Flexible circuit board and manufacturing method thereof

A technology of flexible circuit boards and manufacturing methods, which is applied in the direction of printed circuit manufacturing, printed circuits, printed circuit components, etc., can solve problems such as yield reduction, hole shape deformation, etc., to improve efficiency, prevent hole shape deformation, and excellent quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

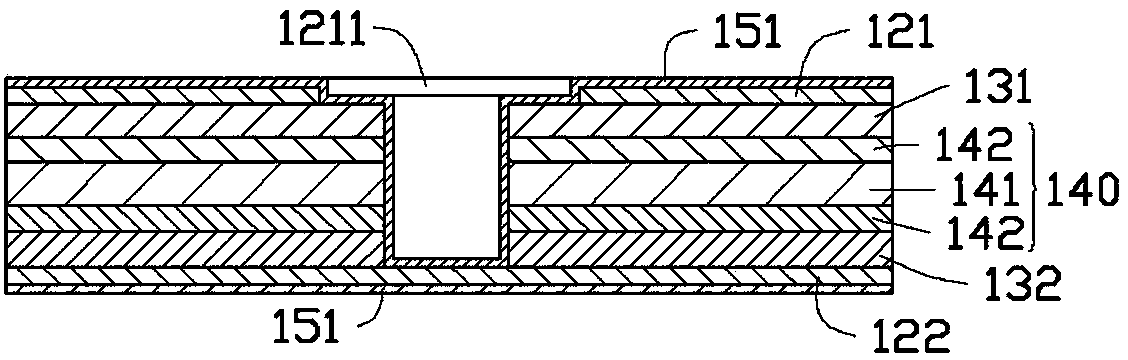

[0016] see Figure 1 to Figure 6 , an embodiment of the present invention provides a method for manufacturing a flexible circuit board, comprising the following steps:

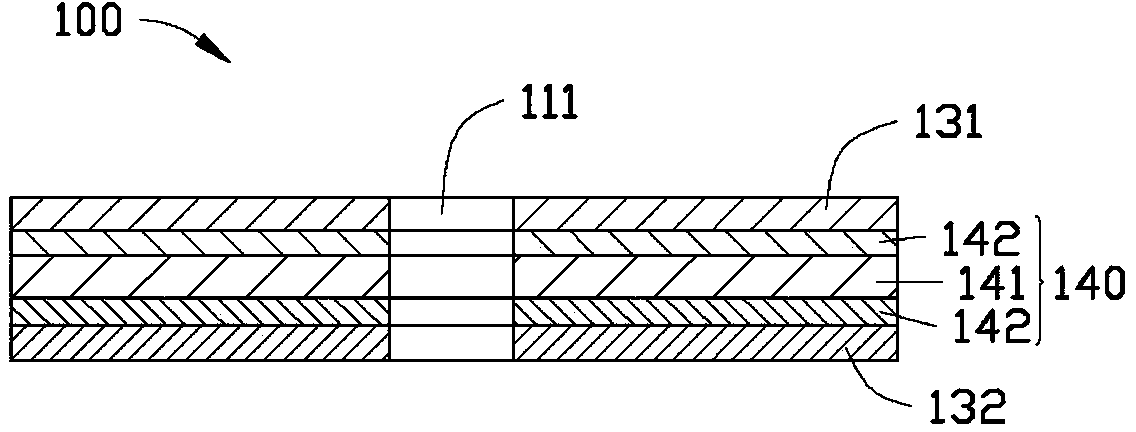

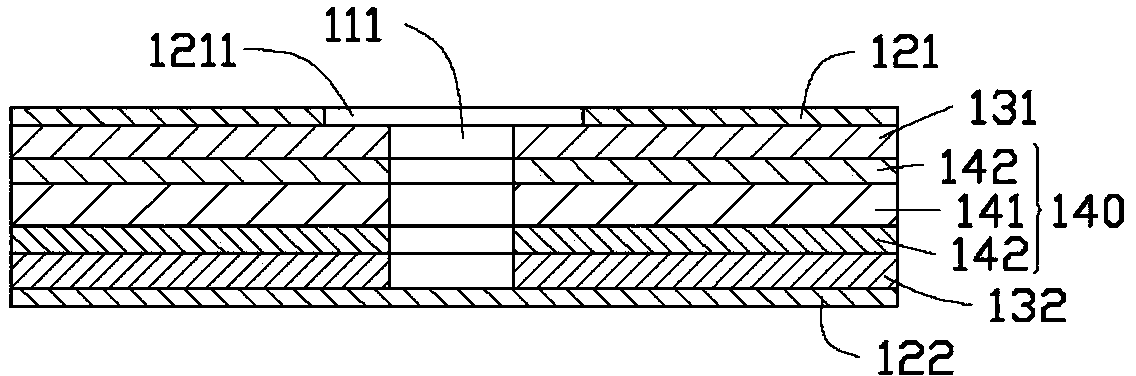

[0017] Step 1: See figure 1 , providing a flexible double-sided copper-clad substrate 100 , using a mechanical drilling method to make through holes 111 in the flexible double-sided copper-clad substrate 100 .

[0018] The flexible double-sided copper-clad substrate 100 includes an insulating base layer 140 and a first copper foil layer 131 and a second copper foil layer 132 disposed on opposite sides of the insulating base layer 140 . The insulating base layer 140 includes a polyimide layer 141 and a Teflon layer 142 arranged on opposite sides of the polyimide layer 141. In this embodiment, the Teflon layer 142 has a thickness of 6.25 microns, and The thickness of the imide layer 141 is 12.5 microns, and the ratio of the thickness of each Teflon layer to the polyimide layer is 1:2. The first copper foil la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com