Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about "Piercing presses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

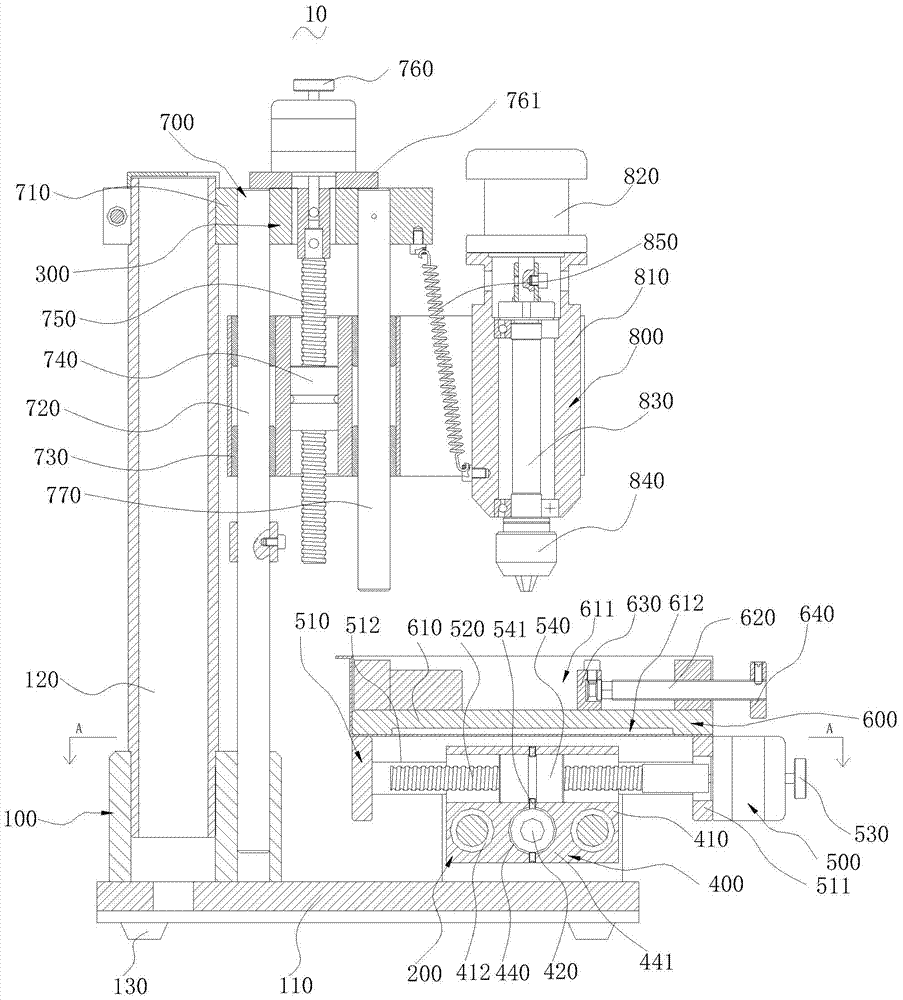

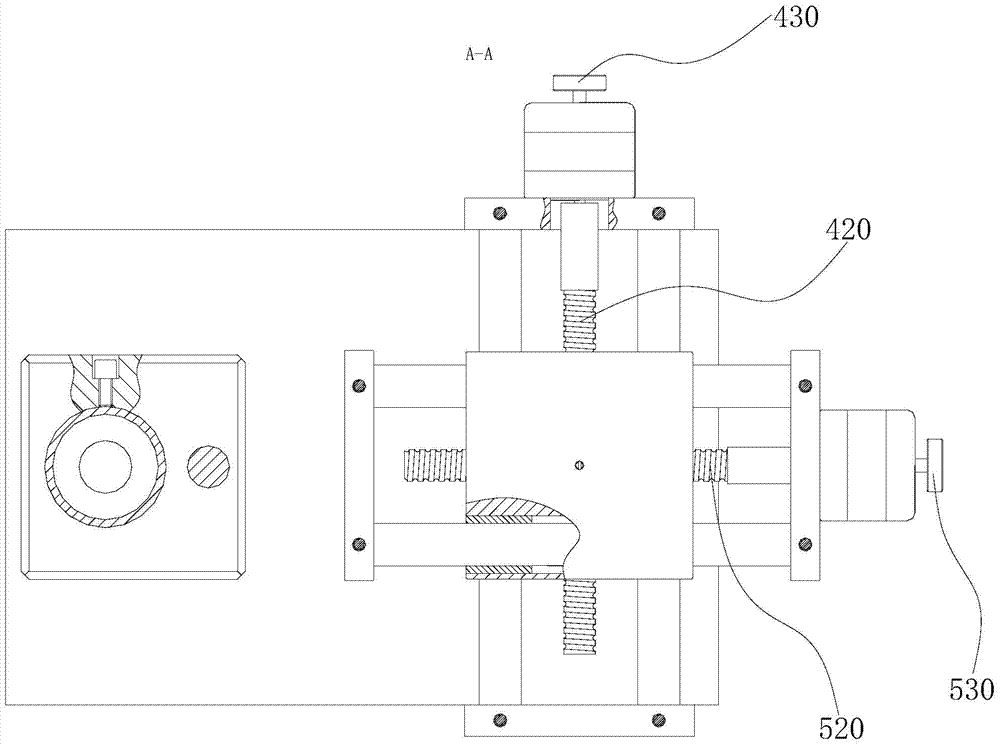

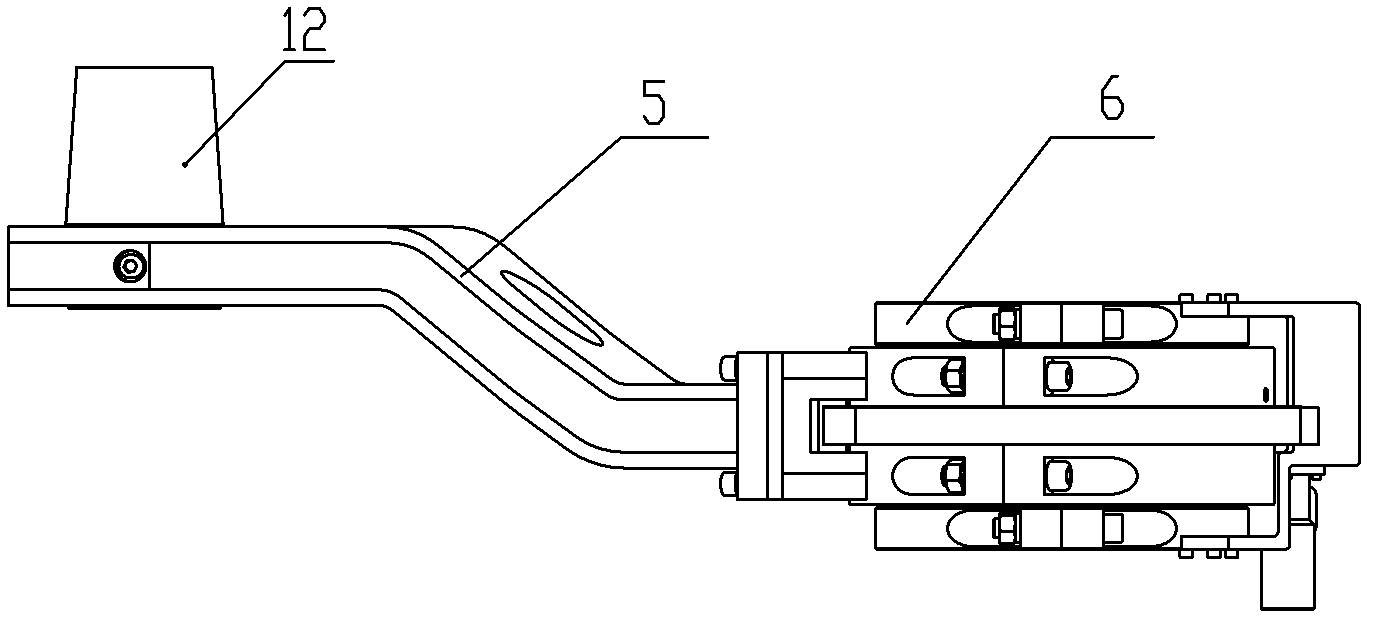

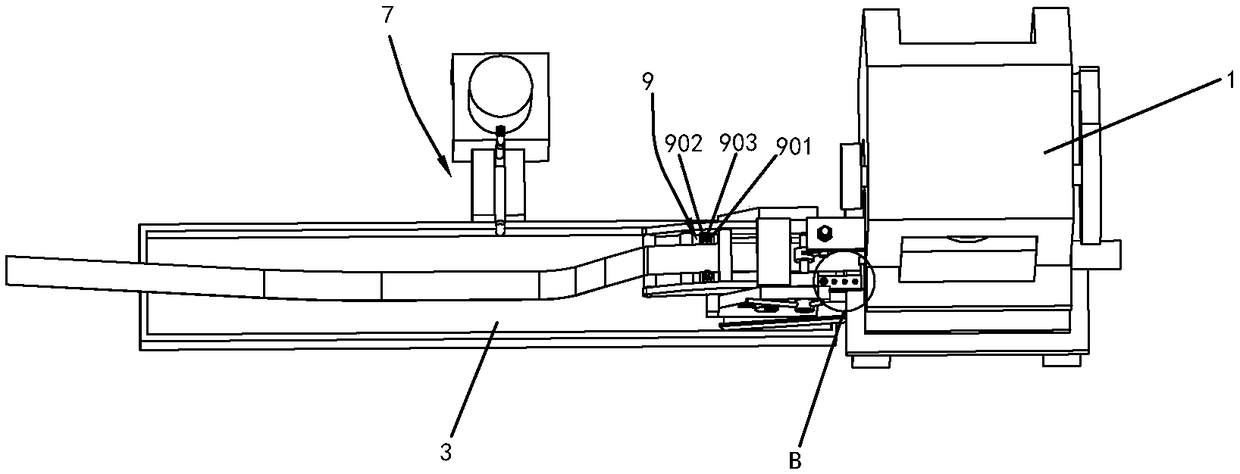

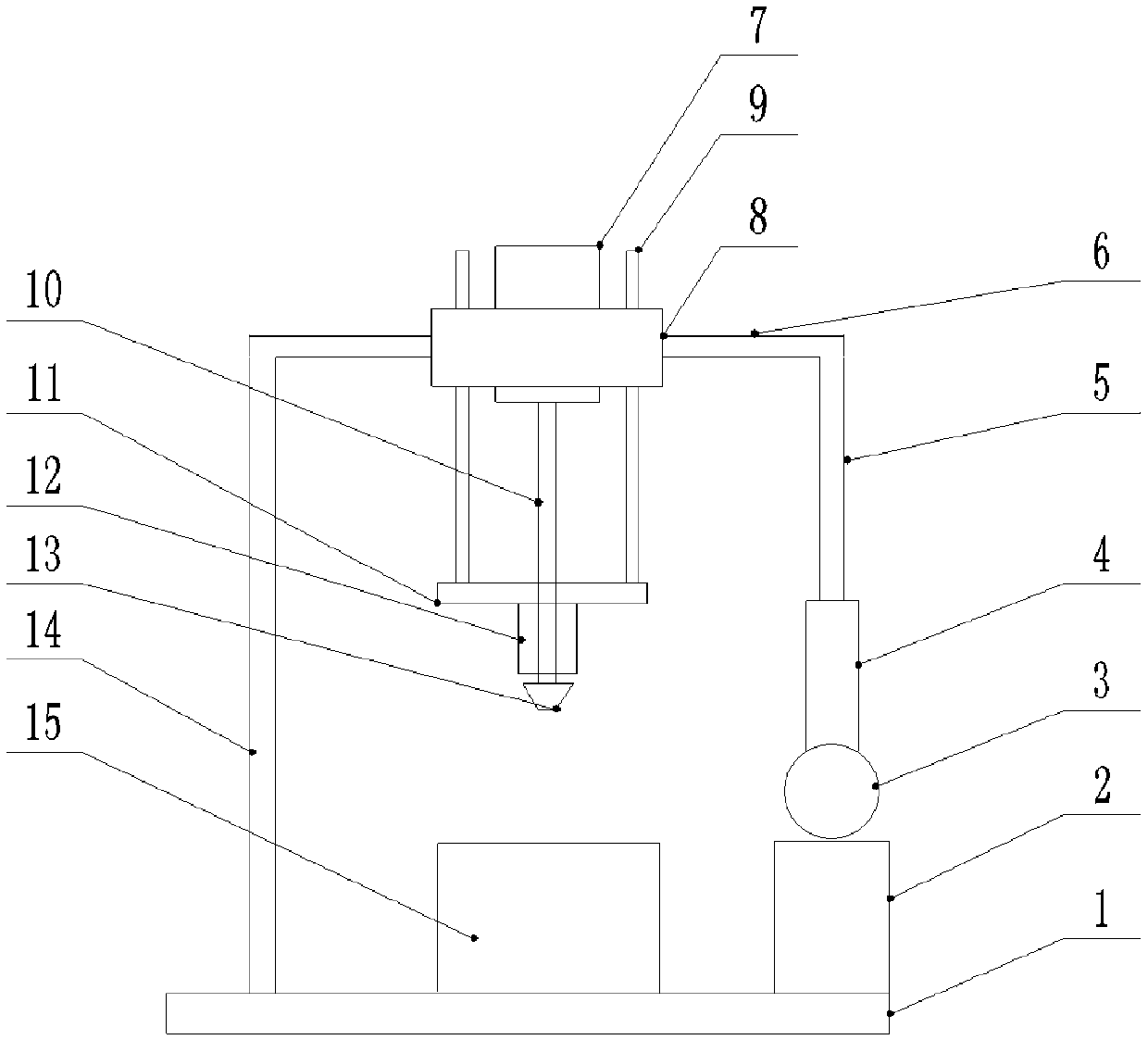

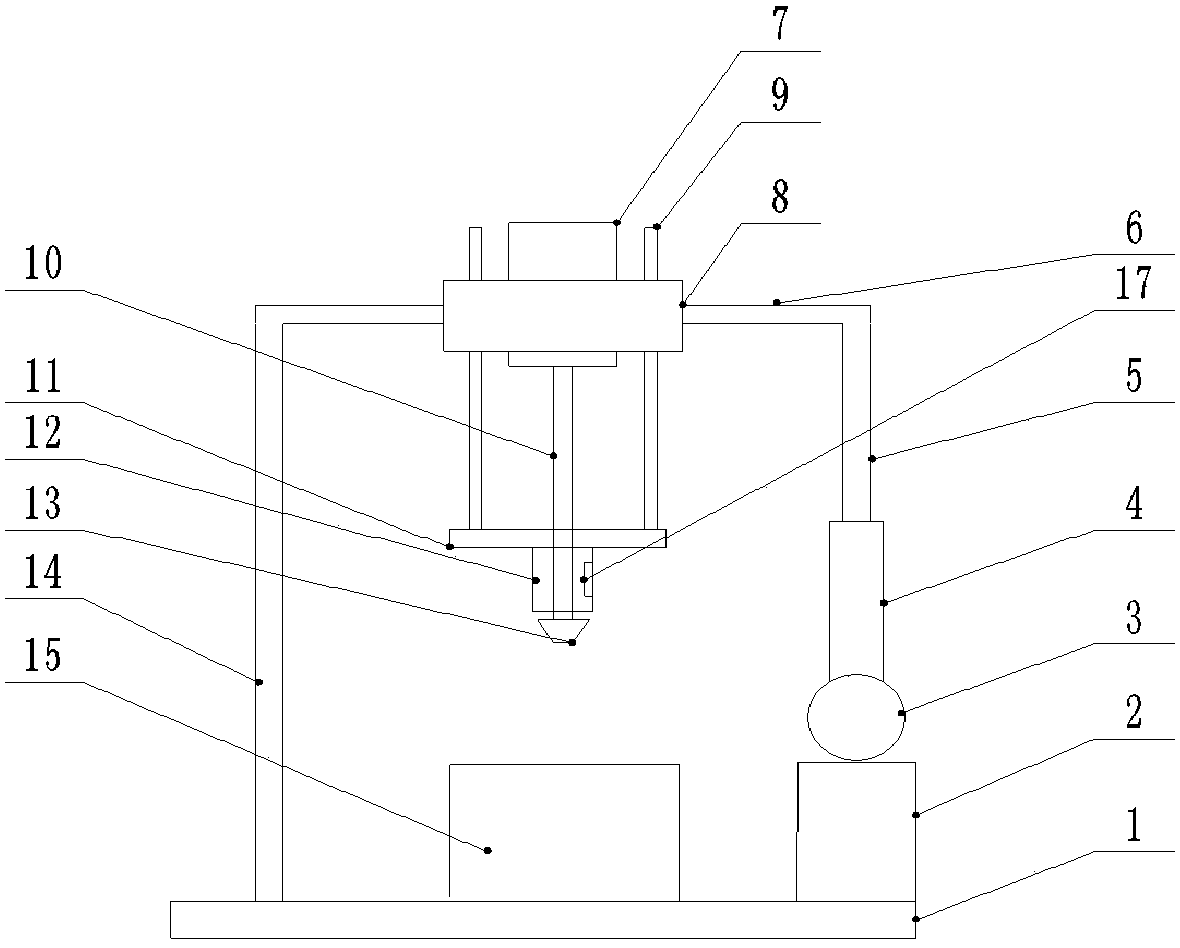

Stamping device and stamping machine

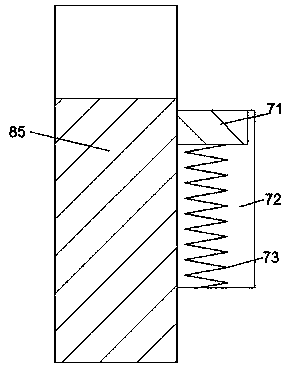

The invention discloses a stamping device. The stamping device comprises a Z-axis displacement mechanism and a stamping mechanism, wherein the Z-axis displacement mechanism comprises a Z-axis bracket, a Z-axis guide column, a Z-axis lifting table, a Z-axis screw joint part, a Z-axis lead screw and a Z-axis adjusting knob; the stamping mechanism comprises a stamping shaft sleeve, a stamping cylinder, a stamping shaft and a stamping head; the stamping shaft sleeve is fixedly arranged on the Z-axis lifting table; the stamping cylinder is fixedly arranged on the end part of the stamping shaft sleeve; the stamping shaft is arranged in the stamping shaft sleeve in a sliding way; the two ends of the stamping shaft are connected with the stamping cylinder and the stamping head respectively. The stamping device is provided with the Z-axis displacement mechanism and the stamping mechanism which is connected with the Z-axis displacement mechanism, and the Z-axis displacement mechanism can be used for driving the stamping mechanism to move more flexibly in order to match the external displacement device having two degrees of freedom, so that a plurality of stamping holes which are distributed irregularly can be stamped.

