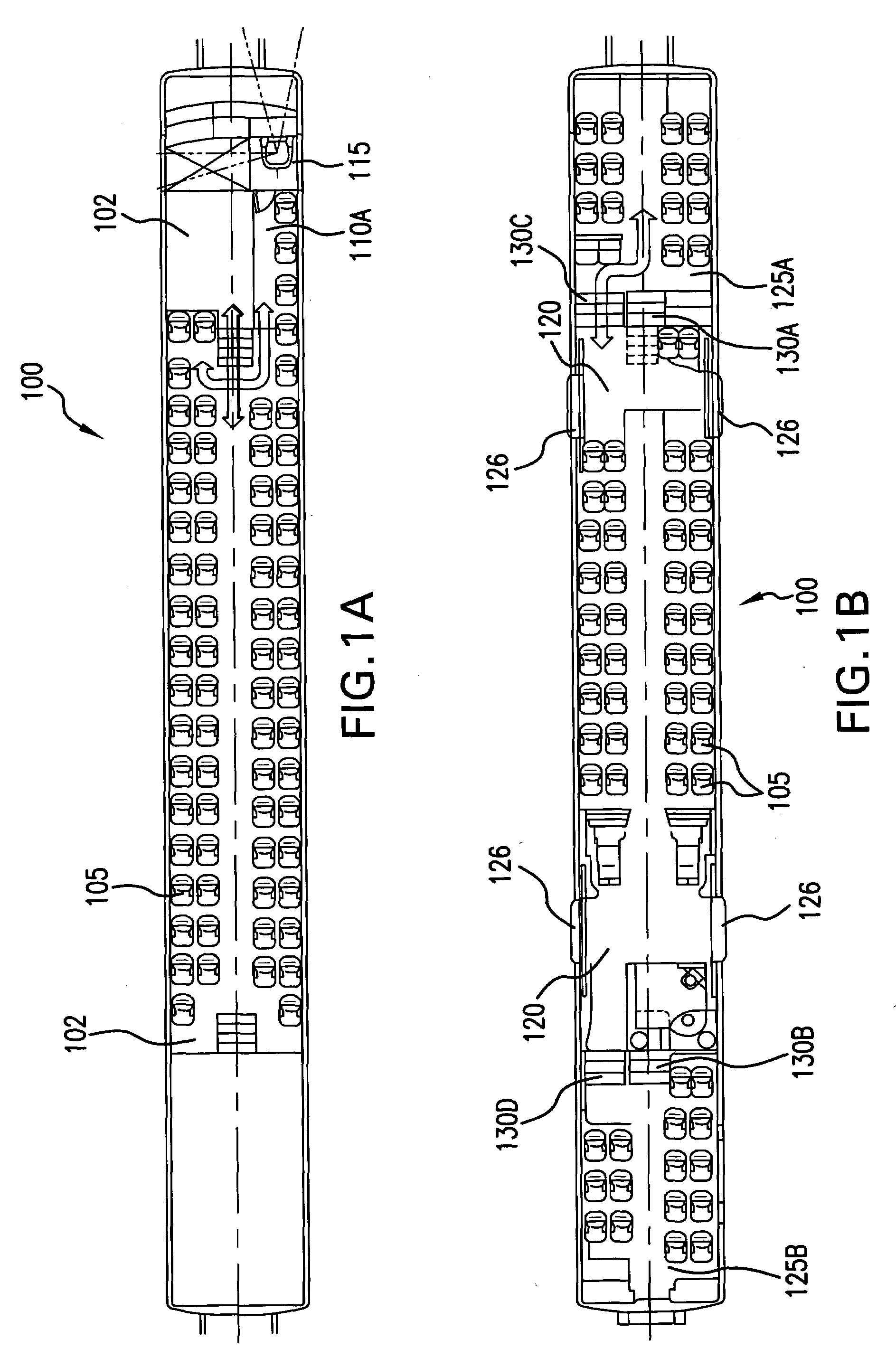

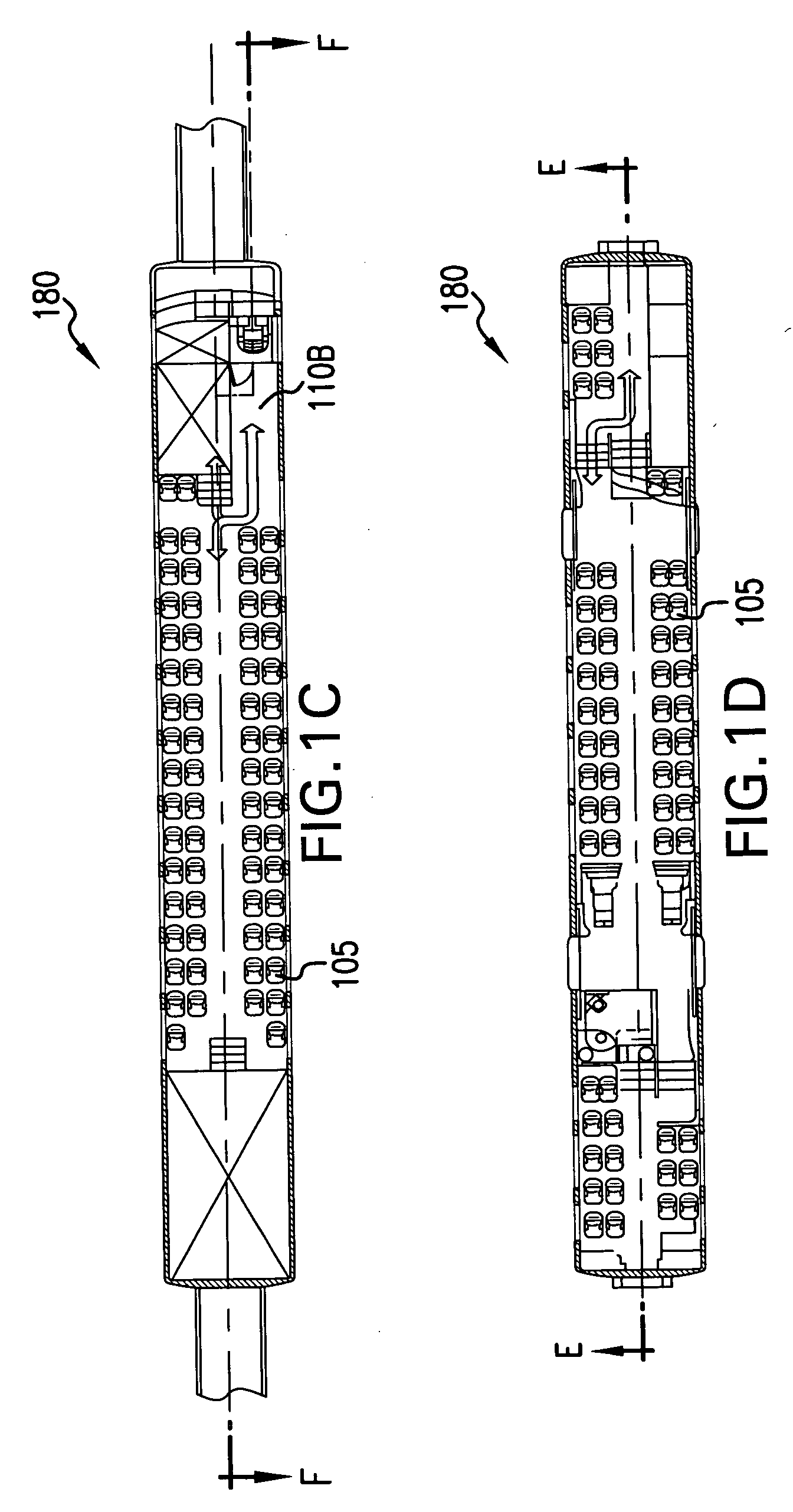

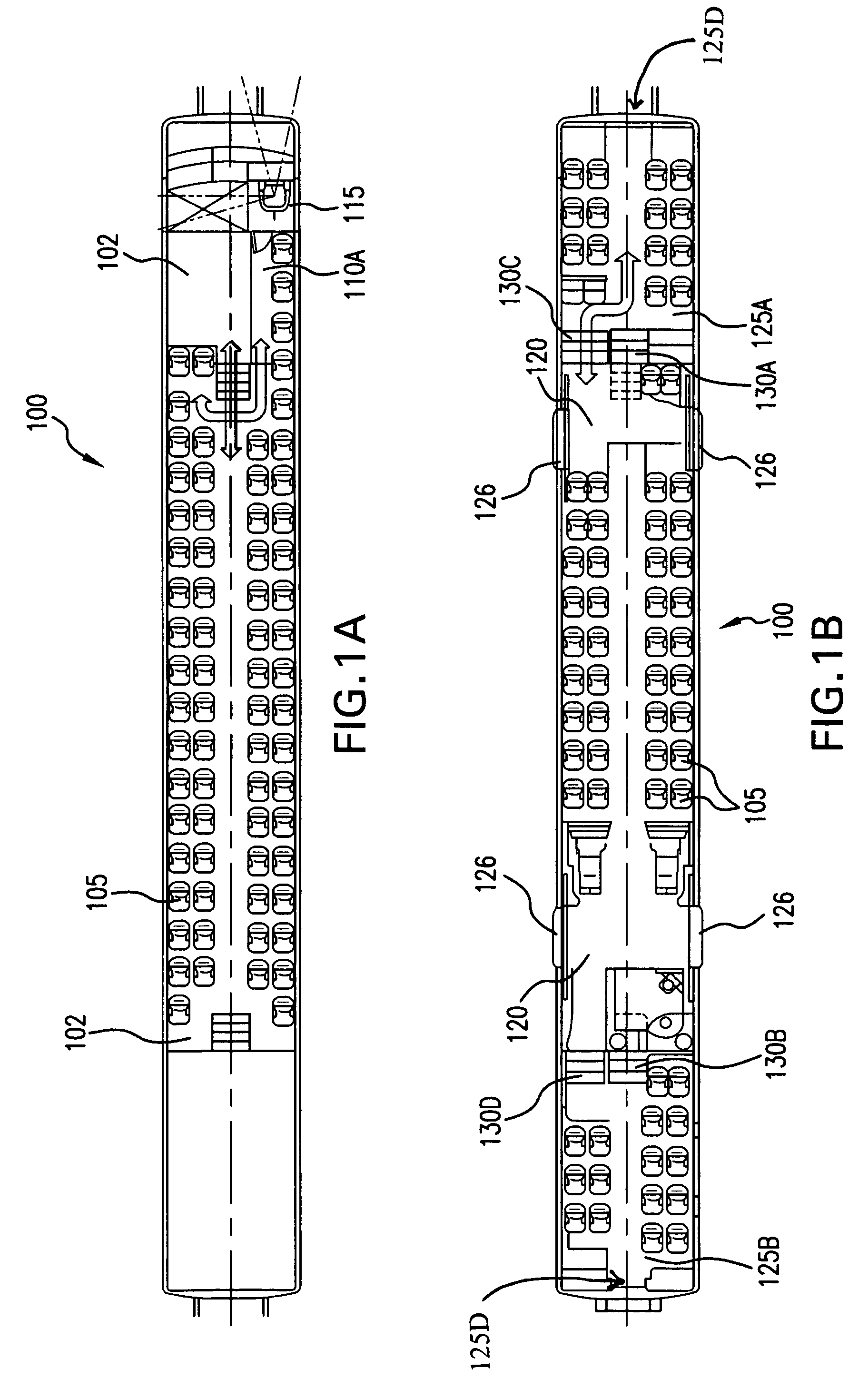

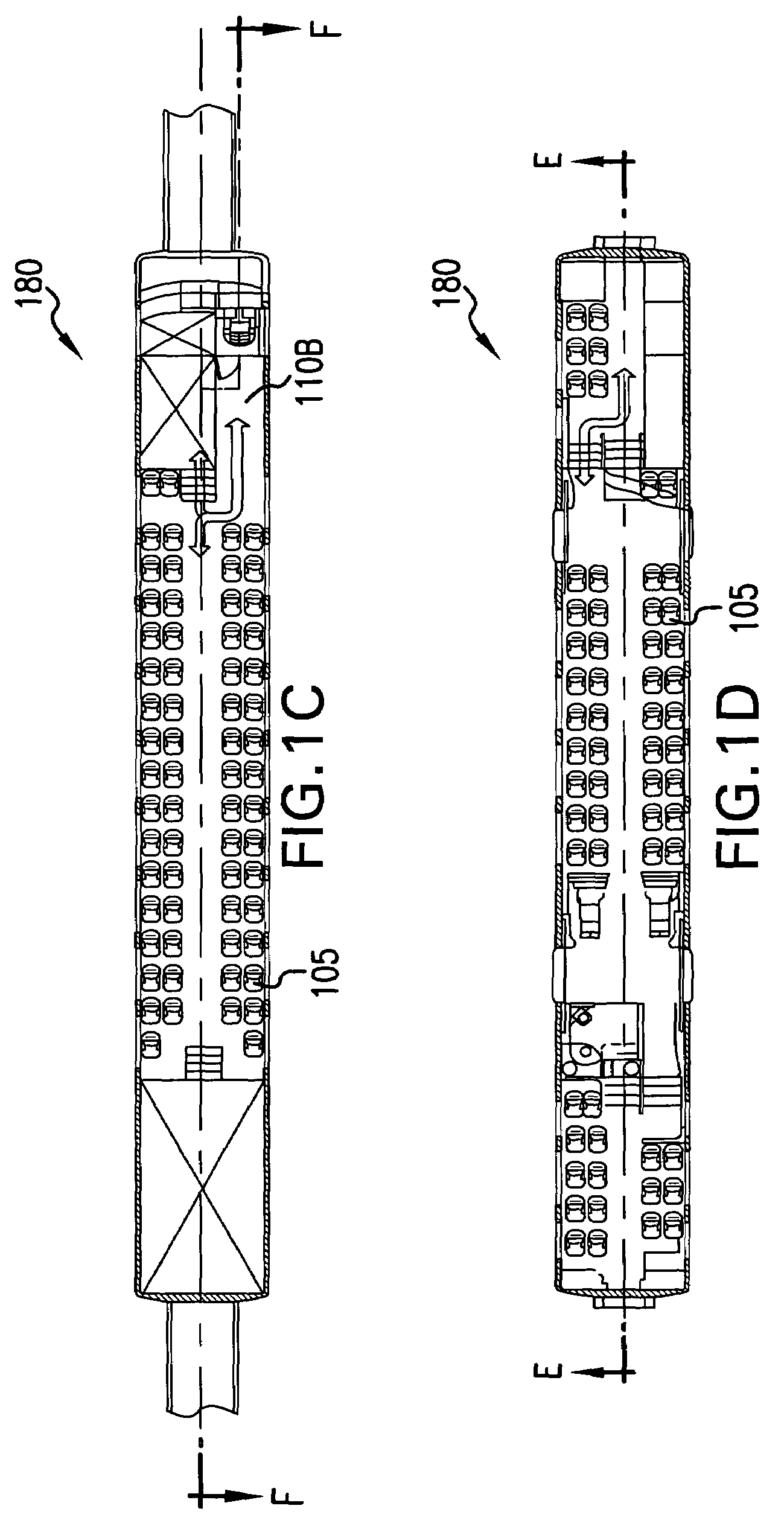

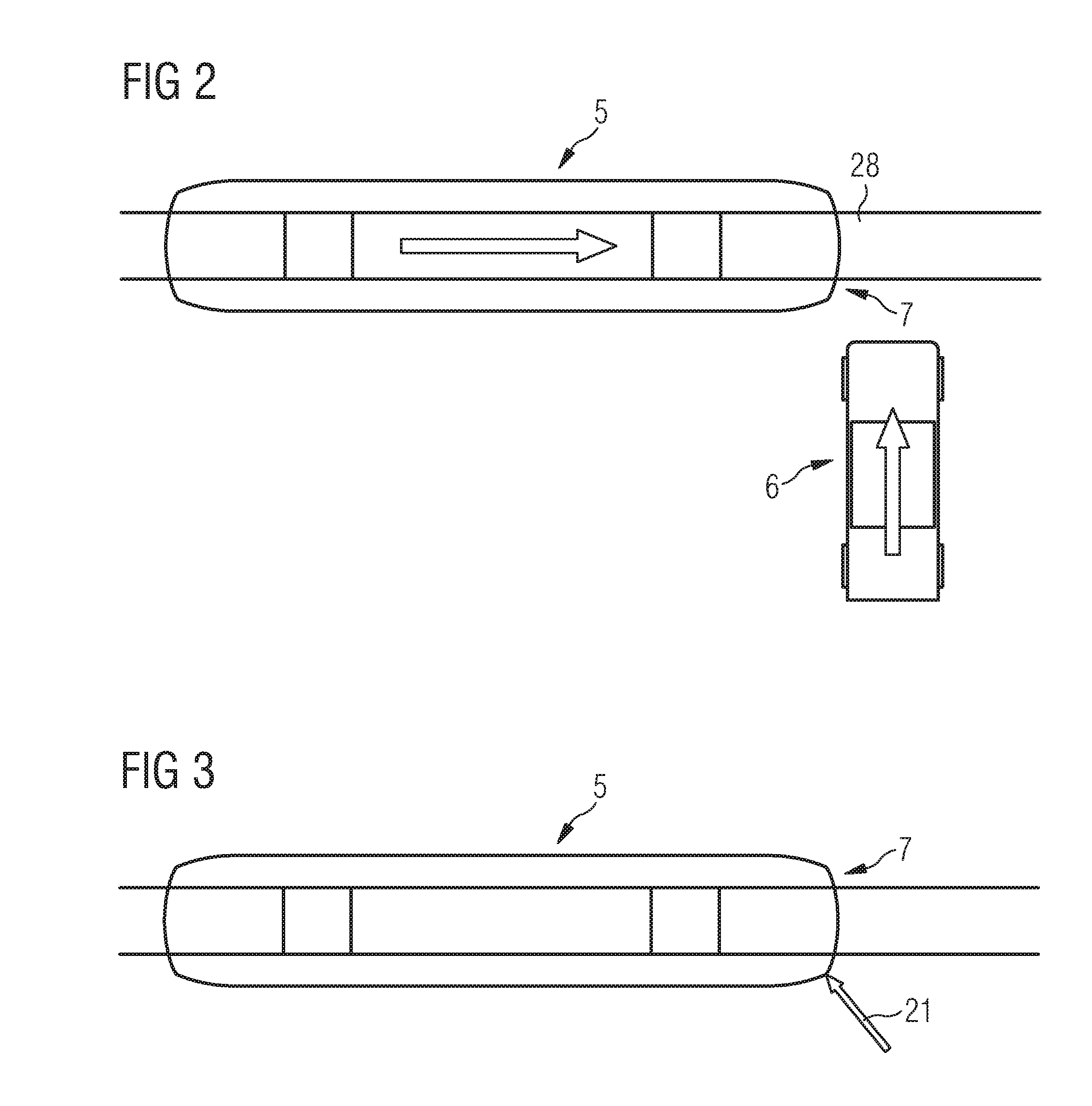

Passenger rail car

A passenger rail car includes a lower passenger compartment that includes a plurality of passenger seats. The passenger rail car also includes an upper passenger compartment that includes a plurality of passenger seats. A control cab for a rail car operator is elevated above the floor of the lower passenger compartment, and is located forward of the passenger seats and behind the crash energy management region. The front end of the passenger rail car may be slanted to provide a greater field of view for the rail car operator.