Owner:江门市蓬江区飞帆实业有限公司

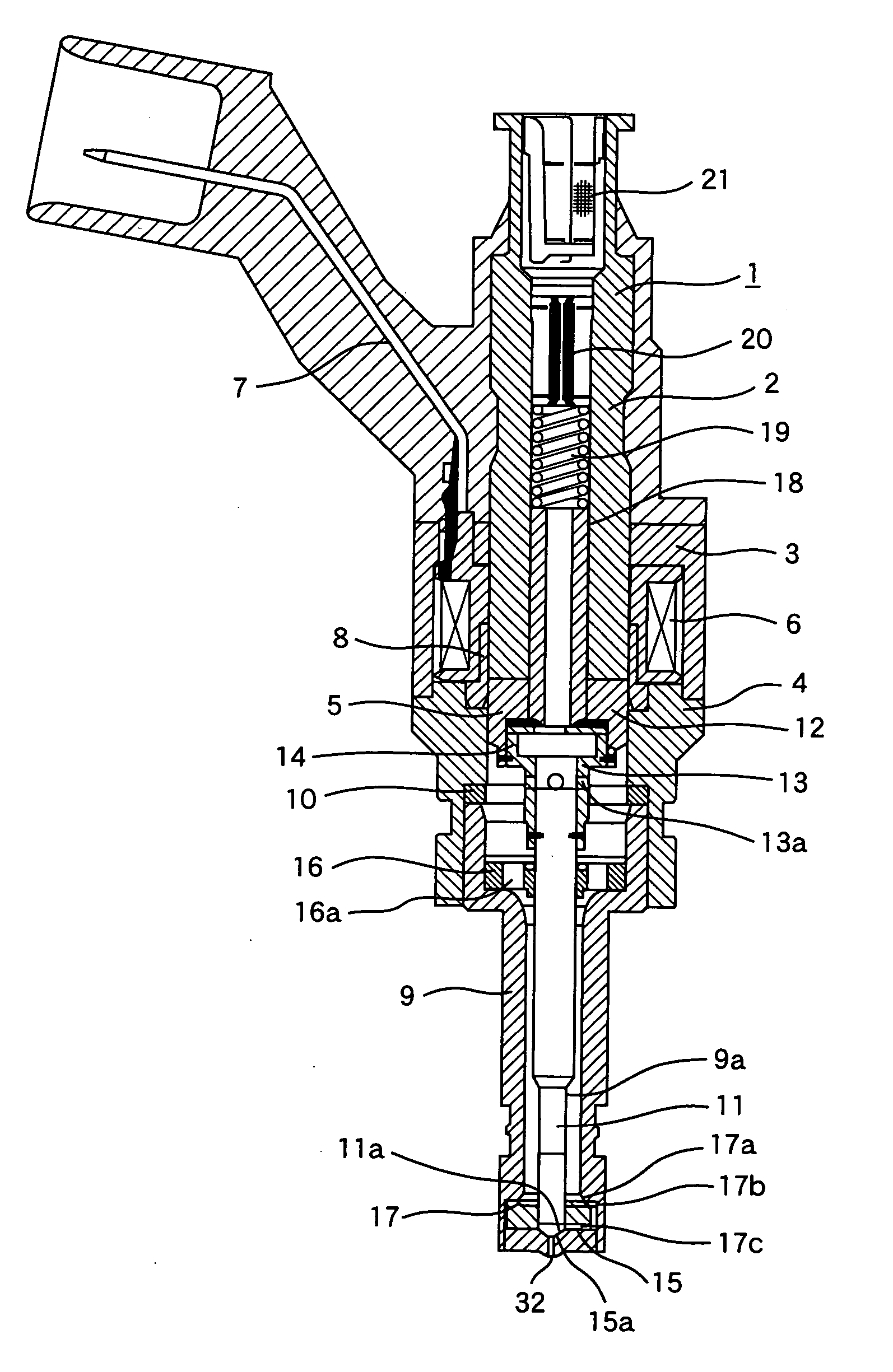

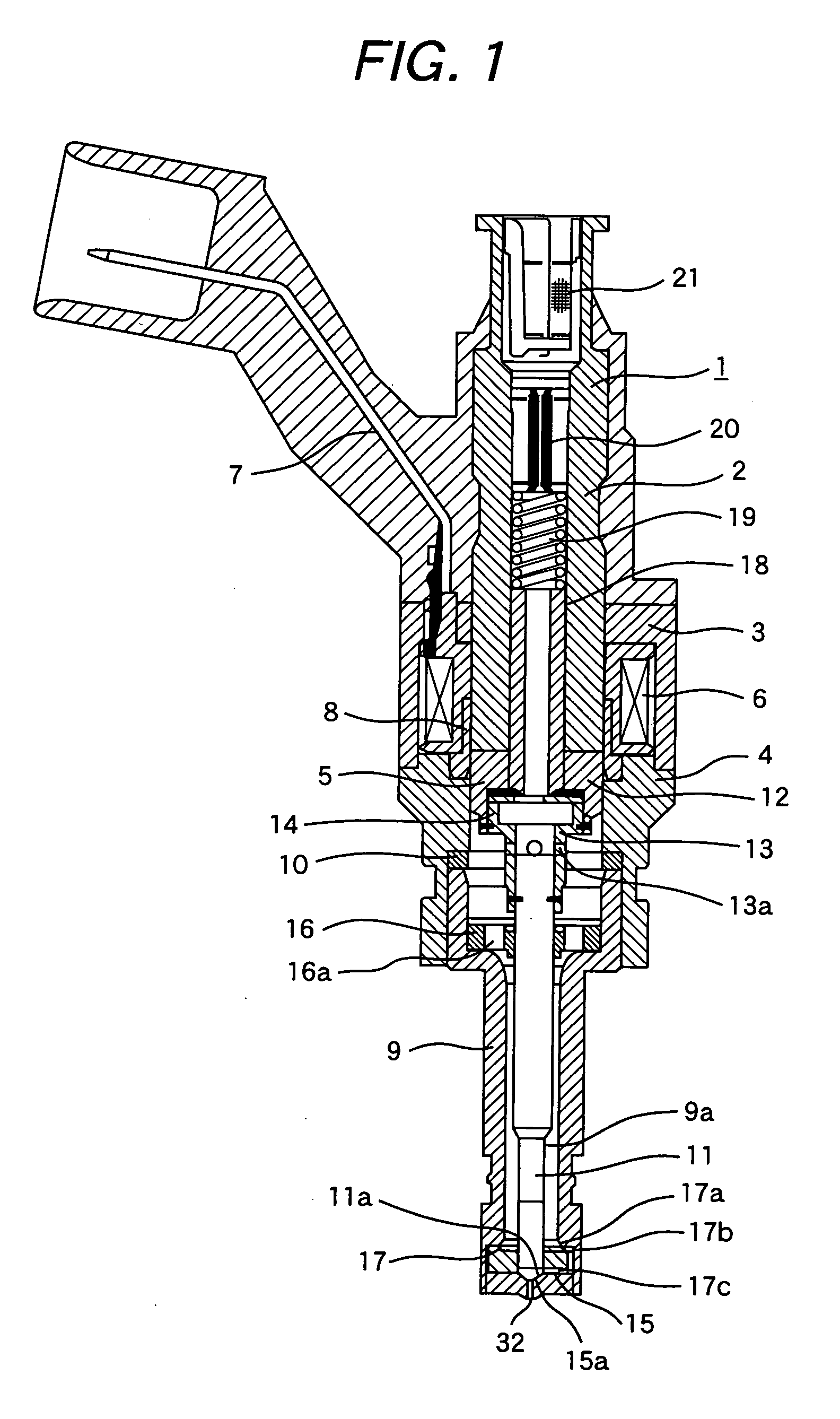

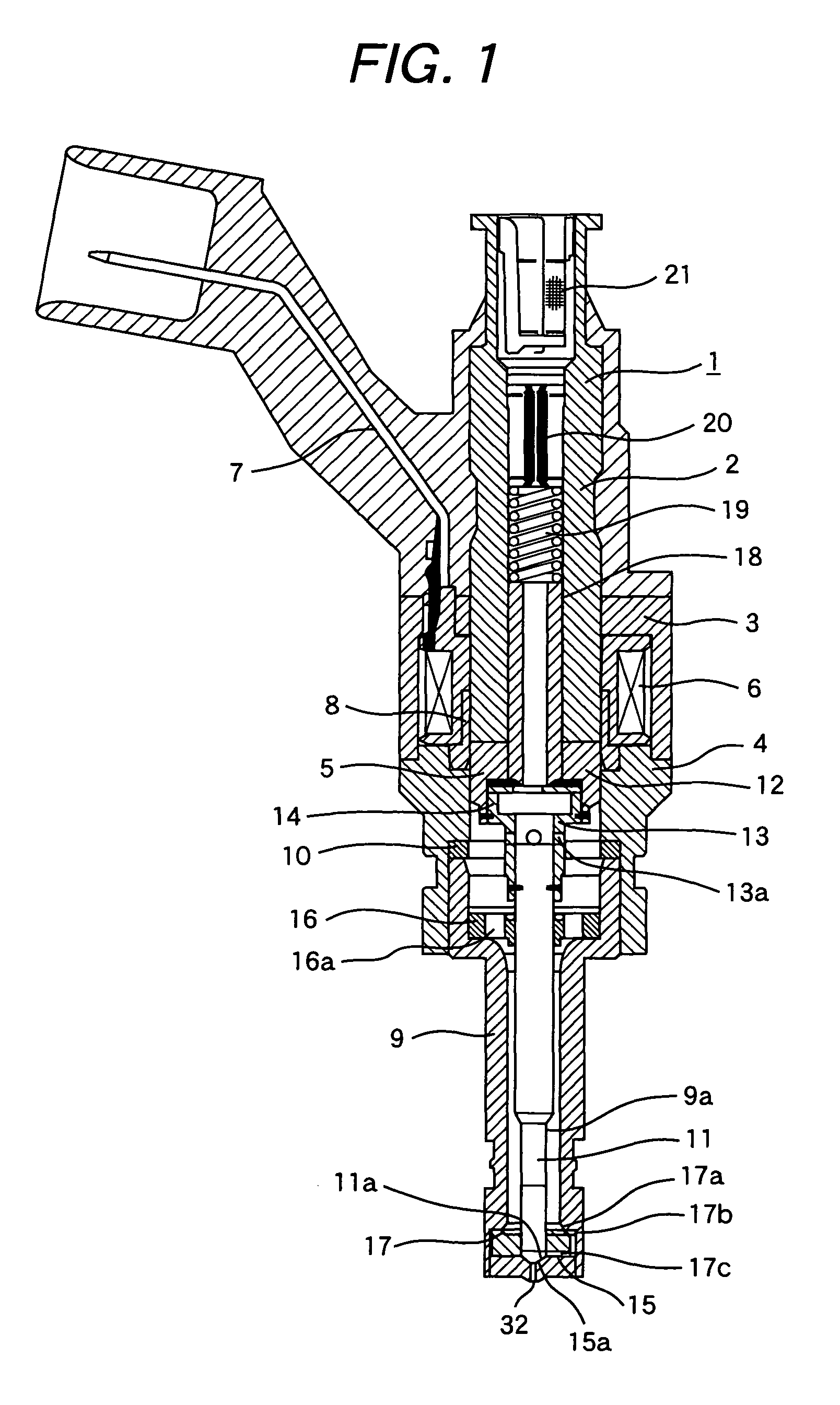

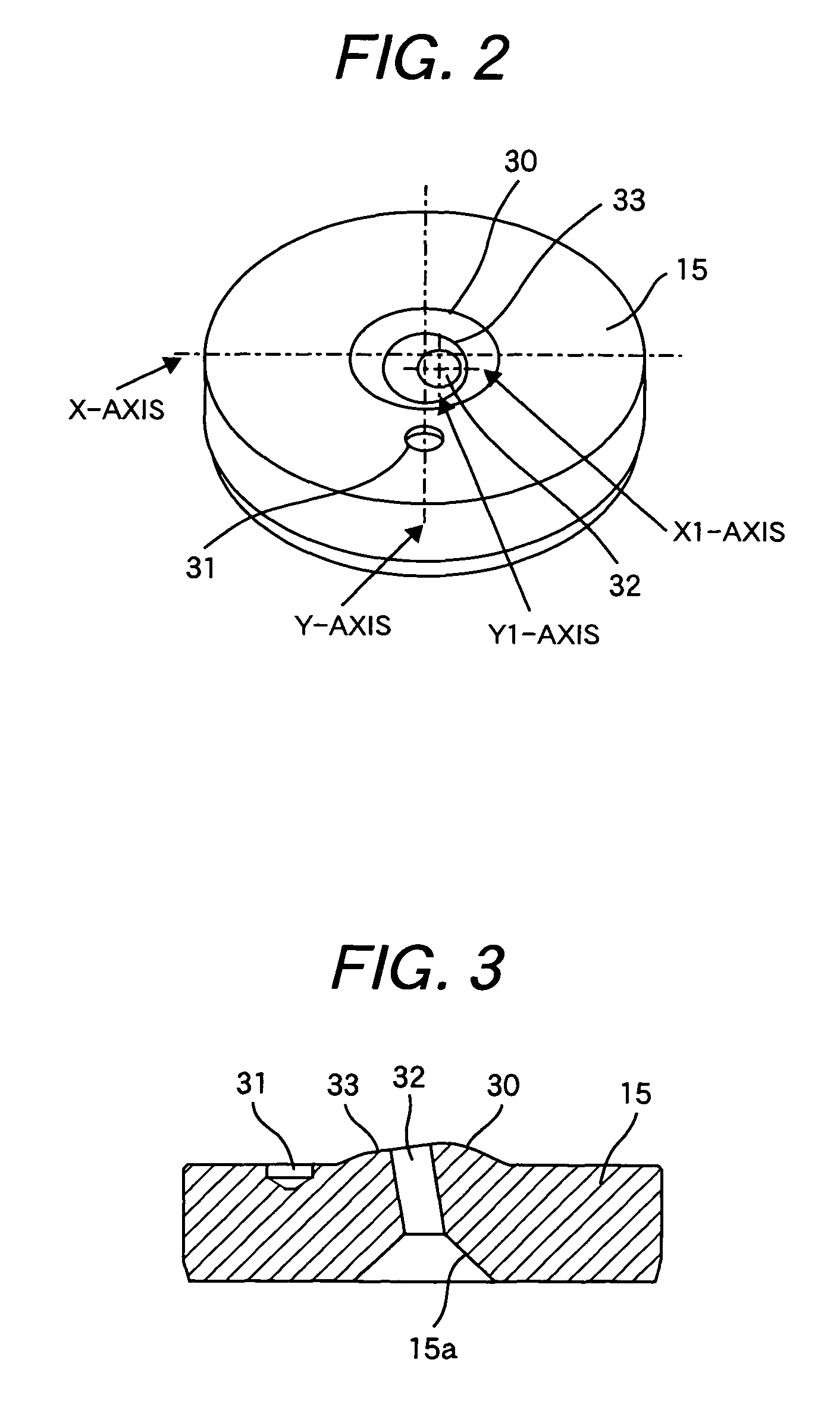

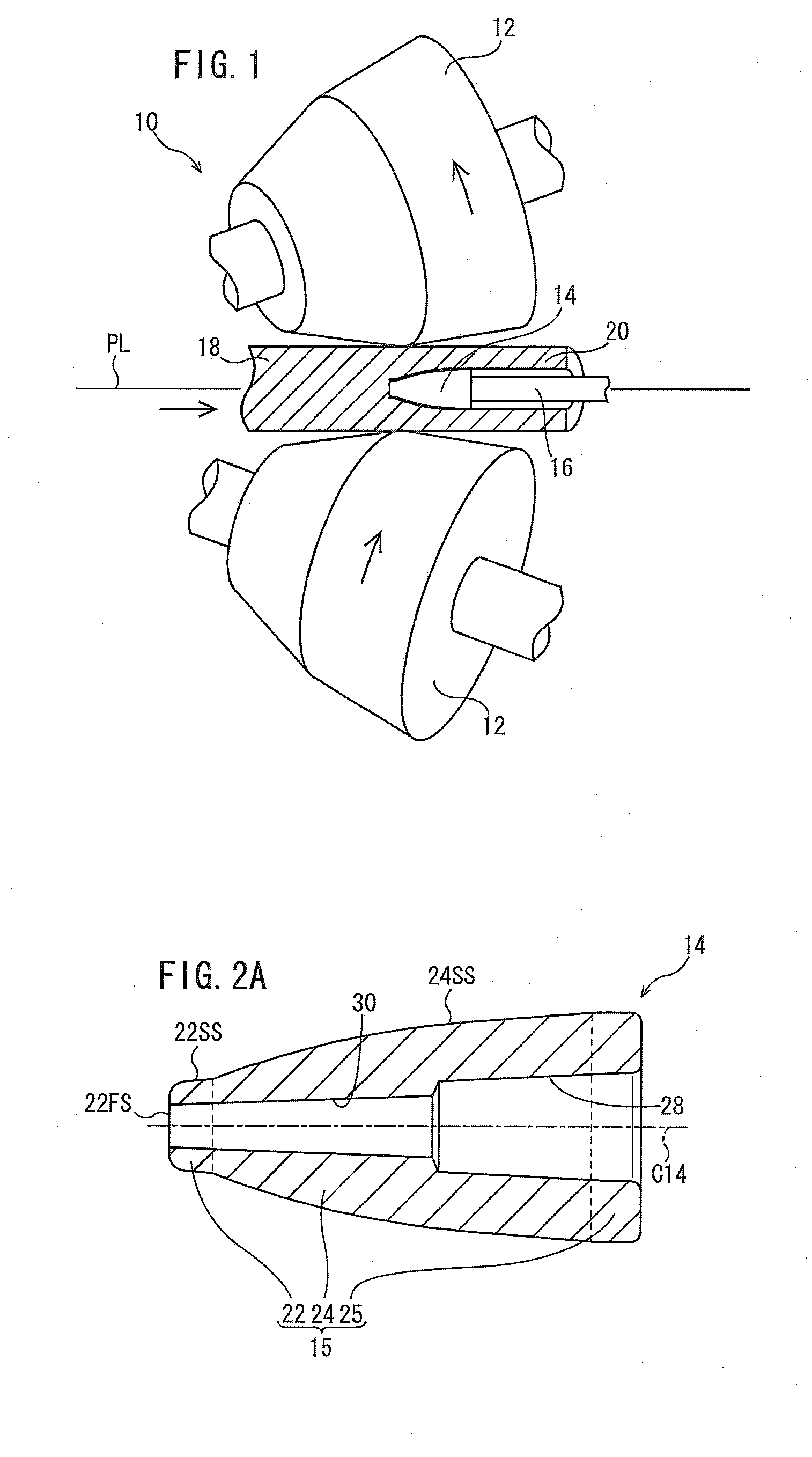

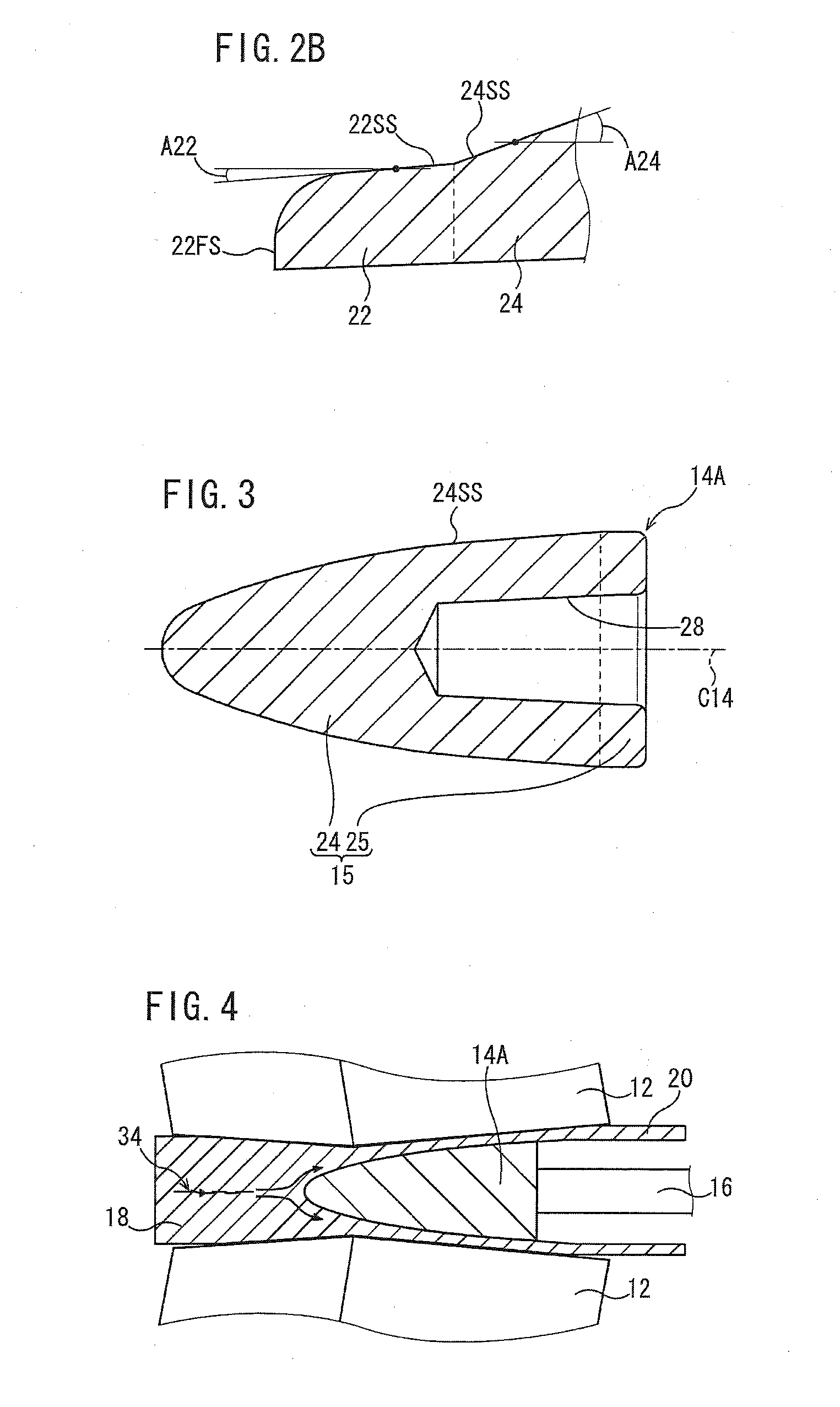

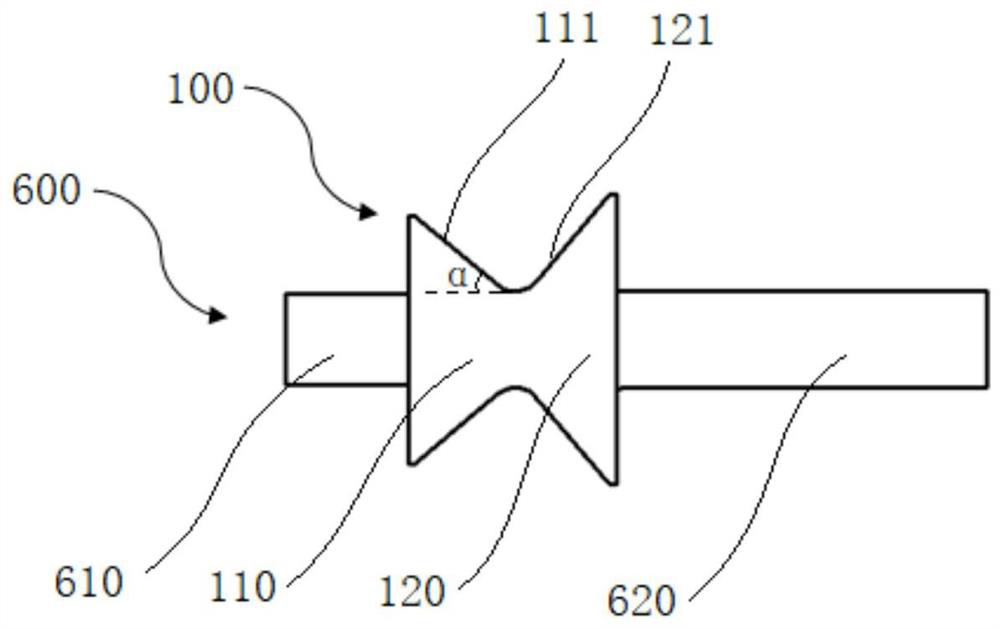

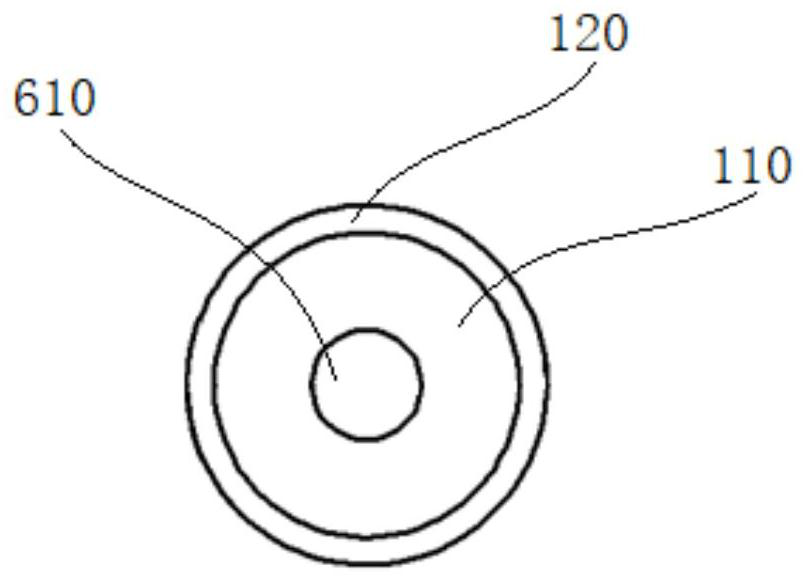

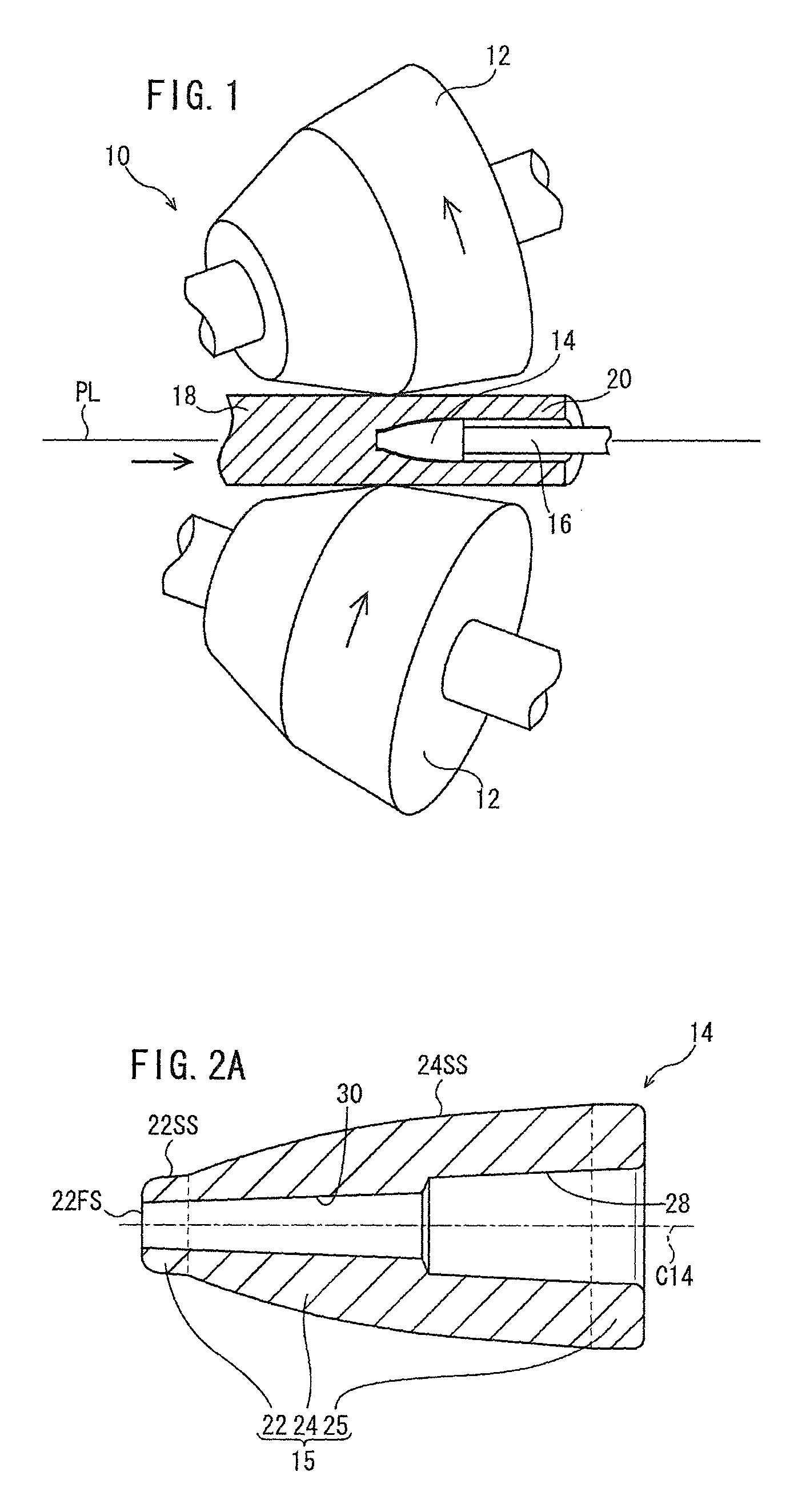

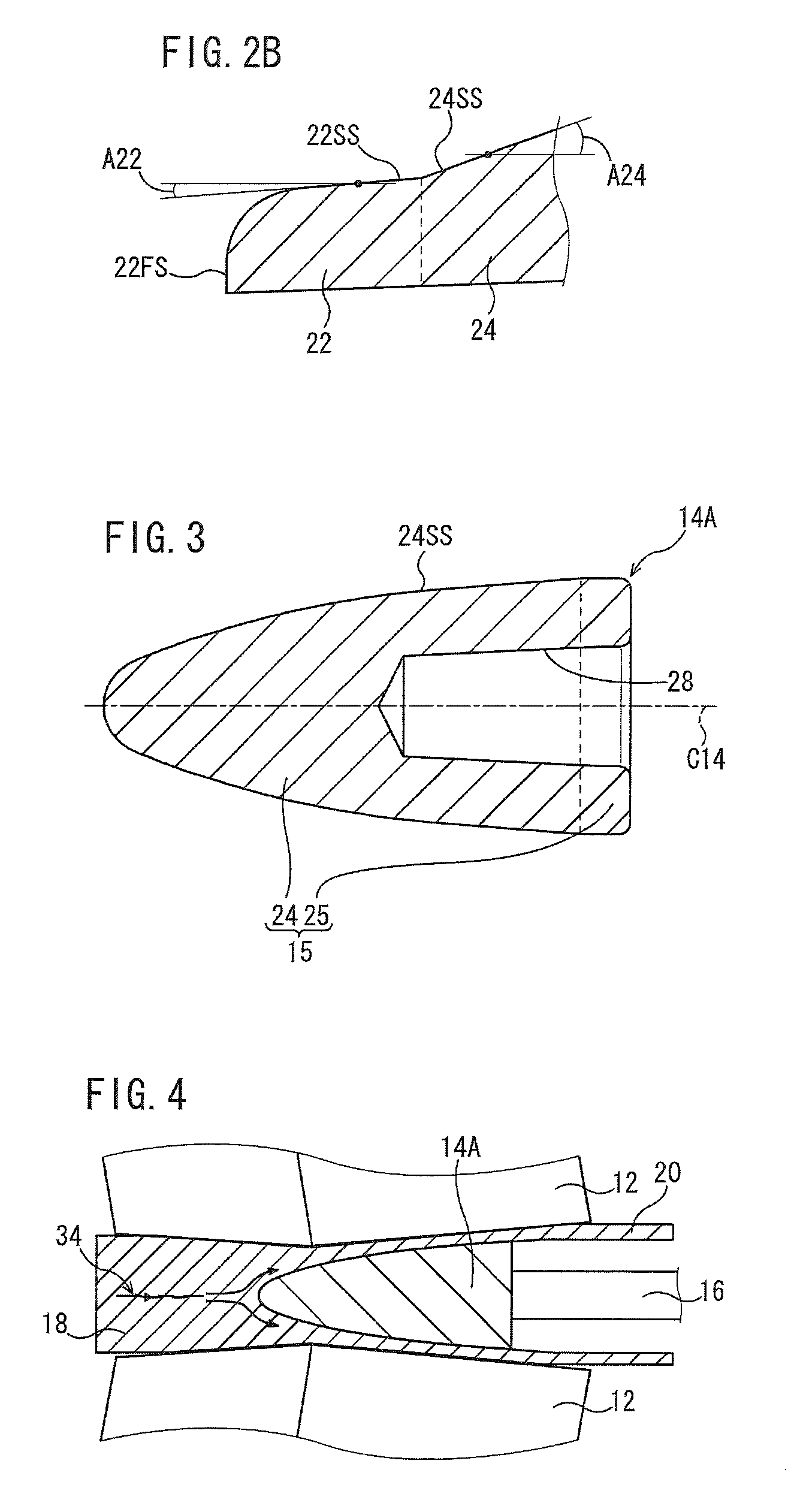

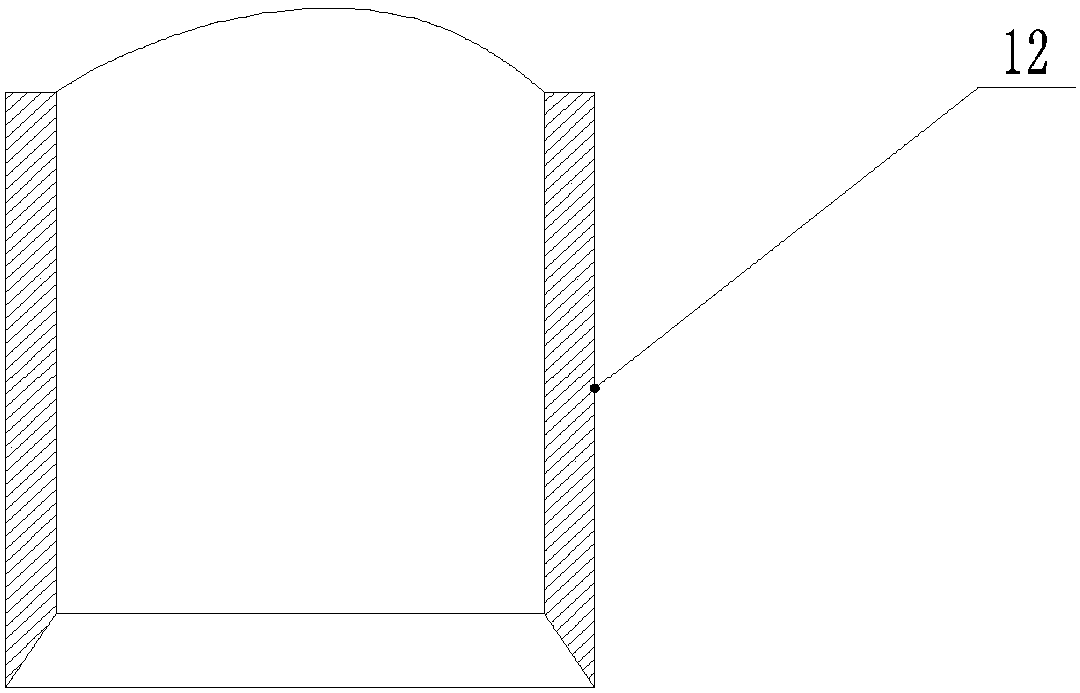

Injection valve and method of making orifice

InactiveUS20070057093A1Improve spray uniformityEasy to processValve arrangementsPiercing pressesOrifice plateEngineering

An injection valve has a nozzle body, a valve needle positioned in the nozzle body, an actuator for actuating the valve needle, and an orifice plate fixed at an end of the nozzle body. The orifice plate has a valve seat for cooperate with the valve needle and an orifice for injecting a fluid. The orifice plate is provided with a projection having a convex-curved surface on an orifice outlet side of the orifice plate. A flat surface portion is formed in the area of the convex-curved surface, and the outlet of the orifice is located in the flat surface portion.

Owner:HITACHI LTD

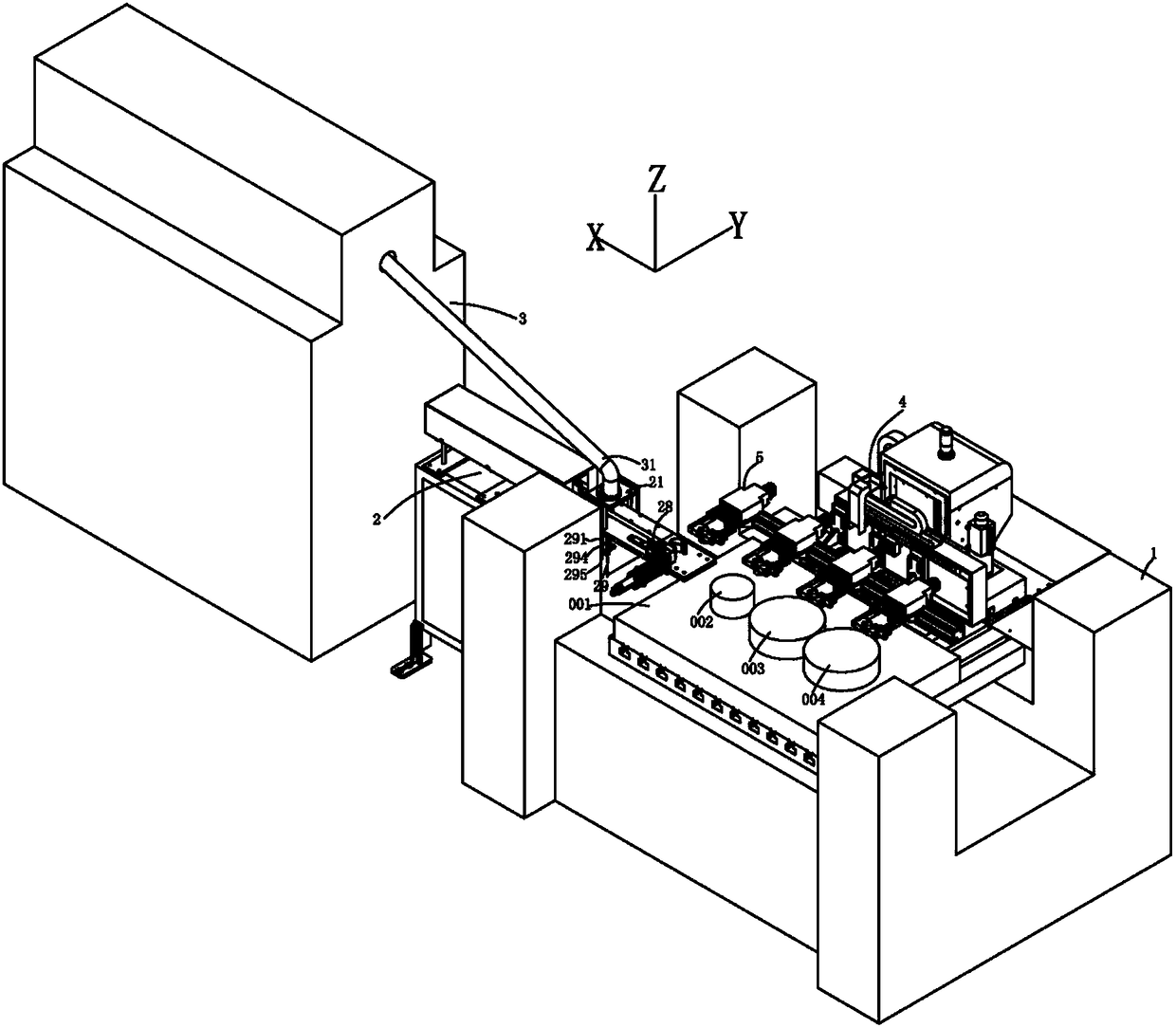

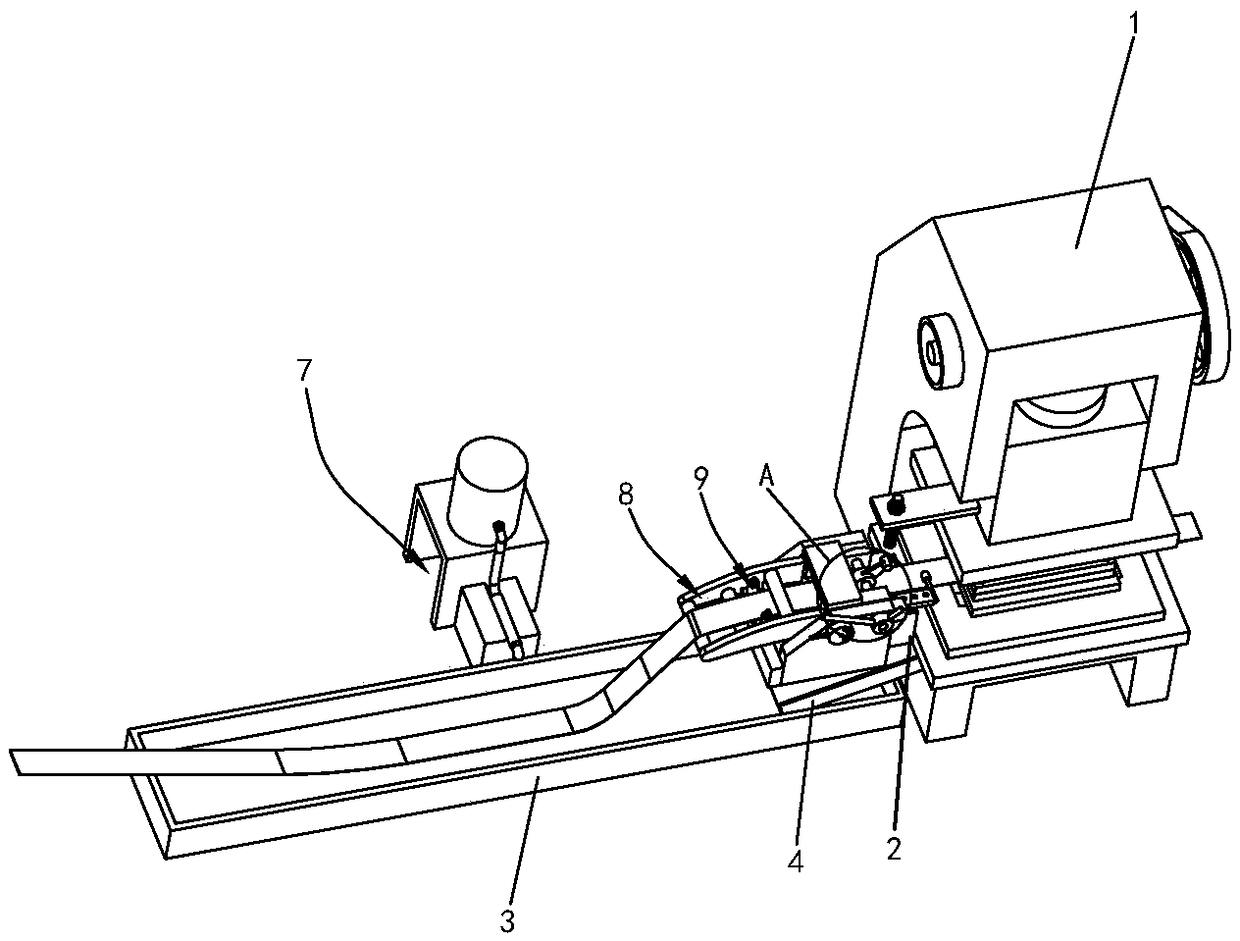

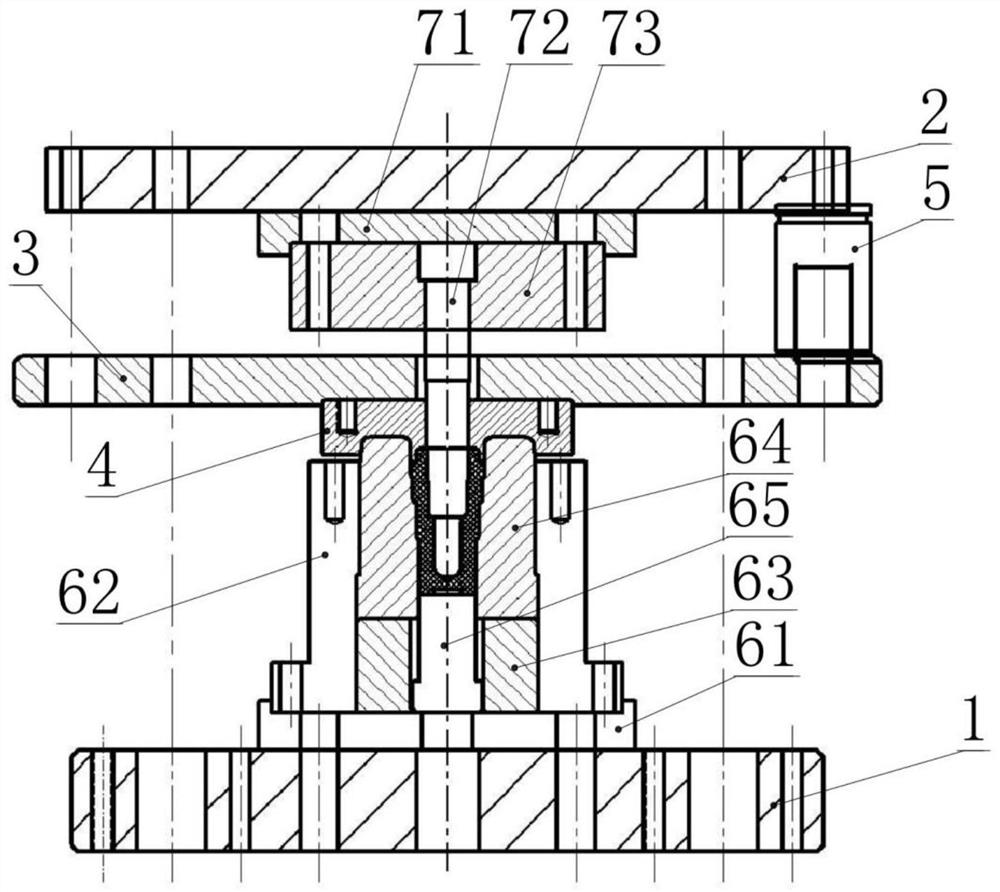

Full-automatic nut forging machine

ActiveCN108555210ATransplanting speed is fastSimple structureNutsPiercing pressesPunchingEngineering

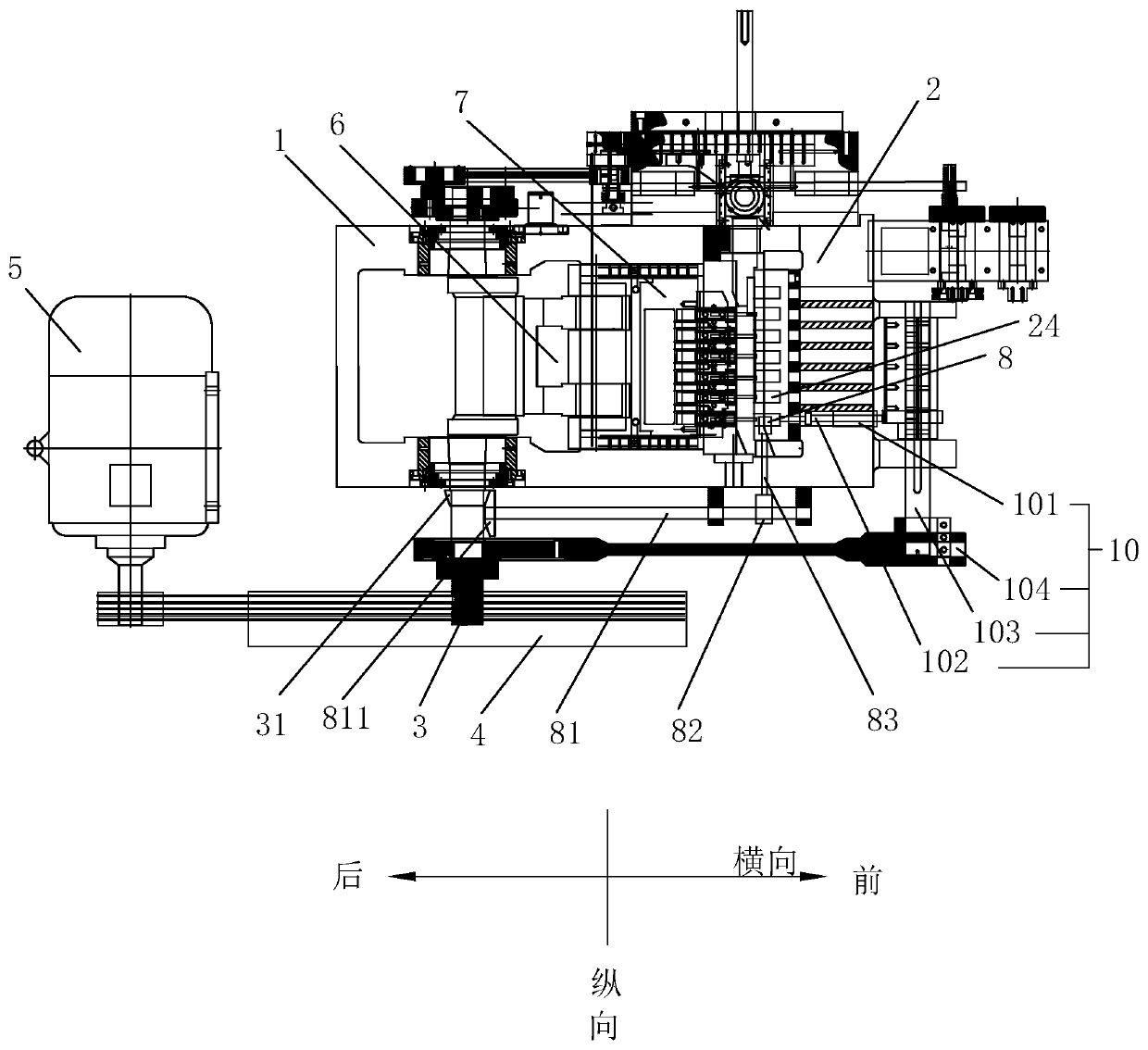

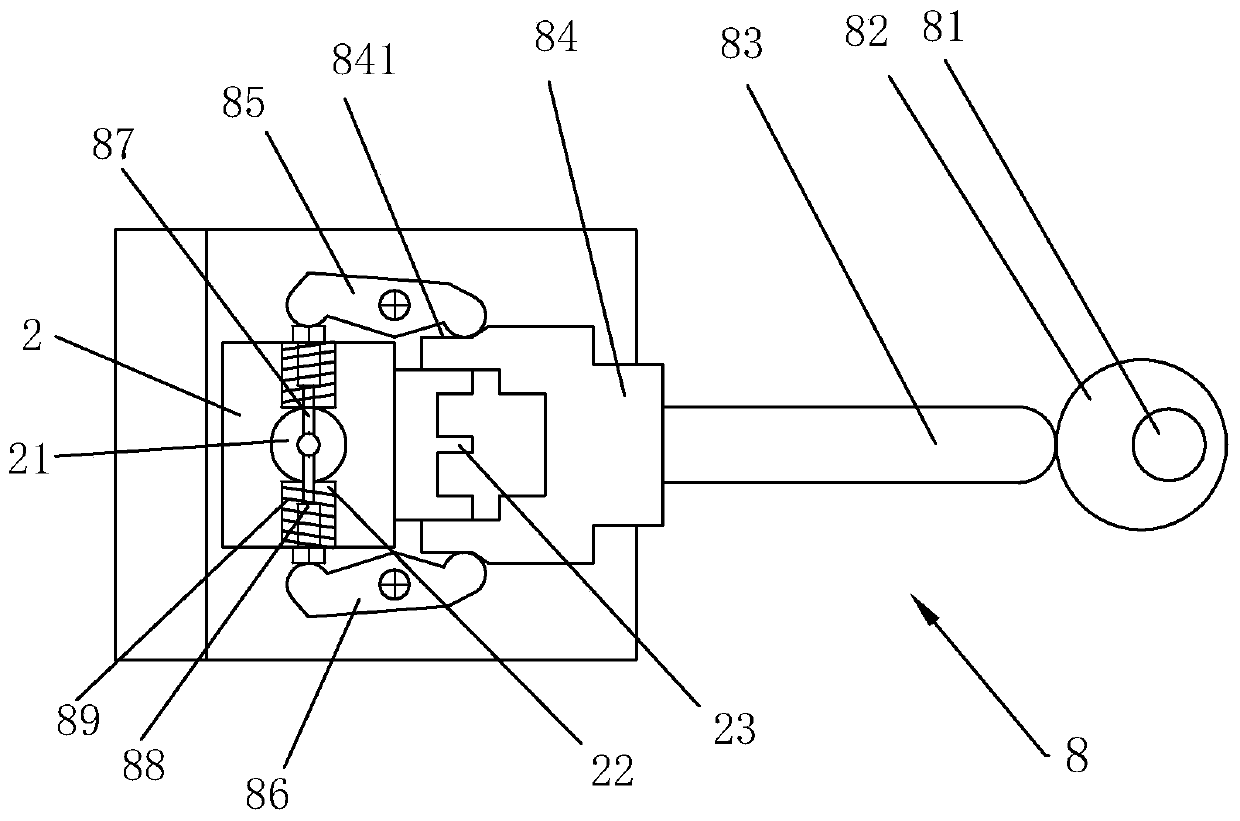

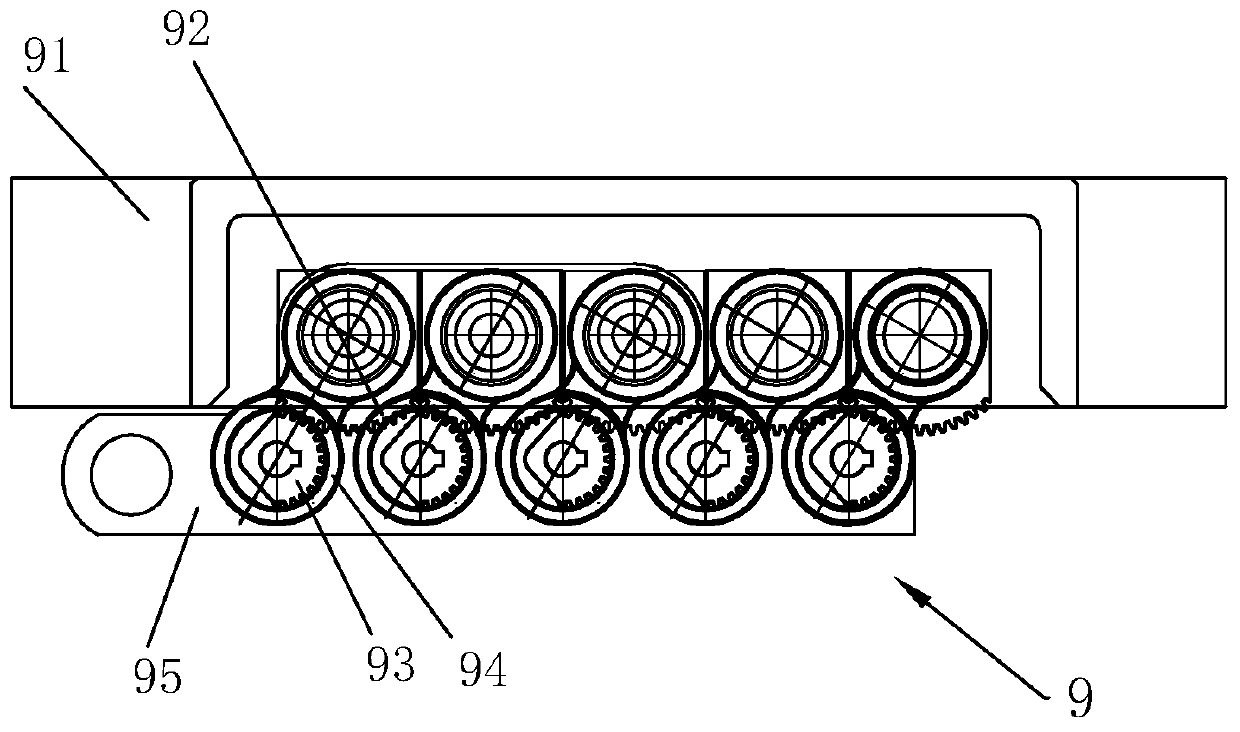

The invention discloses a full-automatic nut forging machine which comprises a forging bed, wherein a cabinet of the forging bed is provided with an upsetting station, a molding station, a punching station and a material receiving station; the forging bed is also provided with an upsetting mold, a shaping mold and a punching mold; the side edge of the cabinet is provided with a material receivingmachine and a heating furnace, a discharge pipe of the heating furnace is connected with a material receiving nozzle of the material receiving machine, the material receiving machine is also in movable butt joint with a material moving mechanism at the front end of the cabinet; the heating furnace is used for heating a nut blank; the discharge pipe is used for overturning the nut blank by 90 degrees; the material receiving machine is used for horizontally pushing the overturned nut blank to the butt joint position with the material moving mechanism; the material moving mechanism is provided with four material clamping components, drives the material clamping components to synchronously move, horizontally transfers the nut blanks / nuts on the butt joint position of the material receiving machine, upsetting station, molding station and punching station to the upsetting station, the molding station, the punching station and the material receiving station, and is matched with the forging bed to complete upsetting, molding, punching and material receiving.

Owner:东莞辉科机器人自动化股份有限公司

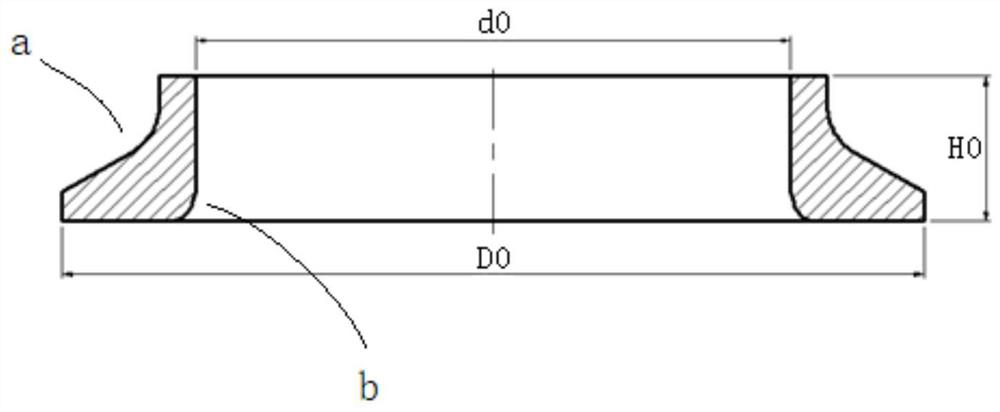

Forging process and equipment for high-temperature-resistant and high-pressure-resistant stainless steel ring

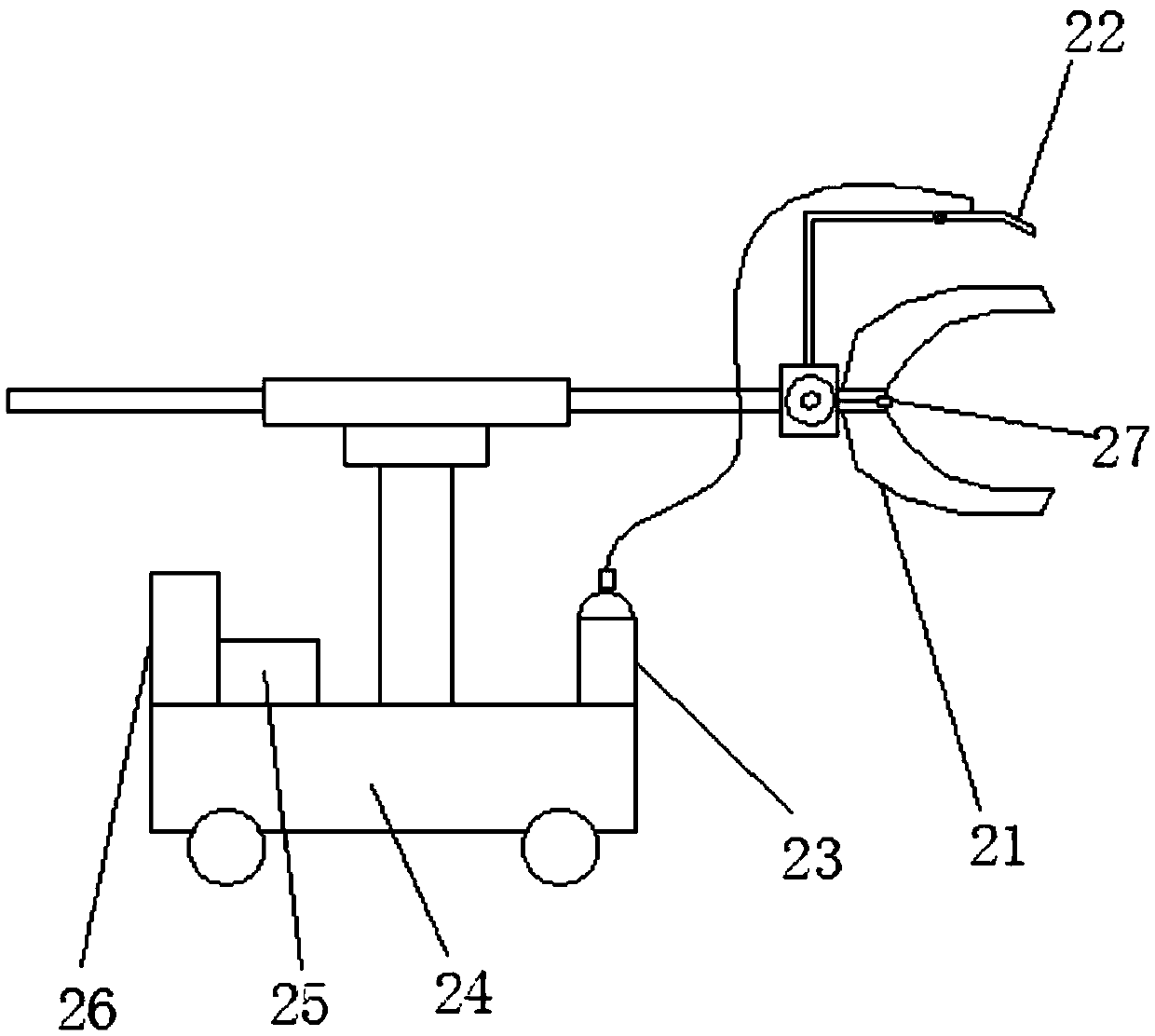

InactiveCN109590417ARealize the heating effectRealize the insulation effectPiercing pressesHeating/cooling devicesPunchingForging manipulator

The invention relates to the technical field of forging and discloses forging process and equipment for a high-temperature-resistant and high-pressure-resistant stainless steel ring. The forging process comprises the following process steps of step 10, blanking, step 20, heating before upsetting, step 30, upsetting, step 40, punching, step 50, heating before ring milling, step 60, ring milling andstep 70, slow cooling. The stainless steel ring is transferred in each forging workstage and between workstages by using a forging manipulator, the front end of the forging manipulator is provided with an infrared thermometer for online measuring of the temperature of a blank and a flame heating device for online heating and heat preservation of the blank, and the forging manipulator turns on theflame heating device in the process of transferring the blank to carry out heating and heat preservation on the blank of the stainless steel ring. By the adoption of the forging process and equipment, good control over the temperature of the blank of the stainless steel ring in the forging process is realized, so that the forging quality is improved, and the forging energy consumption is reduced.