Owner:HYUNDAI ROTEM CO

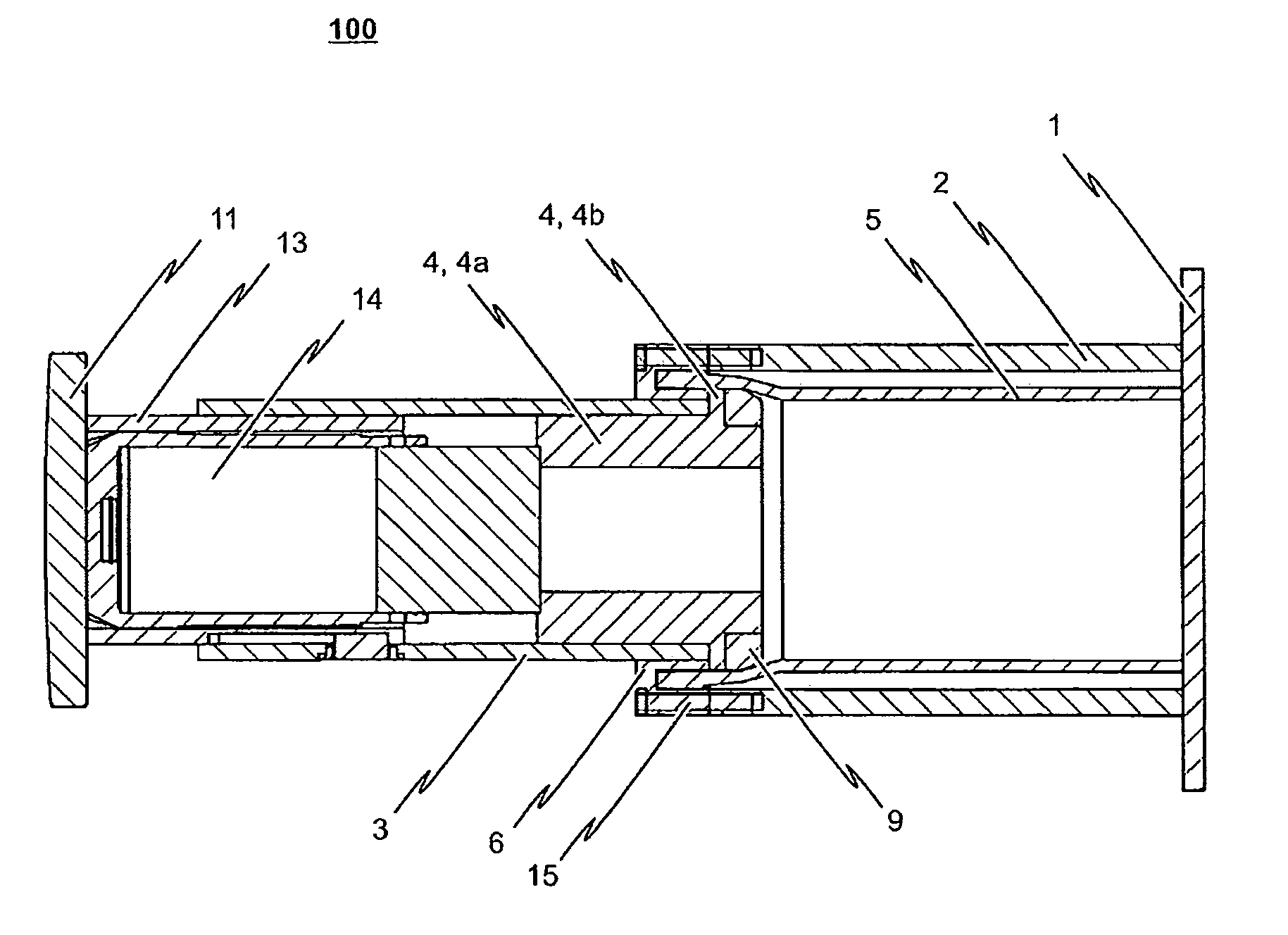

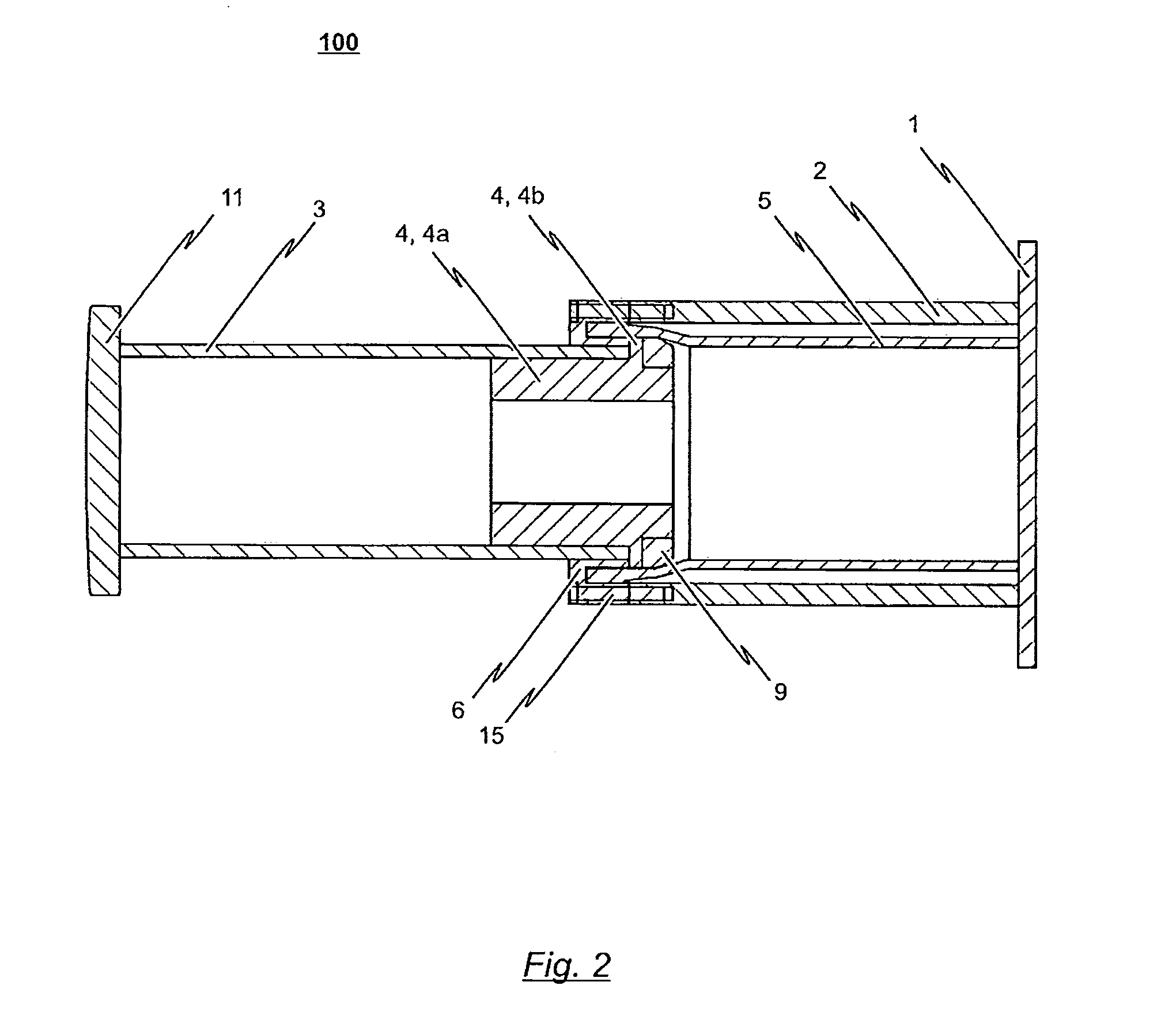

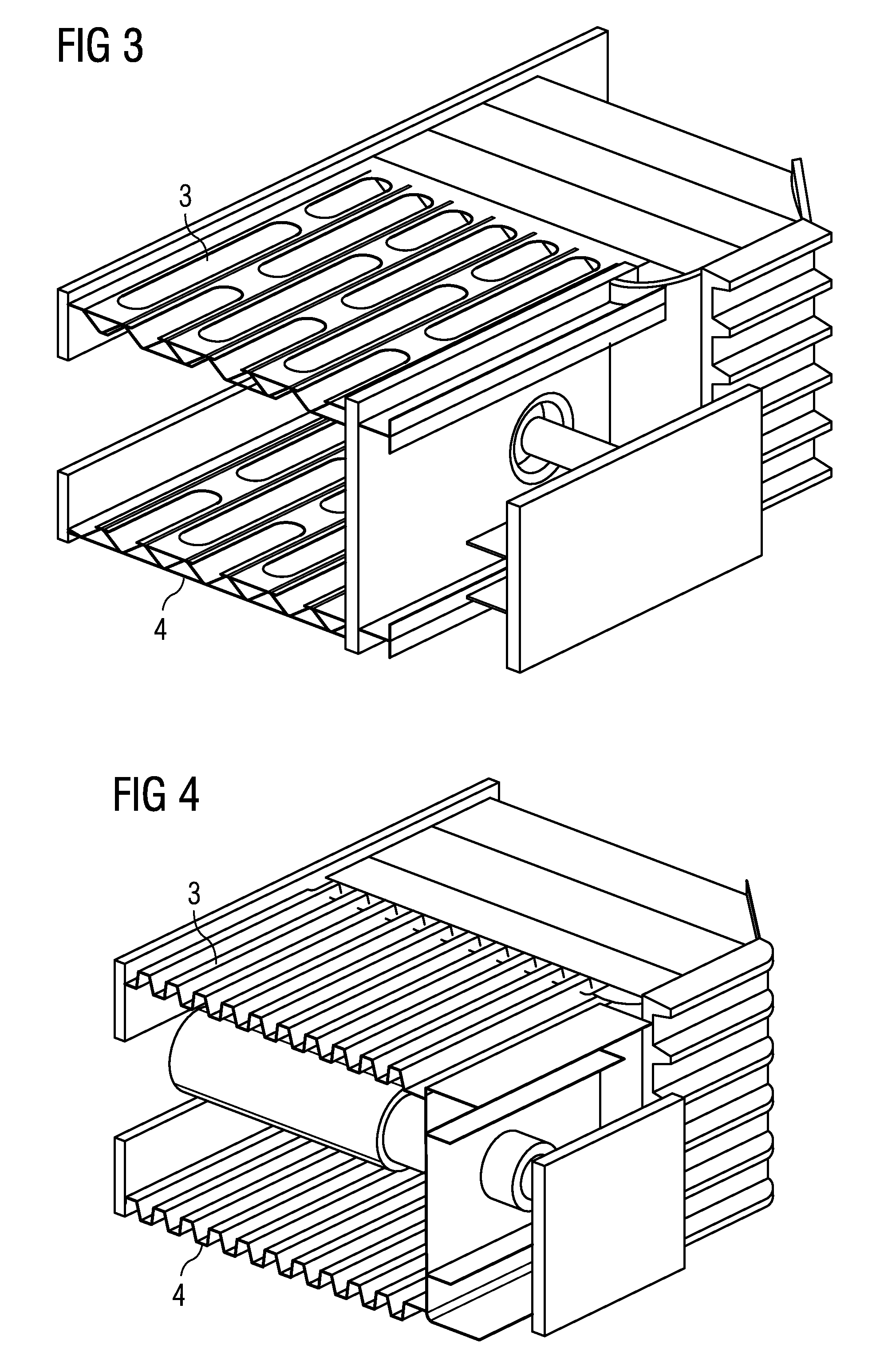

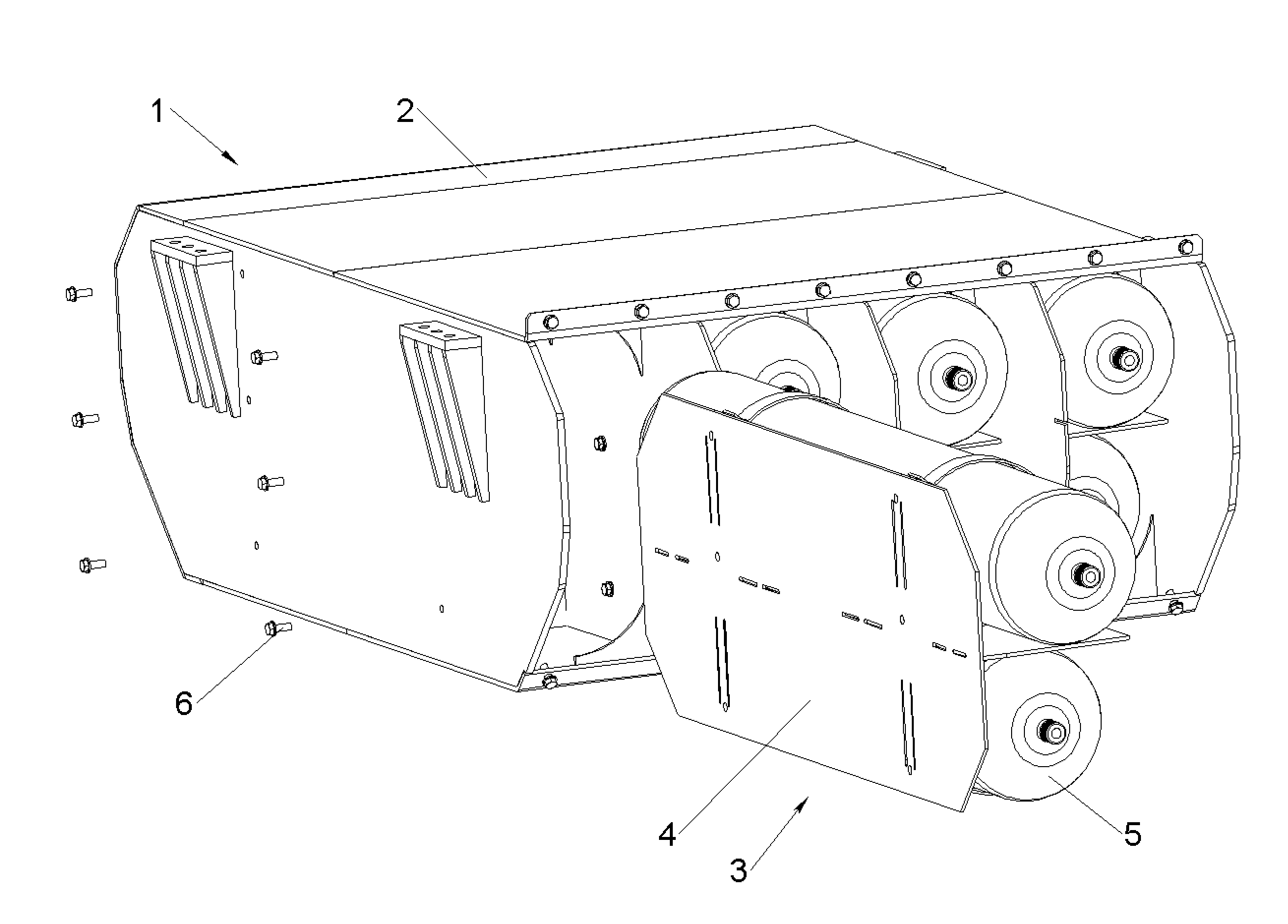

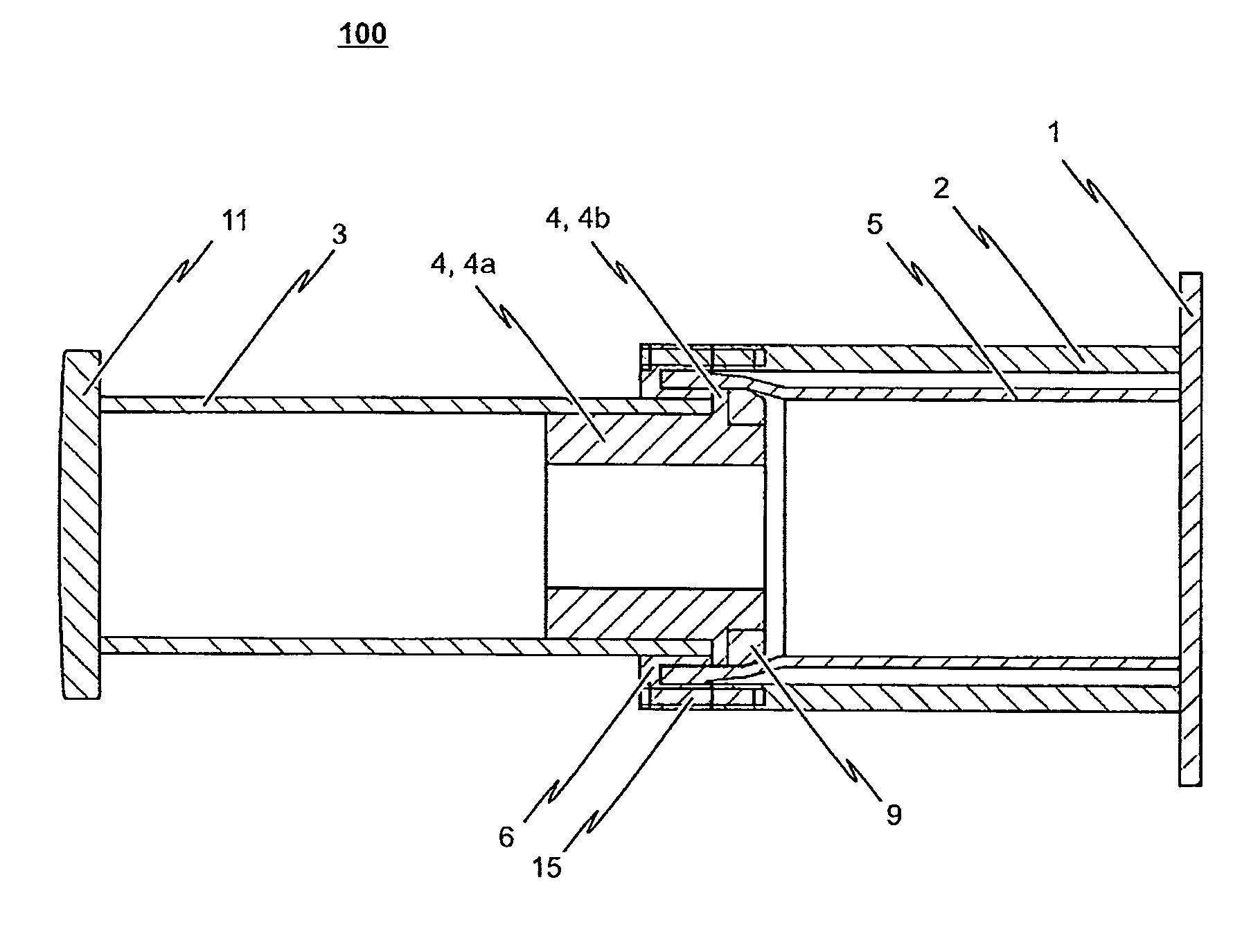

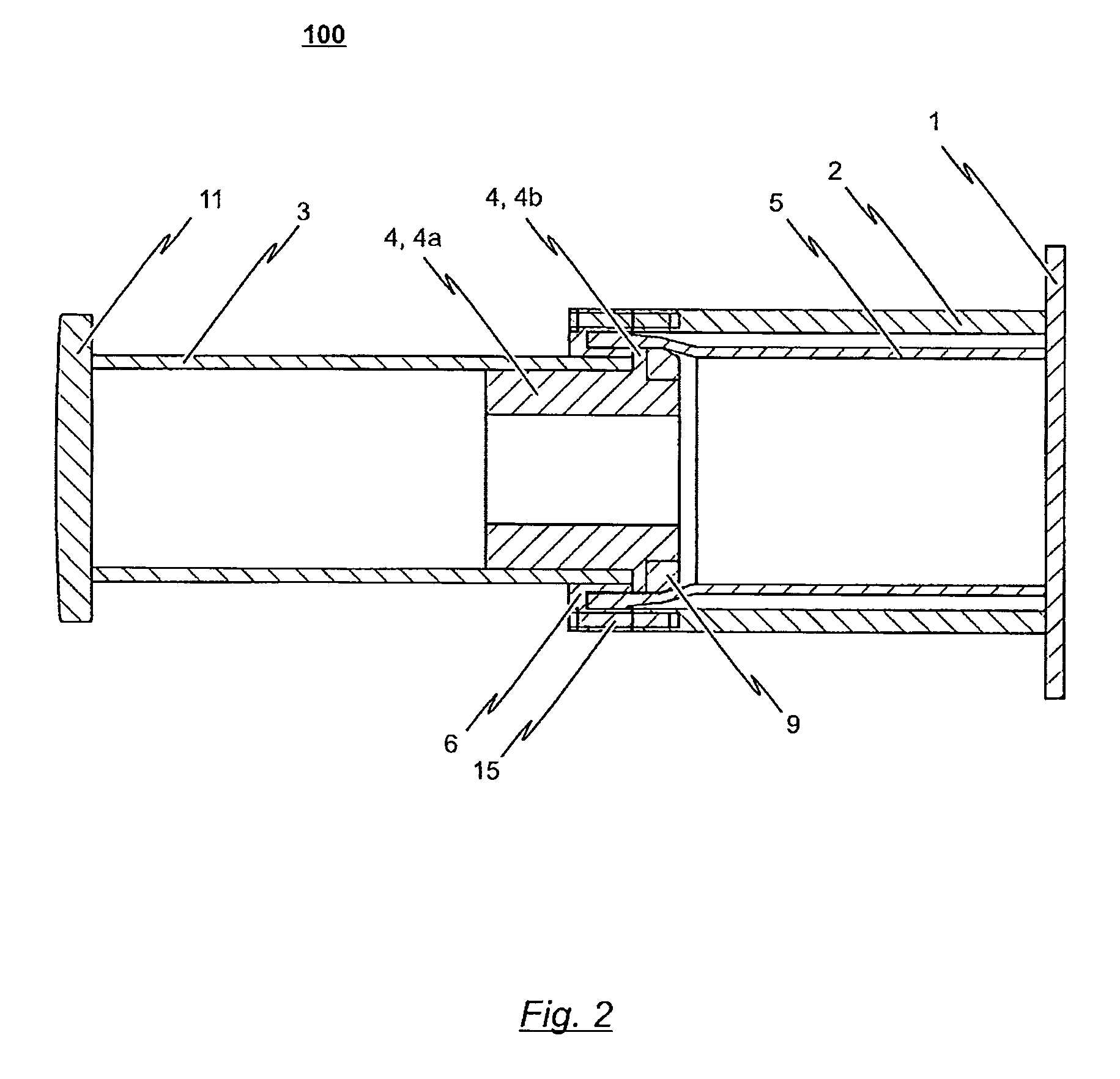

Shock absorber

InactiveUS20090065462A1Protection from damageBuffer carsClimate change adaptationEnergy absorptionEngineering

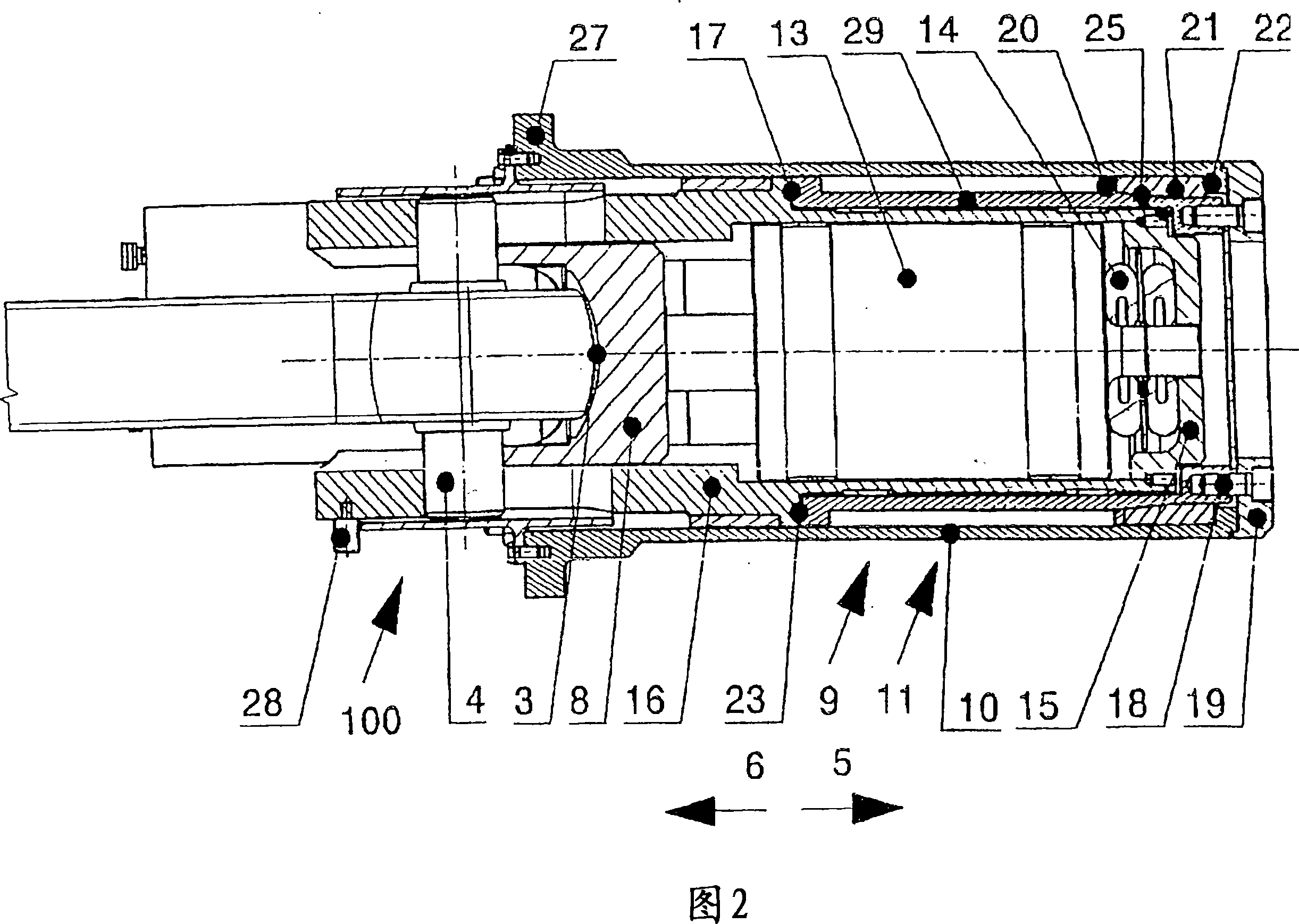

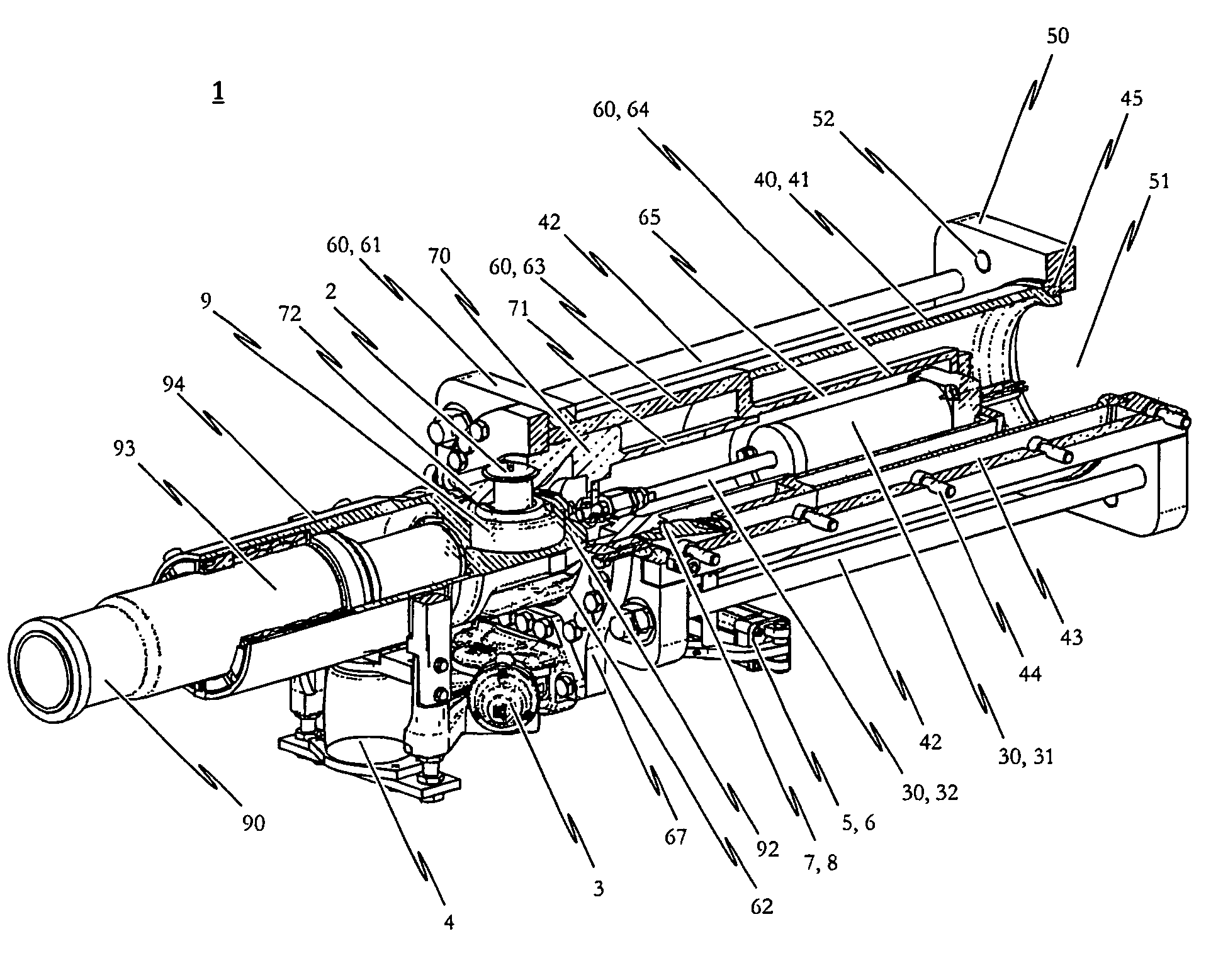

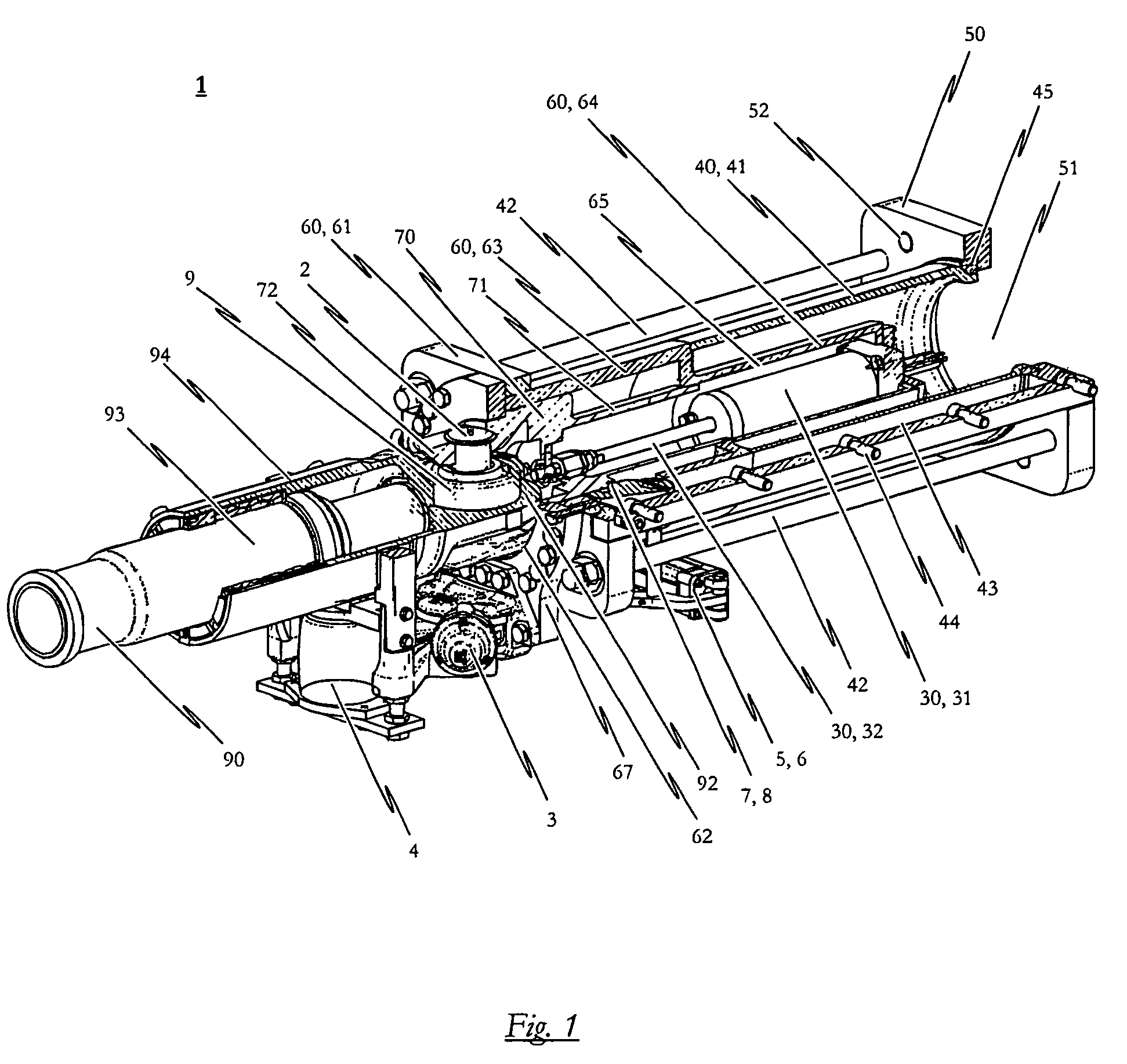

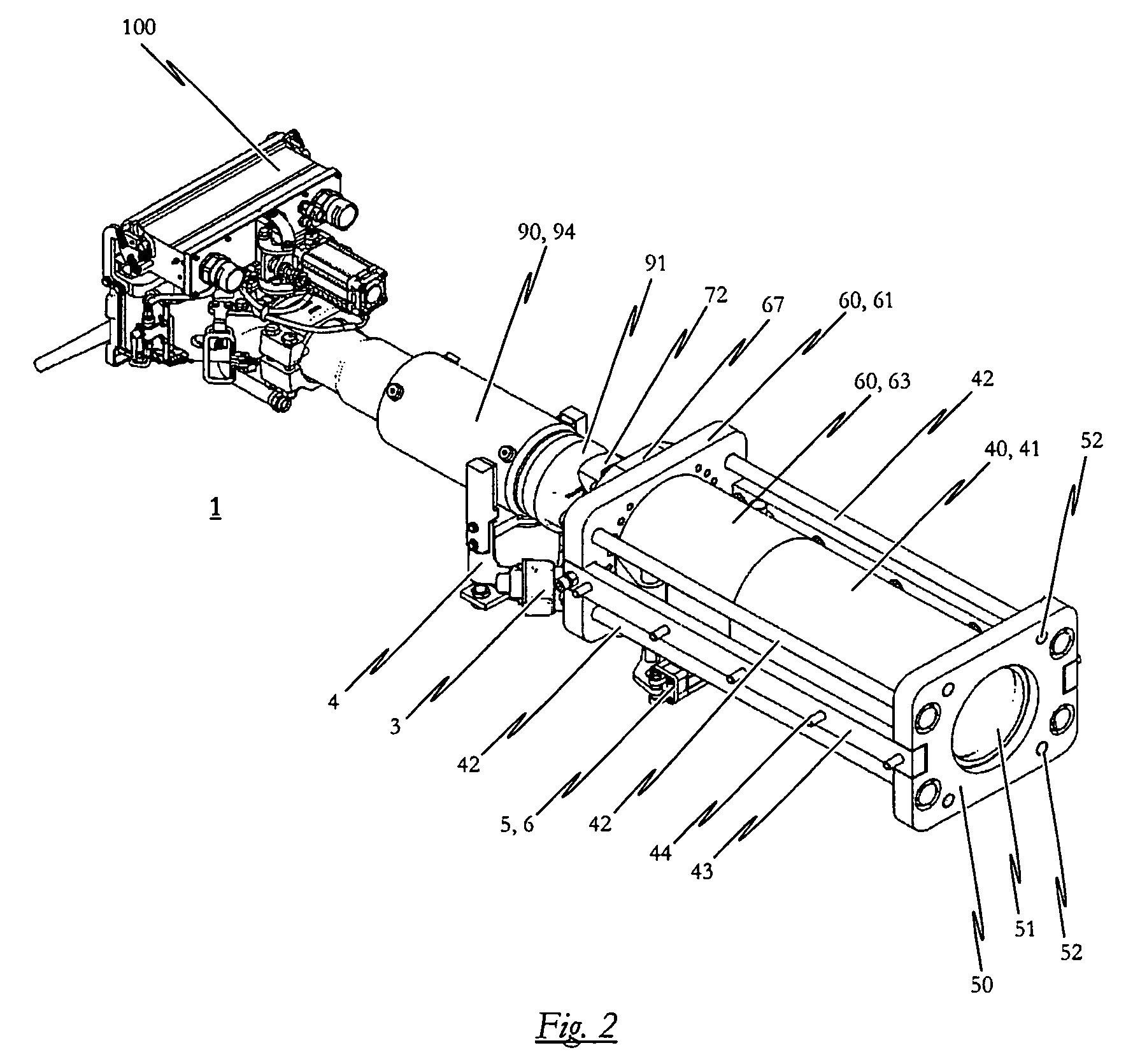

The invention relates to a shock absorber (100), in particular for use as an additional irreversible shock-absorbing stage together with a component for transferring force. In order to achieve the reliable dissipating of high impact energies, a shock absorber (100) comprising the following is indicated in accordance with the invention: a base plate (1); a force-transferring element (3) having a tensioning element (4); an energy-absorbing element in the form of a deformation tube (5) which is connected by a first end section to the base plate (1); and a connecting element (6) for the disengageable connecting of the force-transferring element (3) to a second end section of the deformation tube (5), wherein the connecting element (6) is pressed against the tensioning element (4) such that the deformation tube (5) is braced between the tensioning element (4) and the base plate (1) without play.

Owner:VOITH PATENT GMBH

Rail vehicle having a driver's cab provided with an energy-absorbing structure adapted to cope with a collision above the frame of the vehicle

InactiveUS6561105B2Simple and inexpensive to implementMitigate such drawbackVehicle seatsRailway wheel guards/bumpersEnergy absorptionEngineering

Owner:ALSTOM TRANSPORT TECH SAS

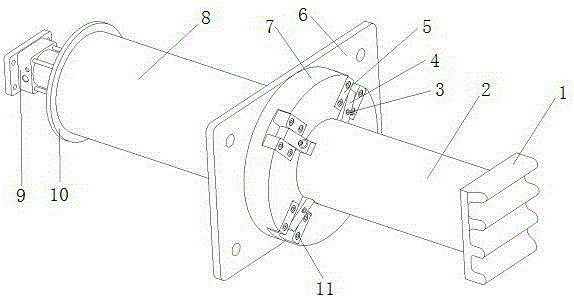

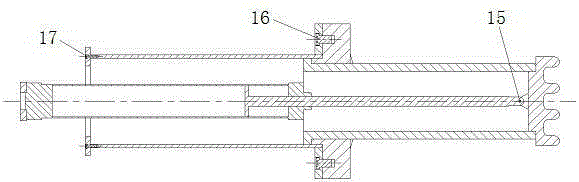

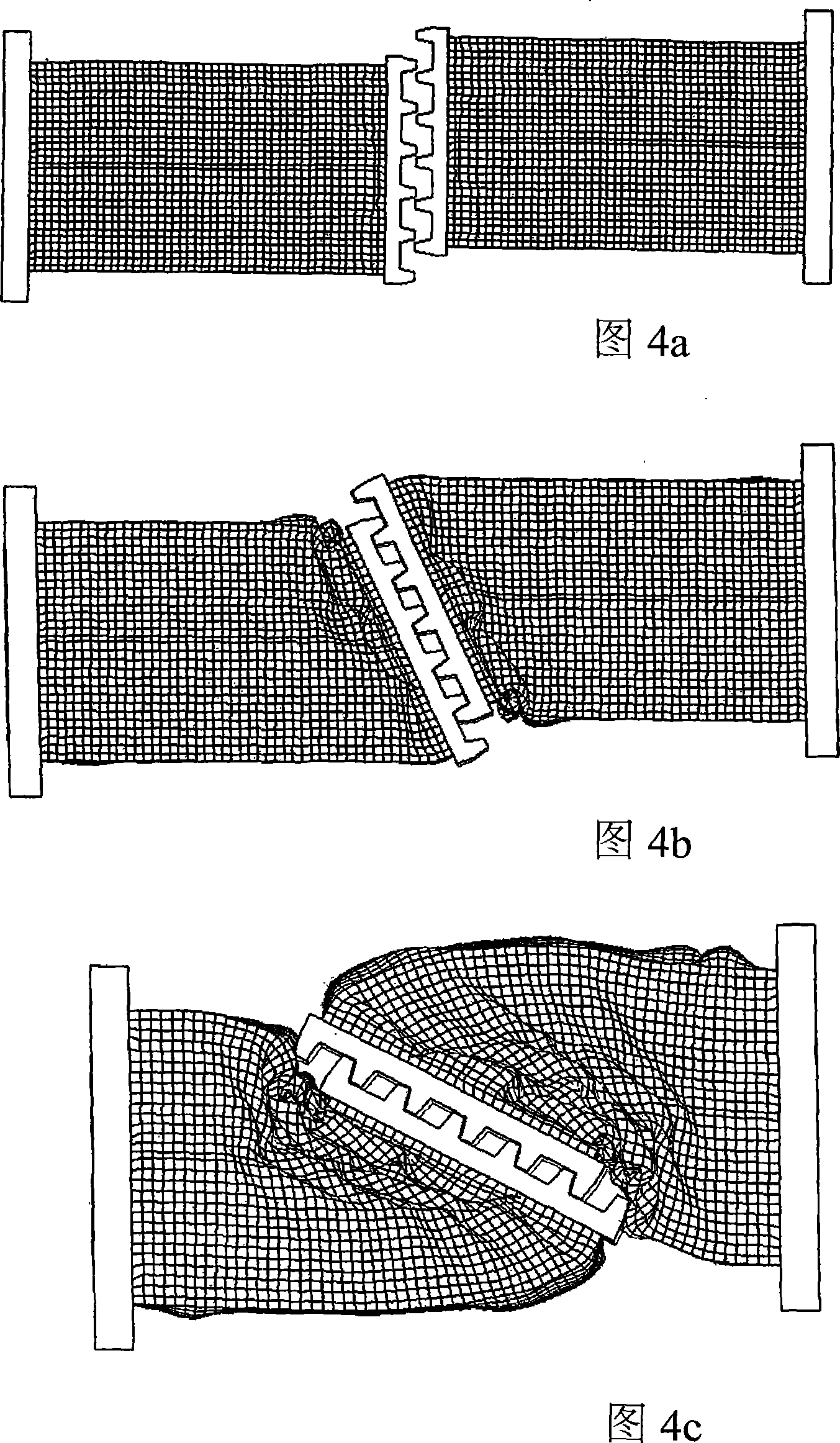

Telescopic device for absorbing collision energy of railway vehicle

ActiveCN105292164ADoes not affect aestheticsProtection securityBuffer carsRailway wheel guards/bumpersAbsorbed energyEngineering

The invention discloses a telescopic device for absorbing collision energy of railway vehicle. The telescopic device comprises two mechanisms which function independently and are respectively mounted on the two sides of a vehicle end part, wherein each mechanism comprises an anti-crawling tooth, a circular energy-absorbing tube, pull rings, cutters, cutter fixing blocks, a mounting base, a cutter base, a guiding cylinder, a double-acting cylinder, a base, bolts, a torsion spring, a dowel, locating grooves, a double-acting electromagnetic valve, a controller and an air storage tank. The telescopic device is characterized in that when the device is in a non-working state, each double-acting cylinder is in a tension state and pulls the corresponding circular energy-absorbing tube to retract inside the corresponding guiding cylinder; each cutter is pressed on the outer wall of the corresponding circular energy-absorbing tube; before trains collide, each double-acting cylinder pushes the corresponding circular energy-absorbing tube to be ejected out under the action of high pressure air; each cutter is pressed on the corresponding locating groove of the corresponding circular energy-absorbing tube under the action of the force of the corresponding spring; when each circular energy-absorbing tube retracts towards the interior of the corresponding guiding cylinder under the action of external force, a cutter cutting type energy absorbing structure absorbs energy; and if the circular energy-absorbing tubes are not hit after stretching out, each circular energy-absorbing tube is separated from the corresponding cutters through pulling the corresponding cutters or jacking up the cutter heads through the corresponding cylinder under the corresponding cutters, and each double-acting cylinder pulls the corresponding circular energy-absorbing tube into the corresponding guiding cylinder.

Owner:CENT SOUTH UNIV

Automatic central buffer coupling

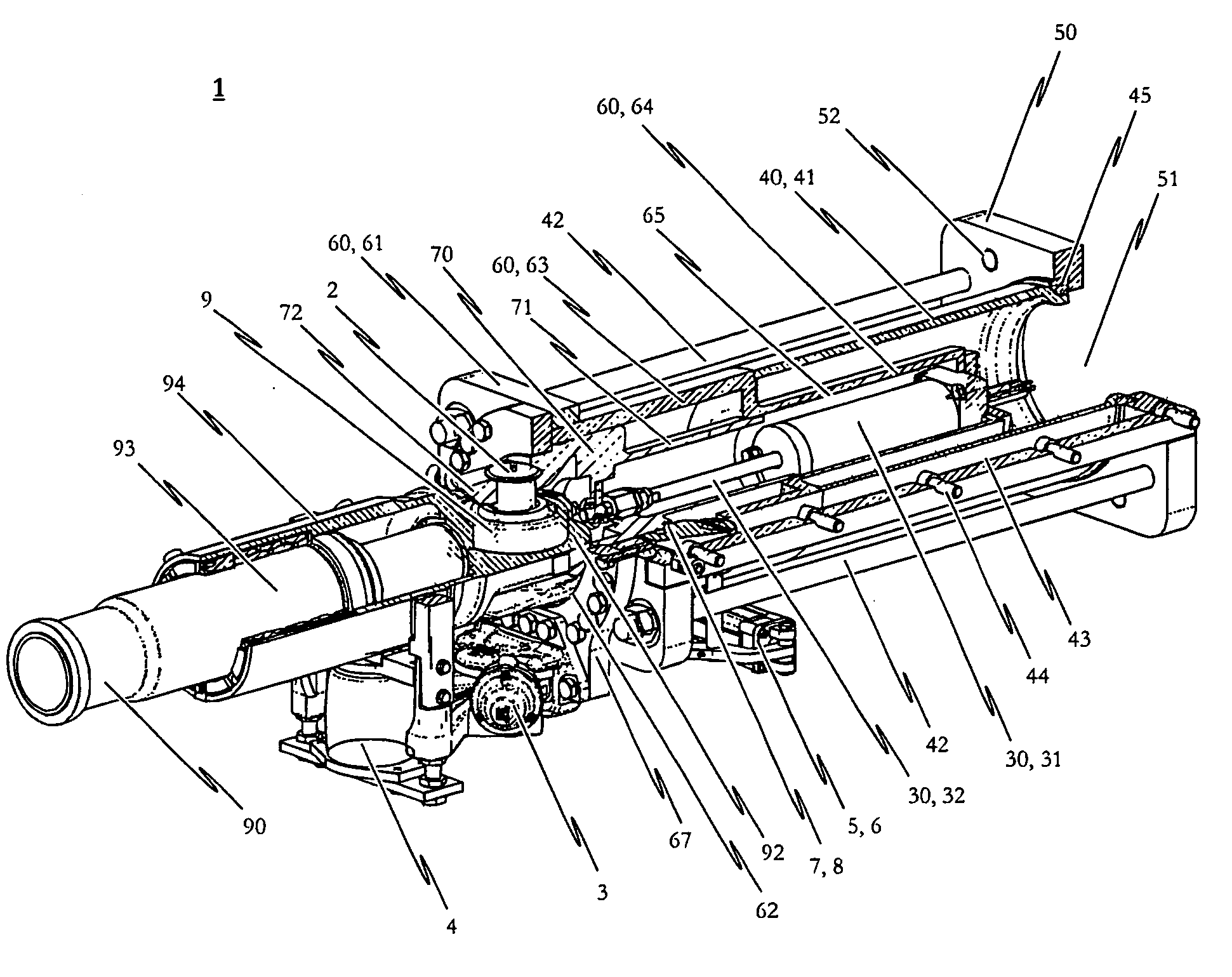

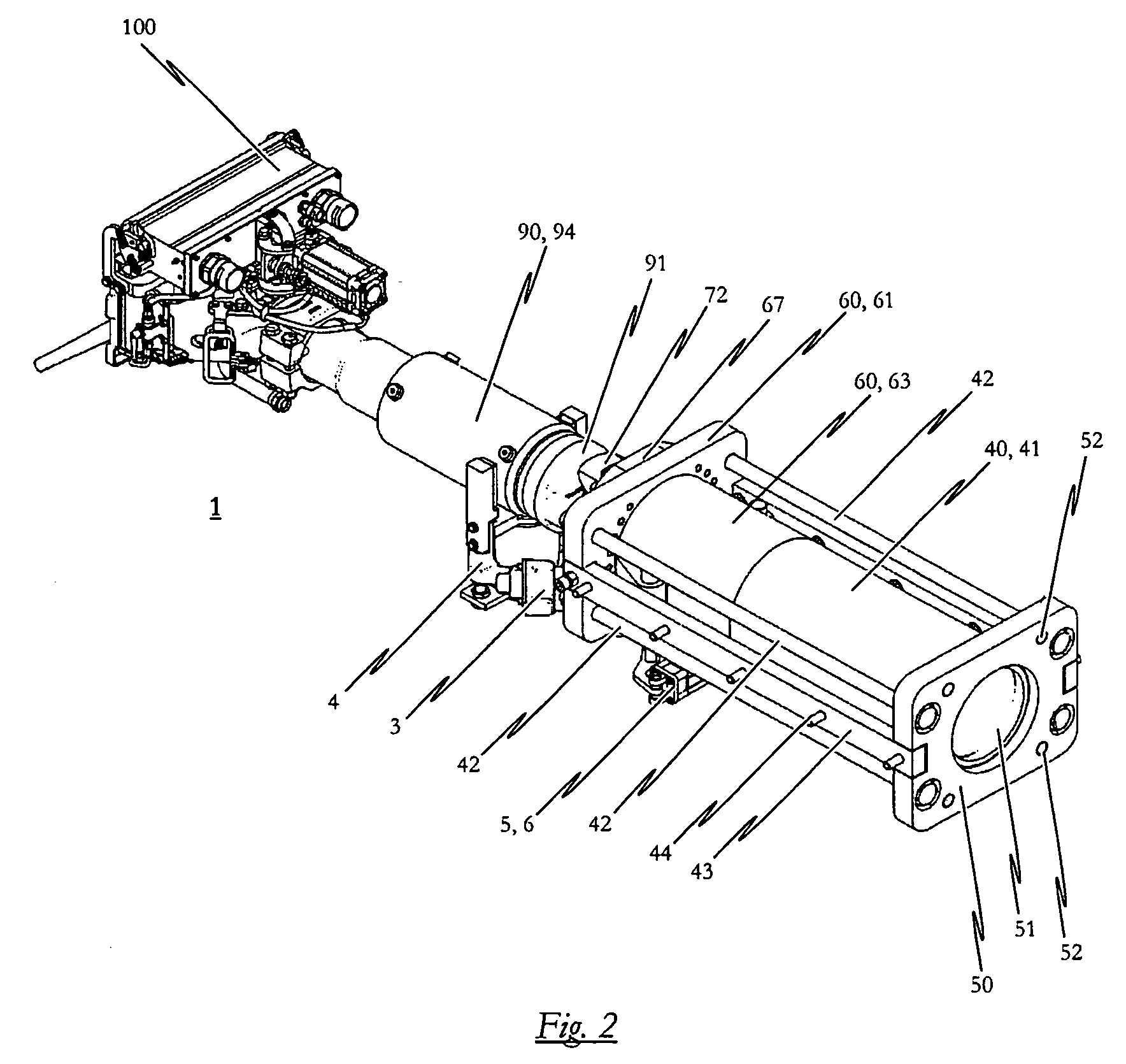

InactiveUS20080277366A1Easy to assembleBuffer carsRailway coupling accessoriesAxial displacementCoupling

The invention relates to an automatic central buffer coupling having a coupling head, a coupling rod and a shock absorber including a destructively-configured force-absorbing member in the form of a deformable tube. The invention provides additional functionality of extendability and retractability to the coupling rod, the and for the central buffer coupling to include a controllable linear drive for the axial displacement of the coupling rod relative the fixing plate and for the bearing block to include a first bearing block component against which adjoins the coupling head-side end of the deformable tube, and a second bearing block component to which the vehicle-side end of the coupling rod is articulated, whereby the second bearing block component is axially displaceable relative the first bearing block component by means of the linear drive.

Owner:VOITH PATENT GMBH

Railway vehicle head structure

ActiveCN106240587AEasy to replaceImprove carrying capacityBuffer carsRailway wheel guards/bumpersAbsorbed energySafety zone

The invention discloses a railway vehicle head structure. The railway vehicle head structure comprises a vehicle body main structure, a vehicle head anti-collision structure and an anti-creeper. A vehicle head is divided into a safety zone of which the longitudinal load strength is decreased progressively in a gradient mode, a secondary deformation zone and a main deformation zone according to the longitudinal direction of a railway vehicle. The safety zone is the vehicle body main structure and comprises a passenger room zone and a driver seat zone. The secondary deformation zone is a zone from a cab front door to an anti-creeper installation plate and comprises the vehicle head anti-collision structure and an anti-creeper installation structure. The main deformation zone comprises a cab floor located in front of the anti-creeper installation plate and the anti-creeper. A first-stage stopping structure is arranged between the secondary deformation zone and the main deformation zone. A second-stage stopping structure is arranged between the safety zone and the secondary deformation zone. According to the railway vehicle head structure, a vehicle body deforms and absorbs energy in a controllable and orderly mode, and the good safety performance is obtained.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

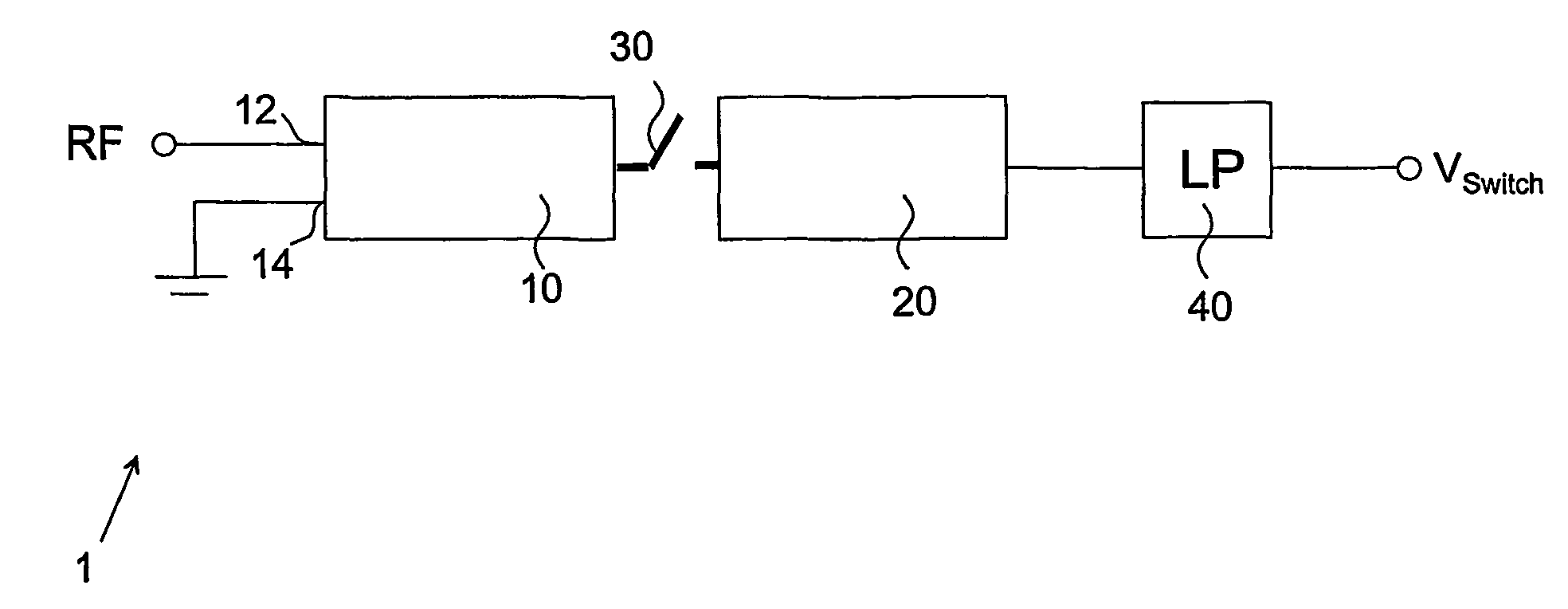

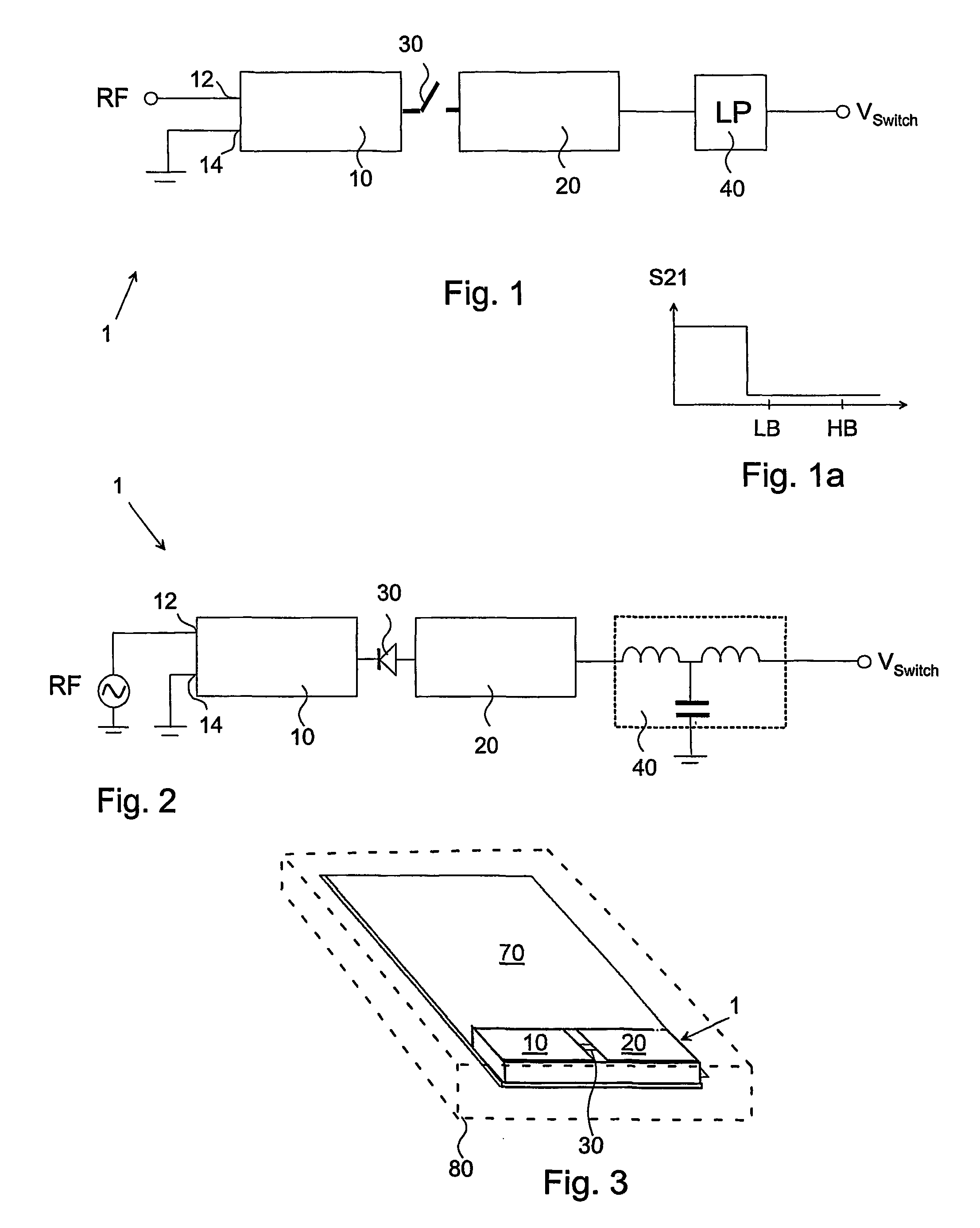

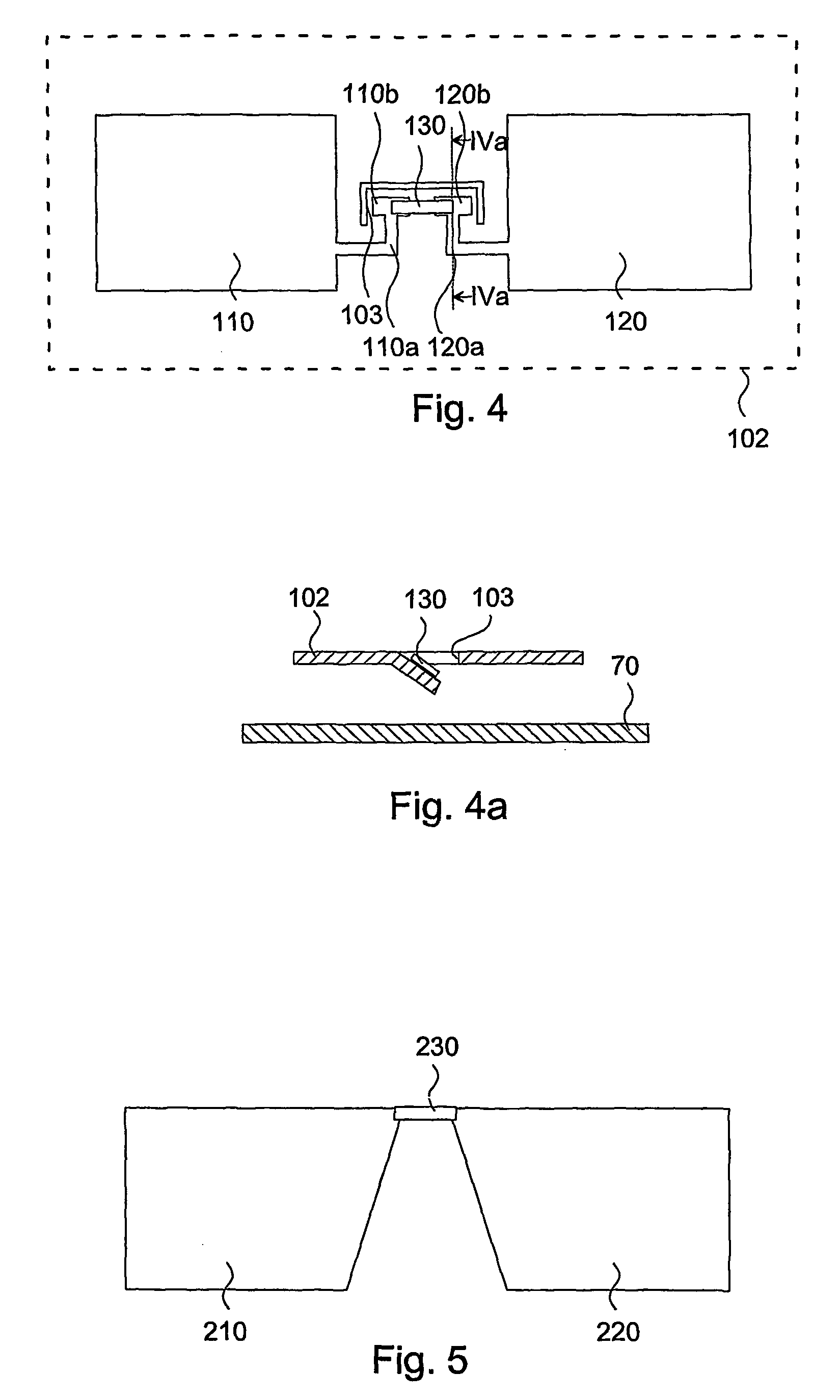

Controllable multi-band antenna device and portable radio communication device comprising such an antenna device

ActiveUS7800544B2Reduce antenna sizeMaintain performanceSimultaneous aerial operationsBuffer carsMulti bandElectrical resistance and conductance

A multi-band antenna device for a portable radio communication device has first and second radiating elements (10, 20′). A controllable switch (30) is arranged between the radiating elements for selectively interconnecting and disconnecting thereof. The state of the switch is controlled by means of a control voltage input (VSwitch). A filter (40) comprising a pure resistance that blocks radio frequency signals is arranged between the second radiating element and the control voltage input. By means of this arrangement, two broad and spaced apart frequency bands are obtained with retained performance and small overall size of the antenna device. A communication device comprising such an antenna device is also provided.

Owner:SAMSUNG ELECTRONICS CO LTD

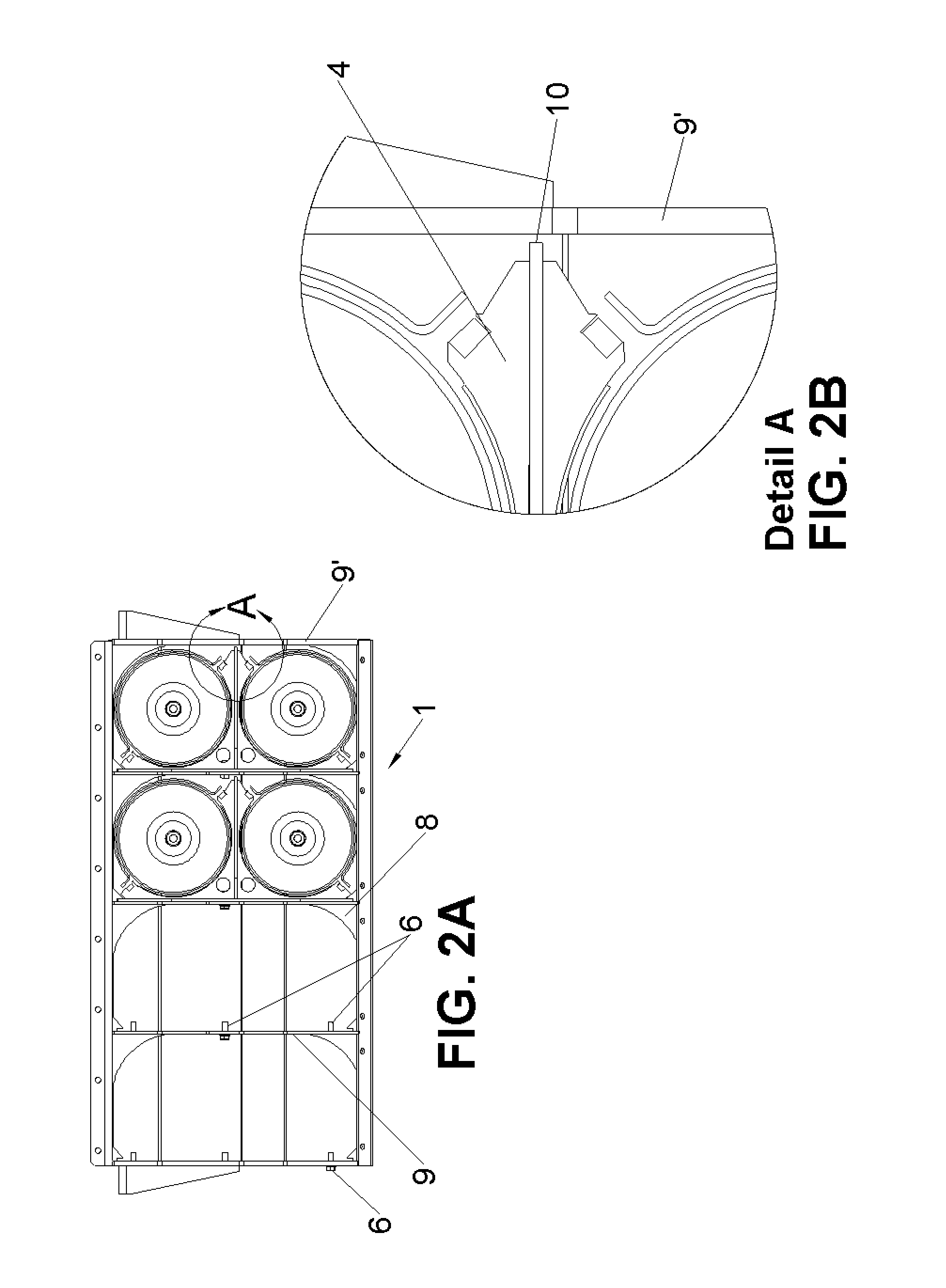

Collision energy absorbing apparatus and railway vehicle equipped with the same

Provided is a collision energy absorbing apparatus capable of mitigating loads to the car body proper, passengers and the like by adding a structure combining a prescribed static strength and collision energy absorption performance to an energy absorbing body of the collision energy absorbing apparatus. In a limited inner space of a car body, a cover 80 that covers energy absorbing bodies 51, 52 combines a prescribed static strength and collision energy absorption performance. The cover 80 prevents irregularities, such as the breakage of cylindrical bodies of aluminum alloy, i.e., the energy absorbing bodies 51, 52 in each of the stages of transportation, storage, assembling and the like of the collision energy absorbing apparatus 50. The cover 80 having static strength fulfills the role of withstanding a prescribed static load and in the event of a collision against an obstacle, the cover 80 is broken earliest and reduces a peak load of crush, with the result that part of the collision energy is used in the breakage of the cover 80. As a result of this, the cover 80 can contribute to the absorption and mitigation of the collision energy.