Owner:JIANGYIN HENGRUN RING FORGING

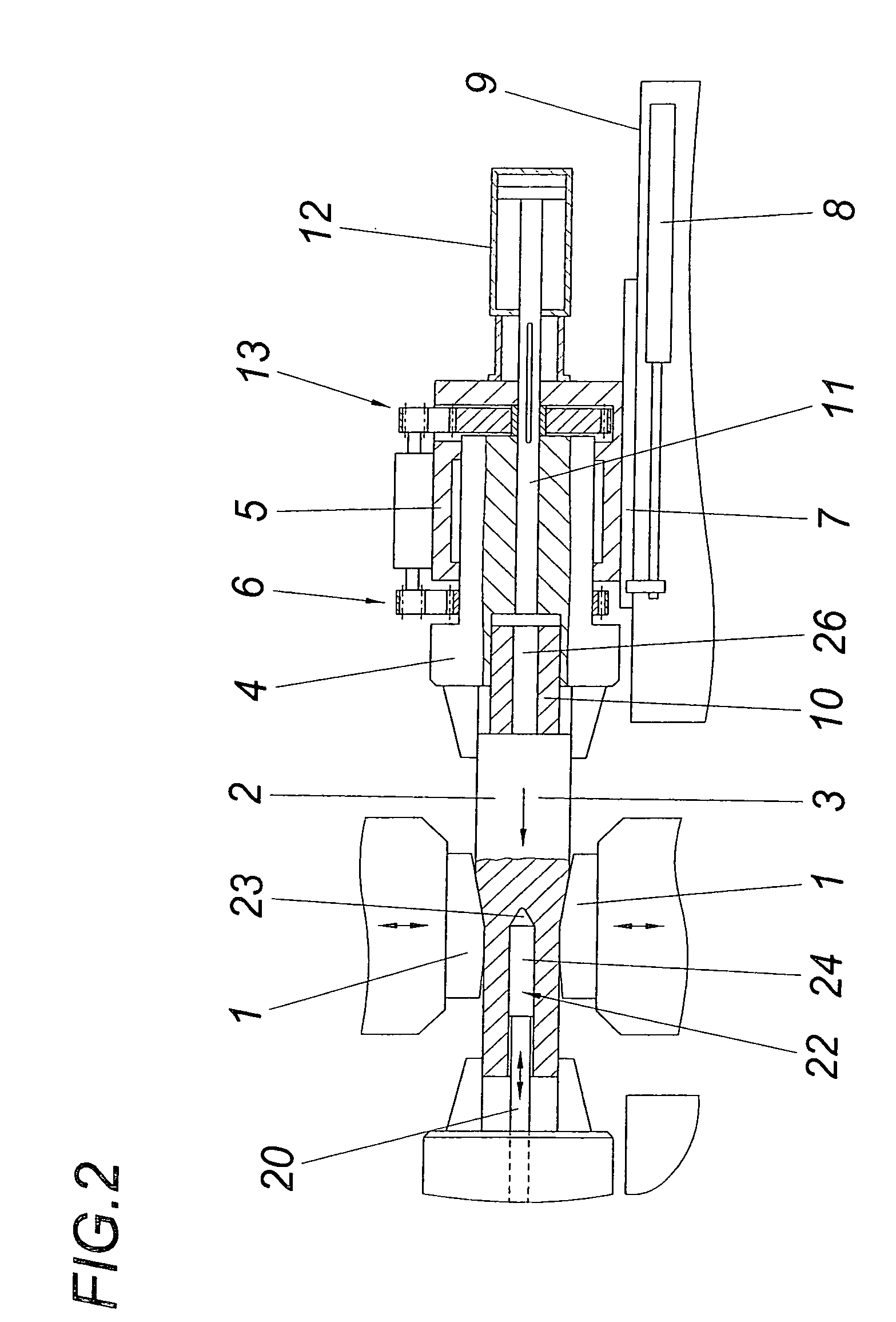

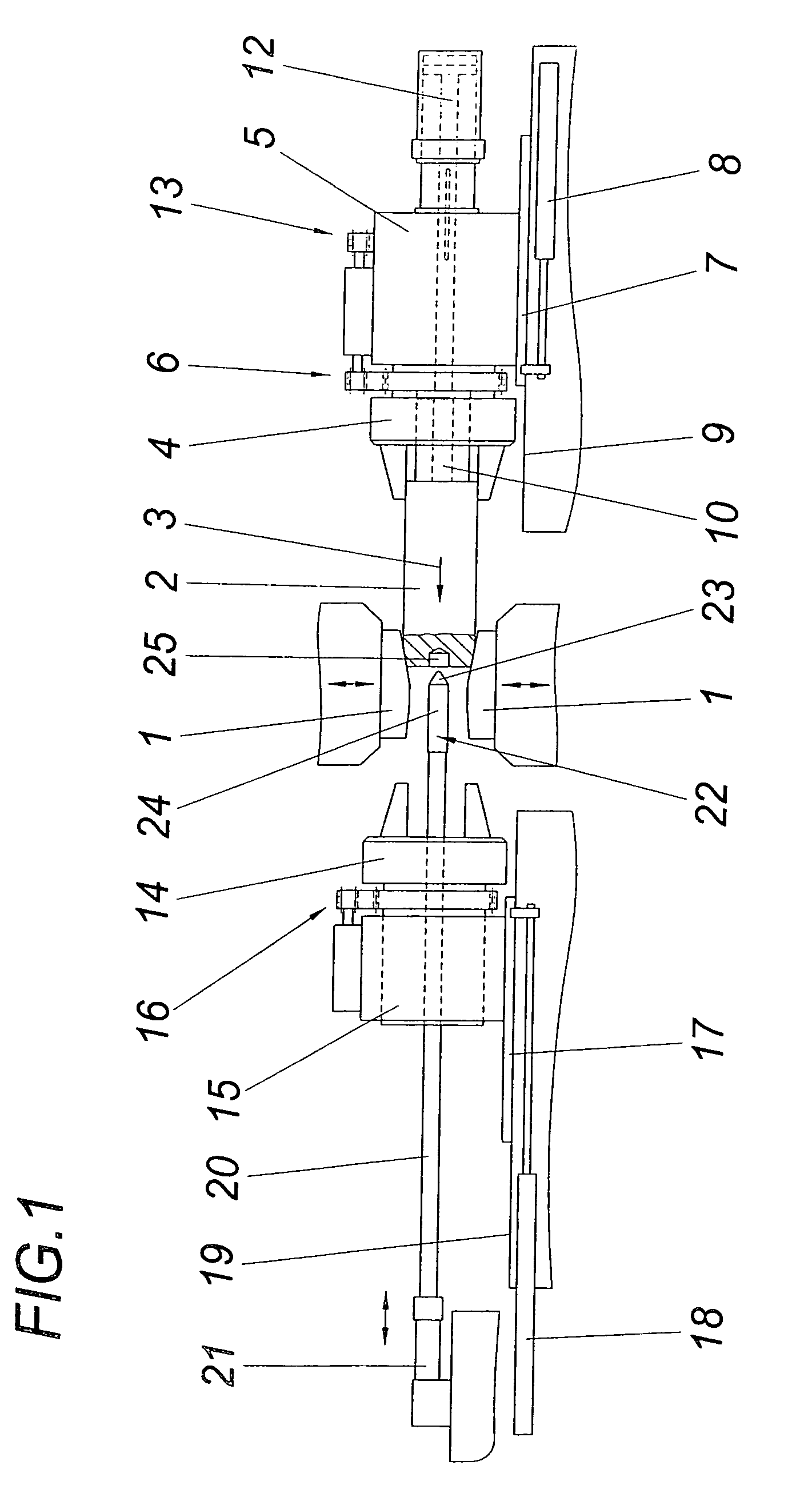

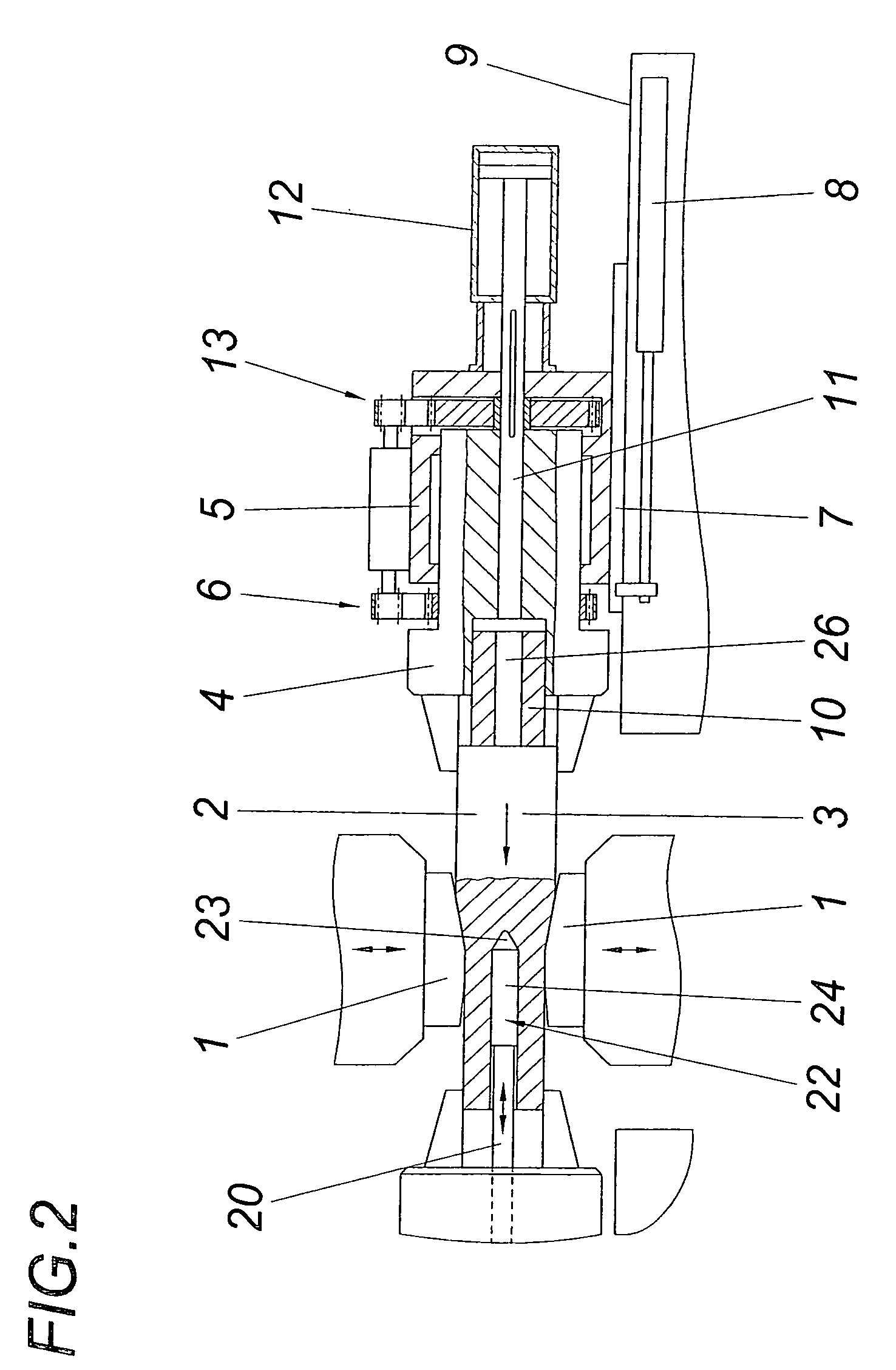

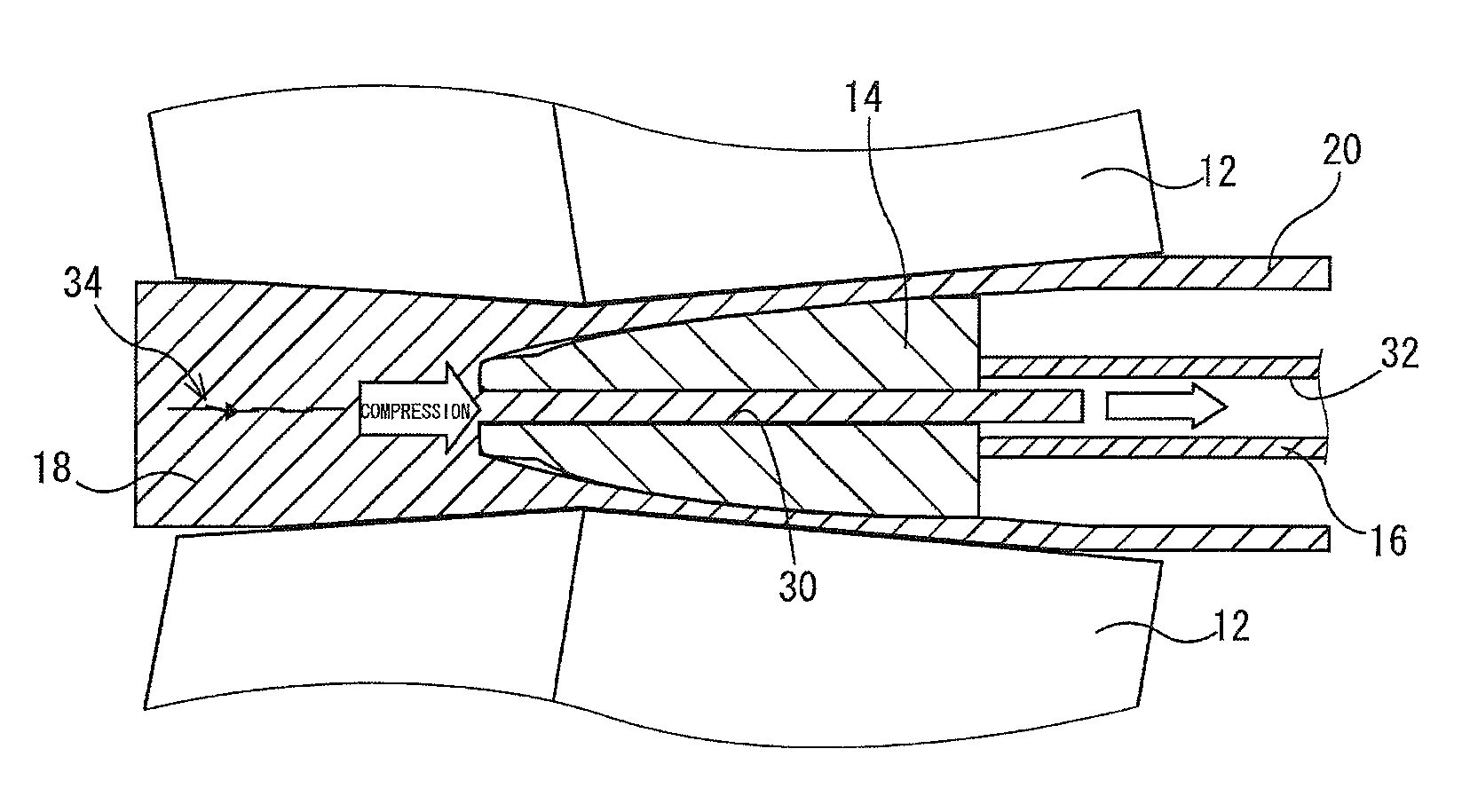

Method and apparatus for producing a cylindriacal hollow body from a blank

ActiveUS20070186604A1Feed of the workpiece can be increased considerablyImprove construction conditionsForging hammersPiercing pressesAxial forceSwaging

A method is described for producing a cylindrical hollow body from a blank, with the workpiece being opened in the core region by successive swaging which is angularly offset against each other about the axis of the workpiece and being simultaneously pushed onto a piercing mandrel. In order to improve the piercing it is proposed that the workpiece is pressed during the swaging with a predeterminable axial force against the piercing mandrel which can be advanced against the workpiece against this axial force, which piercing mandrel is moved back to its initial position synchronous with the axial feed of the workpiece between the successive swaging steps.

Owner:GFM BETEILIGUNGS & MANAGEMENT

Wind power door frame flange production equipment based on sliding type workbench

ActiveCN114733989AConvenience to workEasy to forgeMetal-working apparatusDirt cleaningElectric machineryScrew thread

The invention relates to the technical field of wind power door frame flange production, in particular to wind power door frame flange production equipment based on a sliding worktable, which comprises a bottom table, a pushing mechanism and a cleaning mechanism, a middle table is fixedly connected to the top end of the bottom table, an upper table is fixedly connected to the top end of the middle table, and a hydraulic rod is arranged at the top end of the upper table; a pressing plate is arranged in the middle of the upper table, a first threaded rod is connected into a threaded hole through threads, and a first motor is arranged at one end of the bottom table. And the movable working table top and the movable table can enable the device to forge and punch raw materials, meanwhile, a user does not need to take out high-temperature waste materials, and therefore the situation that the user is scalded can be avoided, and the use safety of the user is improved. The device can automatically clean the oxide skin, and can automatically stop after cleaning is finished, so that a user can use the device very conveniently, meanwhile, the workload of the user can be reduced, the working intensity of the user can be reduced, and the working efficiency of the user can be improved.

Owner:SHANXI TIANBAO GRP CO LTD

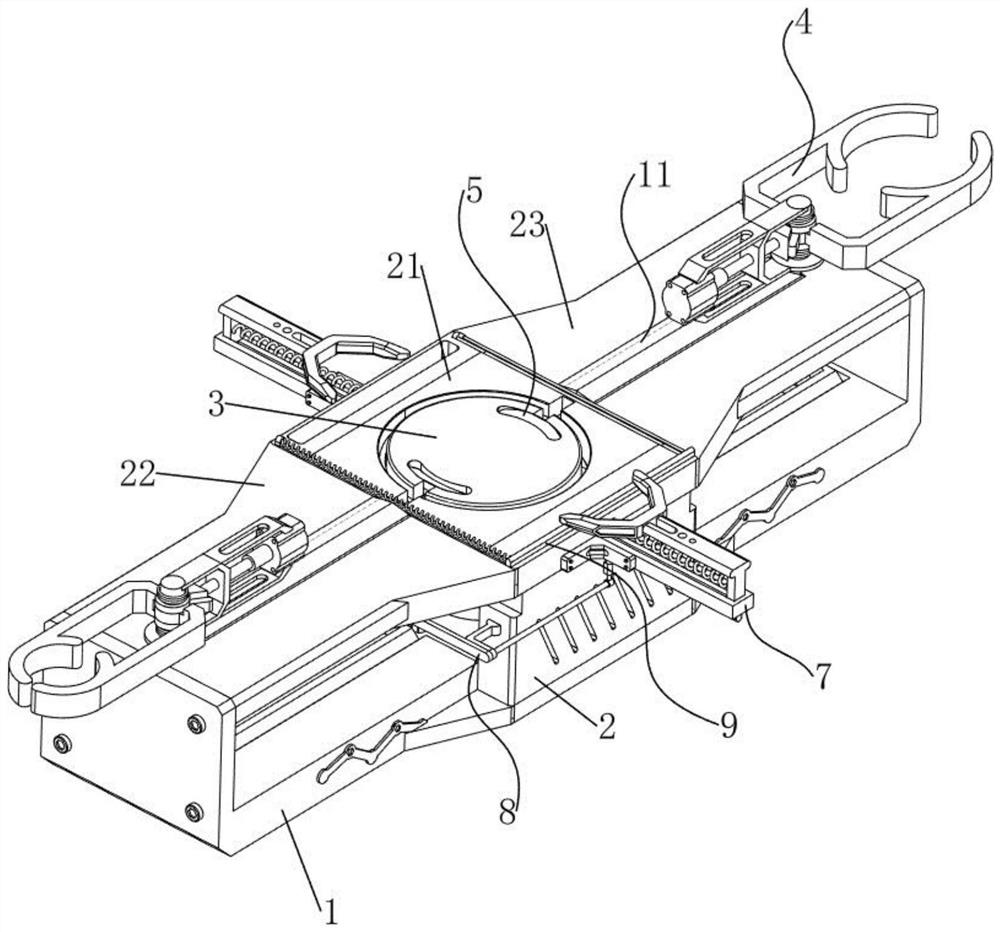

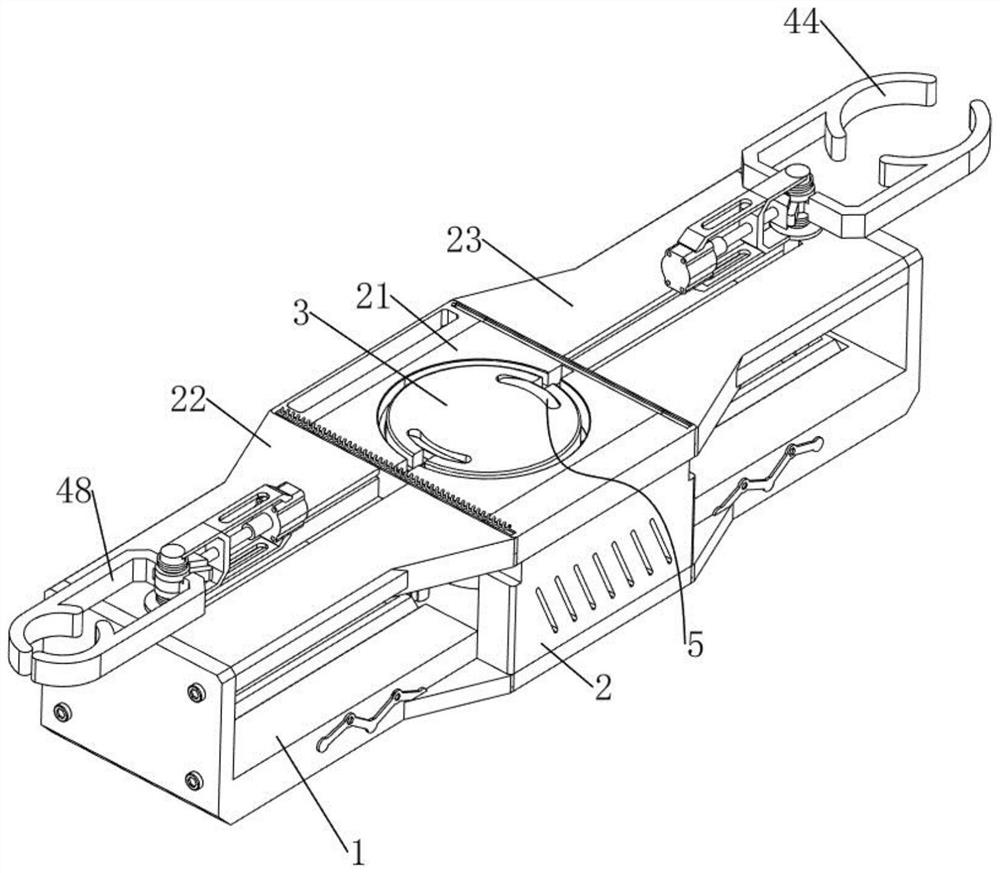

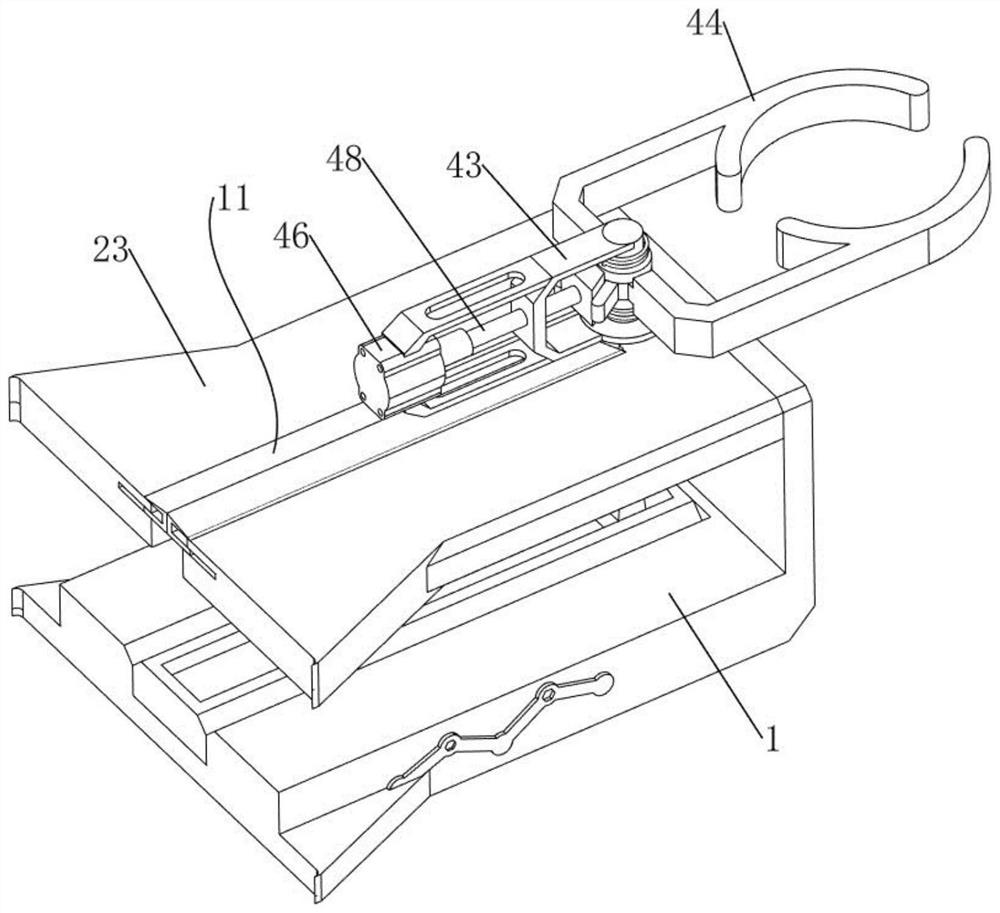

Tool arranged on press machine and used for forging wind power flange blank and punching through center hole

ActiveCN114505436AQuick take outQuick operabilityFinal product manufacturePiercing pressesEngineeringWind power

The invention relates to a tool, in particular to a tool arranged on a press machine and used for forging a wind power flange blank and punching through a center hole. The tool for forging the wind power flange blank and punching the center hole on the press machine can adapt to various different flange plates, can clamp the flange plates and can quickly turn over the flange plates. The tool arranged on the press machine and used for forging the wind power flange blank and punching through the center hole comprises a bottom plate, supporting plates, a mounting plate and the like, the supporting plates are arranged at the eccentric position of the upper side of the middle of the bottom plate in a front-back symmetry mode, and the mounting plate is connected between the upper portions of the two supporting plates. The flange plate can be supported through the forging table, the first clamping plate and the second clamping plate can be used for rapidly taking out and placing the flange plate, the second air cylinder is started to enable the clamping block to clamp the flange plate, and the rotating connecting plate can be used for face changing operation of the flange plate.