Owner:HITACHI LTD

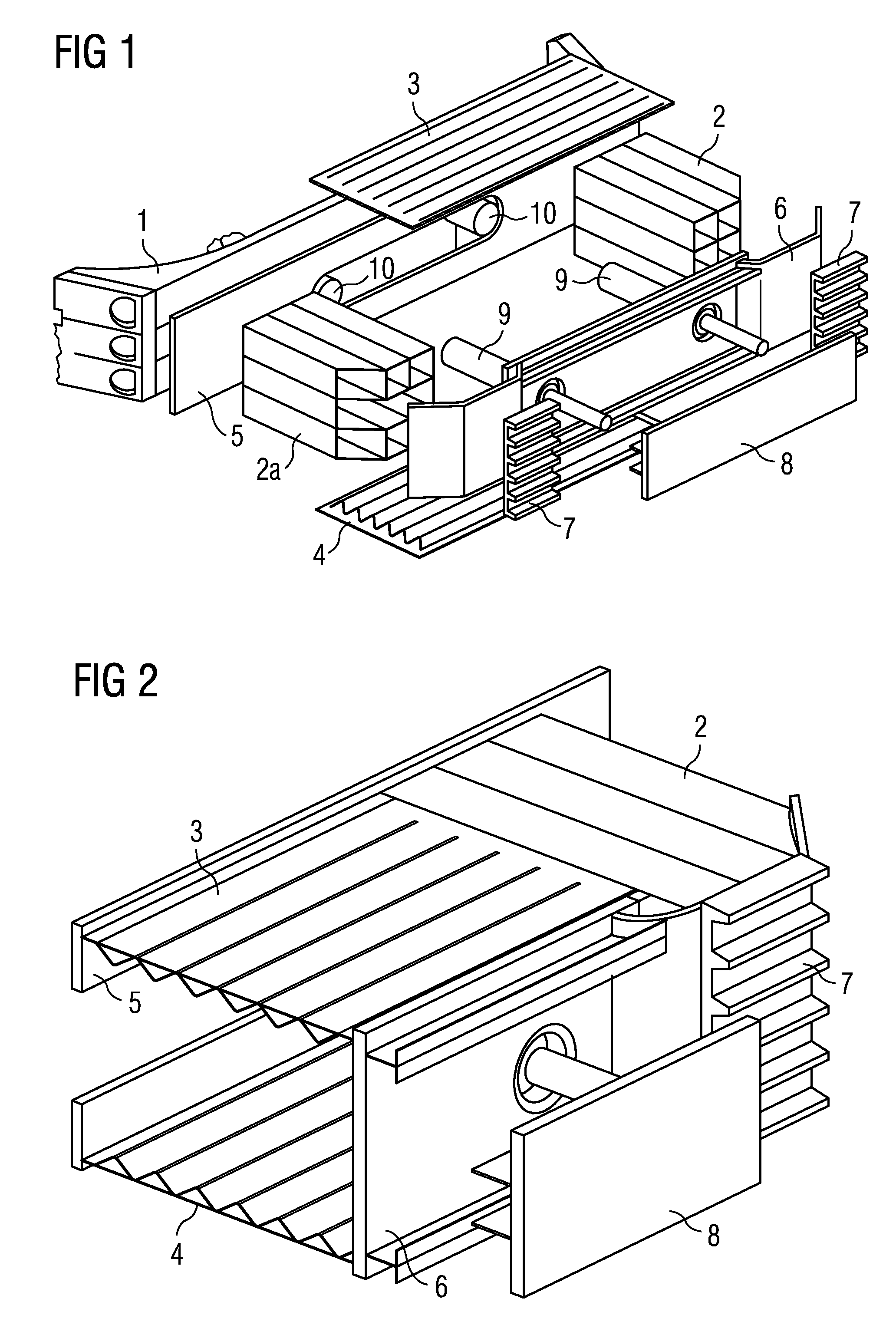

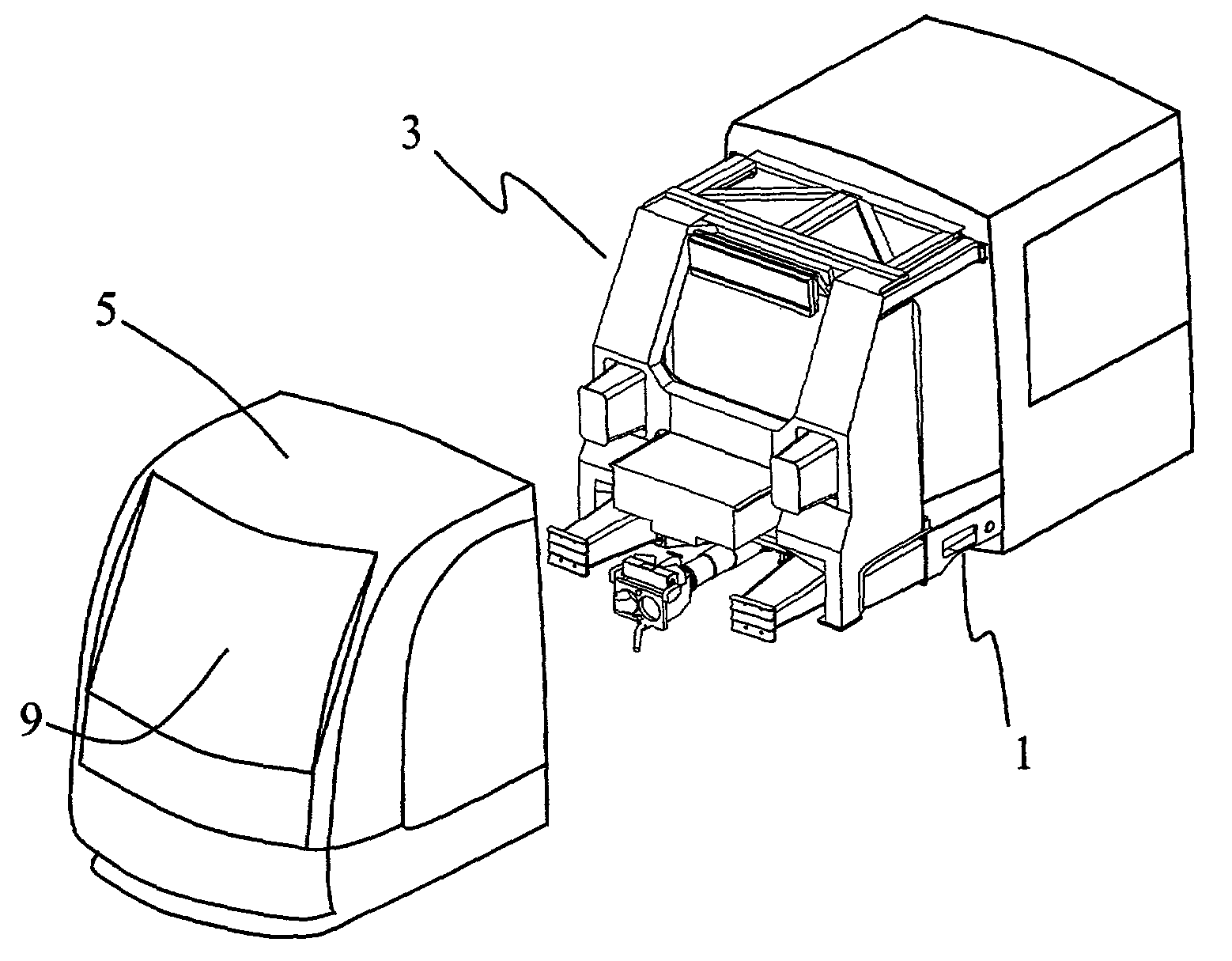

Crash module for a rail vehicle

InactiveUS20120325108A1Quickly and easily repairedEasy to replaceBuffer carsUnderframesEngineeringCompressive strength

A crash module for a rail vehicle includes at least one crash element, which is arranged in front of the vehicle structure. At least one transverse profiled element is provided, which is connected to the at least one crash element and which has a substantially lower compressive strength in the longitudinal direction of the rail vehicle than in the transverse direction.

Owner:SIEMENS MOBILITY AUSTRIA GMBH

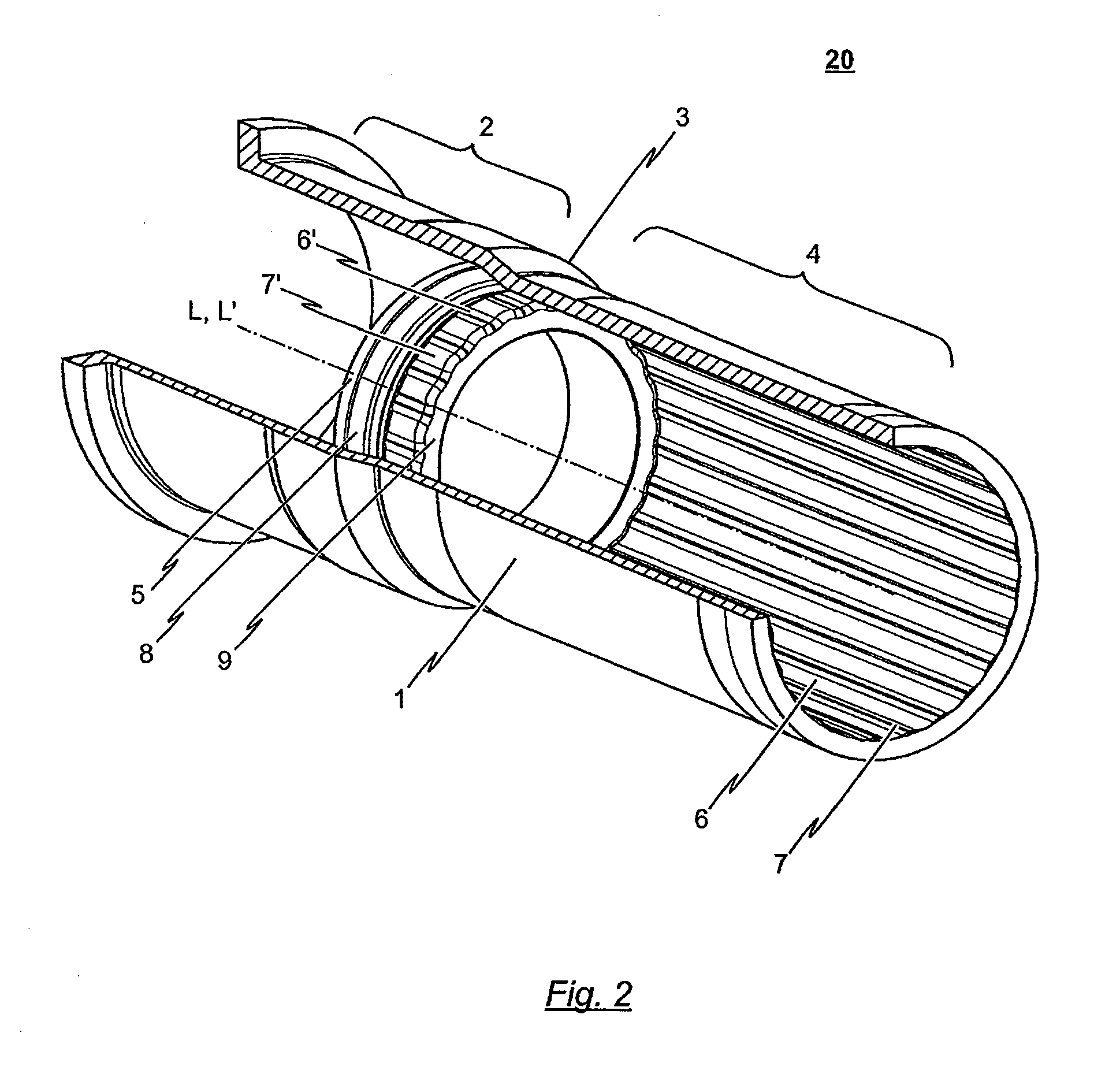

Energy-Absorbing Device Particularly For A Shock Absorber For A Track-Guided Vehicle

An energy-absorbing device, particularly for a shock absorber of a track-guided vehicle, has an energy-absorbing element designed as a deformation tube and a counter element which interacts with the deformation tube such that upon a critical impact force being exceeded, the counter element and the deformation tube exhibit a relative movement toward one another while at least a portion of the impact energy introduced into the energy-absorbing device is simultaneously absorbed. For the energy absorbtion to take place according to a predictable sequence of events when force is introduced non-axially into the energy-absorbing device, the counter element is connected to the deformation tube by means of a form-fit connection circumferential to the deformation tube so as to prevent twisting of the counter element relative the deformation tube.

Owner:VOITH PATENT GMBH

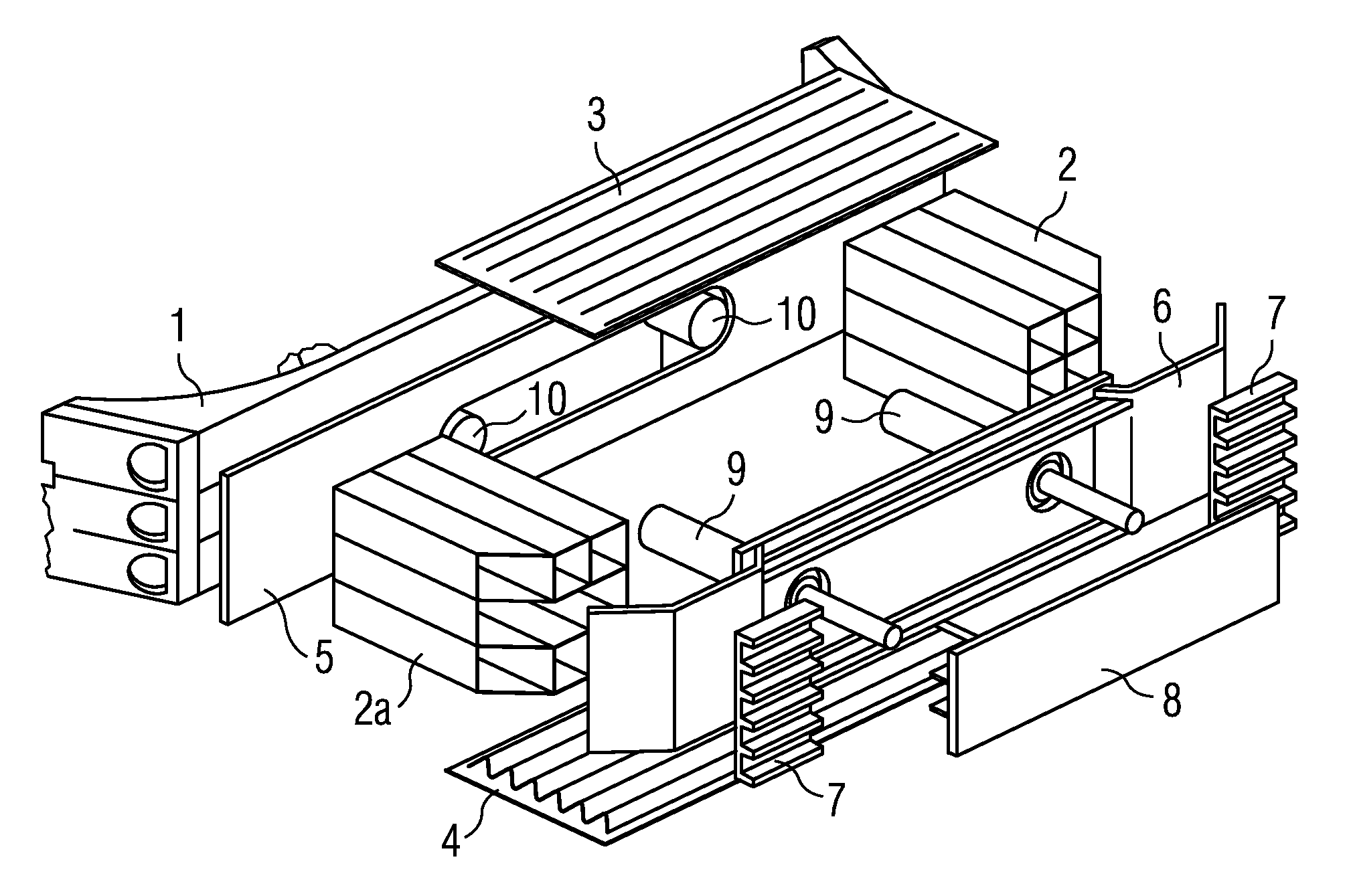

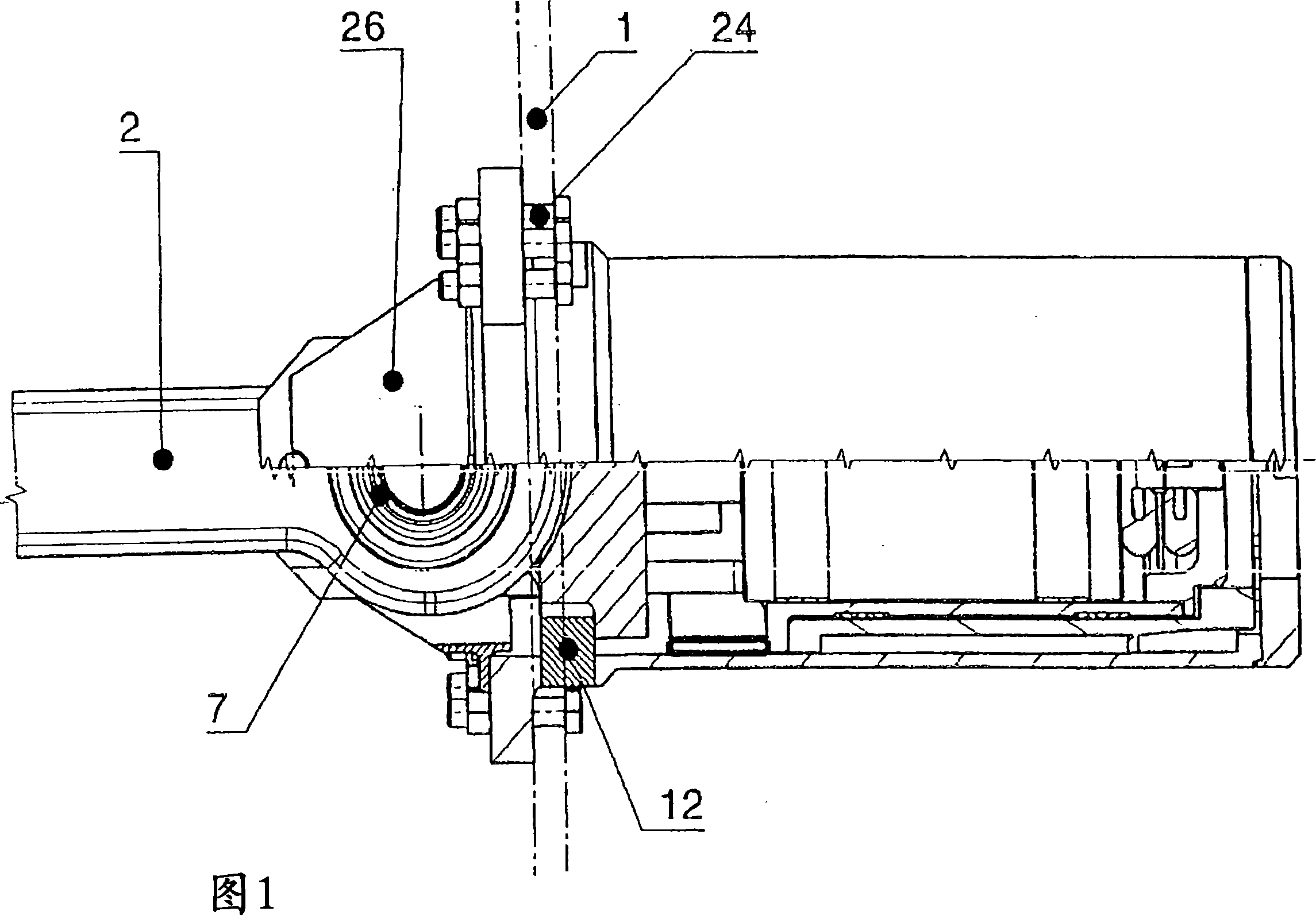

Pulling and pushing device for a central buffer coupling of rail vehicles

InactiveCN101142115AAvoid acceleration peaksSo as not to damageBuffer carsDraw-gearBogieEnergy absorption

The device has a coupling arm with head born elastically pref. via a stabilizer joint. The joint transmits traction and pressure forces into the bogie via an outer housing (10) and energy absorption systems (9,11). The systems are switched in series and are located in the housing. One and / or both systems have an irreversibly deformable deformation element (23), e.g. a mechanical shock absorption part. This is e.g. a tube, which is deformed by a nozzle (25) or a pressure ring (21), after a set pressure and / or traction load limit on shear ring (20) and / or pin has been exceeded. -

Owner:FAIVELEY TRANSPORT REMSCHEID

Passenger rail car

Owner:HYUNDAI ROTEM CO

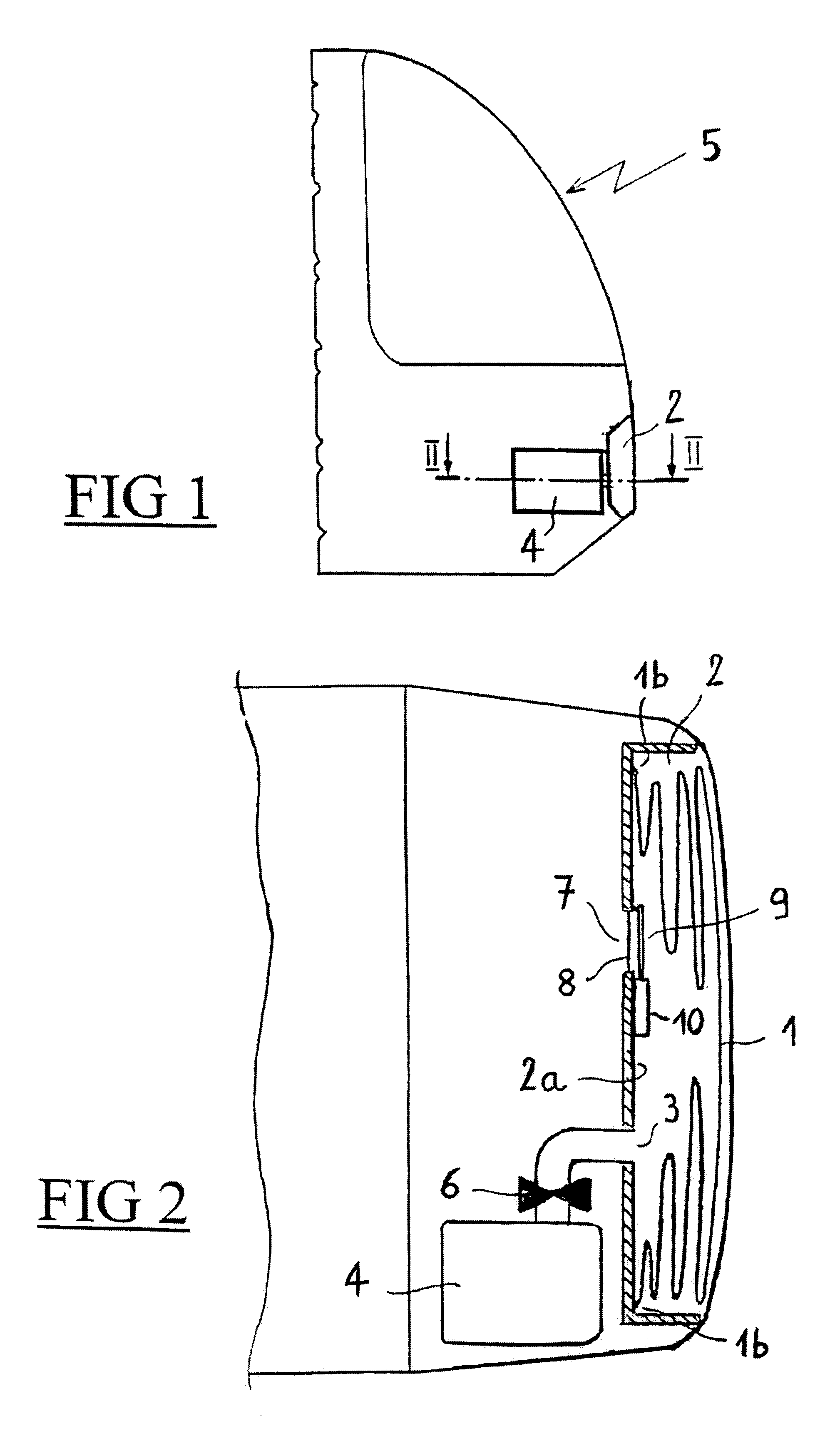

Inflatable air bag release and membrane protection device

A release device for releasing an inflatable element for protecting a vehicle against impact, which element, once inflated, presents a general shape that fits closely over the region of the vehicle to be protected, said inflatable element being held, in a folded state, in a compartment that includes a wall that is connected in sealed manner to an edge of an opening of said inflatable element, wherein, facing said opening, said wall includes gas release means that are protected during inflation of the inflatable element by a closure flap controlled by actuator means that remove said closure flap once the inflatable element is deployed.

Owner:ALSTOM TRANSPORT TECH SAS

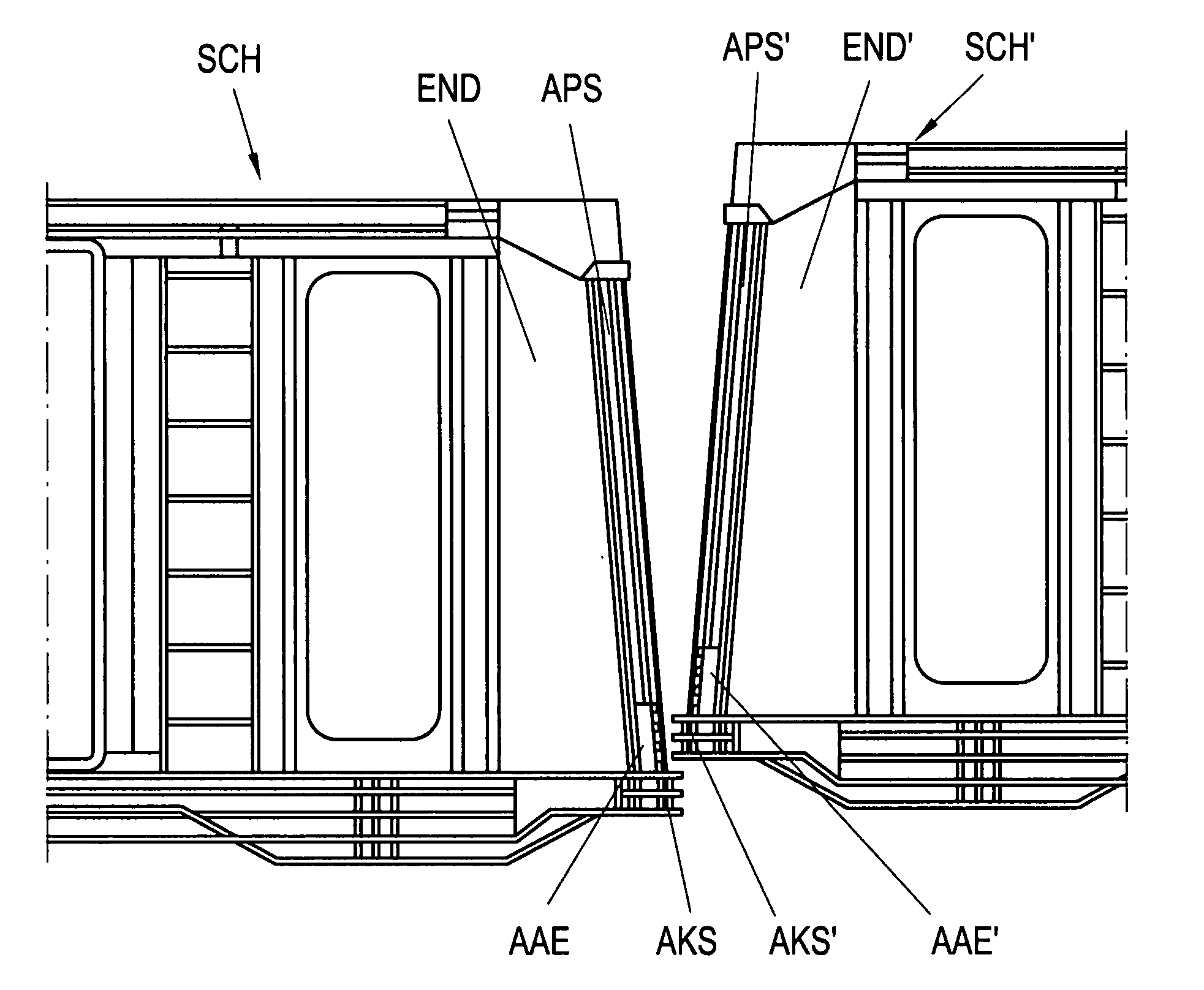

Rail vehicle having an attached deformation zone

ActiveUS20140020596A1Good deformation behaviorHigh pressure forceBuffer carsEngineeringTransverse beam

A rail vehicle having an attached deformation zone is presented. The rail vehicle has at least one end transverse beam provided in an end face region and corner pillars arranged substantially vertically and extend from the end transverse beam. The deformation zone is provided at the end face having a front transverse beam arranged parallel to the end transverse beam and spaced therefrom in an end-face direction and at least one force transmission element arranged between the end transverse beam and the front transverse beam. The element transmits longitudinal compressive forces between the end transverse beam and the front transverse beam without plastic deformation up to a defined value and failing when the defined value is exceeded.

Owner:SIEMENS MOBILITY AUSTRIA GMBH

Release device for releasing an inflatable element and a protection device for providing impact protection to a vehicle fitted with such a release device

InactiveUS20020005142A1Easy to deployBuffer carsPedestrian/occupant safety arrangementActuatorGas release

A release device for releasing an inflatable element for protecting a vehicle against impact, which element, once inflated, presents a general shape that fits closely over the region of the vehicle to be protected, said inflatable element being held, in a folded state, in a compartment that includes a wall that is connected in sealed manner to an edge of an opening of said inflatable element, wherein, facing said opening, said wall includes gas release means that are protected during inflation of the inflatable element by a closure flap controlled by actuator means that remove said closure flap once the inflatable element is deployed.

Owner:ALSTOM TRANSPORT TECH SAS

Crash module for a rail vehicle

ActiveUS20100218701A1Avoid collisionEnsuring energy dissipationBuffer carsBufferEngineeringMechanical engineering

A crash module for a rail vehicle is provided. The crash module includes a crash element, a frontal impact plate and a rear connecting plate, wherein a guide element is provided between the frontal impact plate and the rear connecting plate. The guide element has the form of a plate and is oriented essentially in a longitudinal direction of the rail vehicle.

Owner:SIEMENS MOBILITY AUSTRIA GMBH

Automatic central buffer coupling

The invention relates to an automatic central buffer coupling having a coupling head, a coupling rod and a shock absorber including a destructively-configured force-absorbing member in the form of a deformable tube. The invention provides additional functionality of extendability and retractability to the coupling rod, the and for the central buffer coupling to include a controllable linear drive for the axial displacement of the coupling rod relative the fixing plate and for the bearing block to include a first bearing block component against which adjoins the coupling head-side end of the deformable tube, and a second bearing block component to which the vehicle-side end of the coupling rod is articulated, whereby the second bearing block component is axially displaceable relative the first bearing block component by means of the linear drive.

Owner:VOITH PATENT GMBH

Anticlimber for Railroad Vehicles

InactiveUS20080314282A1Accurately measurableSolve the lack of spaceBuffer carsBufferEngineeringMechanical engineering

Owner:SIEMENS TRANSPORTATION SYST

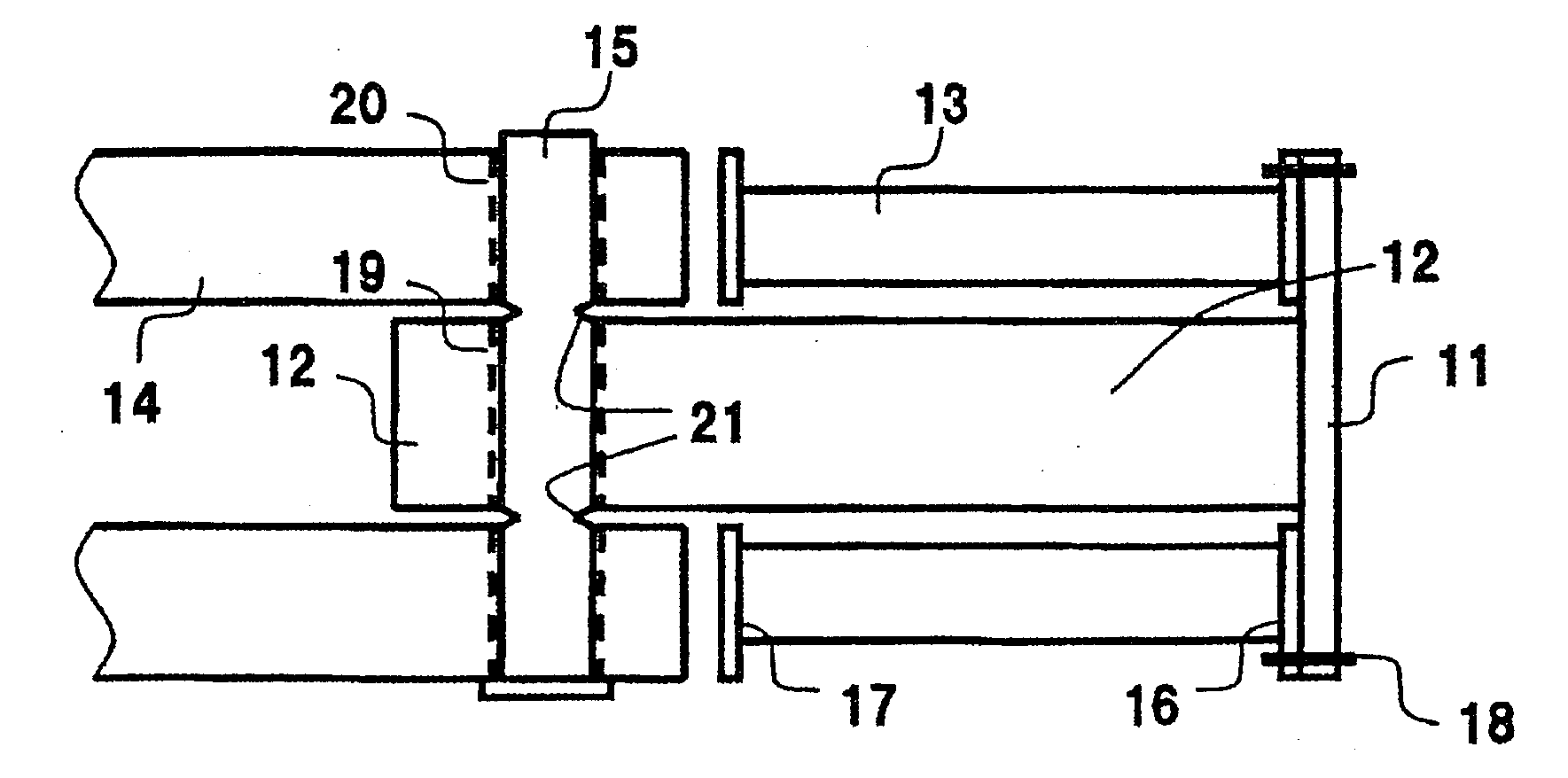

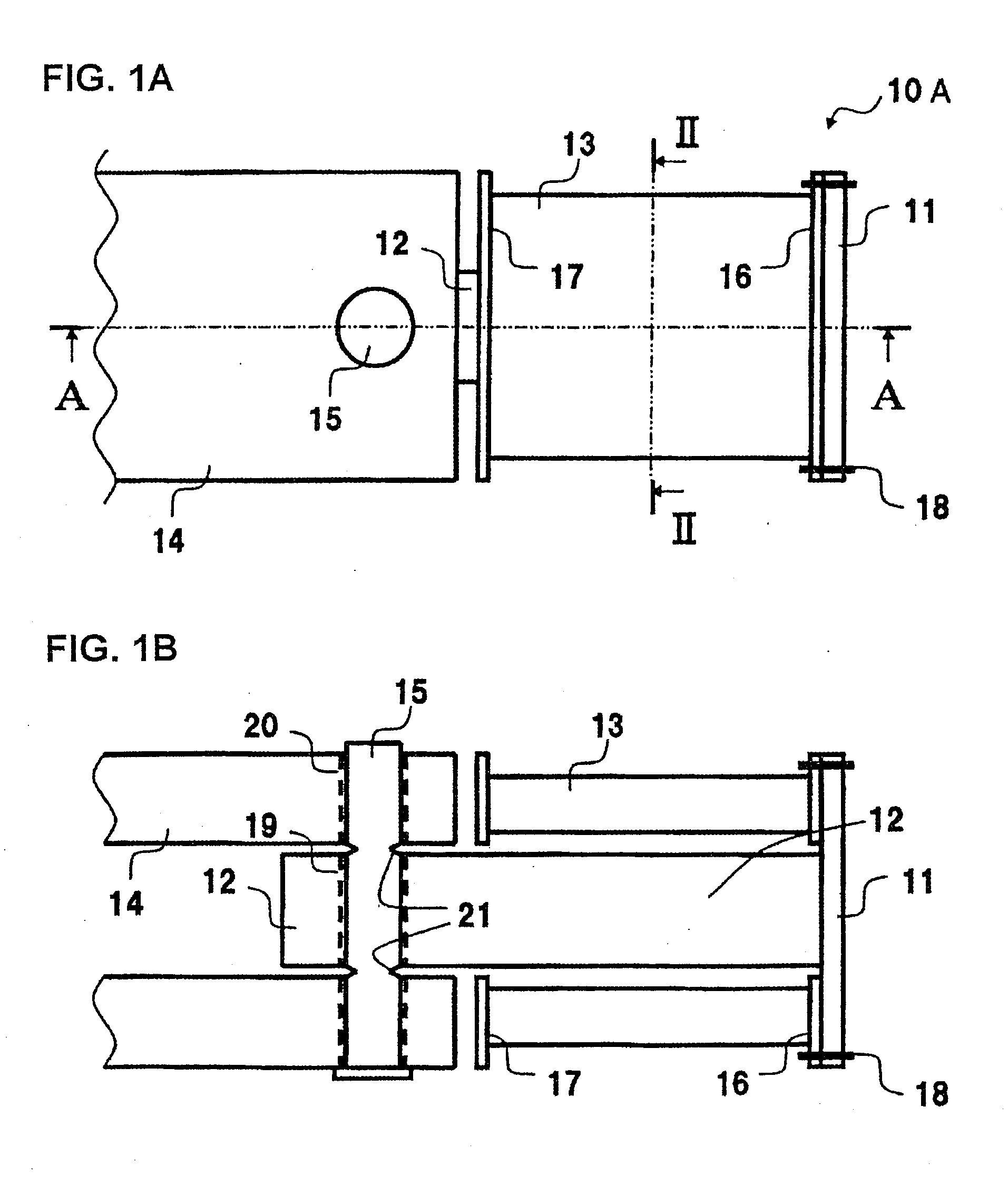

Transportation device

InactiveUS20080236440A1Avoid frequent replacementReduce attachmentBuffer carsRailway wheel guards/bumpersShock absorberEngineering

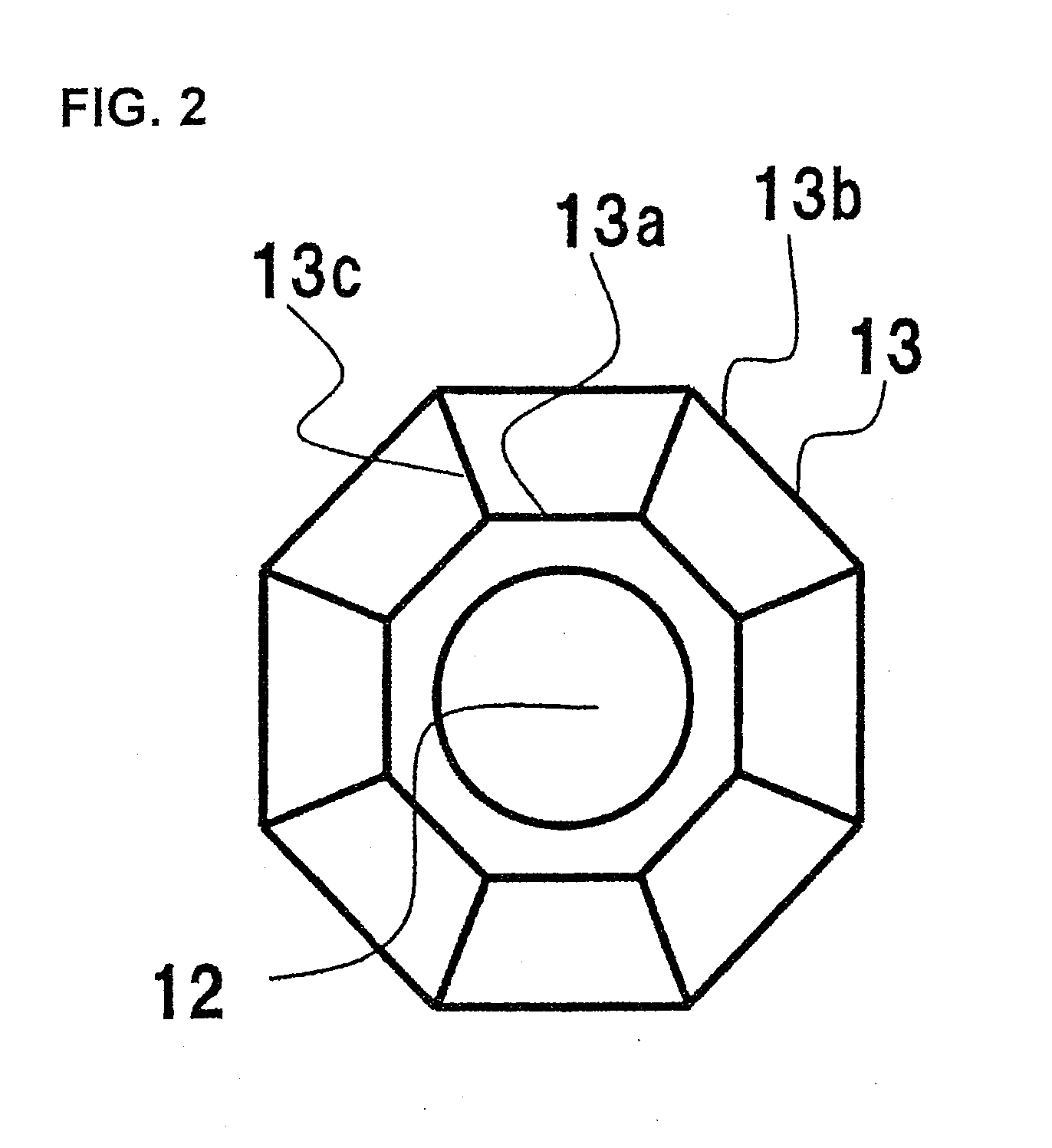

The invention provides a shock absorbing structure capable of turning the function of the shock absorber on and off according to the level of shock during collision, thereby reducing the frequency of replacing shock absorbers. On a rear surface of a load operating unit 11 constituting a shock absorbing device 10A are attached a load transmitting shaft 12 and a shock absorber 13. The load transmitting shaft 12 is passed through the center of the shock absorber and is connected to a supporting unit 14 via a pin 15 that extends toward the radial direction. The rear end of the shock absorber 13 faces the supporting unit 14 with a clearance therebetween. The pin 15 has notched grooves 21 formed thereto. When small load is applied, the load is transmitted from the load operating unit 11 through the load transmitting shaft 12, the pin 15 and the supporting unit 14 to the main body, so that the load is not applied on the shock absorber 13. When large load is applied, the pin 15 breaks from where the notched grooves 21 are formed, by which the surface of the closing plate 17 collides against the supporting unit 14, so that the load is transmitted to the shock absorber 13 and the shock is absorbed effectively.