Owner:SHANXI TIANBAO GRP CO LTD

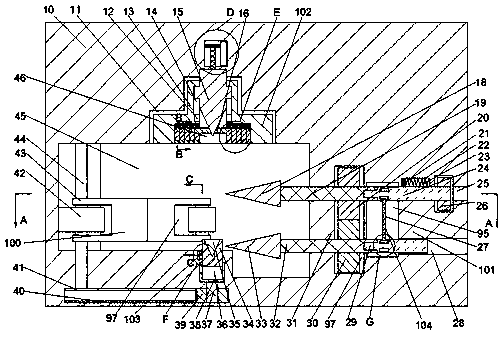

Automatic forging centering device

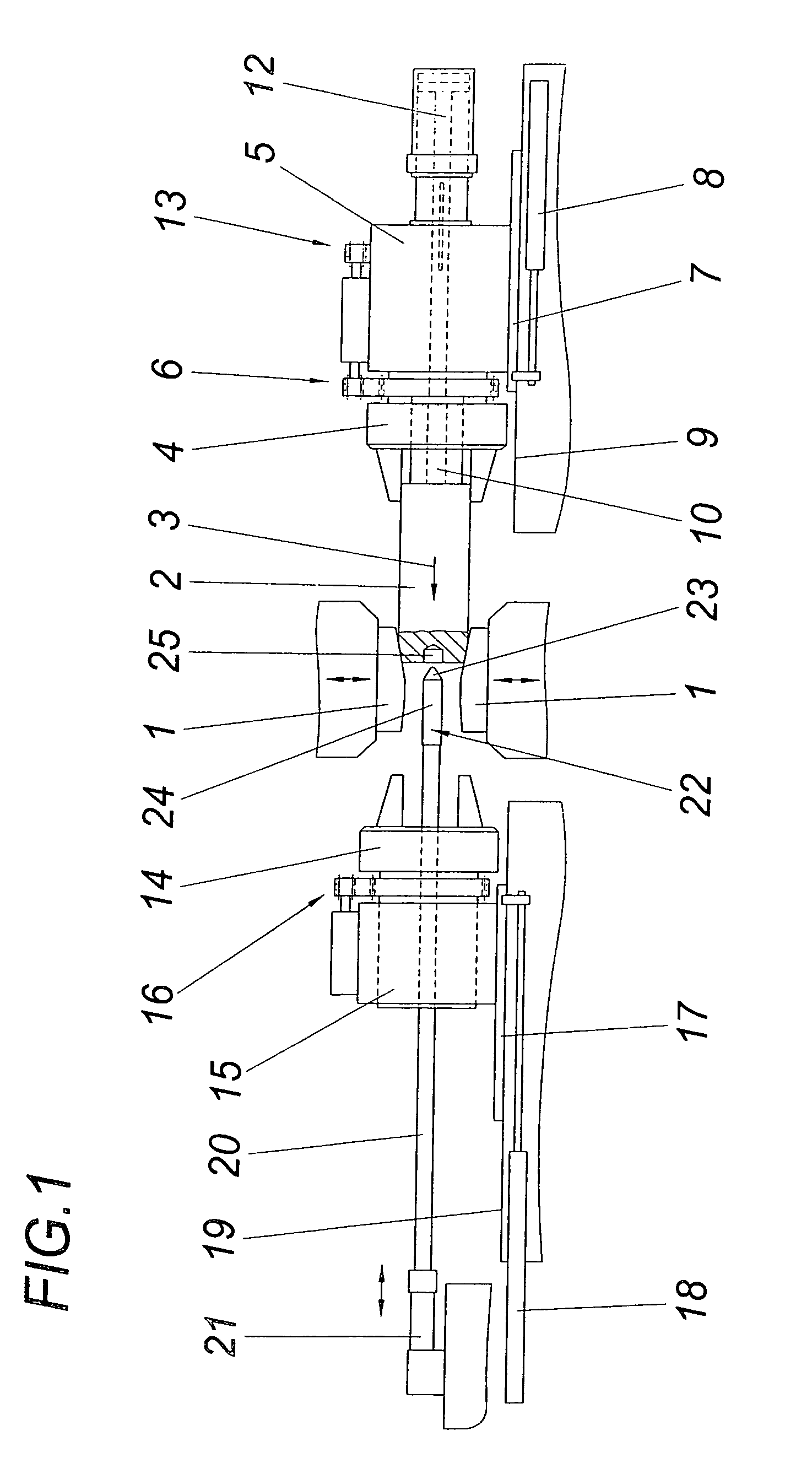

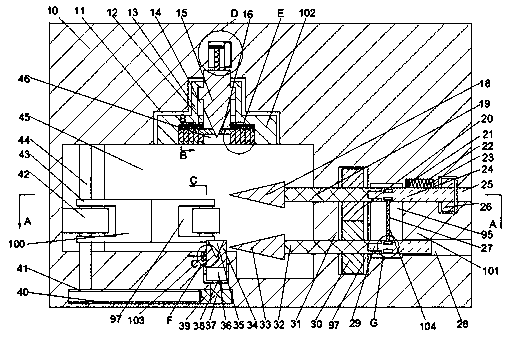

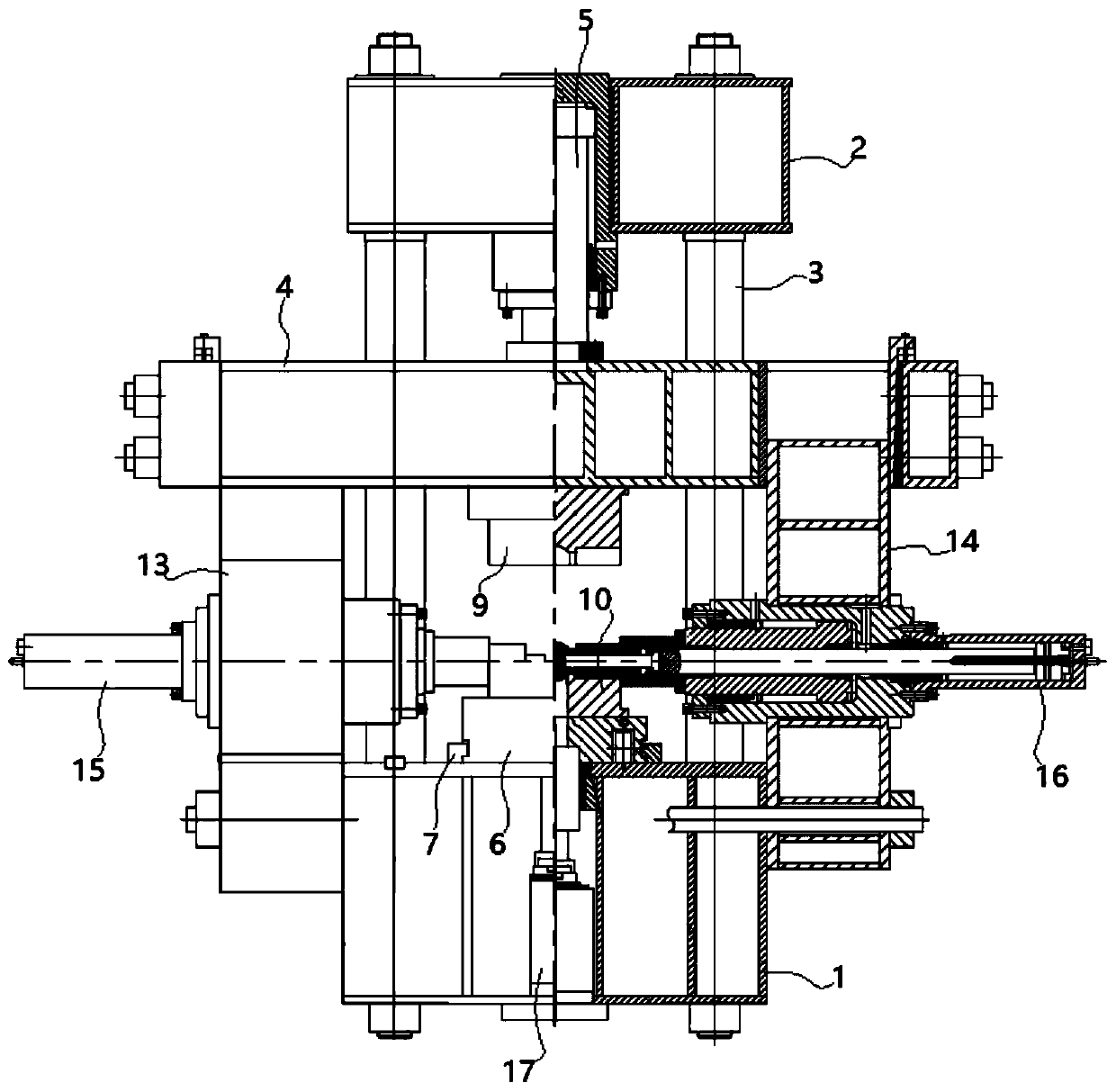

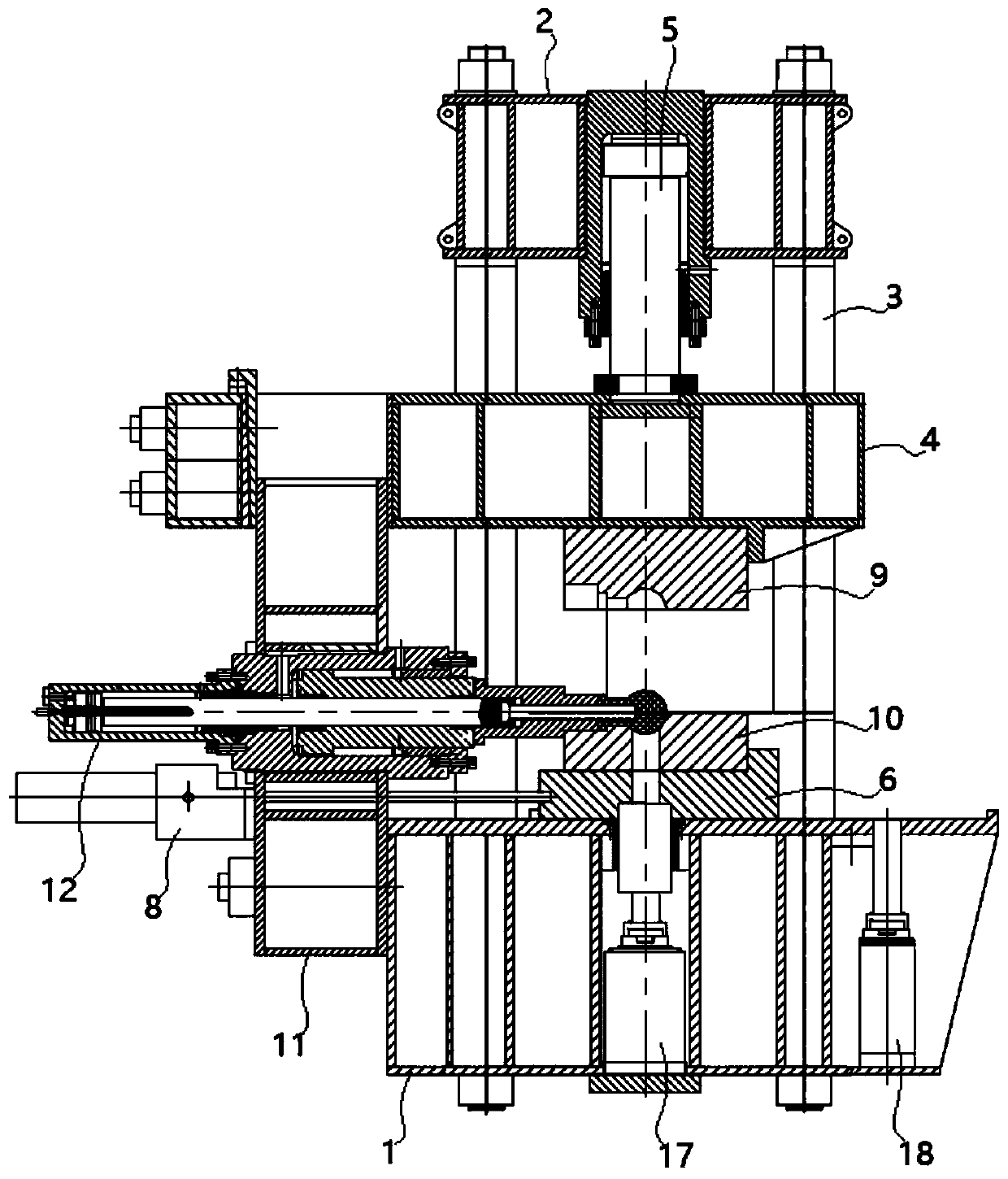

ActiveCN102189210AReduce labor intensityRealization of labor intensityPiercing pressesForging/hammering/pressing machinesPunchingGear wheel

The invention discloses an automatic forging centering device which solves the technical problem in the forging processing in the prior art, particularly in the center hole punching which requires operators to control centering manually according to experience. The device mainly comprises an upper punching component, a lower punching component and a centering component. The upper punching component comprises an upper punch, an upper rotation arm, an upper guide sleeve, a motor A, a rotary shaft sleeve A, a sliding shaft sleeve and the like; the lower punching component comprises a lower rotation arm, a lower punch, a lower guide sleeve, a motor, a rotary gear and the like, wherein the lower guide sleeve is fixed on an stand column of a hydraulic host through a bolt; the centering component comprises two clamp arms, two sets of hydraulic oil cylinders, one set of synchronous gear, a tile seat, a shaft, a lug seat and the like. The tile seat and lug seat are connected with a movable beam of the hydraulic host. As an accessory of a four-column forging hydraulic press, the device is mainly used for automatically processing products such as various flanges, center hole plates and the like, and is particularly suitable for cogging forgings with centre holes. The device can realize automatic continuous production without secondary heating.

Owner:LIAOYANG POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY

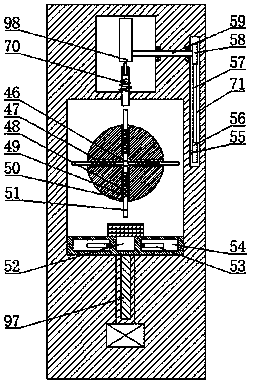

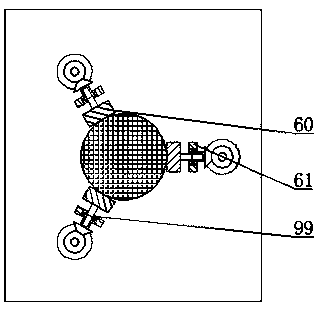

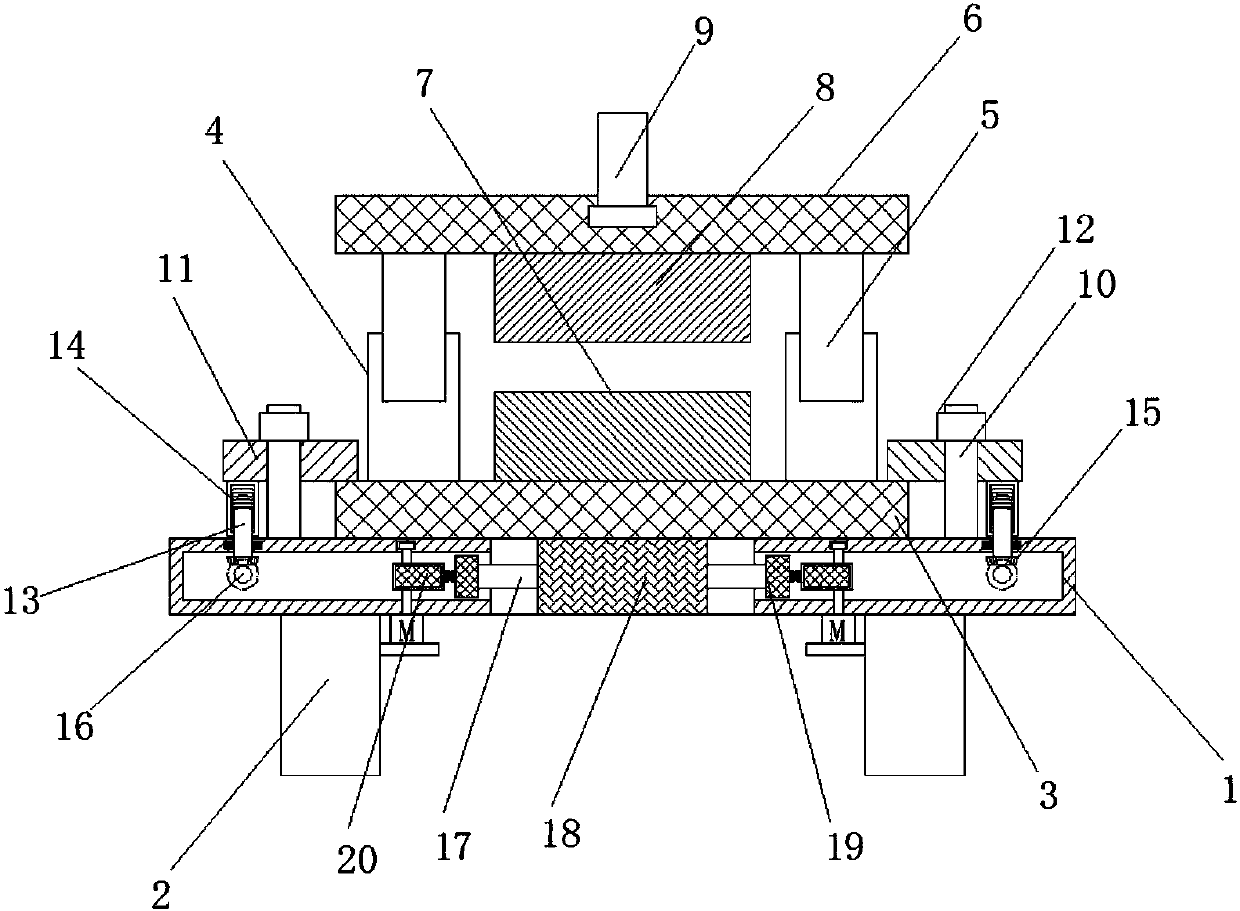

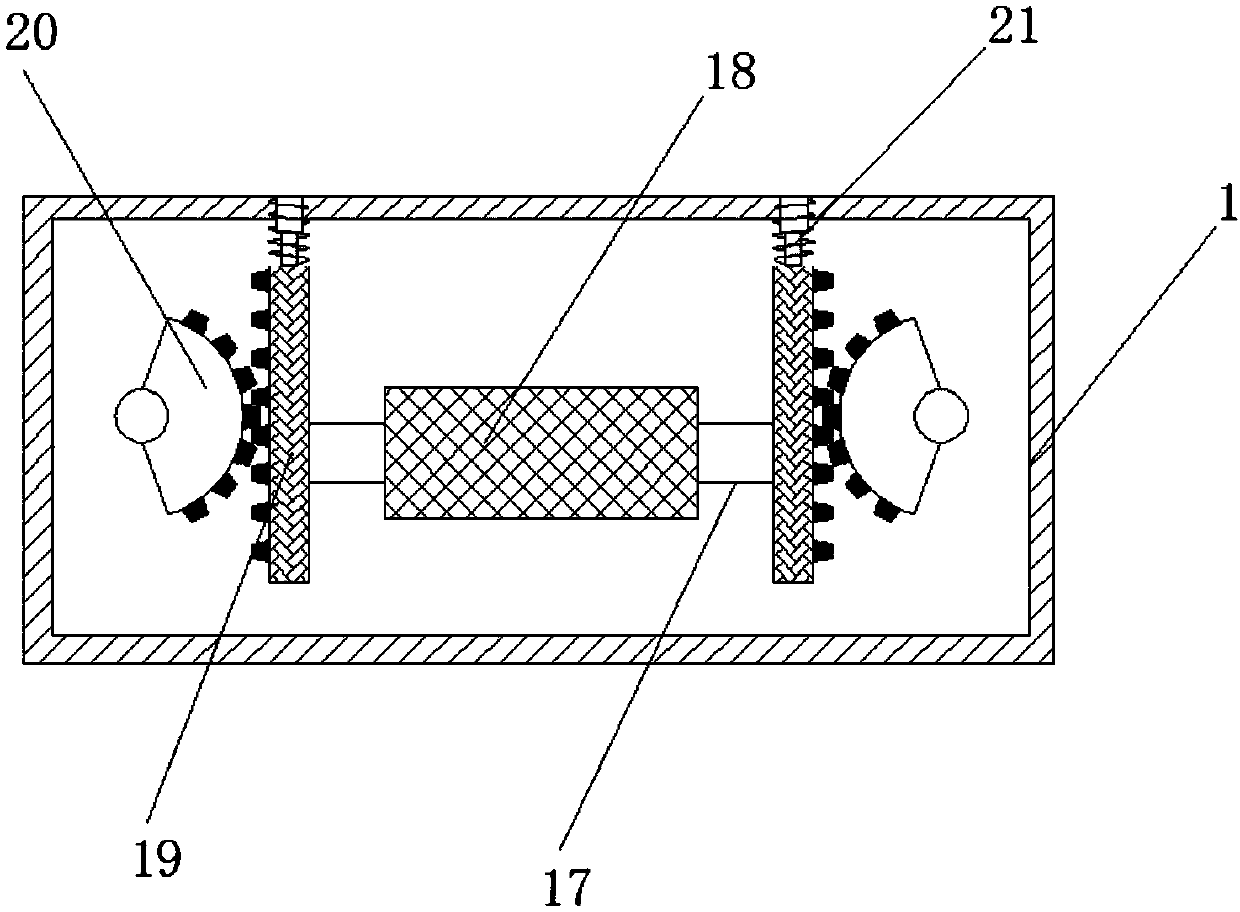

Metal forging device

InactiveCN109290502AAvoid lostAvoid casualtiesPiercing pressesUpsetting pressesEngineeringShape function

The invention discloses a metal forging device. The metal forging device comprises a forging box. The forging box comprises a machining cavity. A clamping jaw mechanism is arranged in the machining cavity. The clamping jaw mechanism comprises a crank. The crank can rotate front and back in the machining cavity. Change of the radius of a part to be machined can be controlled through front-back rotation of the machining cavity. The clamping jaw mechanism further comprises a rolling wheel. The metal forging device is simple in structure and convenient to operate. The metal forging device realizesthe forging, drilling and shaping functions of metal subjected to heat processing. According to the metal forging device, a forging device on the market is combined with a ring machining device, andlosses or personnel casualties caused by material falling in the process of transporting materials can be avoided.