Owner:HITACHI LTD

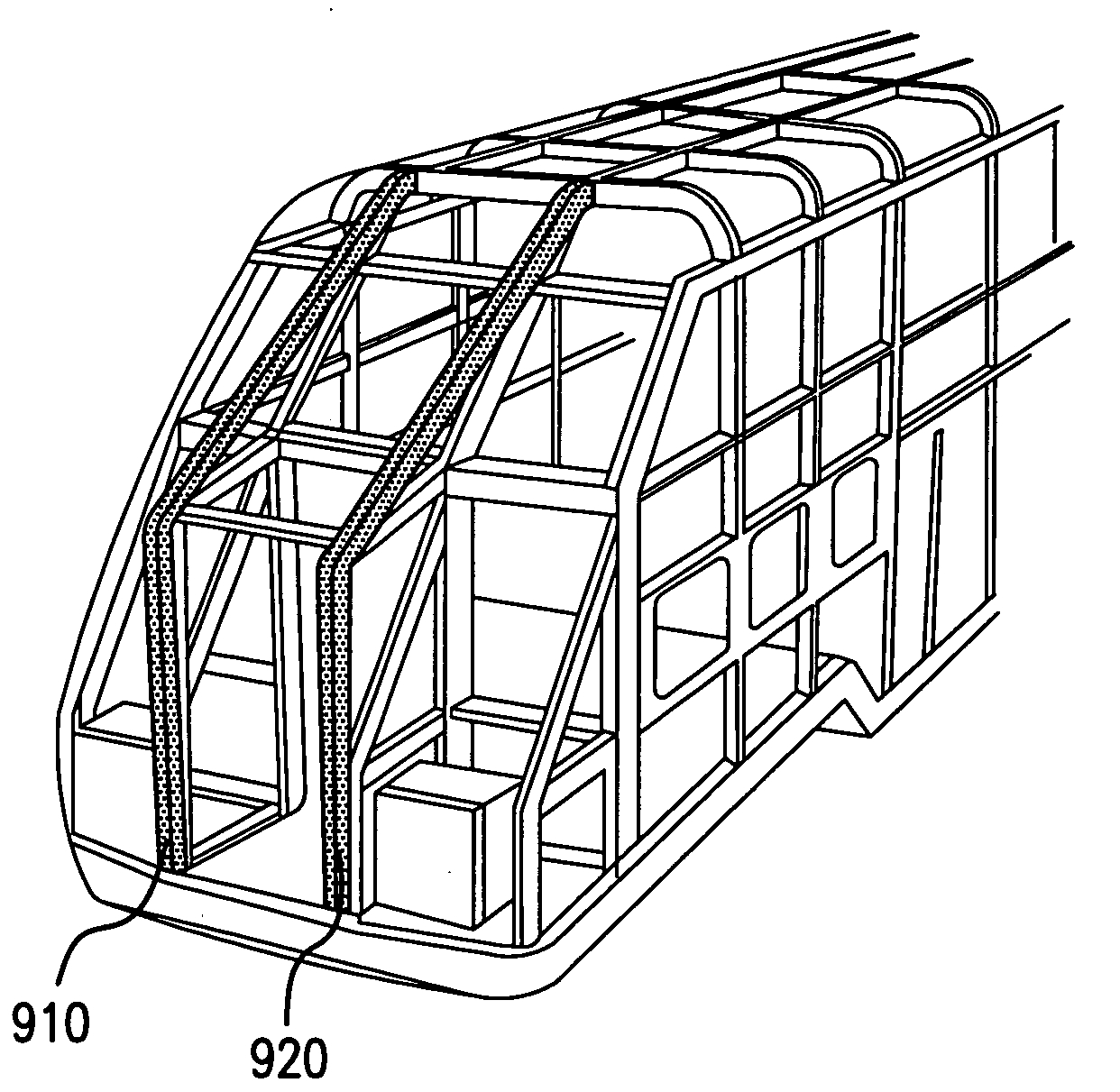

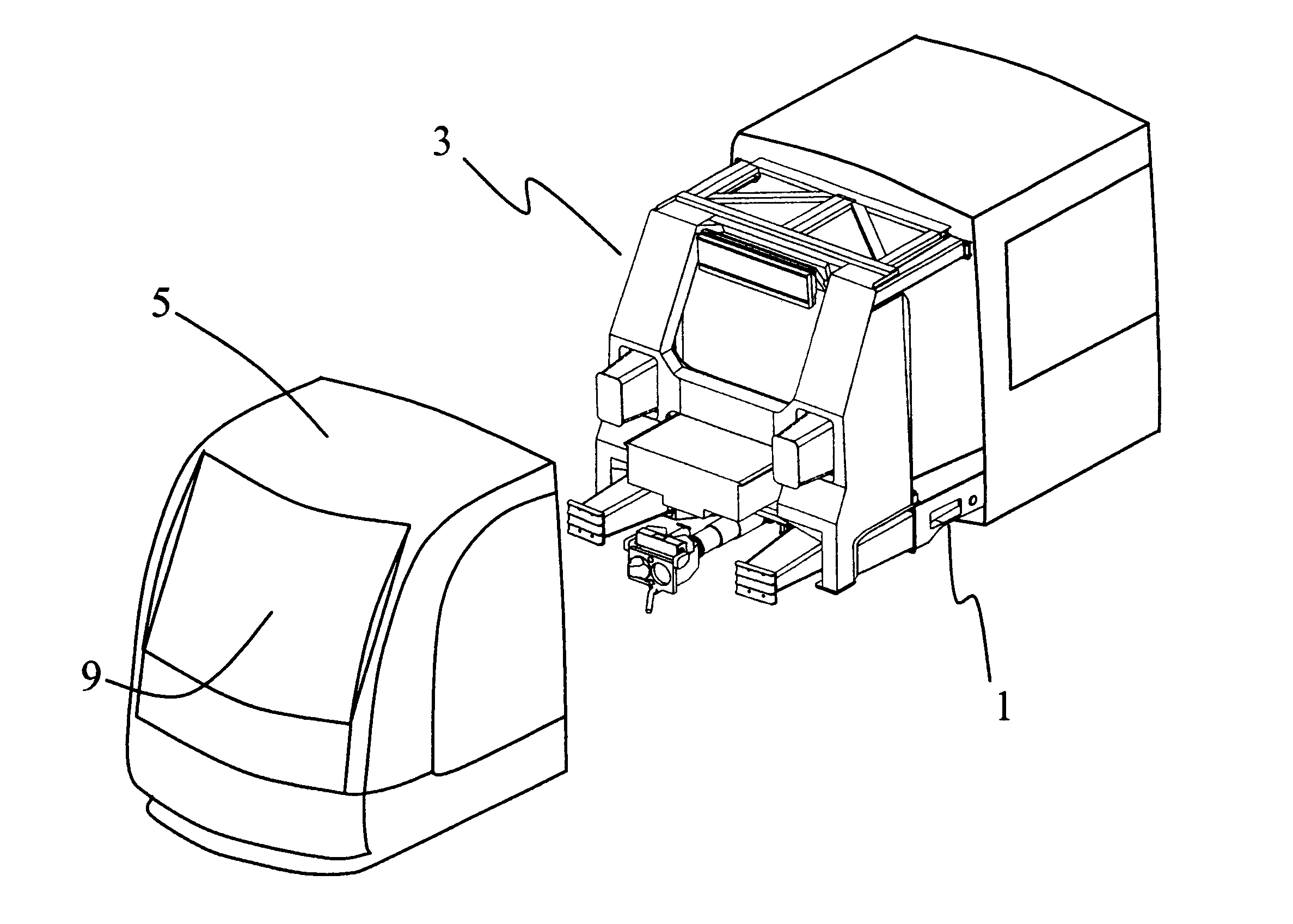

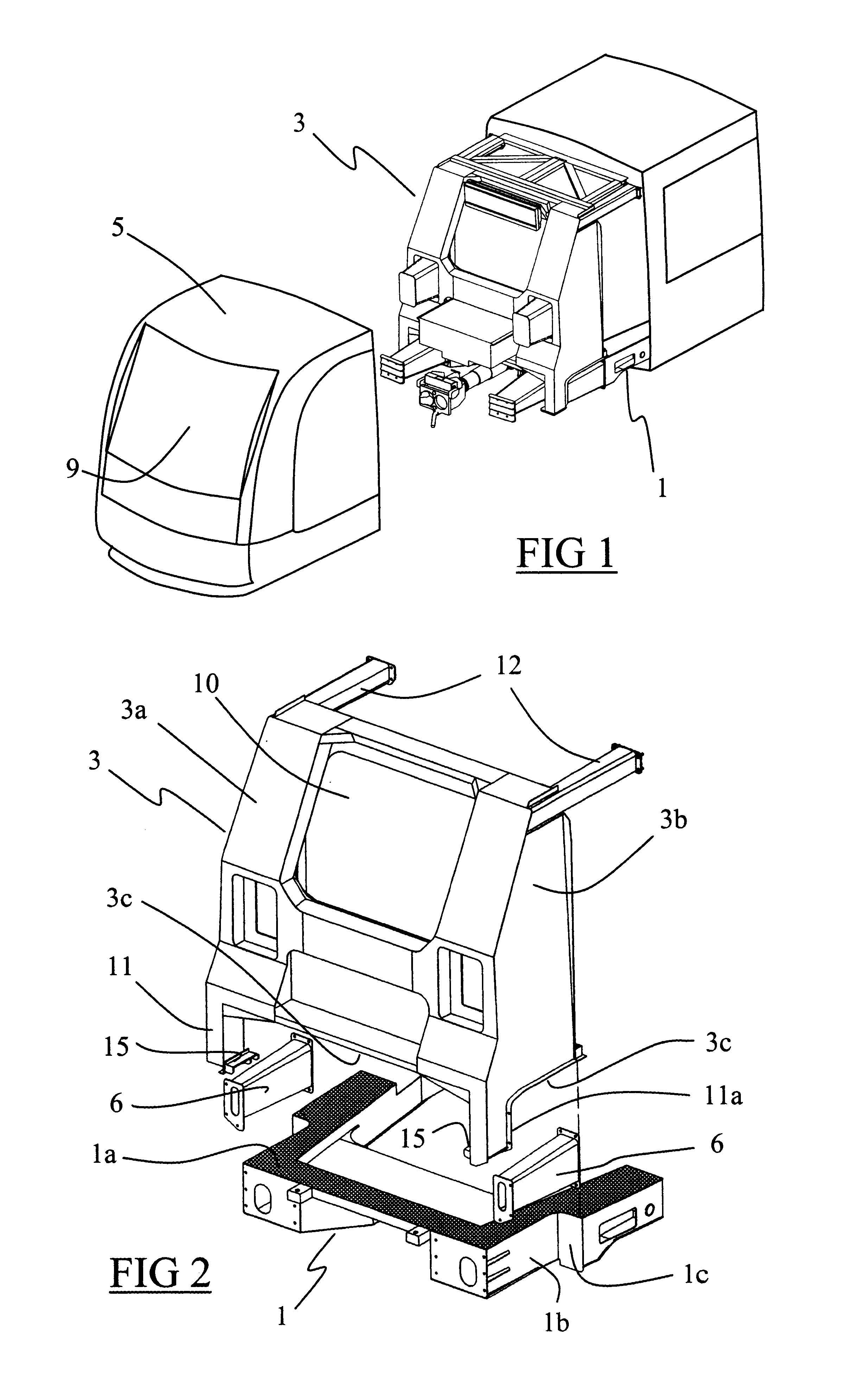

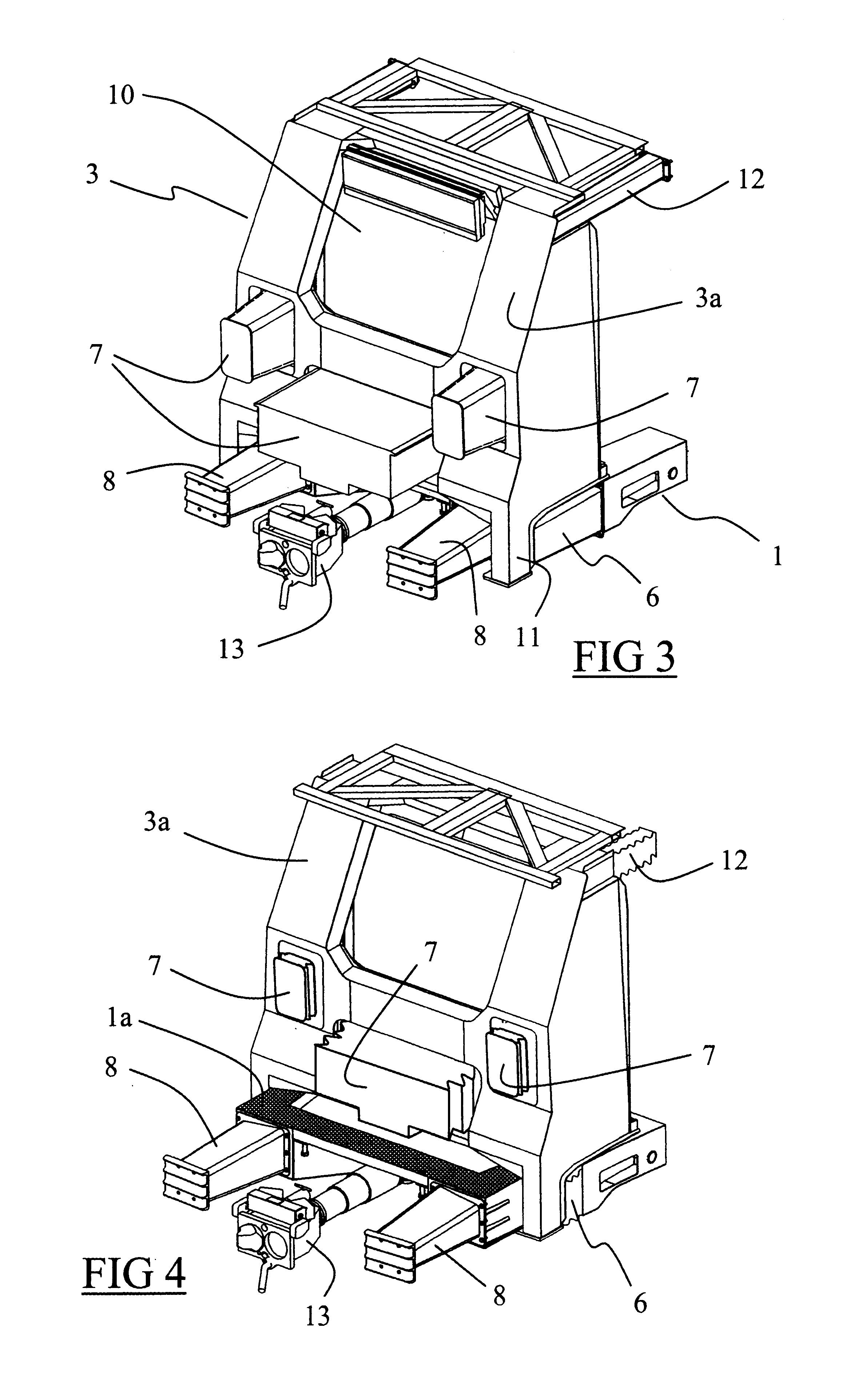

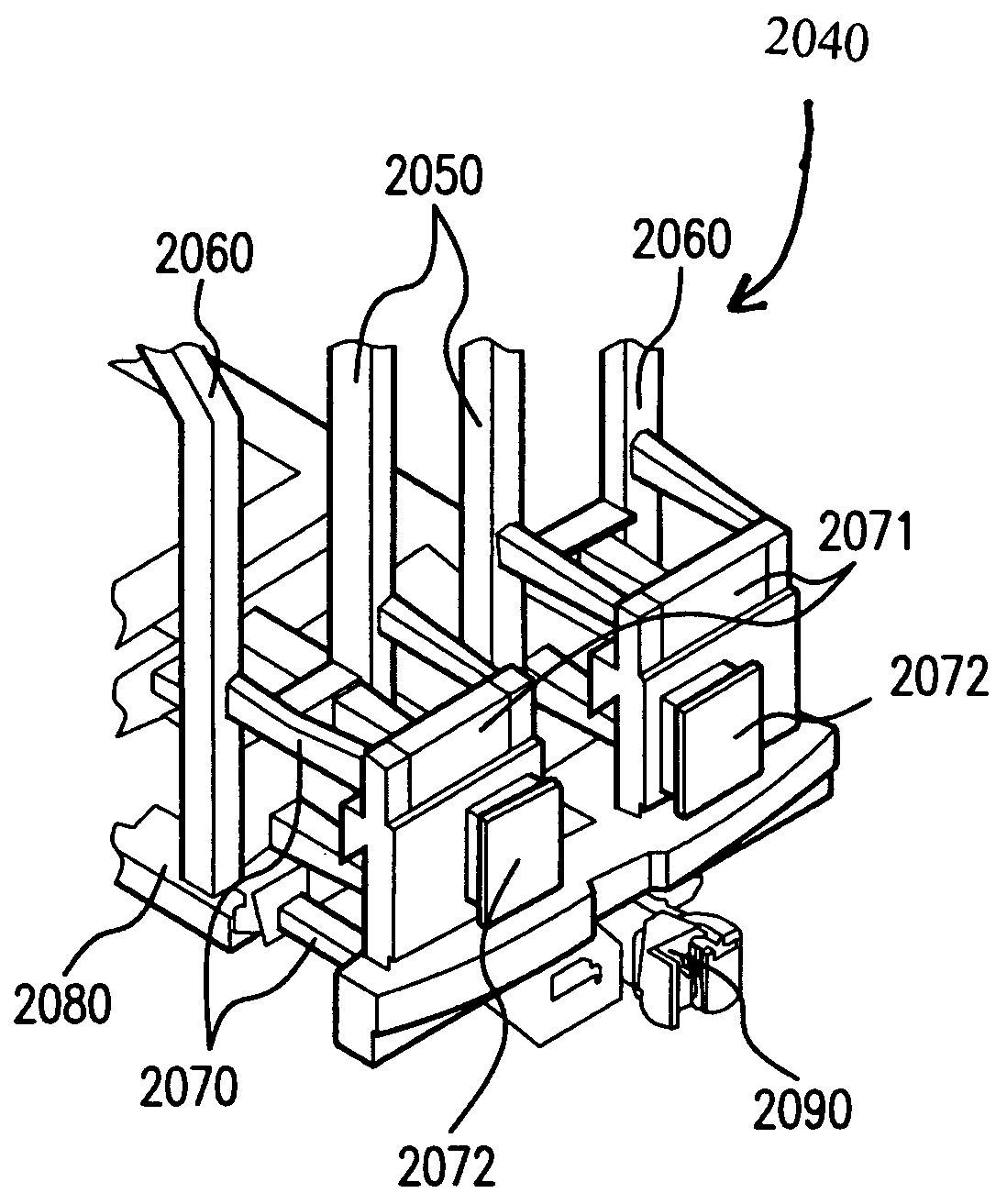

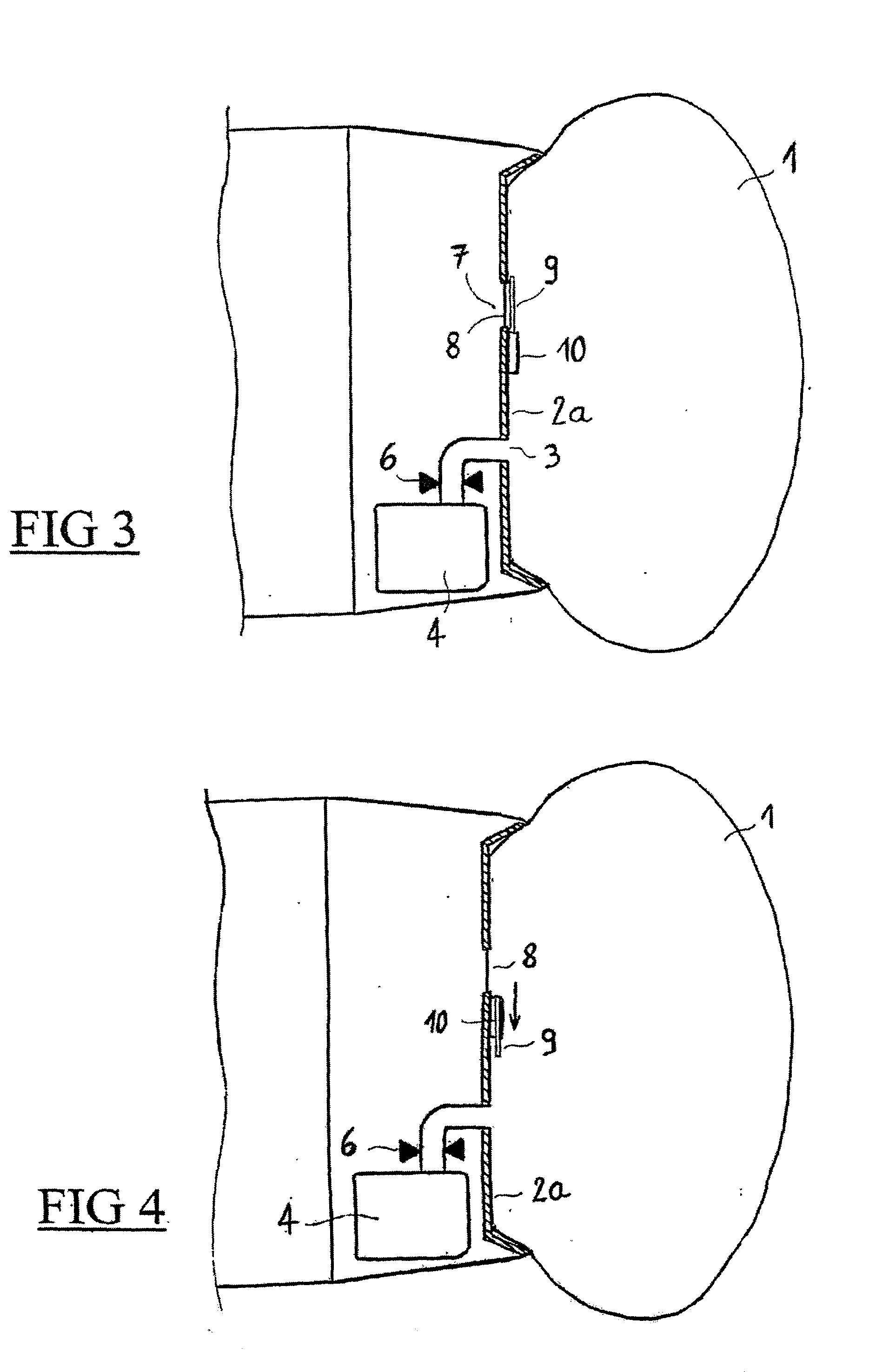

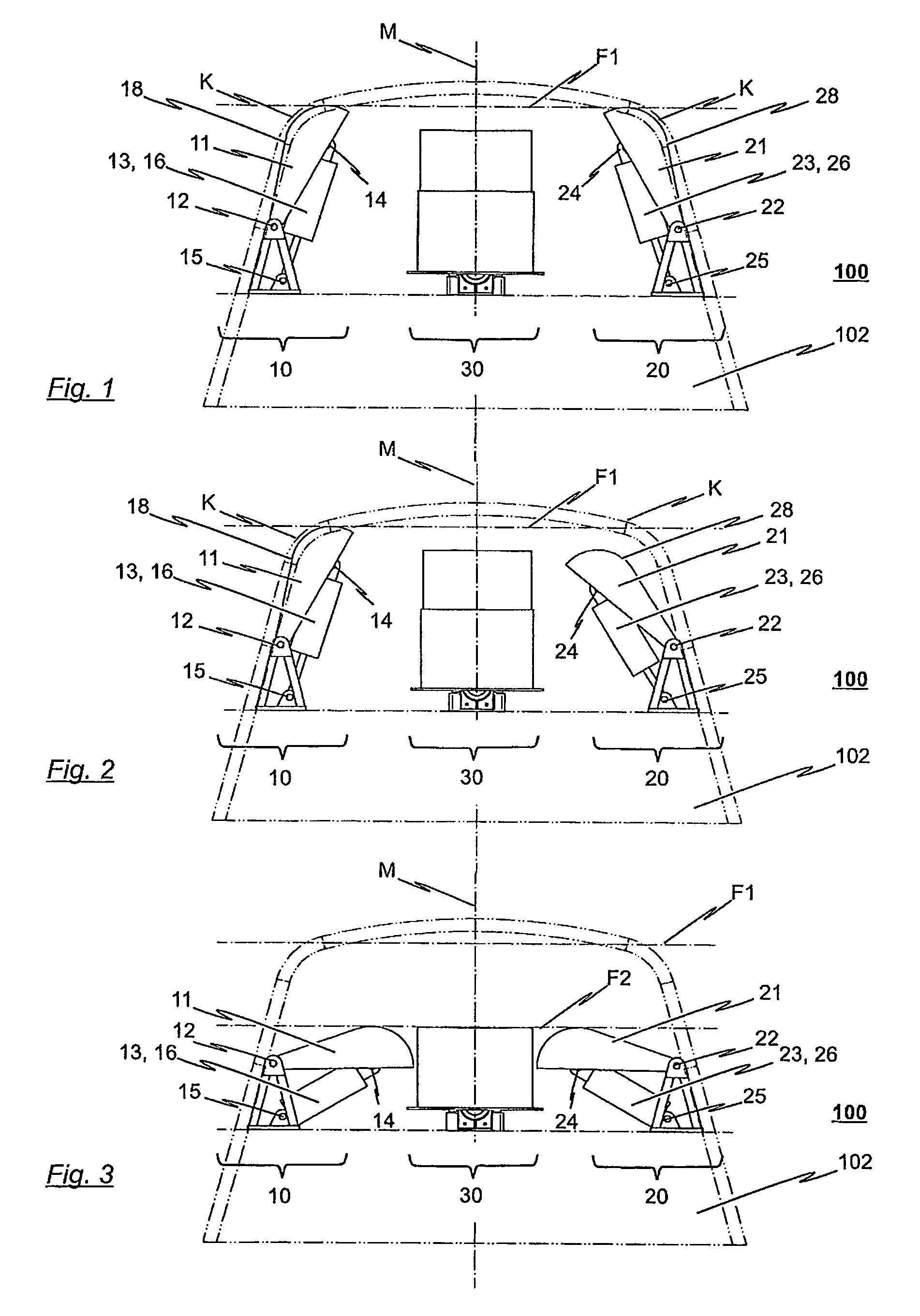

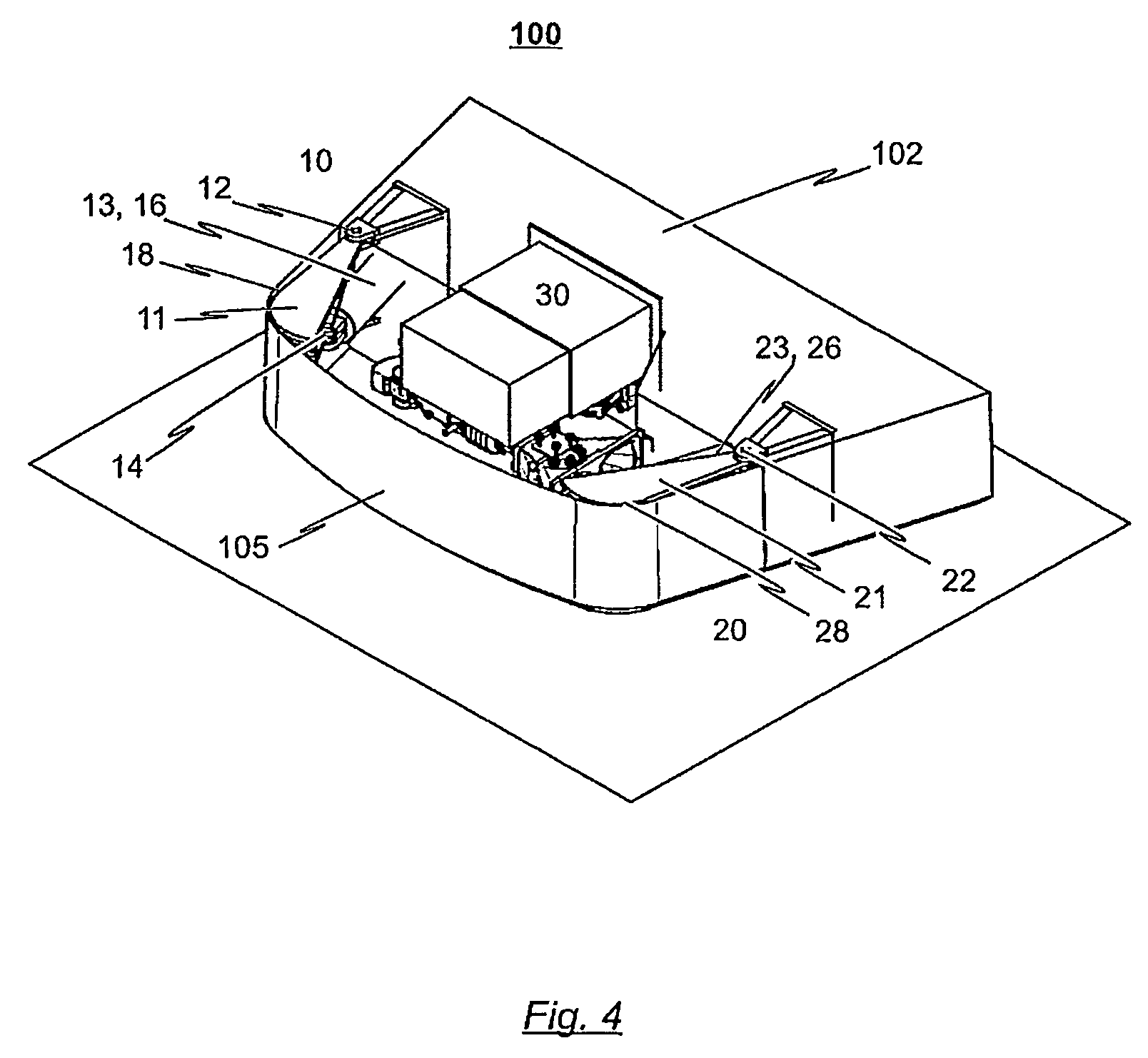

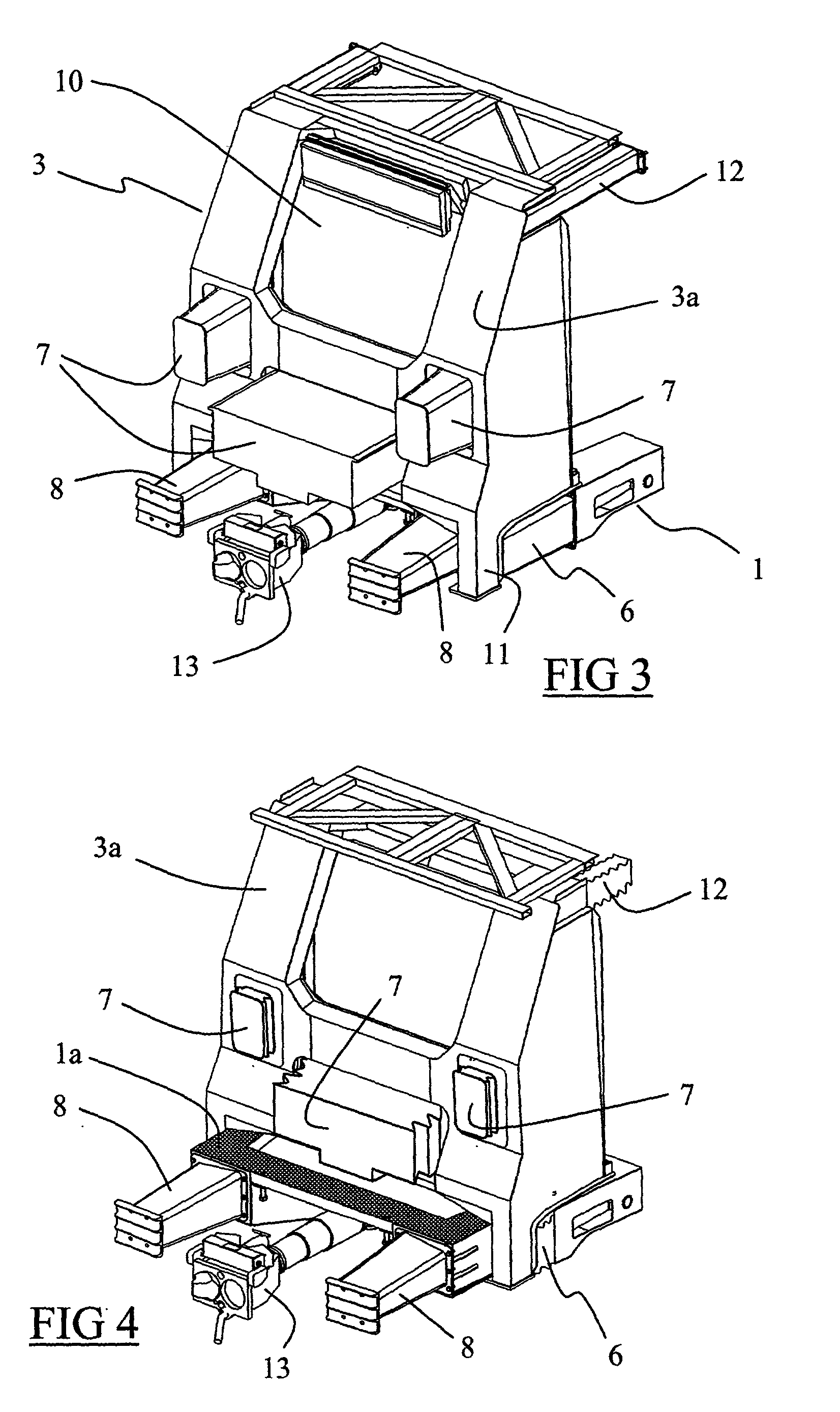

Vehicle front-end for mounting to the front face of a track-bound vehicle, in particular a rail vehicle

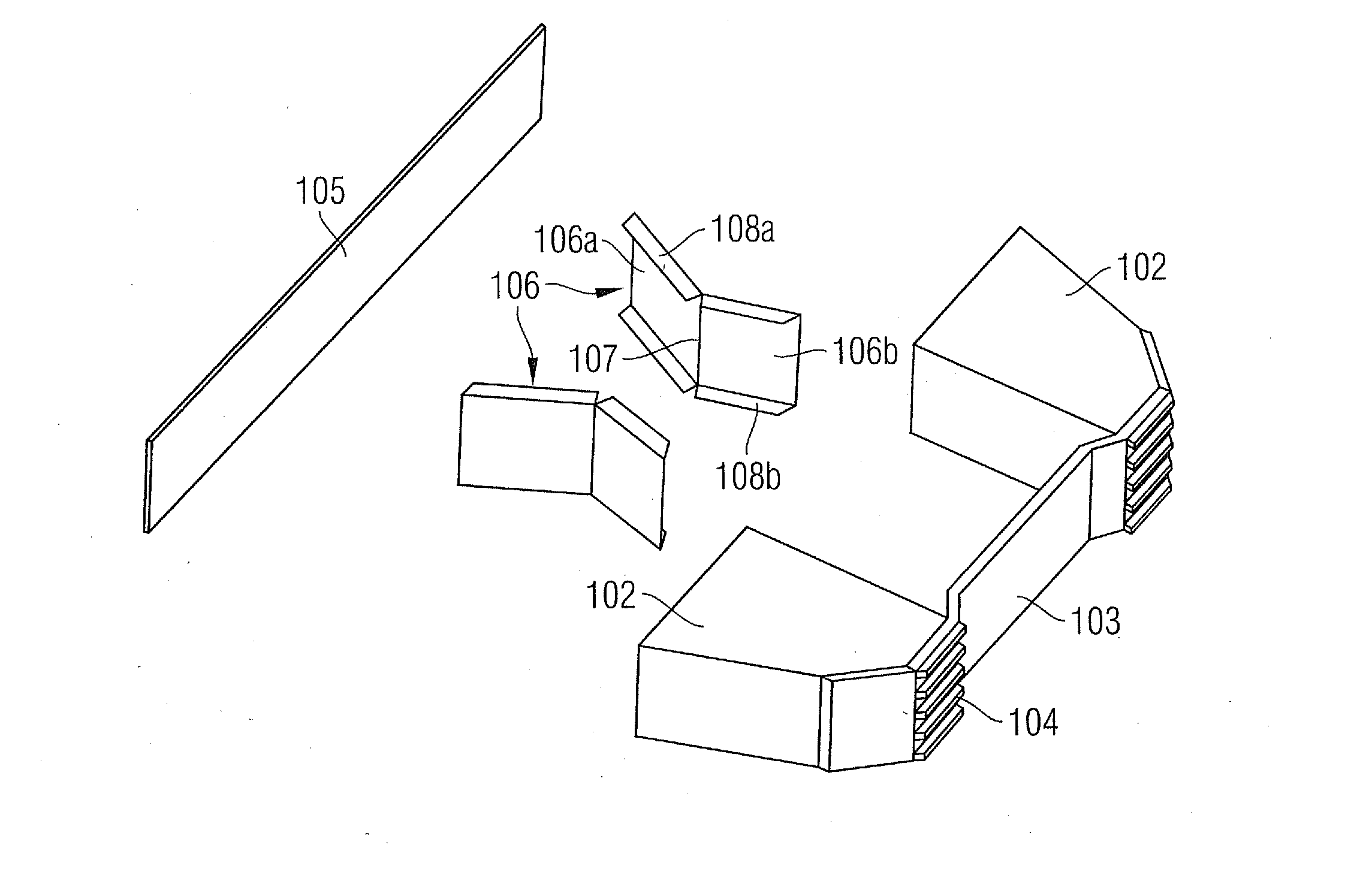

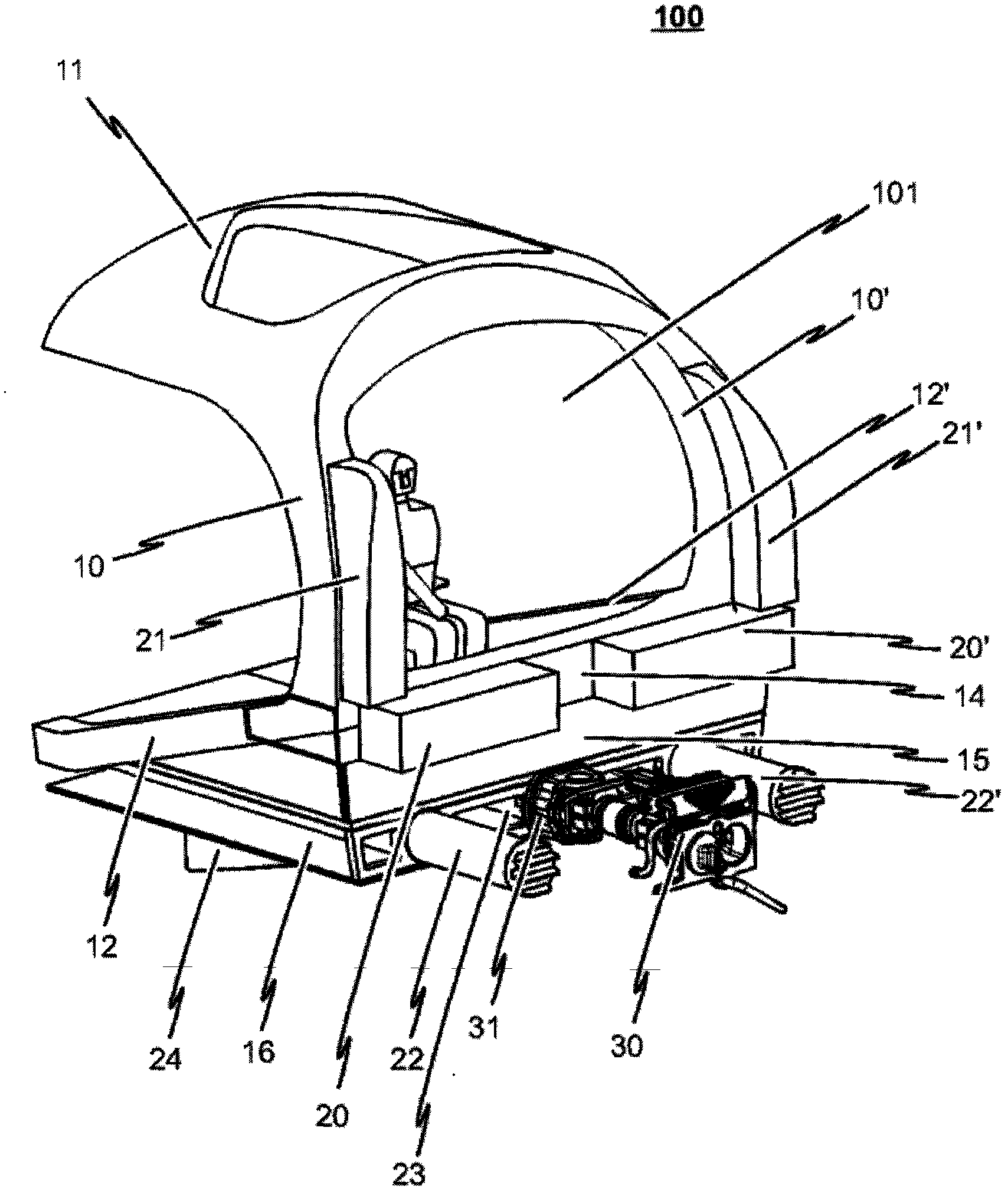

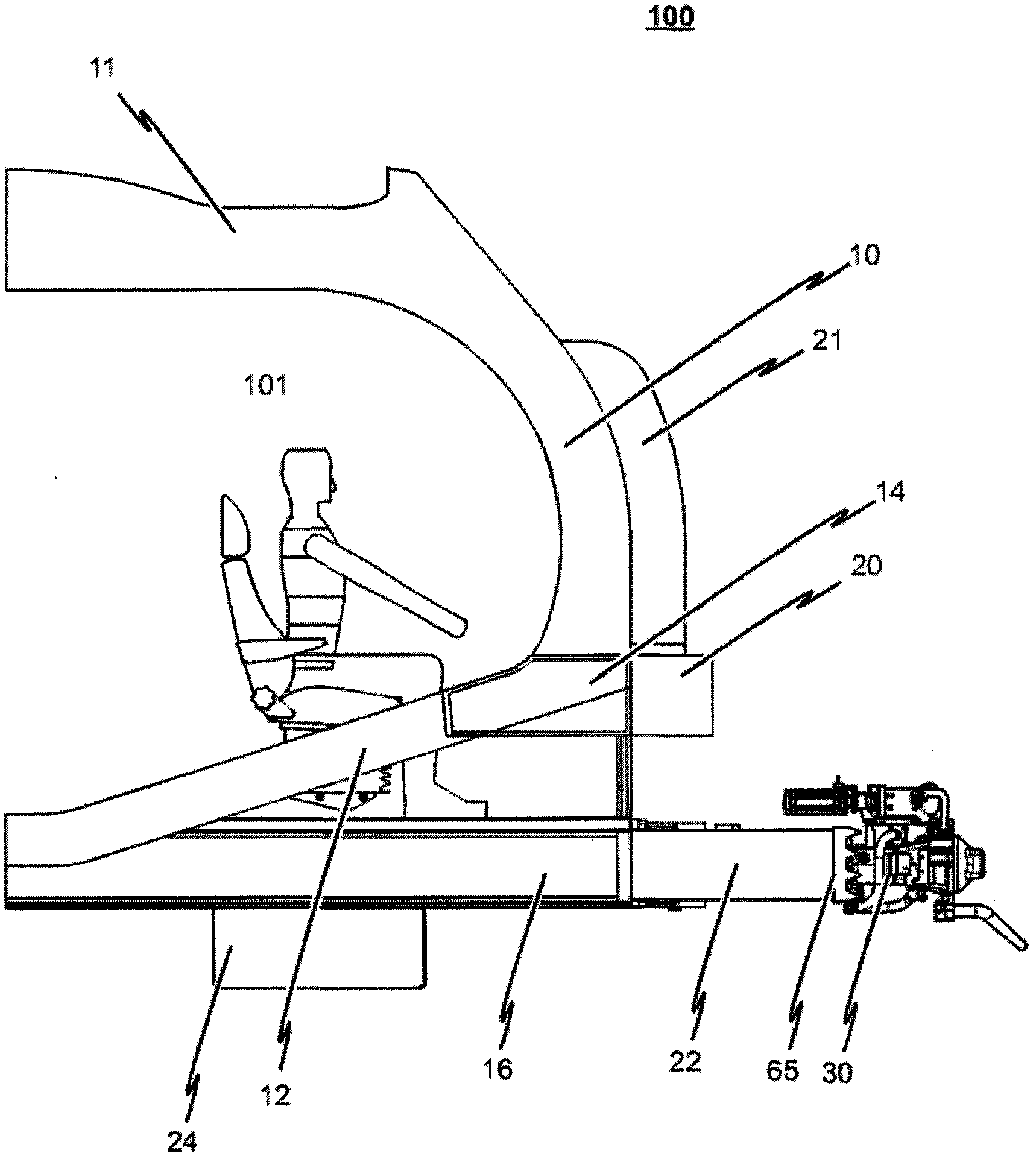

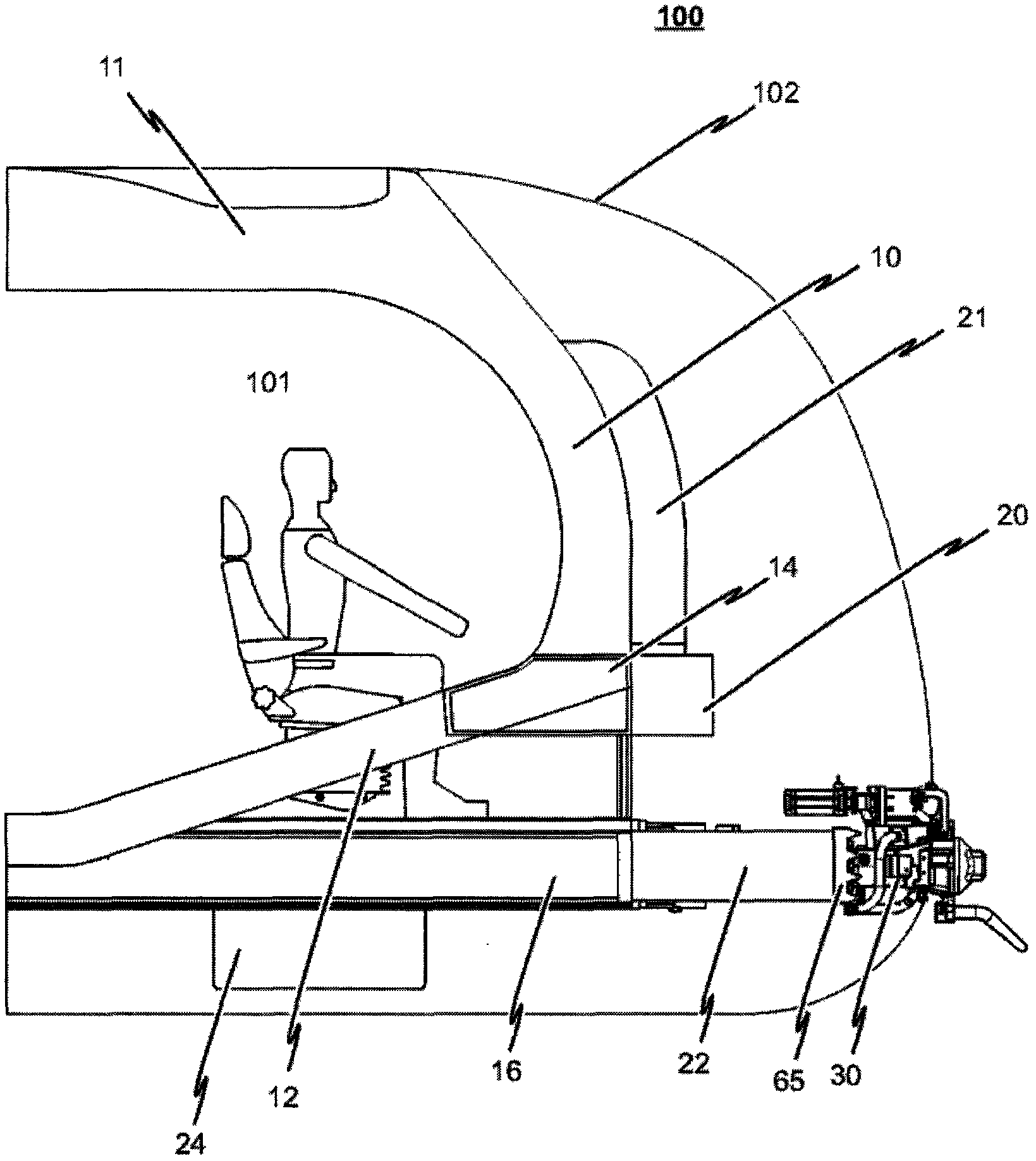

ActiveCN102216141APrevent crashHigh hardnessBuffer carsRailway wheel guards/bumpersVehicle drivingCockpit

The invention relates to a vehicle front-end with a vehicle front-end structure (100) for mounting to the front face of a track-bound vehicle, in particular a rail vehicle, wherein the vehicle front-end structure (100) is completely made of structural elements of fibre composite material or sandwich structures of fibre composite material. The structural elements forming the vehicle front-end structure (100) comprise first structural elements (10, 10', 11, 12, 12', 14, 15, 16) which are directly connected to each other and configured in such a manner that a deformation-resistant, self-supporting head structure is formed for receiving a vehicle driver's stand (101). The structural elements forming the vehicle front-end structure (100) further comprise second structural elements (20, 20', 21, 21', 22, 22', 23, 24, 24') which are connected to the first structural elements (10, 10', 11, 12, 12', 14, 15, 16) and are configured in such a manner that at least a part of the impact energy (collision energy), which is generated in the event of a collision of the track-bound vehicle due to a transmission of impact forces and is introduced into the structure (100), is absorbed by at least a partial irreversible deformation or at least a partial destruction of the second structural elements (20, 20', 21, 21', 22, 22', 23, 24, 24').

Owner:VOITH PATENT GMBH

Shock absorber for the front or rear region of a railborne vehicle having at least one energy absorption device

InactiveUS7810437B2Increase impactHinder pivoting motionBuffer carsRailway wheel guards/bumpersEnergy absorptionEngineering

The invention relates to an energy absorption device as part of a shock absorber for the front or rear region of a railborne vehicle, in particular a streetcar vehicle, wherein the energy absorption device is designed to absorb or dissipate at least a portion of the impact energy which occurs when the vehicle impacts an obstacle. The invention includes a bumper bar which is pivotably connected to the vehicle underframe by a first bearing, a pendulum support connected to the bumper bar by a second bearing and to the vehicle underframe by a third bearing such that the bumper bar and pendulum support form a tripod. The resultant moment of force of the bumper bar pivoting about a pivot axis defined by a first bearing is introduced as linear force into the energy-absorbing mechanism and at least partly absorbed or dissipated there.

Owner:VOITH PATENT GMBH

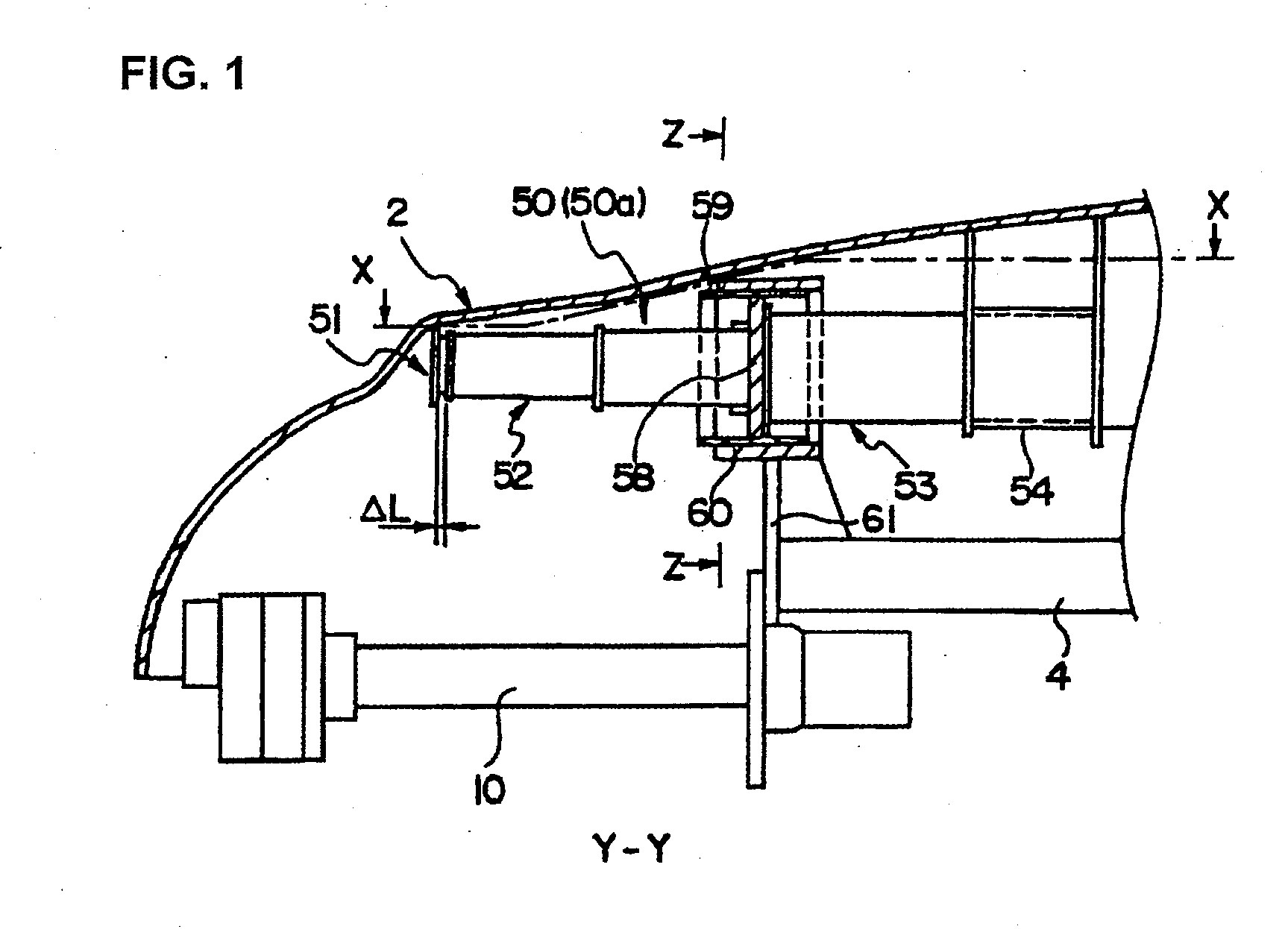

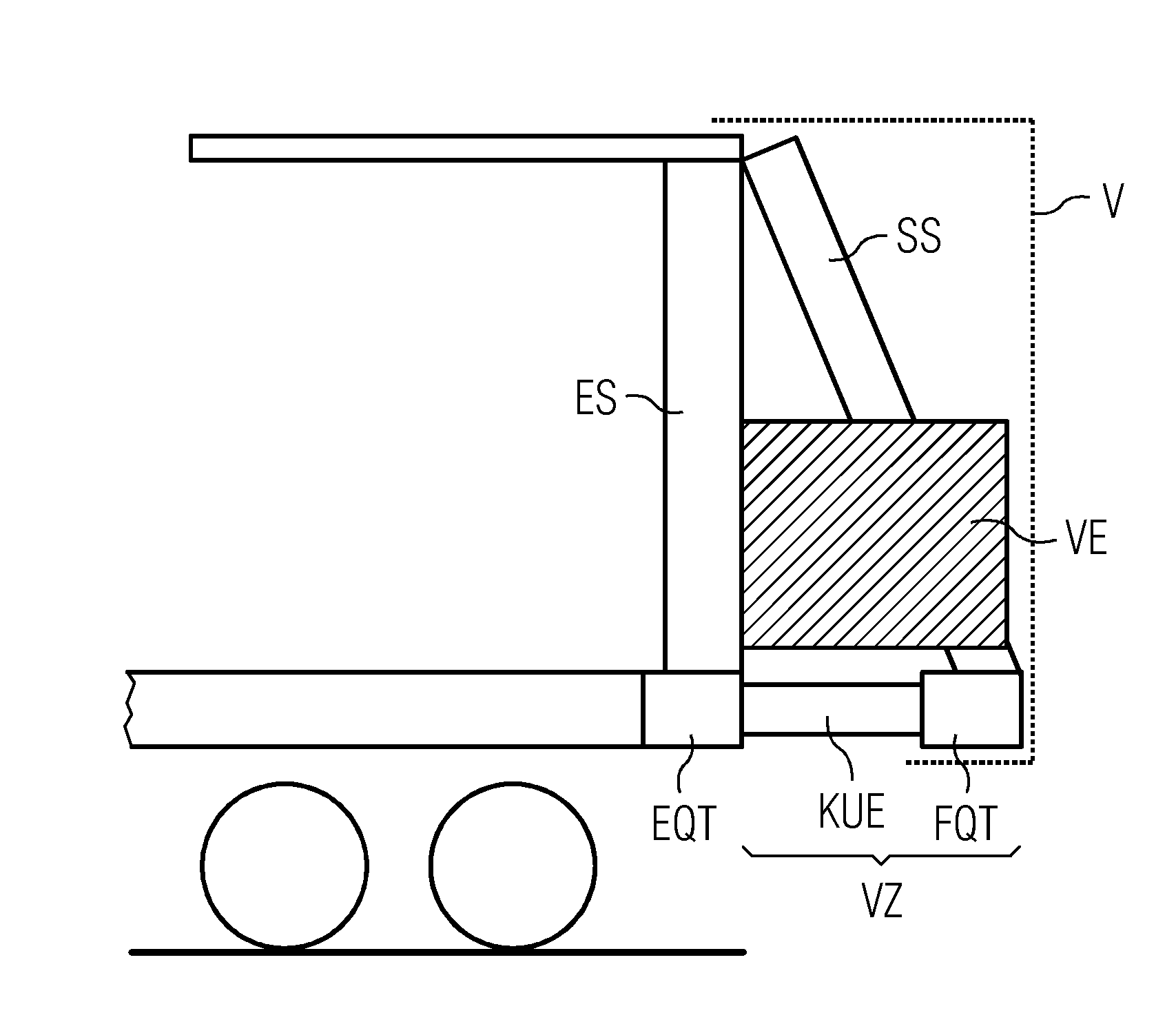

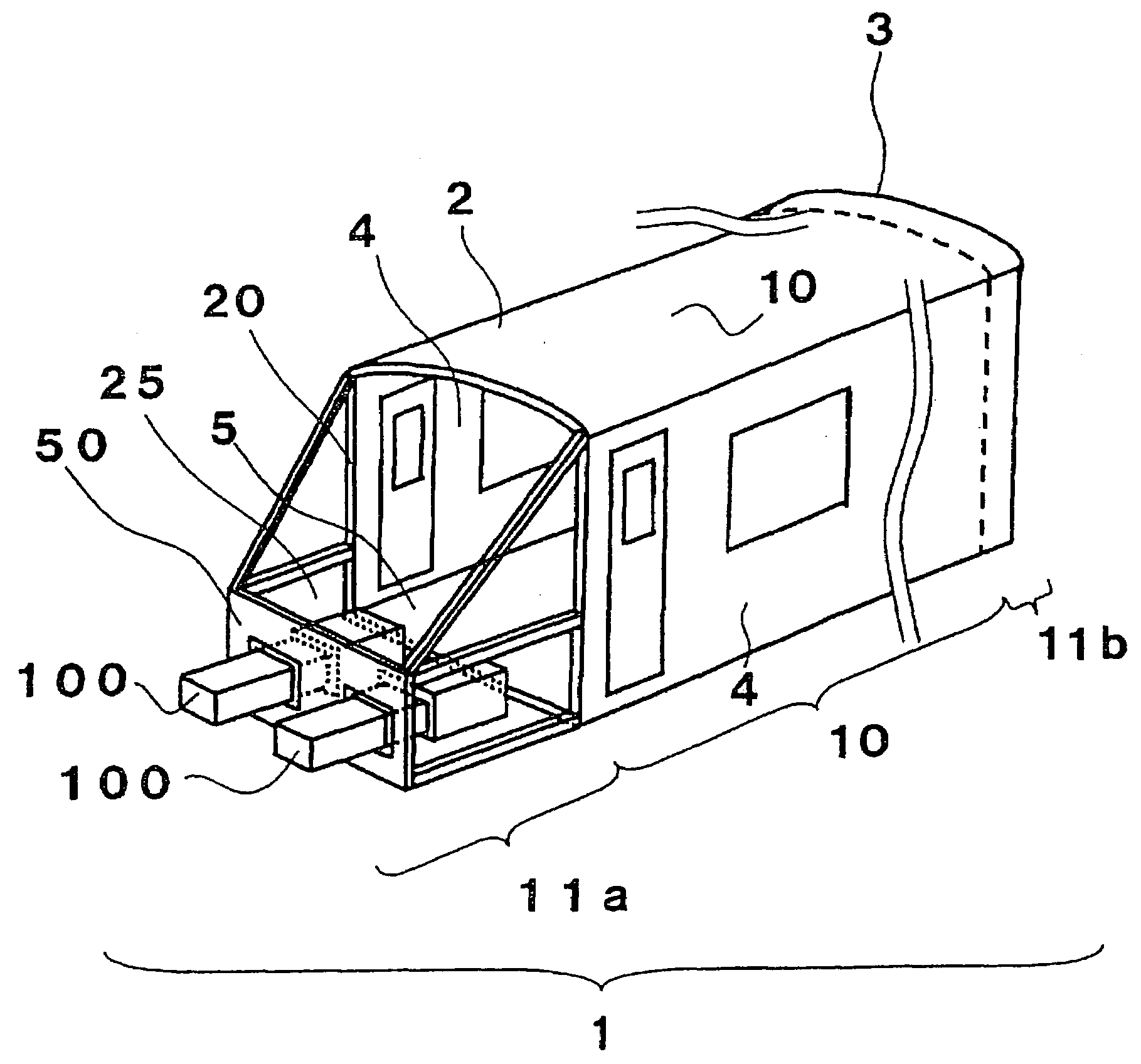

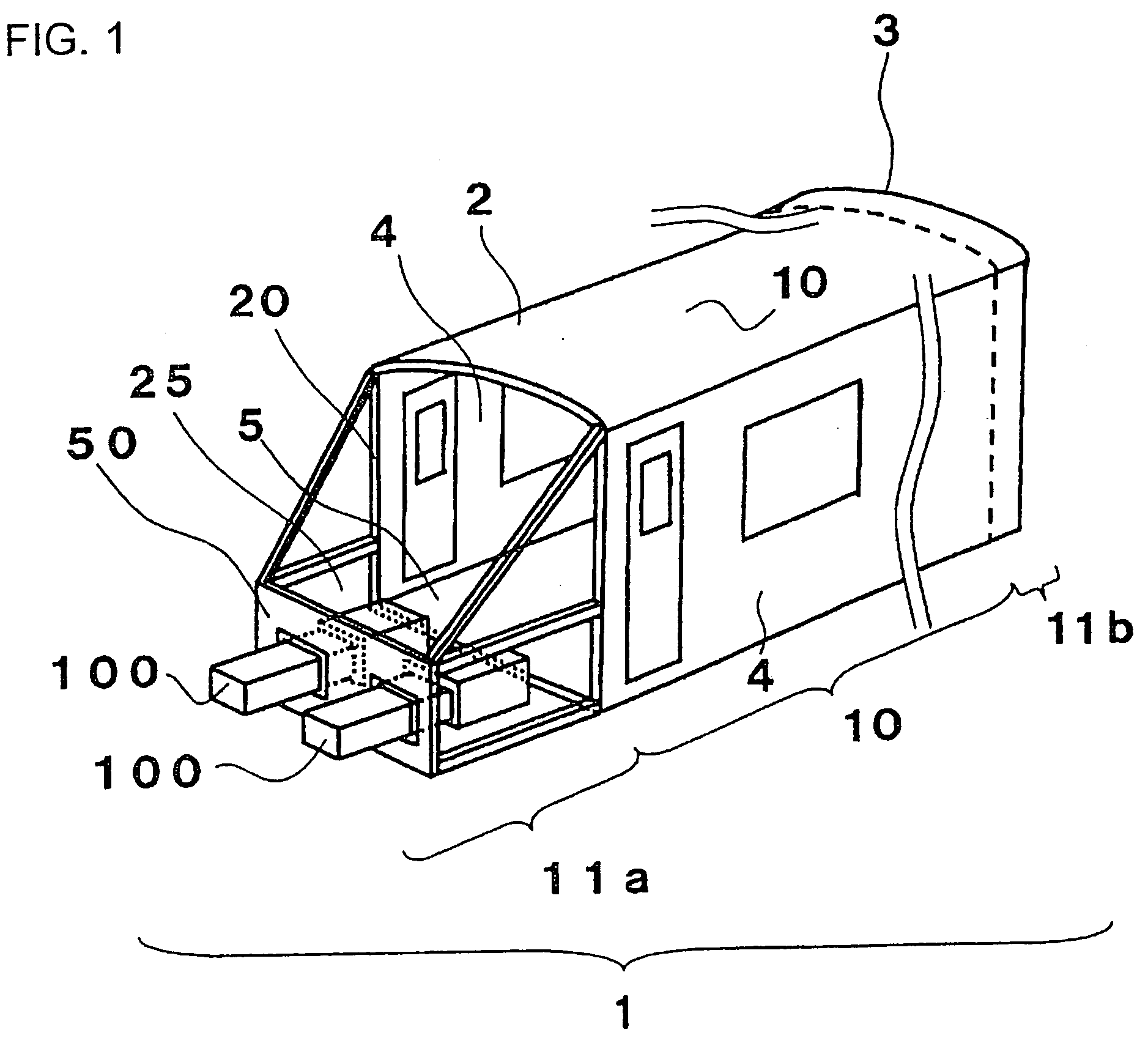

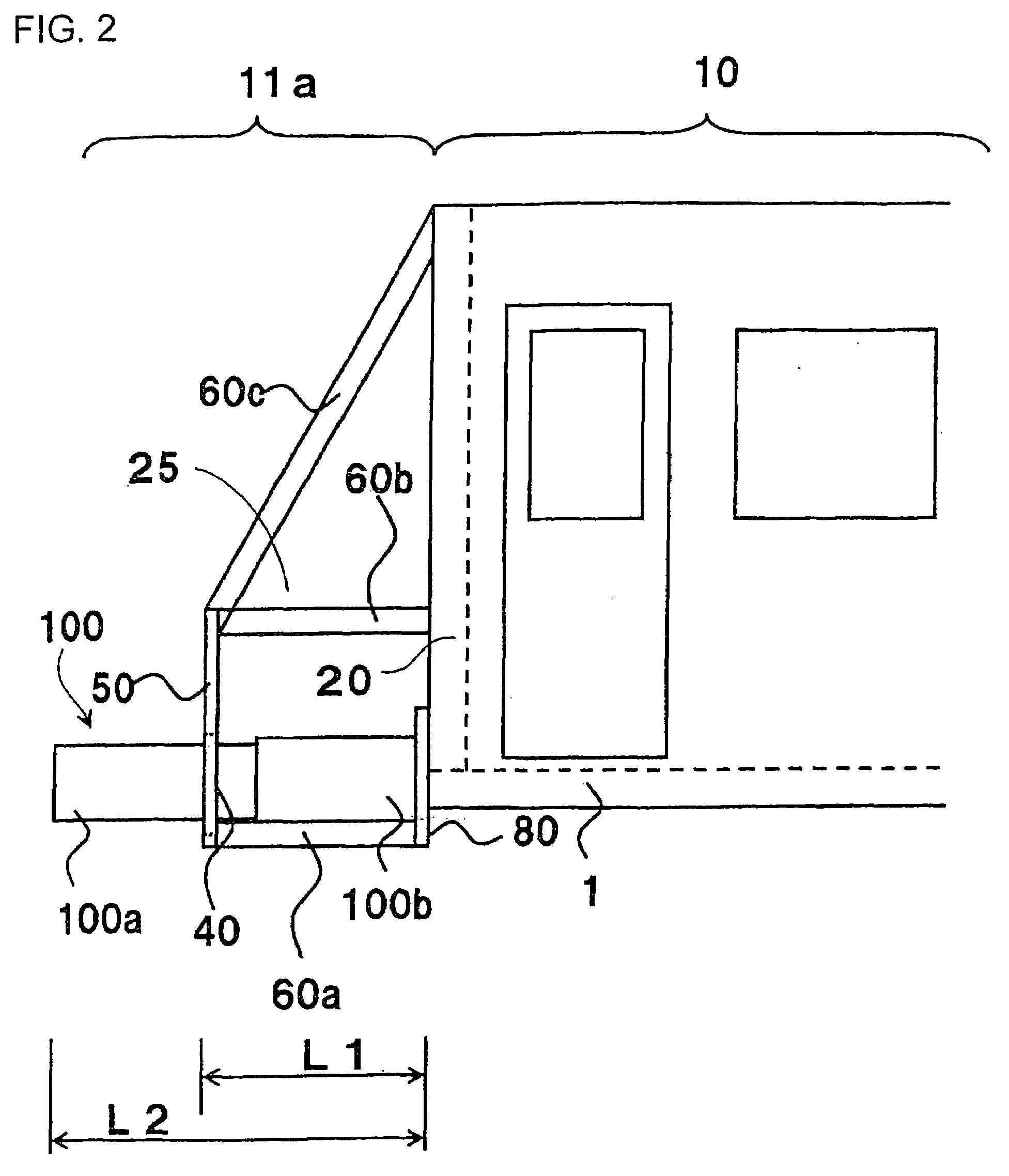

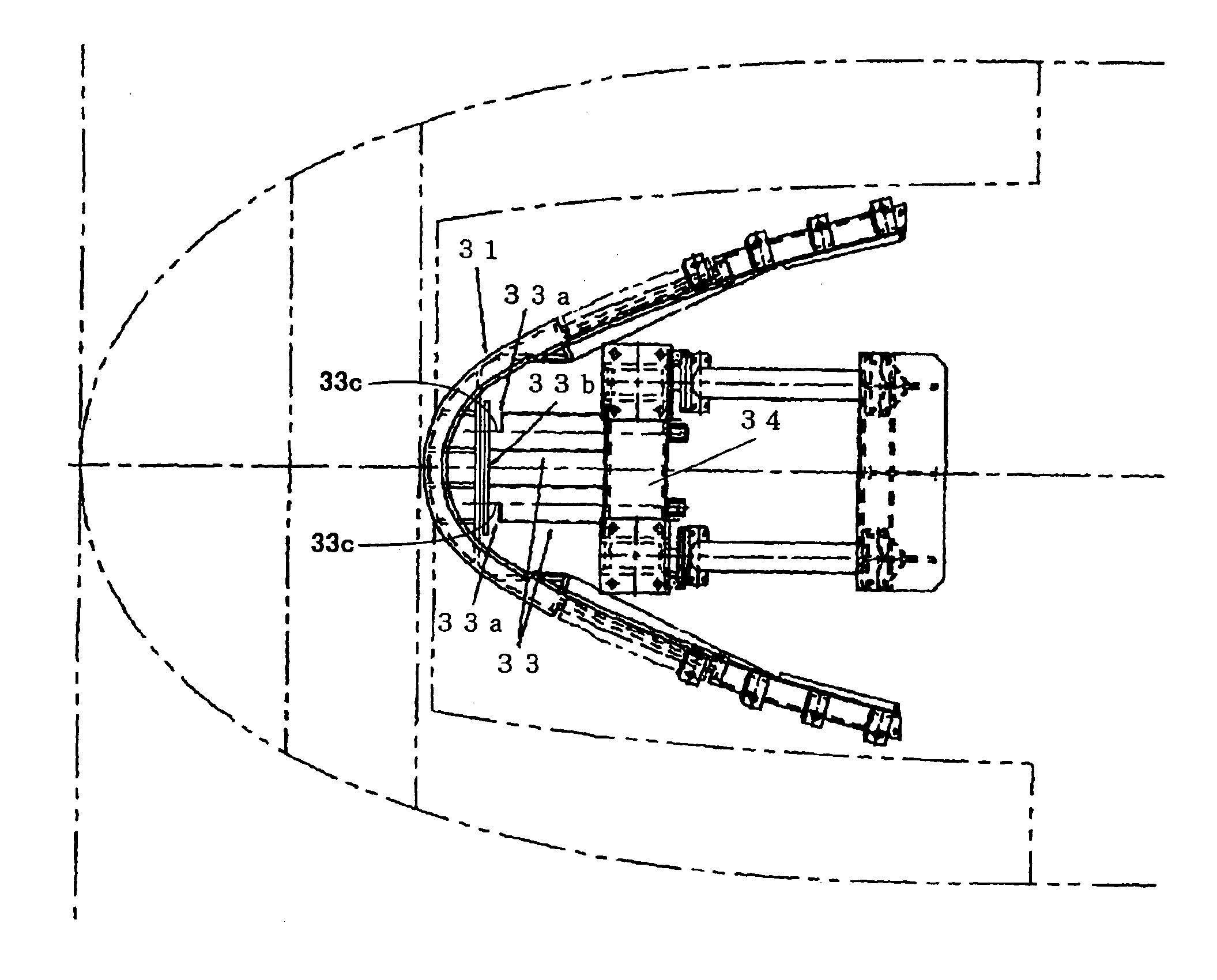

Transportation machine with energy absorbing structure

InactiveUS20070283843A1Efficient disposalTimely protectionBuffer carsRailway wheel guards/bumpersEnergy absorptionEngineering

For a transportation machine such as a railway vehicle, a space for a driver is secured while collision energy is absorbed at a time of collision with a large obstacle, and entry of a flying object into a driving cab is prevented by a rigid structure at a time of collision with the flying object. Windows 40, 40 are provided in a flying object barrier plate 50 provided at a tip end portion of a driving cab 25, and energy absorbing members 100, 100 are penetrated through the windows 40, 40 to be disposed in a form extending outward of the flying object barrier plate 50 from an inside of the driving cab 25. The energy absorbing members 100, 100 of a large absorbing capacity can be efficiently disposed by utilizing a space of the driving cab 25 provided in a vehicle body. A beam member of a crushable zone 11a including the flying object barrier plate 50 is firmly placed and can be connected to a survival zone 10.