Owner:台州椒江佑沐智能科技有限公司

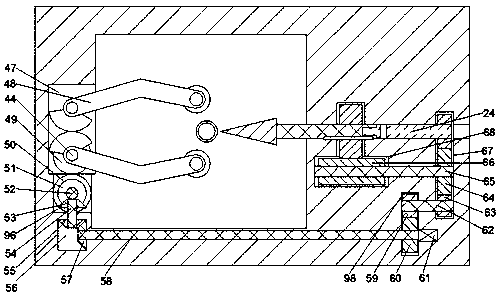

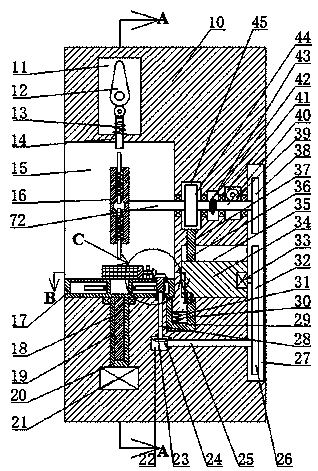

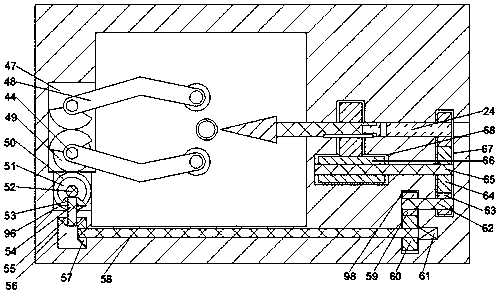

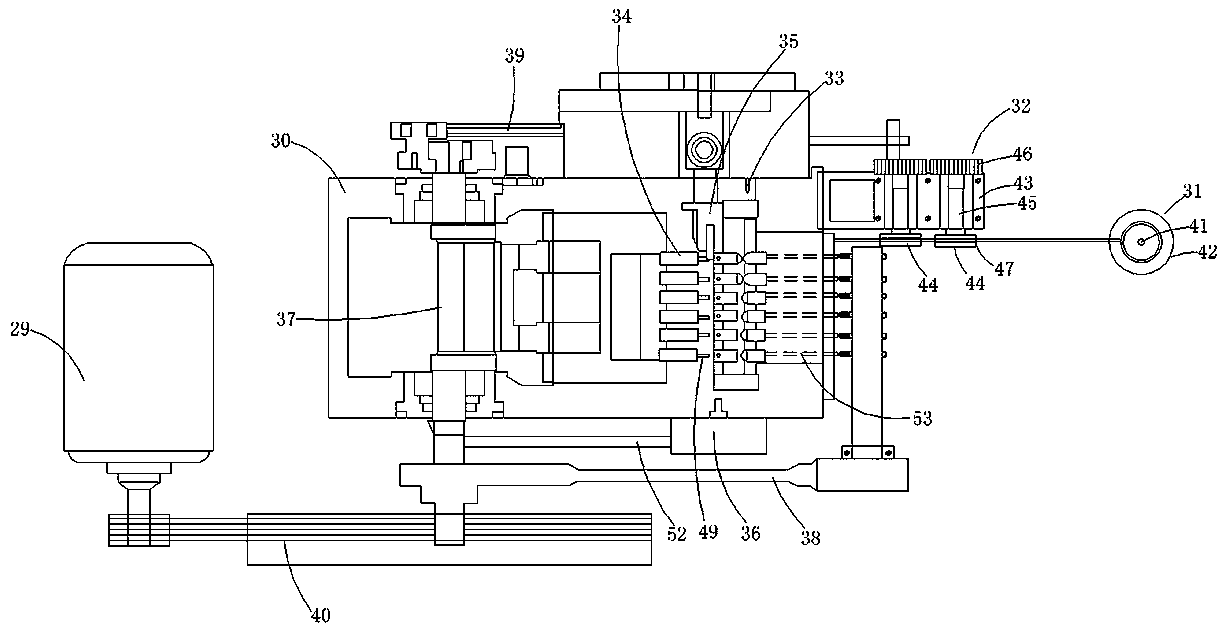

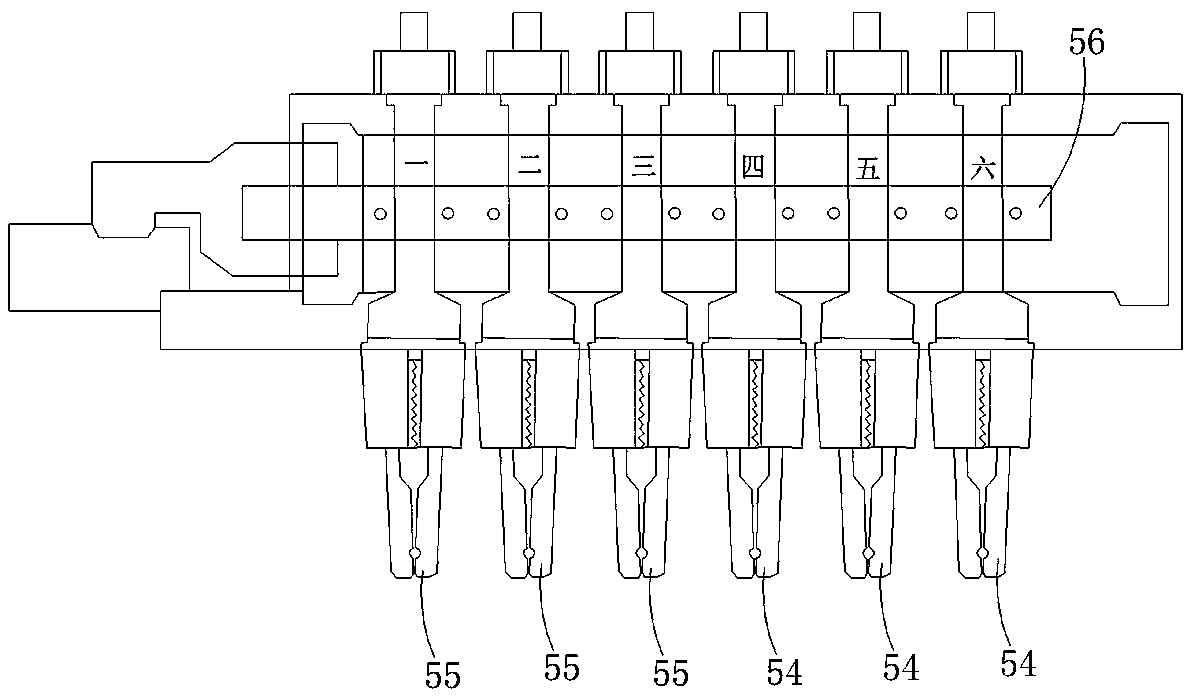

Processing equipment and processing method for gasification furnace body

PendingCN110125296AGuaranteed uptimeImprove processing efficiencyPiercing pressesForging/hammering/pressing machinesProduction effectEngineering

The invention discloses processing equipment and a processing method for a gasification furnace body. The processing equipment is a multi-station side surface double-hole cold header, belongs to the technical field of cold headers and solves the problem that the gasification furnace body is produced by adopting a cold heading technique. The processing equipment comprises a machine body which is provided with a mold; the rear end of the machine body is provided with a crankshaft; one end of the crankshaft is connected with a motor through a belt bull wheel, wherein the motor is used for controlling the crankshaft to rotate; the crankshaft is provided with a connecting rod; the machine body is provided with a slider which is driven by the connecting rod; the machine body is provided with a double-hole stamping device which is used for stamping a product for formation; the double-hole stamping device is in transmission connection with the crankshaft; and the processing method realizes step-by-step processing by adopting the equipment; and a high-efficiency reliable production effect is achieved.

Owner:王刚

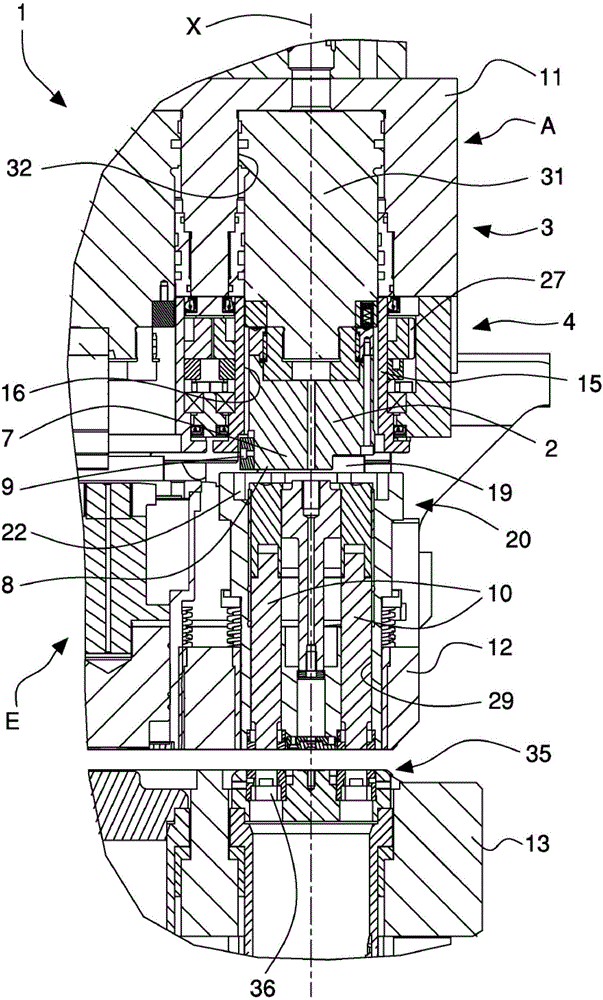

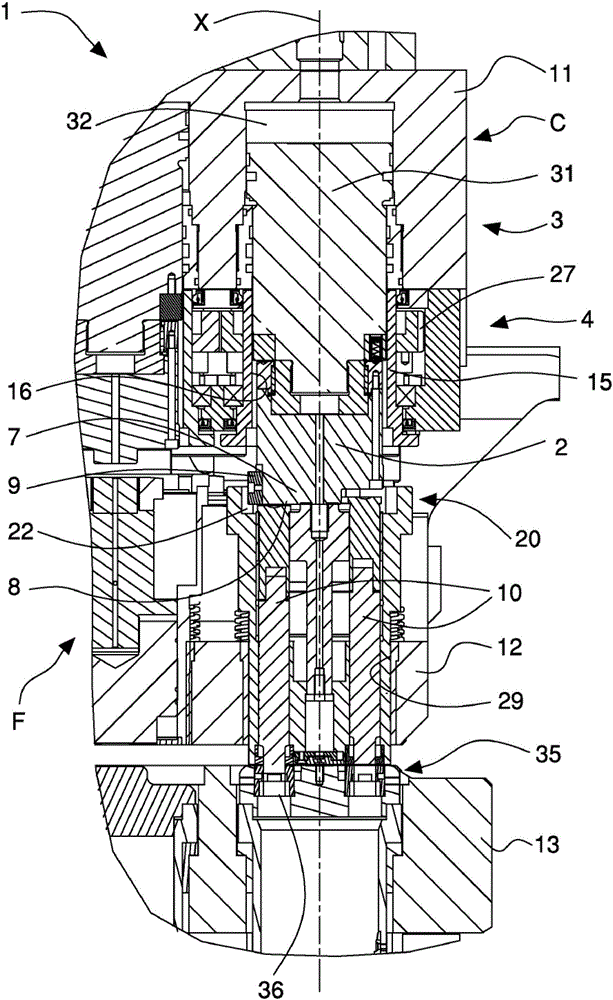

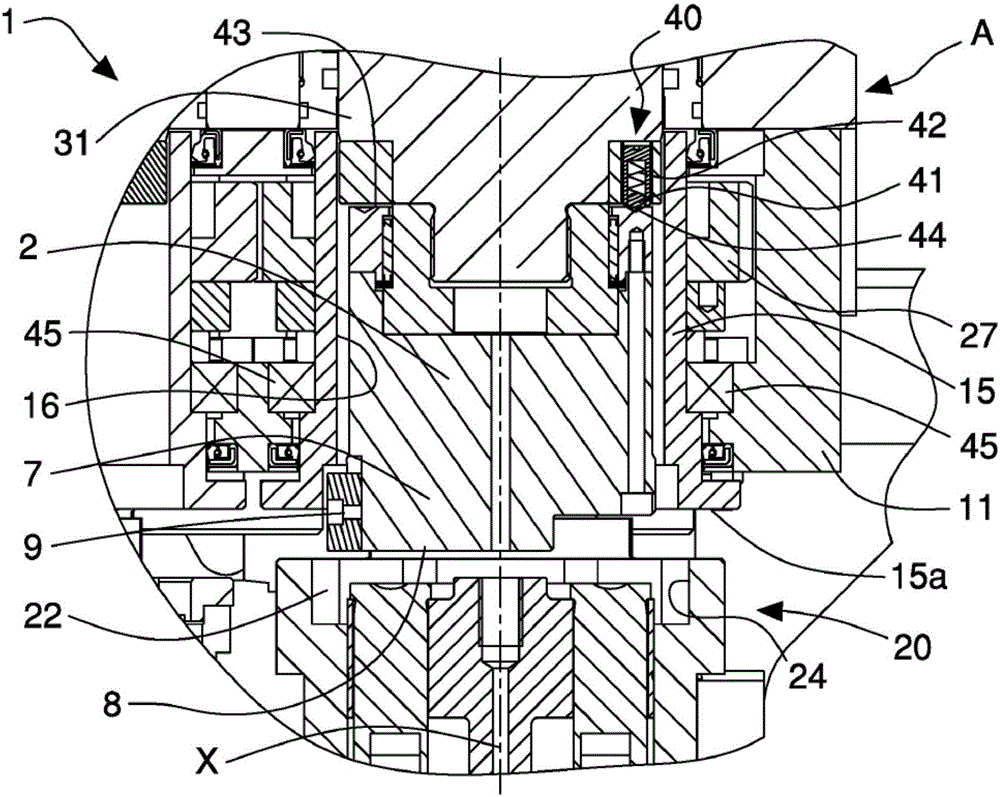

Punching apparatus

A punching apparatus comprises a tool holder unit (20) rotatable around a working axis (X) and provided with a plurality of seats (21) suitable for slidably housing respective punching tools (10), a beating element (2) movable along and around the working axis (X) and provided with an operating end (7) having a beating portion (8), to selectively interact with a set punching tool (10), first driving means (3) for moving the beating element (2) along the working axis (X) so as to move set punching tool (10) and second driving means (4) for rotating the tool holder unit (20) around the working axis (X); the operating end (7) of the beating element (2) comprises a first coupling element (9) and the tool holder unit (20) comprises a plurality of second coupling elements (22) each of which is associated with a respective seat (21) and arranged to couple with the first coupling element (9) in a connection configuration (F) in which the beating element (2) and the tool holder unit (20) are coupled and rigidly rotate; the second driving means (4) in a selection configuration (E) rotates the tool holder unit (20) for positioning the set punching tool (10) so that the latter faces the beating portion (8) of the operating end (7) and allows the first coupling element (9) to couple with the second coupling element (22) that is associated with the seat (21) of the set punching tool (10) and, in the connection configuration (F), rotates the tool holder unit (20) and the beating element (2) which are mutually connected for angularly orienting the set punching tool (10).

Owner:SALVAGNINI ITAL

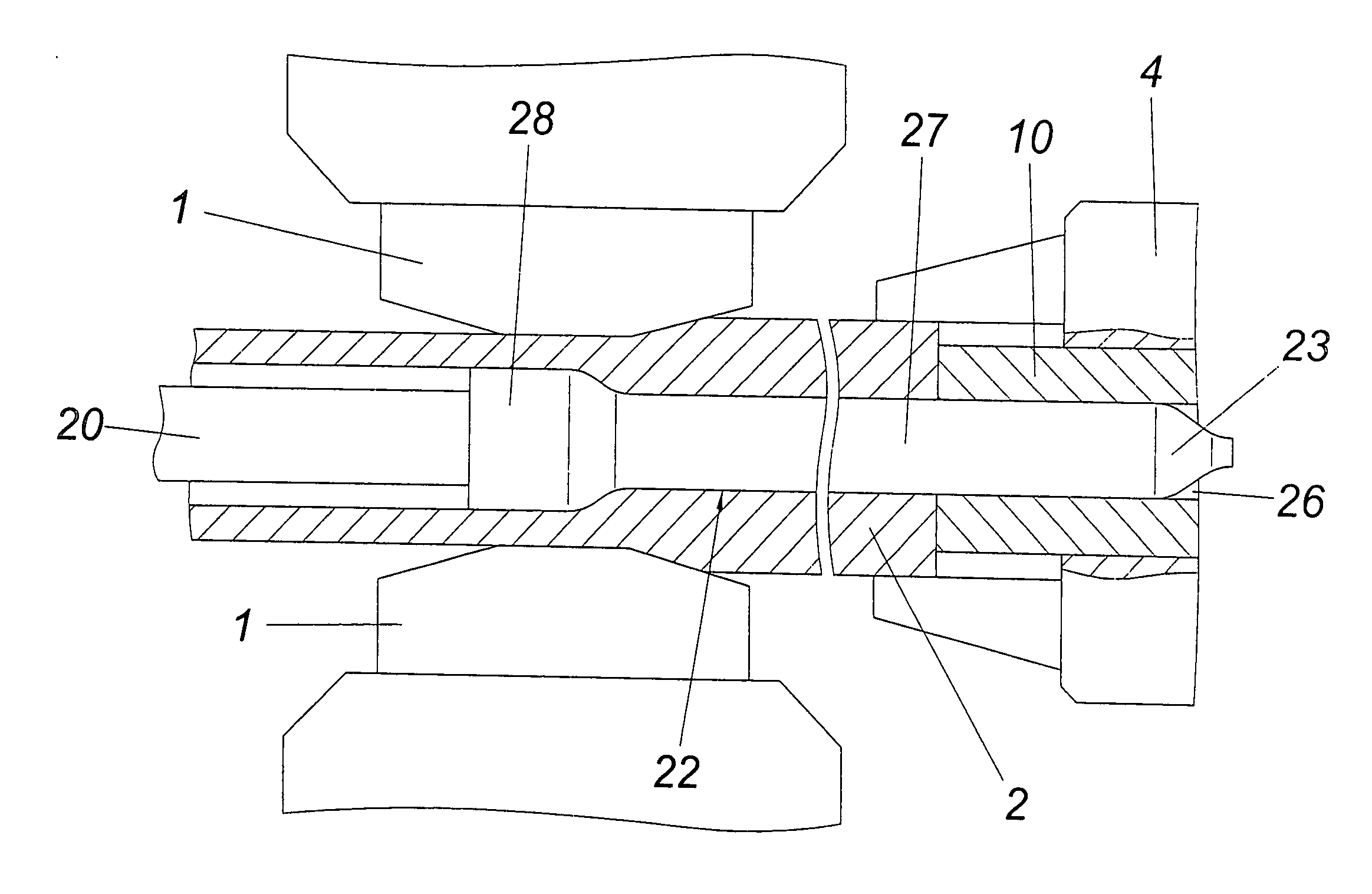

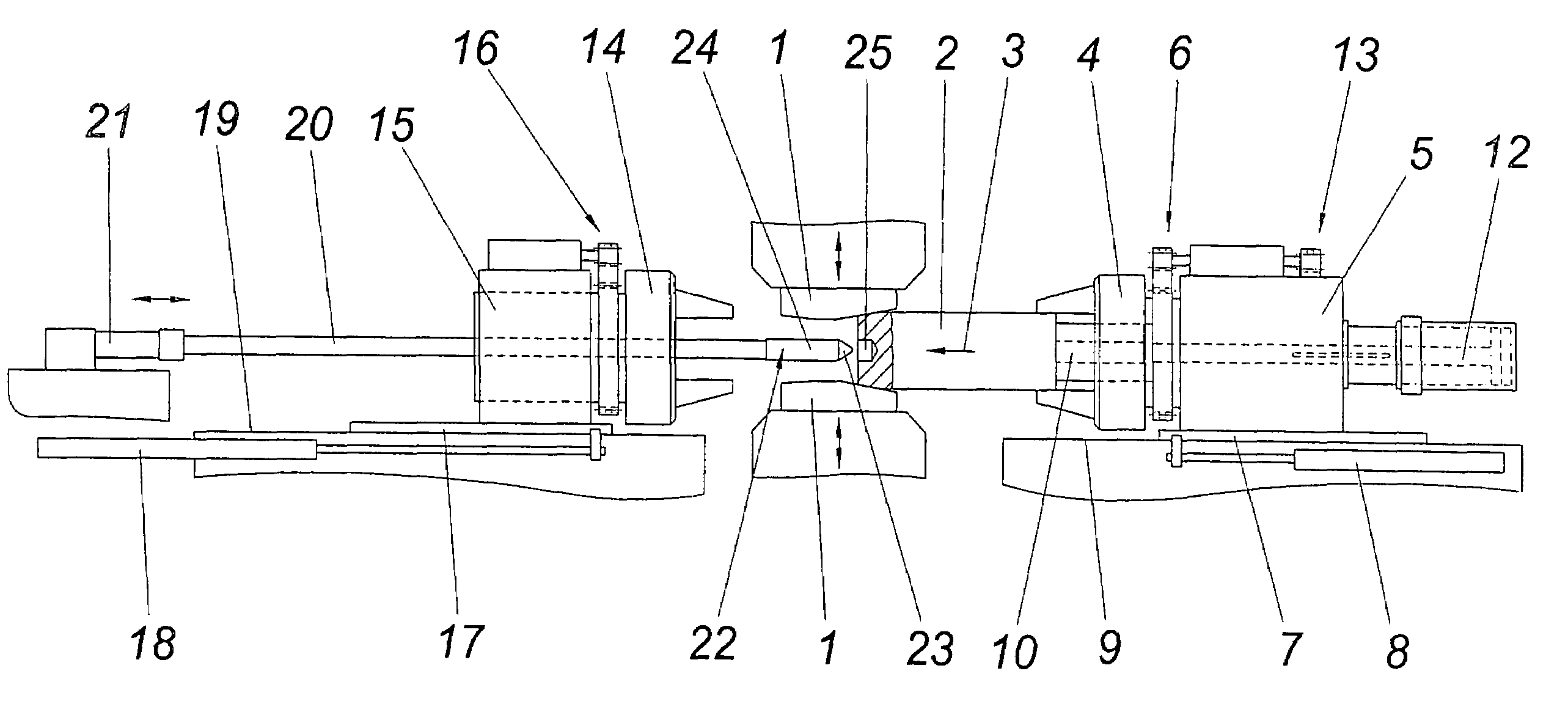

Method and apparatus for producing a cylindrical hollow body from a blank

ActiveUS7434434B2Feed of the workpiece can be increased considerablyImprove construction conditionsForging hammersPiercing pressesEngineeringAxial force

A method is described for producing a cylindrical hollow body from a blank, with the workpiece being opened in the core region by successive swaging which is angularly offset against each other about the axis of the workpiece and being simultaneously pushed onto a piercing mandrel. In order to improve the piercing it is proposed that the workpiece is pressed during the swaging with a predeterminable axial force against the piercing mandrel which can be advanced against the workpiece against this axial force, which piercing mandrel is moved back to its initial position synchronous with the axial feed of the workpiece between the successive swaging steps.