Owner:HITACHI LTD

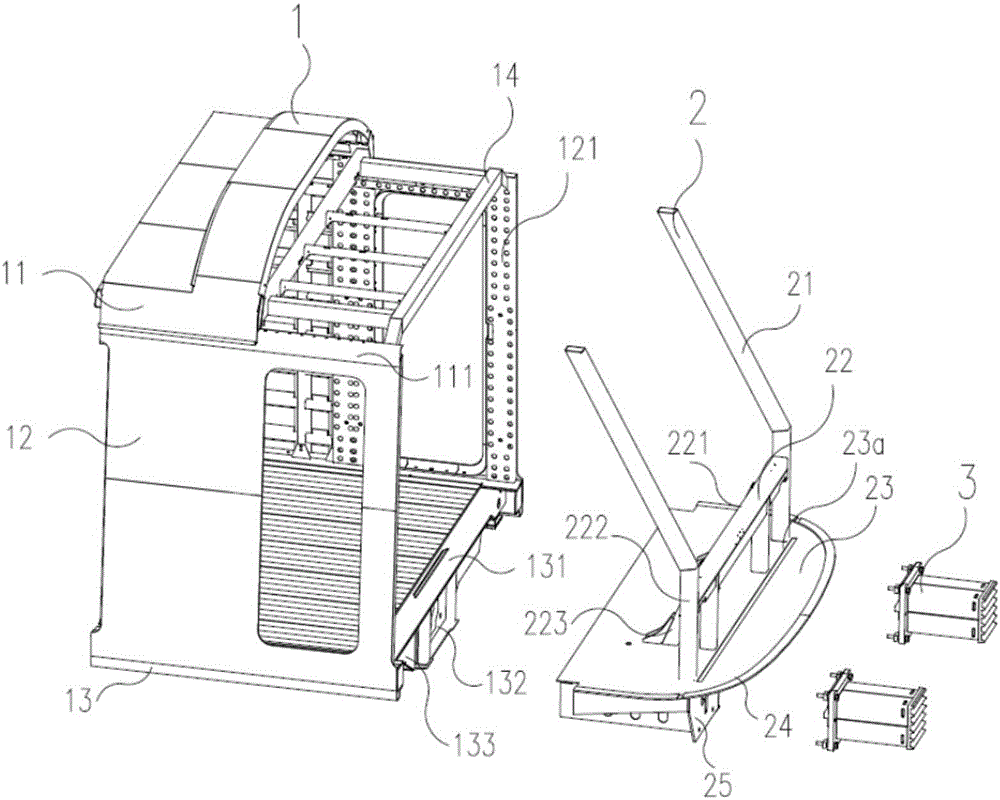

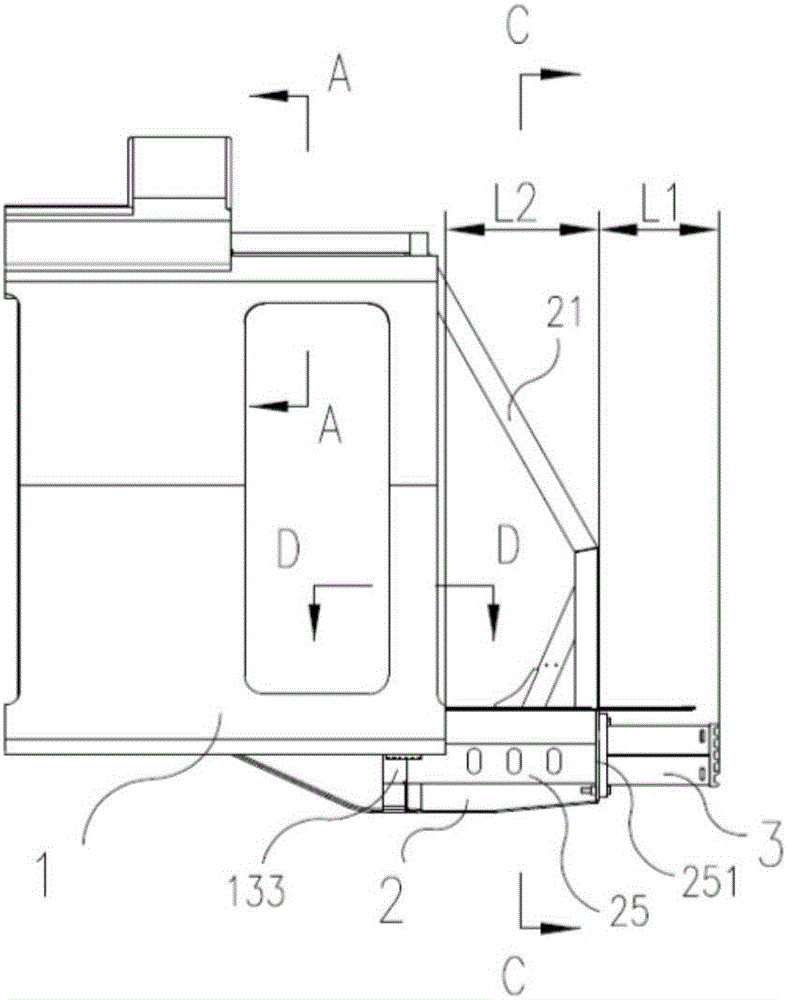

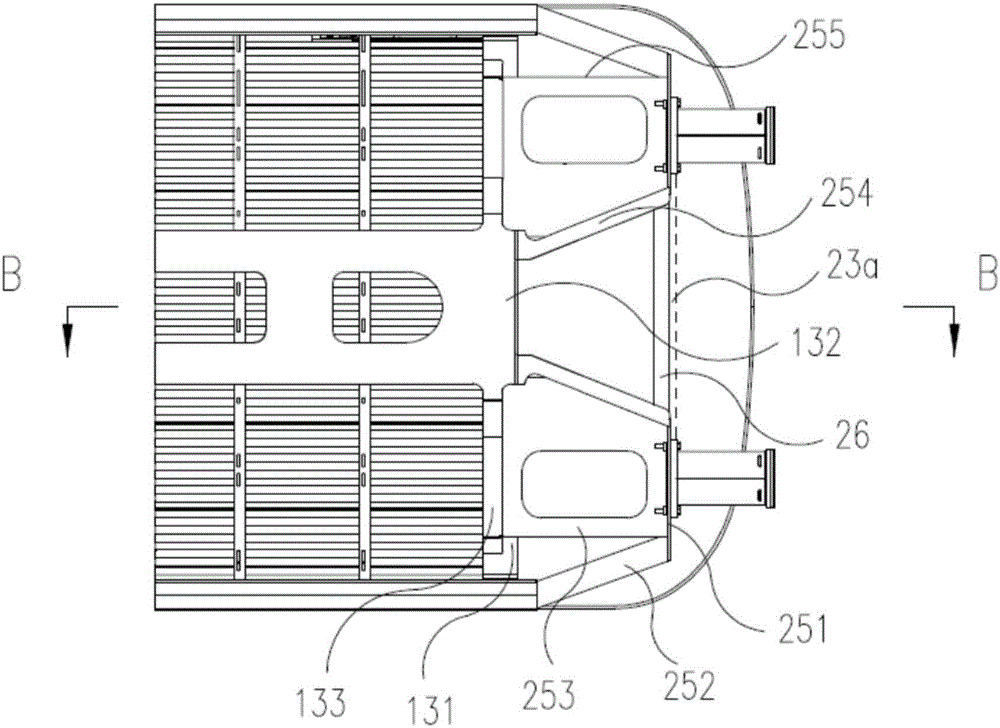

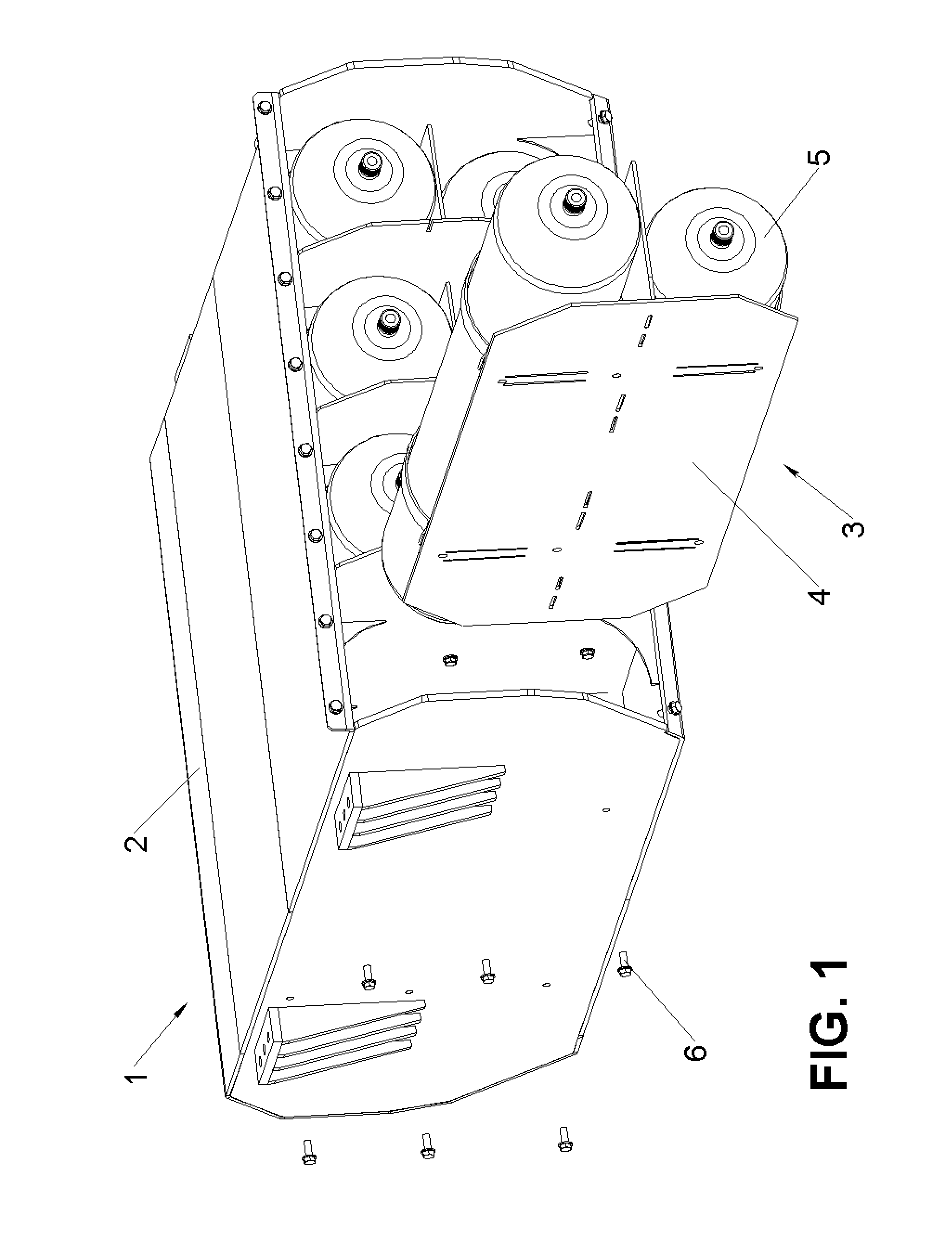

Locomotive natural gas storage and transfer system

ActiveUS20140261073A1Maximize storage capacitySpace minimizationInternal combustion piston enginesBuffer carsTransfer systemNatural gas storage

A locomotive underframe CNG fuel storage system including: a crashworthy enclosure including a removable side panel and a permanent side panel welded into place; and at least one CNG cylinder module, wherein each CNG cylinder module includes a plurality of CNG cylinders stacked vertically, secured to a vertical wall, and separated by a horizontal plate, wherein the horizontal plate extends towards but does not contact the vertical wall when the vertical wall is planar and, further wherein, the horizontal plate supports the vertical wall from moving further out of plane when vertical axial weight causes the vertical wall for move out of plane towards the horizontal plate.

Owner:RAIL GAS TECH

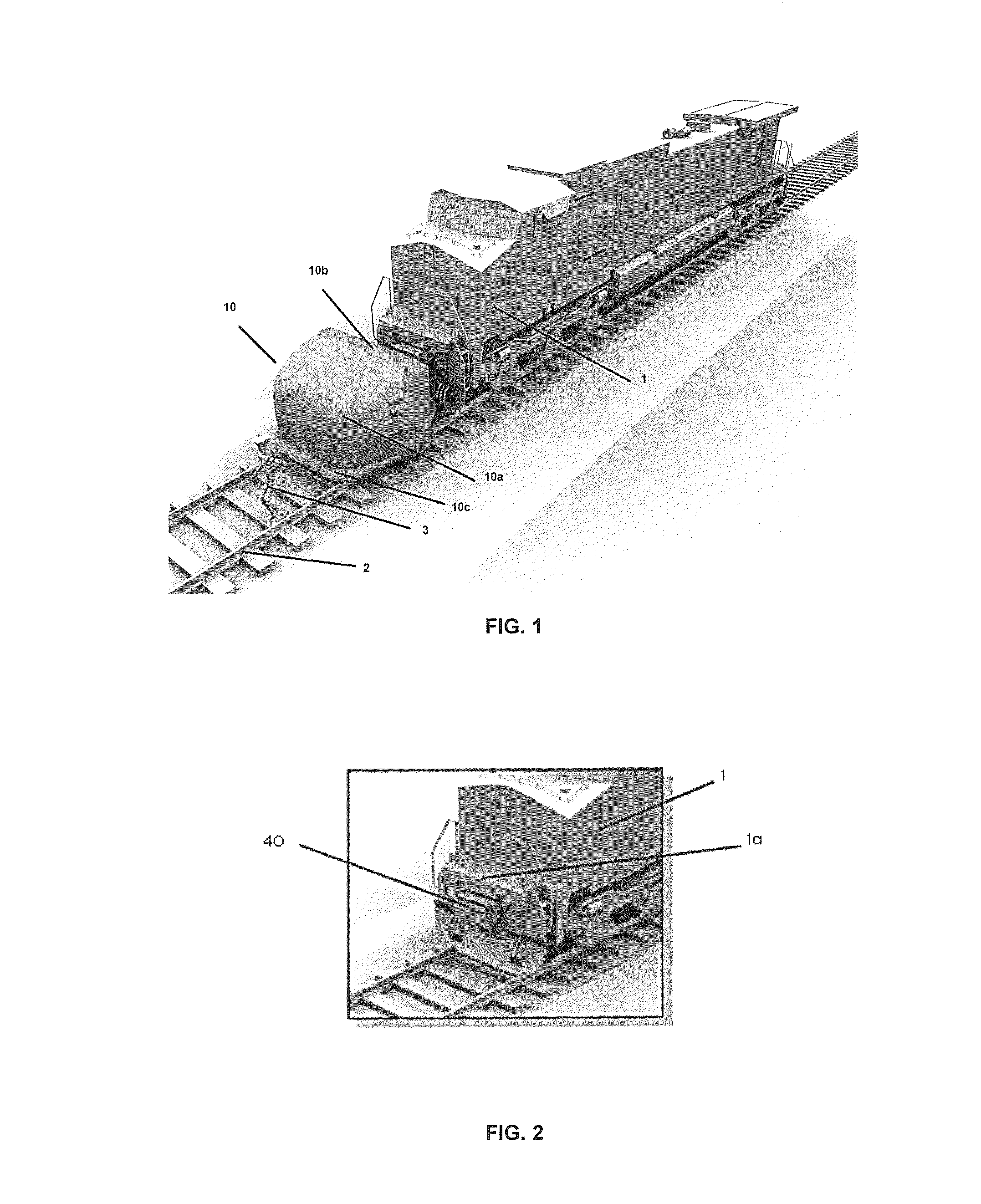

Safety device for railway vehicles

InactiveUS20140007790A1Reducing resulting collision and runningReduce impactBuffer carsPedestrian/occupant safety arrangementReliability engineeringVehicle safety

A safety device for railway vehicles is provided, more specifically a safety device that reduces the negative consequences resulting from collisions or pedestrian accidents involving railway vehicles. As such, the railway vehicle safety device consists of a main impact dampening area and at least one secondary support and resistance area, with the safety device being installed on the railway vehicle's front end, so that the main impact dampening area dampens the force of the impact caused by a collision between the vehicle and a pedestrian.

Owner:VALE LIMITED

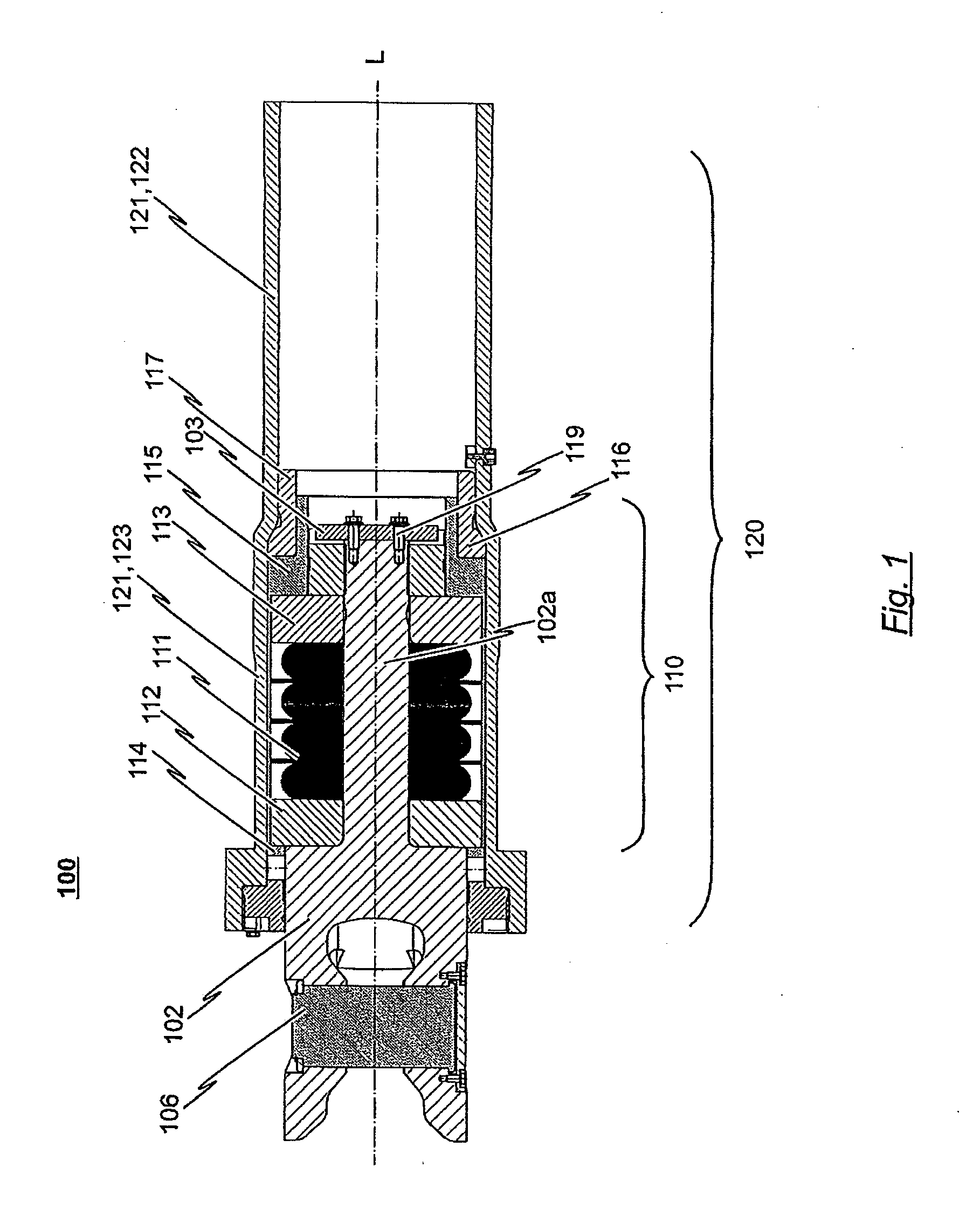

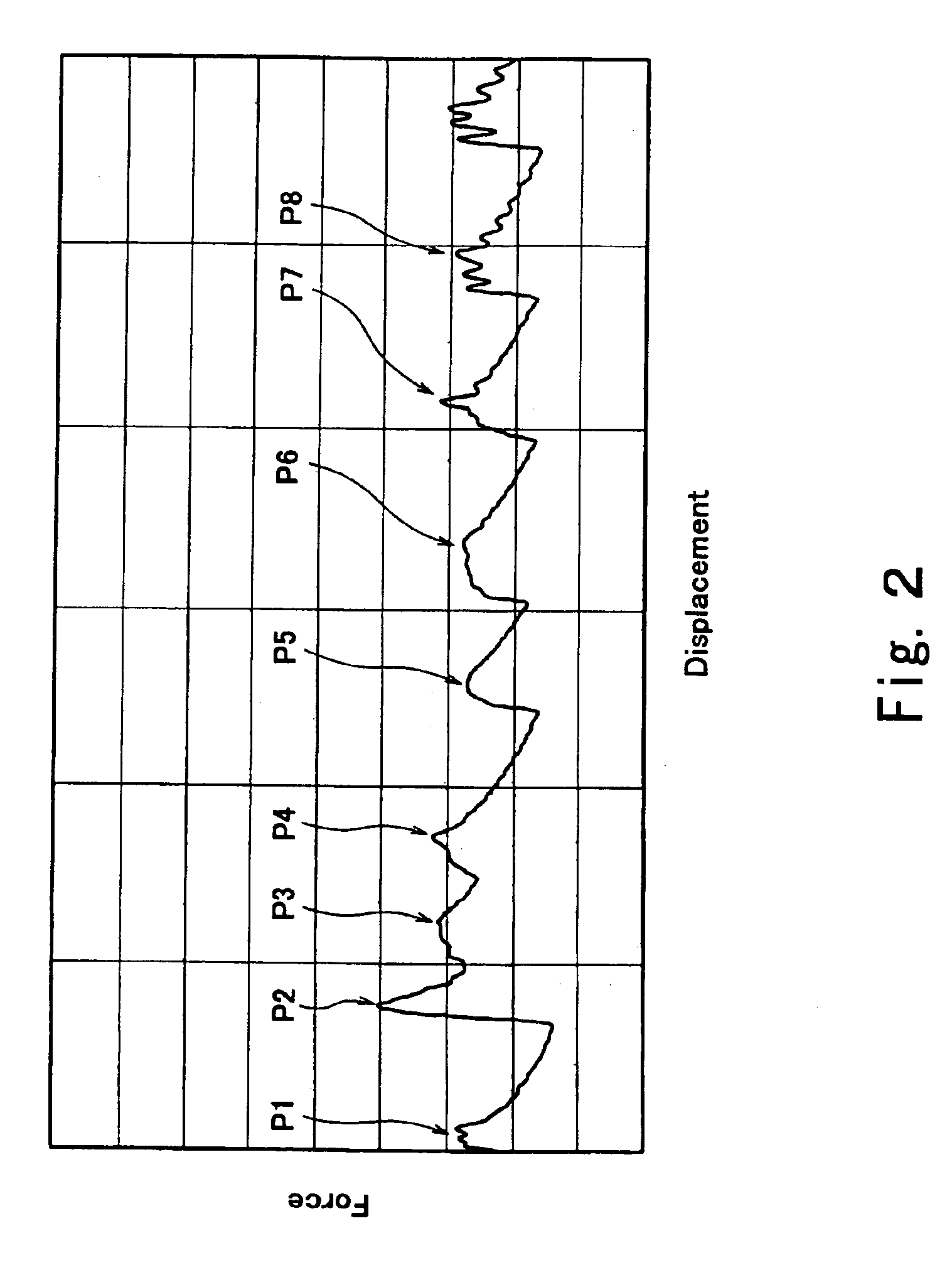

Crumple element comprising a guiding mechanism

ActiveCN101124113ADoes not reduce maximum compression distanceDoes not change the effective sizeBuffer carsBufferEngineeringMechanical engineering

Disclosed is a crumple element for a vehicle, particularly a railway vehicle, comprising a profiled part (CR) that is located between two end plates (AC, AP), has the shape of a tubular case, is provided especially with a polygonal cross section, and is used for dissipating impact energy in case of longitudinal compression caused by plastic deformation. Said crumple element further comprises a guiding element which is disposed parallel to the longitudinal direction of the profiled part (CR) and is connected in a fixed manner to the end plate (AC) facing away from the vehicle. The end plate (AP) that faces the vehicle is provided with a hole (DL) which is shaped such that the guiding element (FH) is able to longitudinally slide therethrough in a contactless manner and can be laterally inclined counter to the longitudinal direction.

Owner:SIEMENS MOBILITY AUSTRIA GMBH

Collision energy absorbing structure of vehicle

InactiveUS6951176B2Low costEasy to manufactureBuffer carsPedestrian/occupant safety arrangementEnergy absorptionMechanical engineering

Owner:KAWASAKI HEAVY IND LTD

Collision attenuating system

InactiveUS6845874B2Reduce severityBuffer carsPedestrian/occupant safety arrangementMobile vehicleEnergy absorption

A collision attenuator for a vehicle including an energy absorbing cylinder, a mounting assembly adapted to secure the energy absorbing cylinder to an end of the vehicle, a contact plate mounted to the energy absorbing cylinder, a control valve for extending and retracting the energy absorbing cylinder in order to move the contact plate with respect to the end of the vehicle. A comparator is operably coupled with the control valve, wherein the comparator is configured to adjust the energy absorbing cylinder based upon a speed signal indicative of the speed of the moving vehicle. A coupler detector is operably coupled with the control valve, wherein the coupler detector inhibits the extension of the energy absorbing cylinder unless the coupler detector determines that the coupler is open. A pivot assembly pivotally secures the contact plate to the energy absorbing cylinder allowing the contact plate to pivot laterally about an upright axis with respect to the energy absorbing cylinder. A quick-release mechanism detachably secures the energy absorbing assembly to the end of the vehicle. A vehicle support portion extends horizontally forward adjacent a bottom edge of the contact plate.

Owner:PAYNE THOMAS S +1

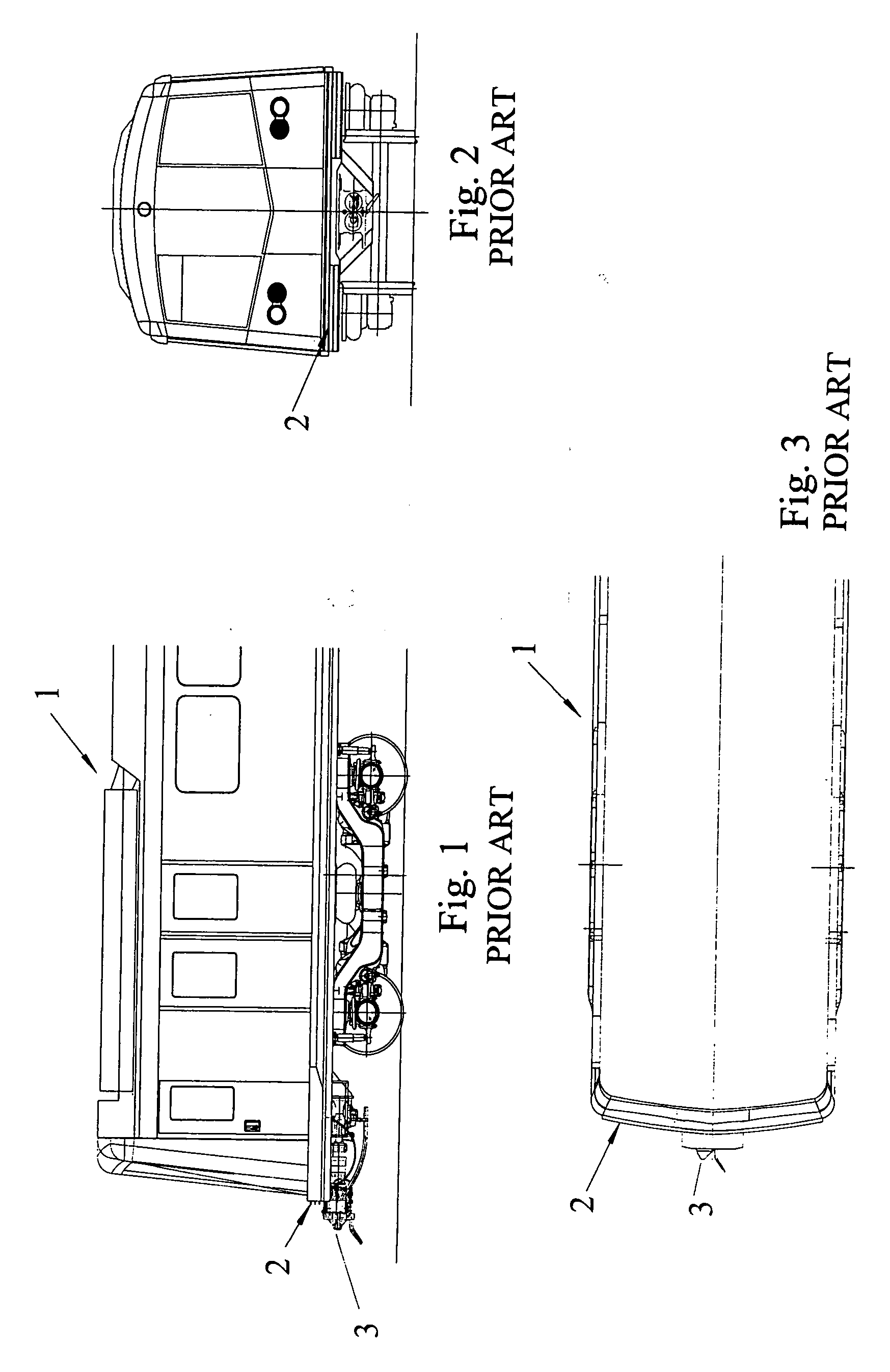

Rail vehicle having a driver's cab provided with an energy-absorbing structure adapted to cope with a collision above the frame of the vehicle

InactiveUS20020073887A1Simple and inexpensive to implementMitigate such drawbackBuffer carsRailway wheel guards/bumpersEnergy absorptionRigid structure

A rail vehicle having an end provided with a driver's cab, said vehicle having a rigid frame extending under said driver's cab, said rail vehicle having a protective shield disposed in front of said driver's cab and provided with a rigid structure, said protective shield resting on said frame and being connected to said frame via at least one energy-absorbing element interposed locally between the shield and the frame.

Owner:ALSTOM TRANSPORT TECH SAS

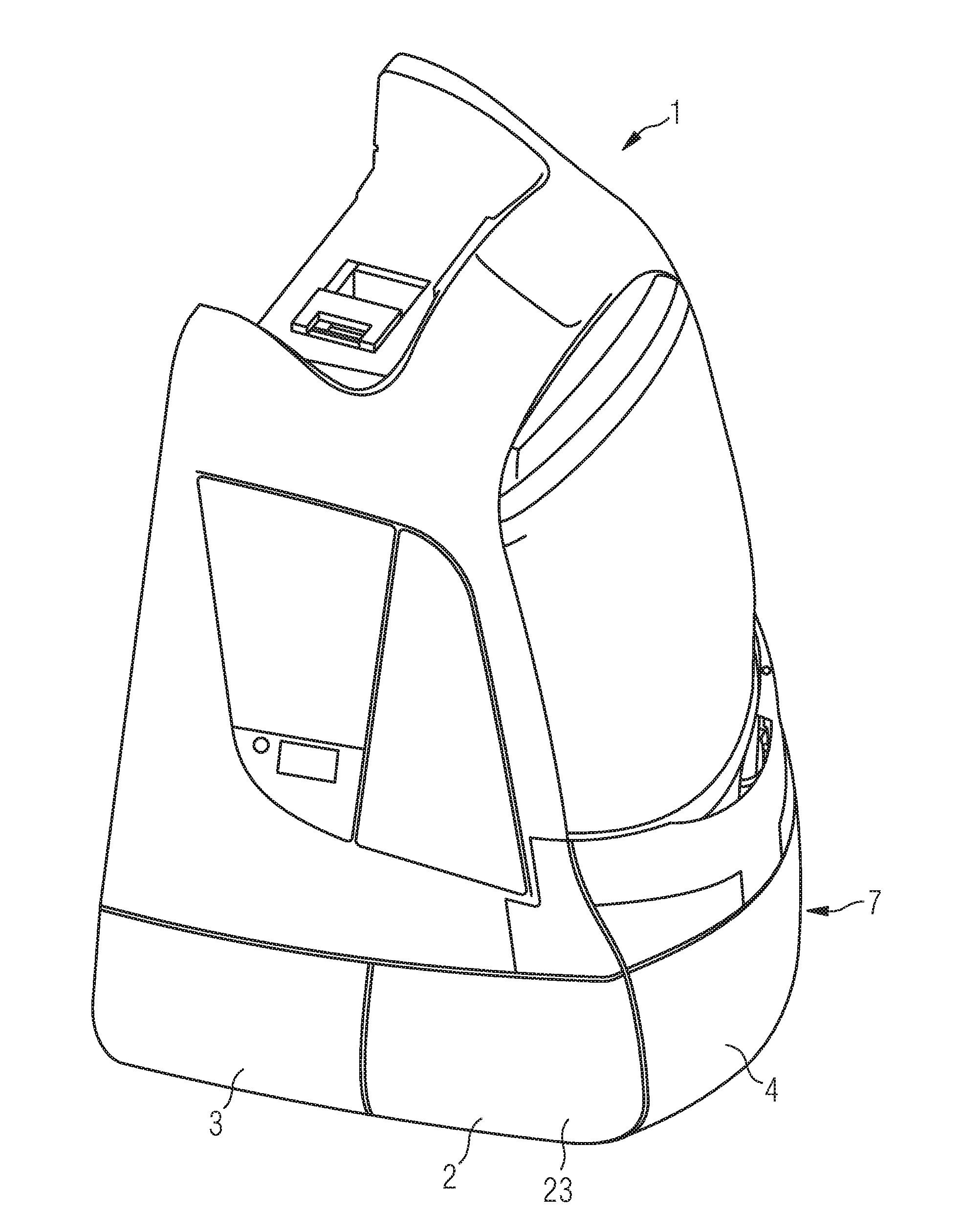

Crash-resistant front apron for a rail vehicle

A crash-resistant front apron for a rail vehicle is provided. The front apron includes an apron cover, a first support part supporting the apron cover, a second support part attached to a frame of the rail vehicle and a friction coupling release mechanism which connects the first support part to the second support part by a friction connection. In the event of a crash of the rail vehicle, in which a collision force acts on the front apron cover causing a torsion of the first support part relative to the second support part, the friction coupling release mechanism releases the friction connection.

Owner:SIEMENS MOBILITY AUSTRIA GMBH

Shock absorber

InactiveUS7735427B2Protection from damageBuffer carsClimate change adaptationEnergy absorptionIrreversible shock

The invention relates to a shock absorber (100), in particular for use as an additional irreversible shock-absorbing stage together with a component for transferring force. In order to achieve the reliable dissipating of high impact energies, a shock absorber (100) comprising the following is indicated in accordance with the invention: a base plate (1); a force-transferring element (3) having a tensioning element (4); an energy-absorbing element in the form of a deformation tube (5) which is connected by a first end section to the base plate (1); and a connecting element (6) for the disengageable connecting of the force-transferring element (3) to a second end section of the deformation tube (5), wherein the connecting element (6) is pressed against the tensioning element (4) such that the deformation tube (5) is braced between the tensioning element (4) and the base plate (1) without play.

Owner:VOITH PATENT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com