Owner:GFM BETEILIGUNGS & MANAGEMENT

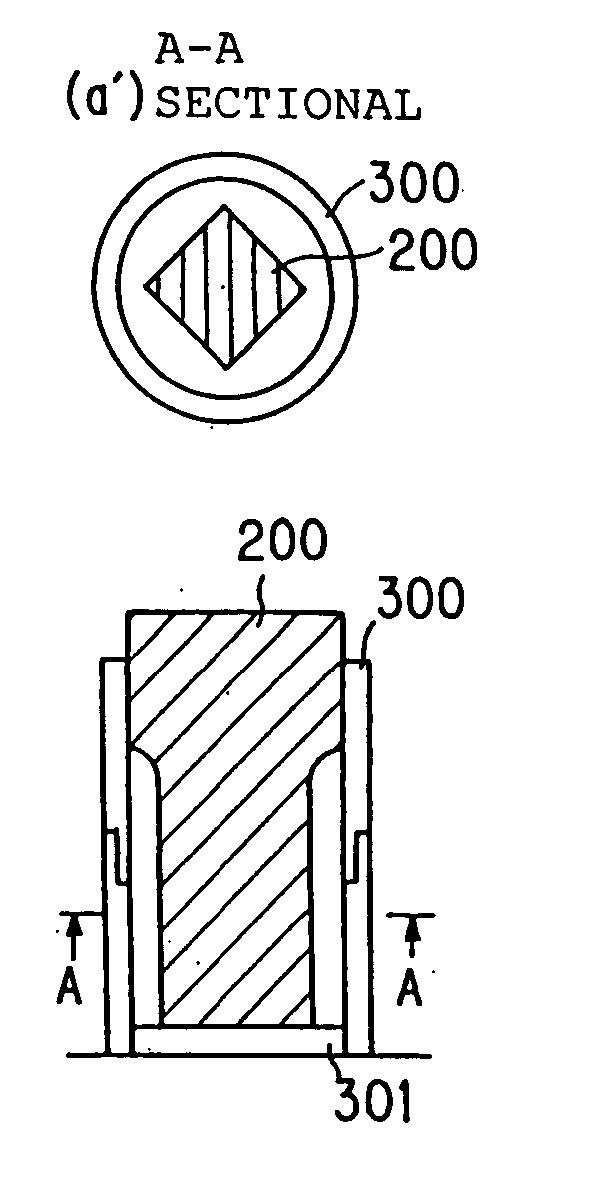

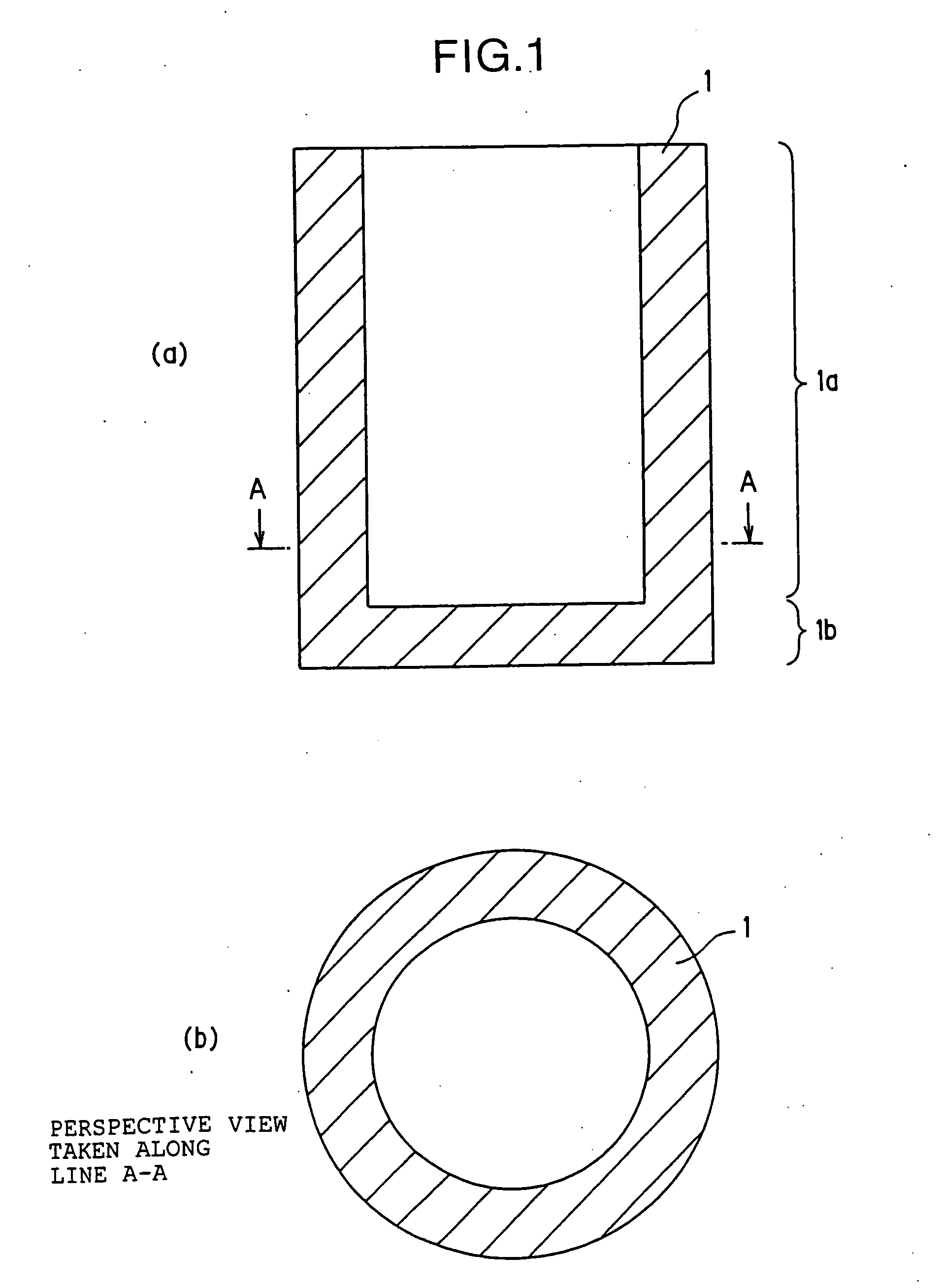

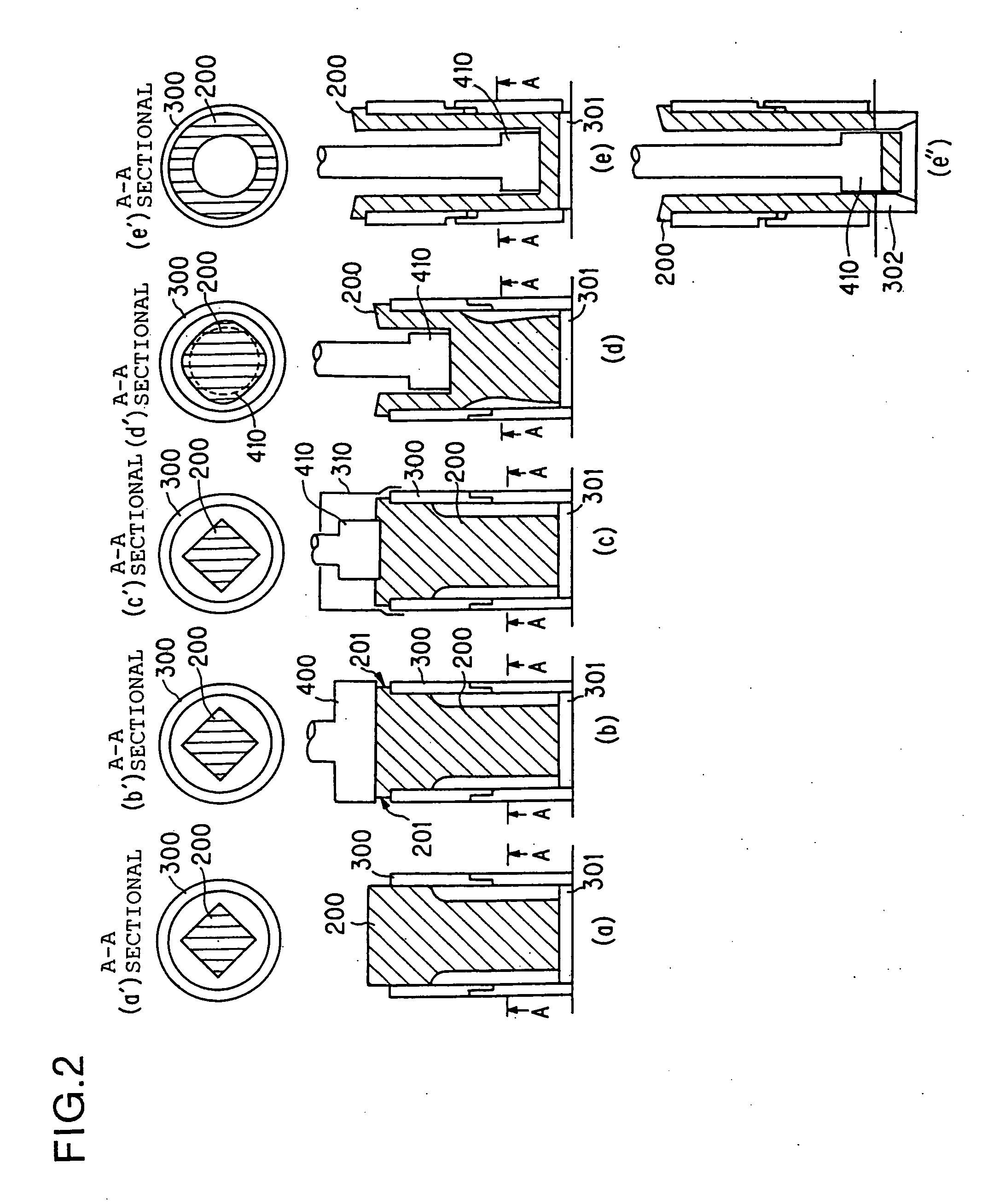

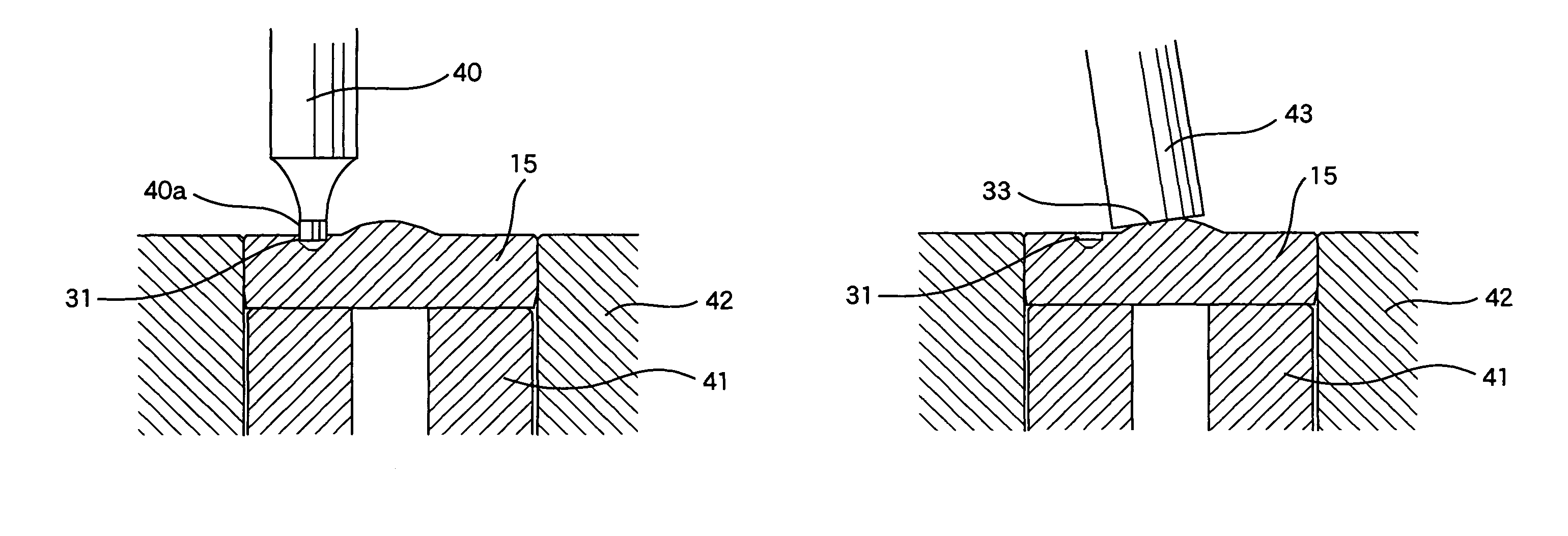

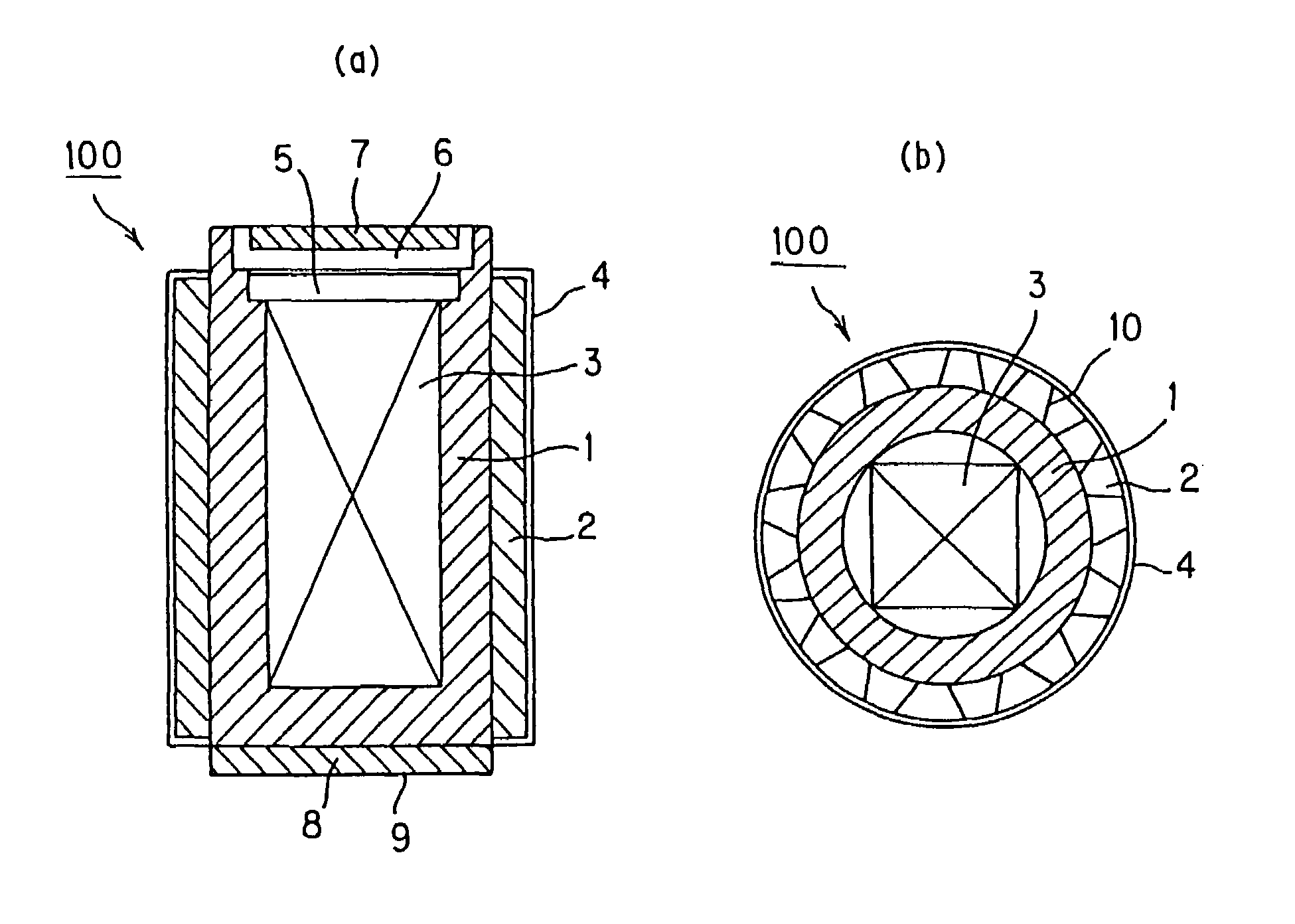

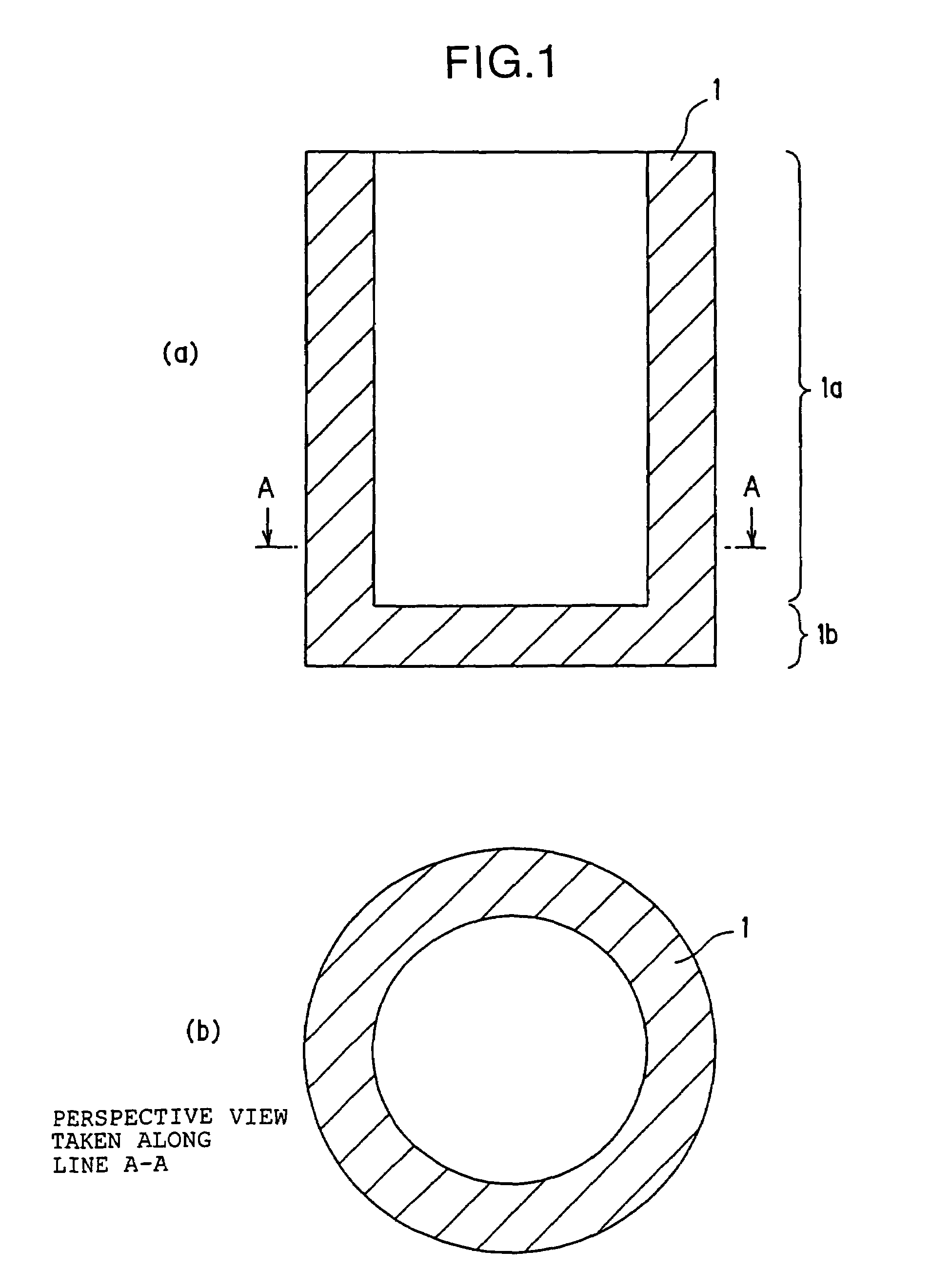

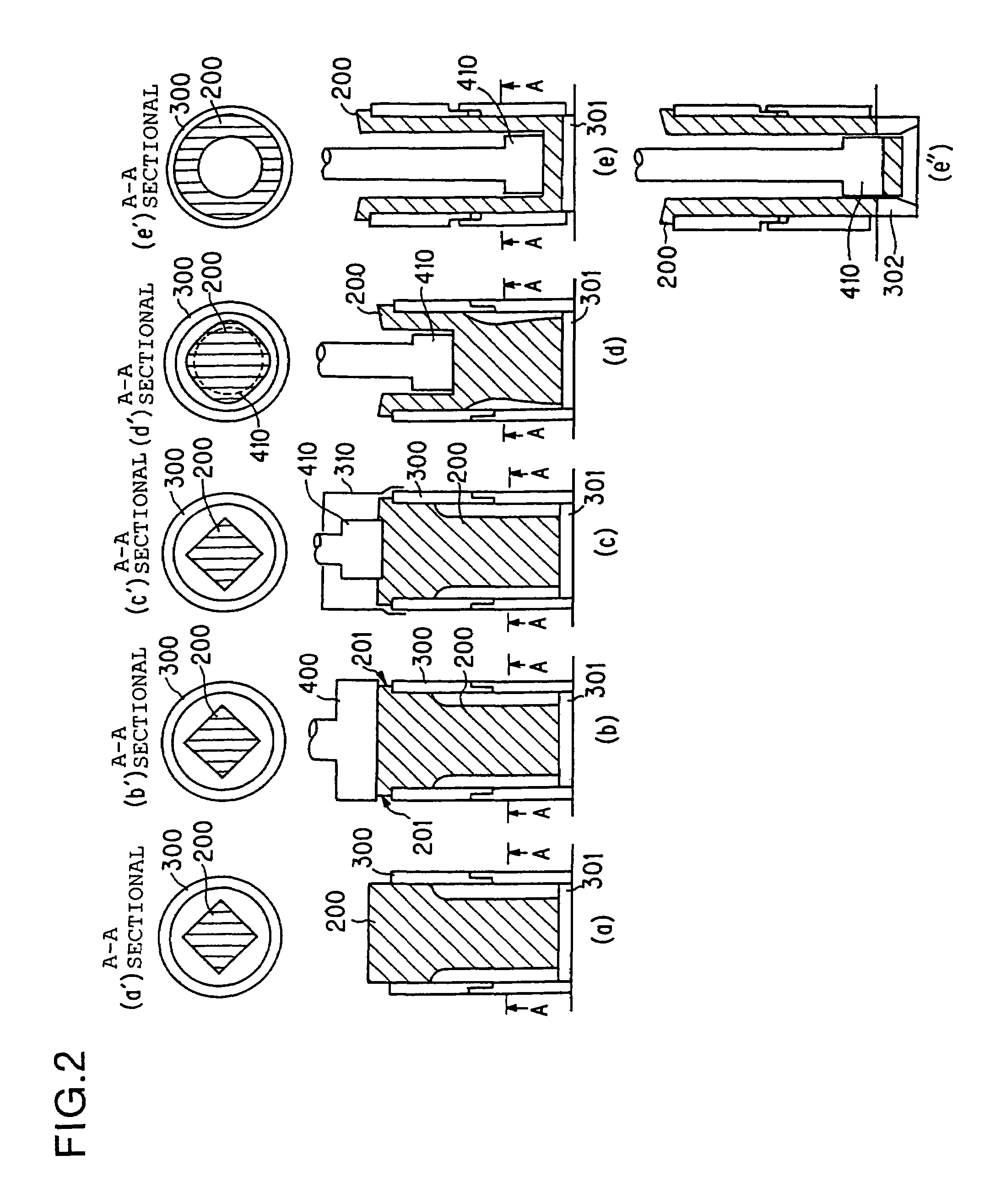

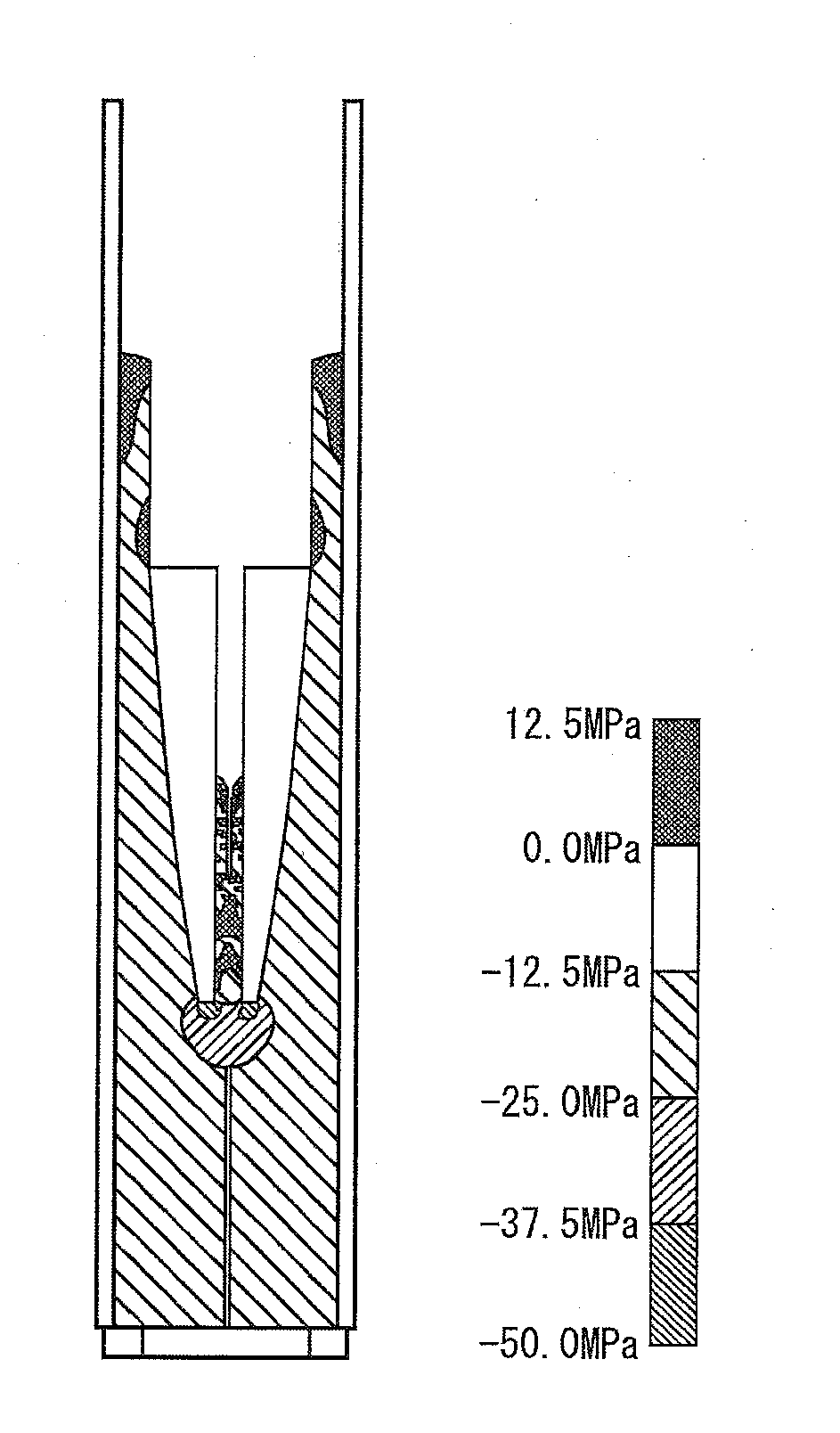

Radioactive substance container, manufacturing apparatus thereof and manufacturing method thereof

InactiveUS20050087704A1Increase in press pressure can be suppressedProduced moreNuclear energy generationPiercing pressesRadioactive agentManufactured apparatus

In the metal billet to be used for hot dilation forming, a forward side with respect to the pressing direction has a quadrate section and its diagonal length is not more than an inner diameter of a container. Moreover, a backward side with respect to the pressing direction has a circular section and its diameter is substantially same as the inner diameter of the container. The metal billet is heated to a temperature suitable for press working and is set into a container for press forming. While a center of a workpiece of the metal billet is being bored by a boring punch to be operated by a pressing machine, the metal billet is hot-dilated so that a bottomed container for a cask is formed.

Owner:MITSUBISHI HEAVY IND LTD

Injection valve and method of making orifice

InactiveUS7874070B2Easy to processImprove homogeneityValve arrangementsPiercing pressesVena contracta diameterNeedle position

An injection valve has a nozzle body, a valve needle positioned in the nozzle body, an actuator for actuating the valve needle, and an orifice plate fixed at an end of the nozzle body. The orifice plate has a valve seat for cooperating with the valve needle and an orifice for injecting a fluid. The orifice plate is provided with a projection having a convex-curved surface on an orifice outlet side of the orifice plate. A flat surface portion is formed in the area of the convex-curved surface, and the outlet of the orifice is located in the flat surface portion.

Owner:HITACHI LTD

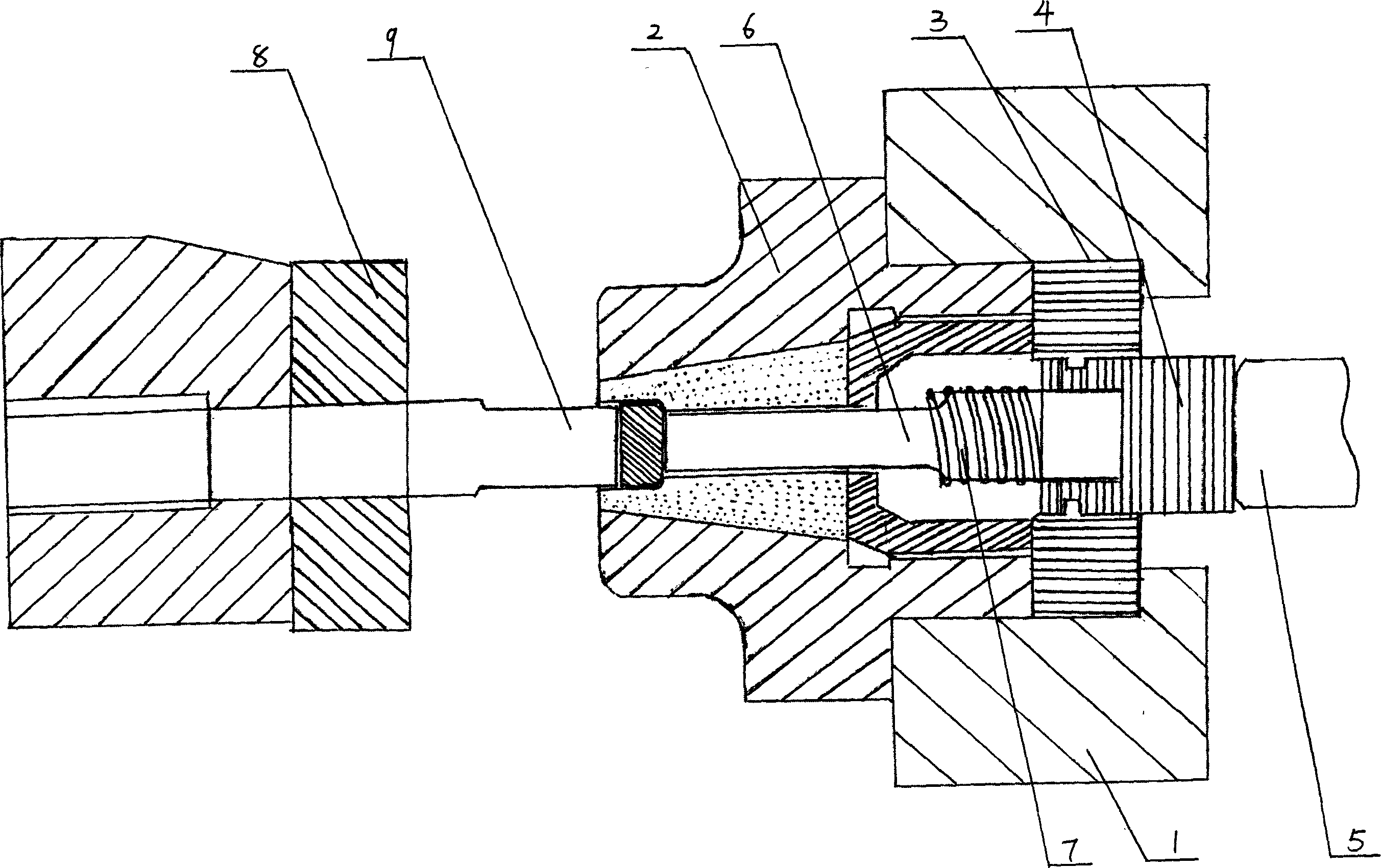

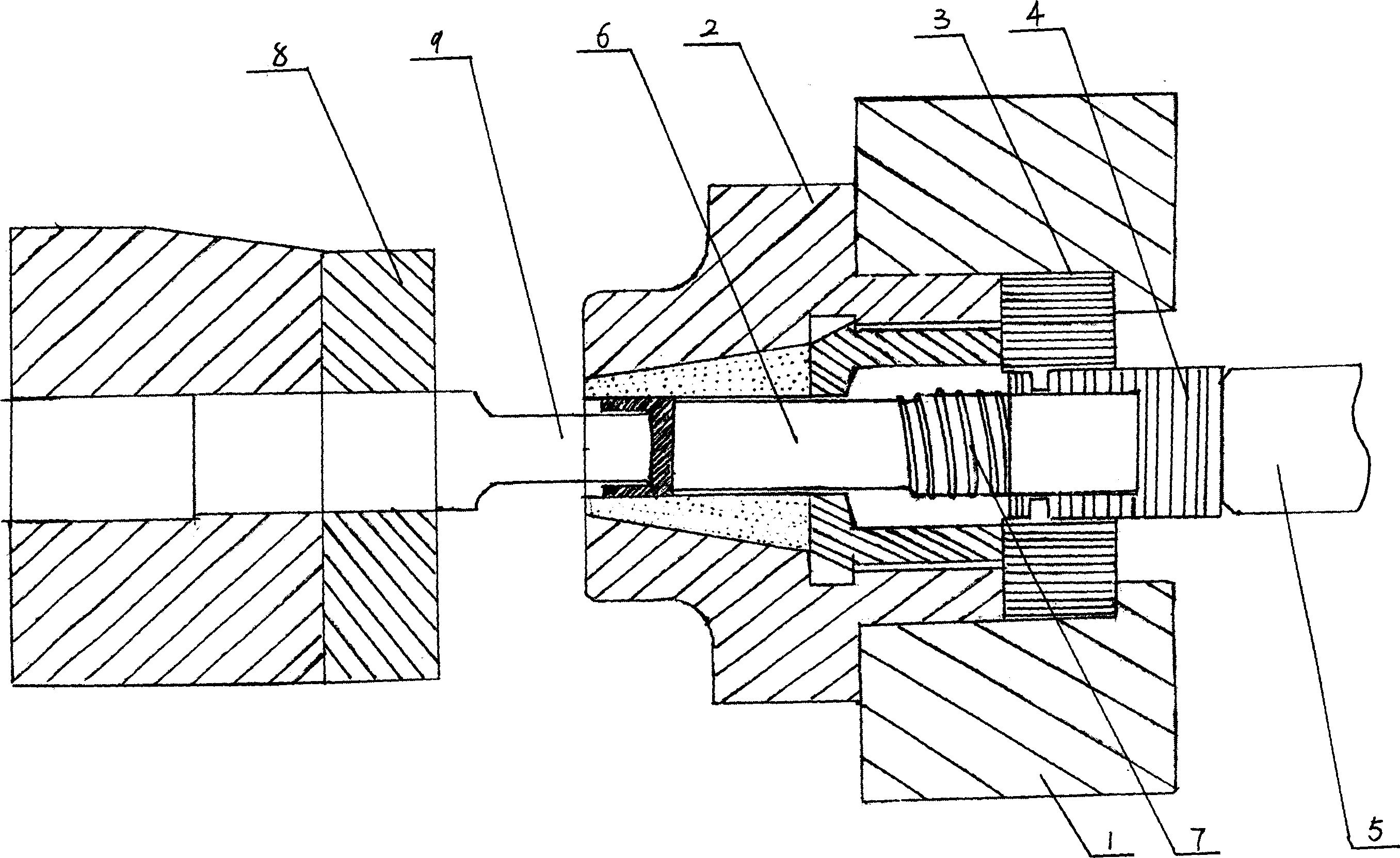

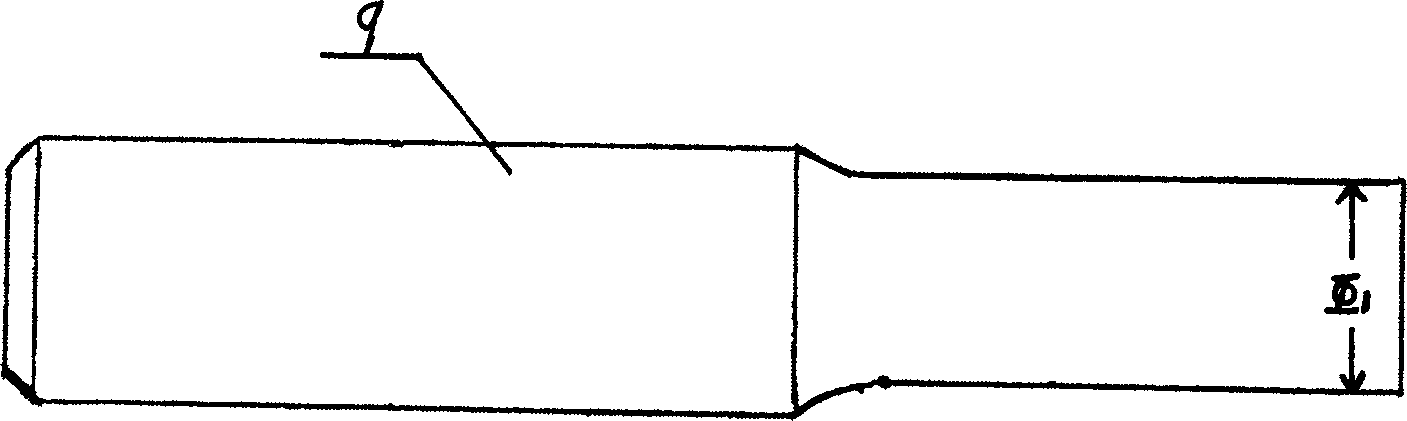

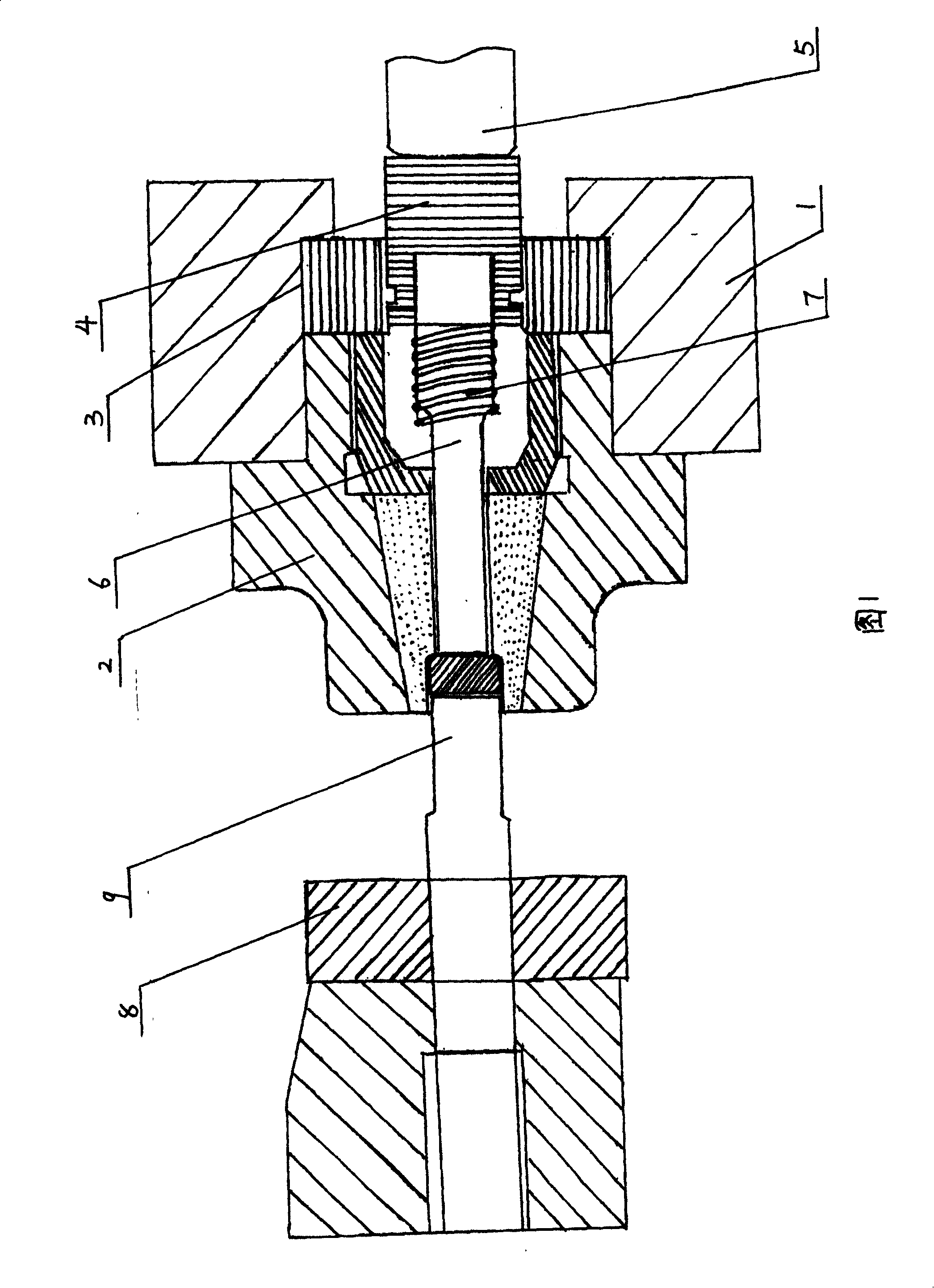

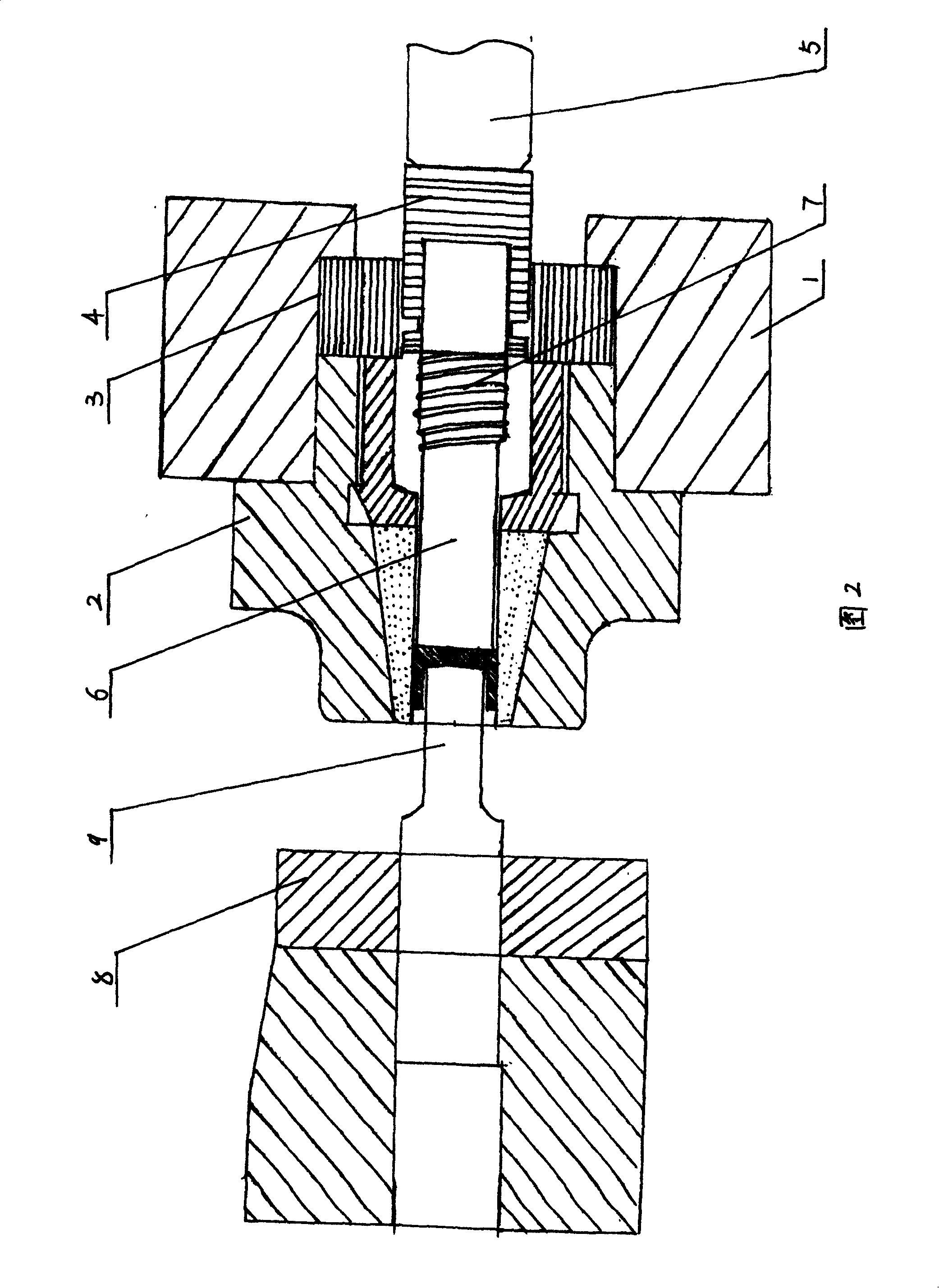

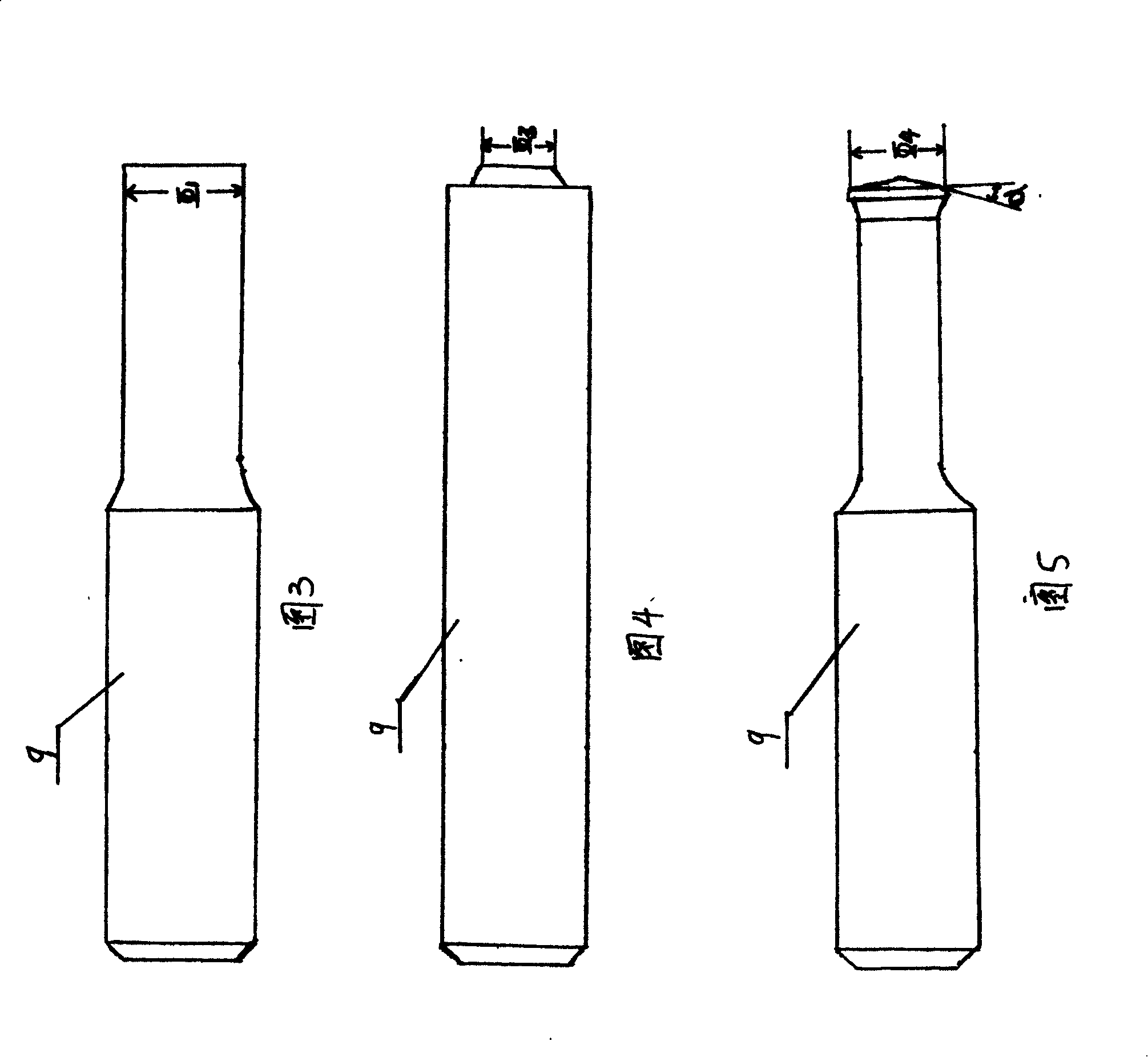

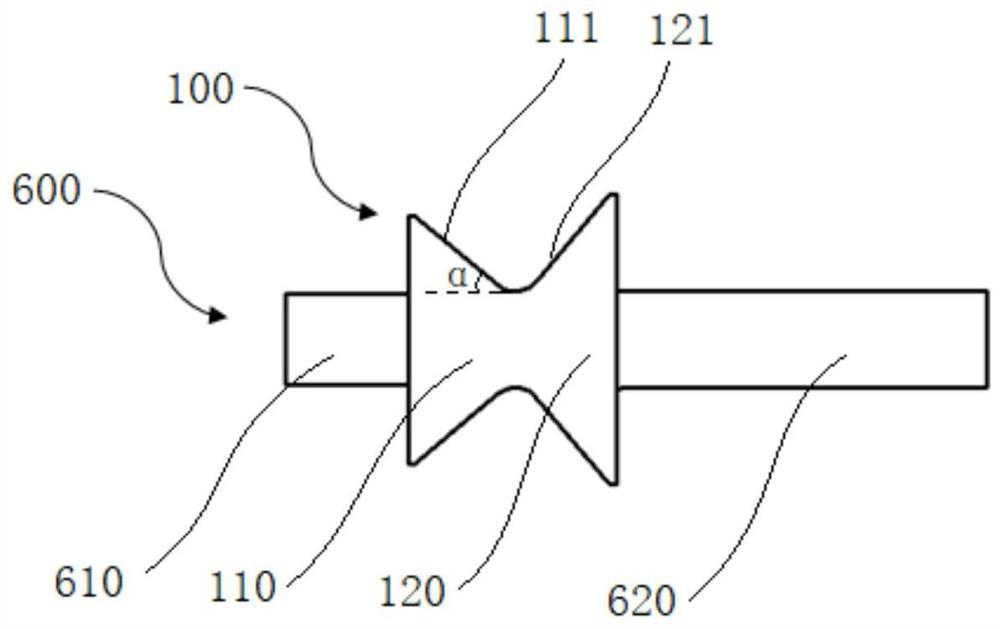

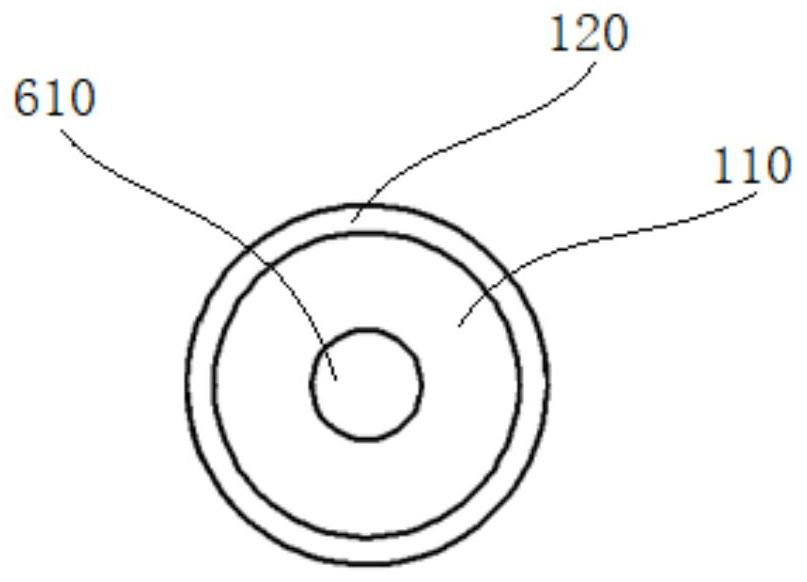

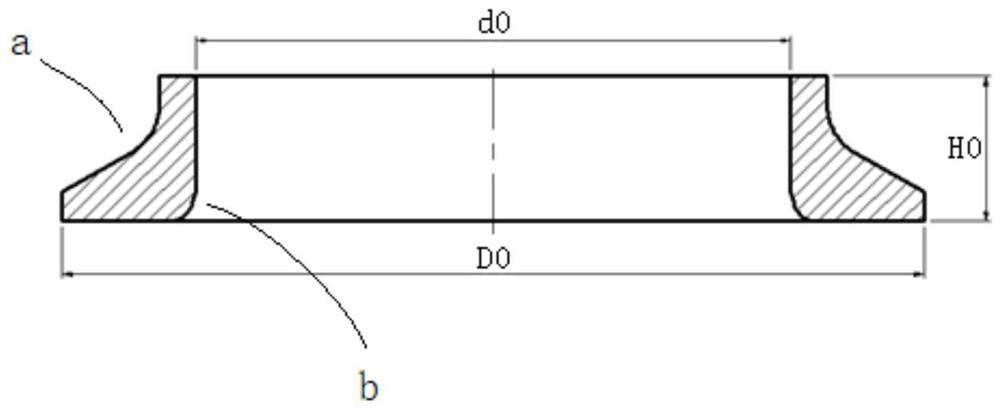

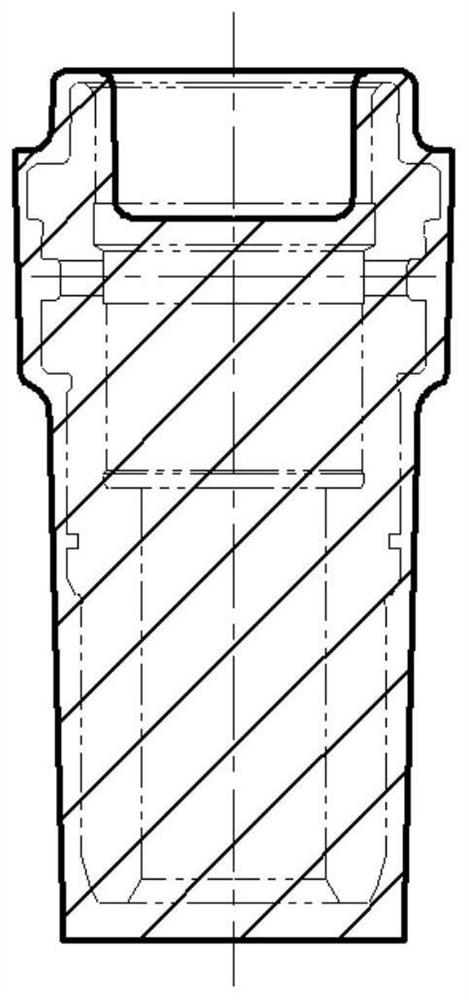

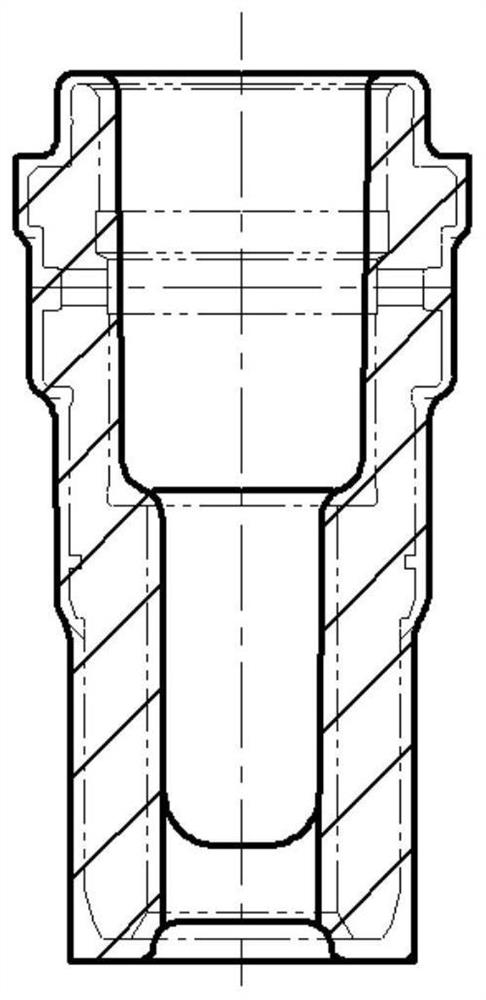

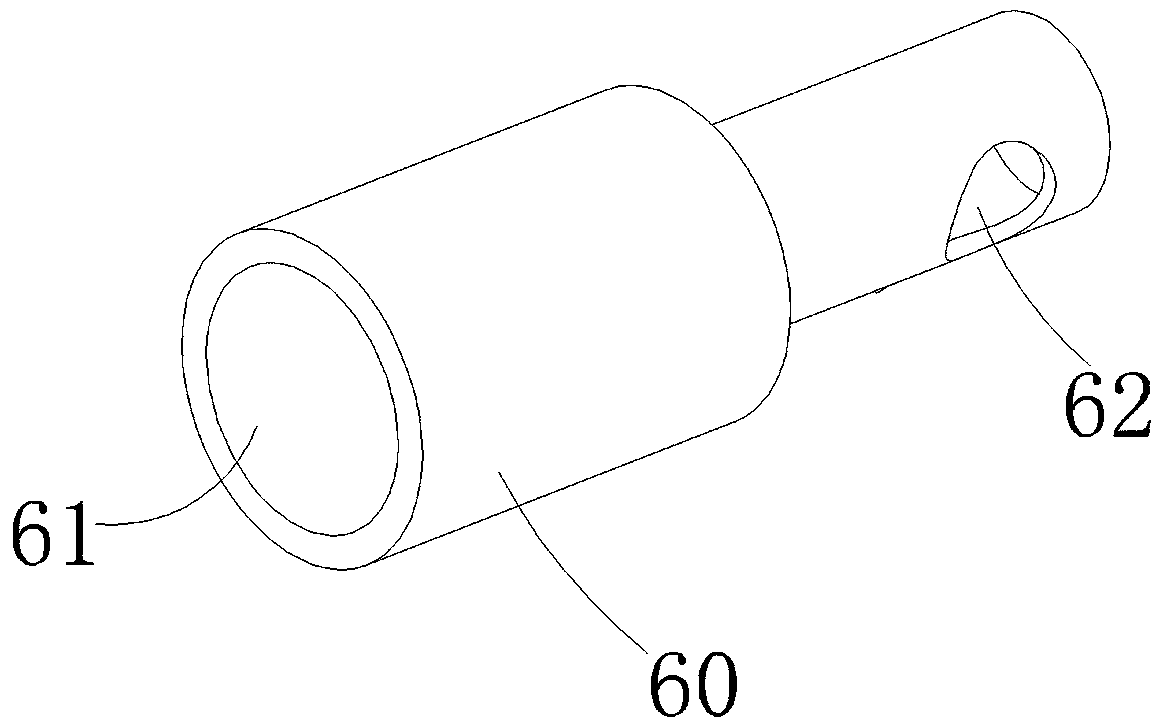

Universal-joint sleeve blank cold-upsetting formation art, and equipment therefor

ActiveCN1861290AReduce pollutionReduce defective ratePiercing pressesUpsetting pressesUniversal jointEngineering

A cold upset technology for manufacturing the axle sleeve blank of universal joint by use of a dedicated apparatus is disclosed. Said dedicated apparatus has a die case and a clamp for front punch rod. Said die case has die shell made of W steel, die core with internal cavity, and front and back punch rod. 1-4 dies are used.

Owner:HANGZHOU NEW CENTURY UNIVERSAL JOINT

Universal-joint sleeve blank cold-upsetting formation art, and equipment therefor

ActiveCN100409970CReduce pollutionReduce defective ratePiercing pressesUpsetting pressesUniversal jointEngineering

A cold upset technology for manufacturing the axle sleeve blank of universal joint by use of a dedicated apparatus is disclosed. Said dedicated apparatus has a die case and a clamp for front punch rod. Said die case has die shell made of W steel, die core with internal cavity, and front and back punch rod. 1-4 dies are used.

Owner:HANGZHOU NEW CENTURY UNIVERSAL JOINT

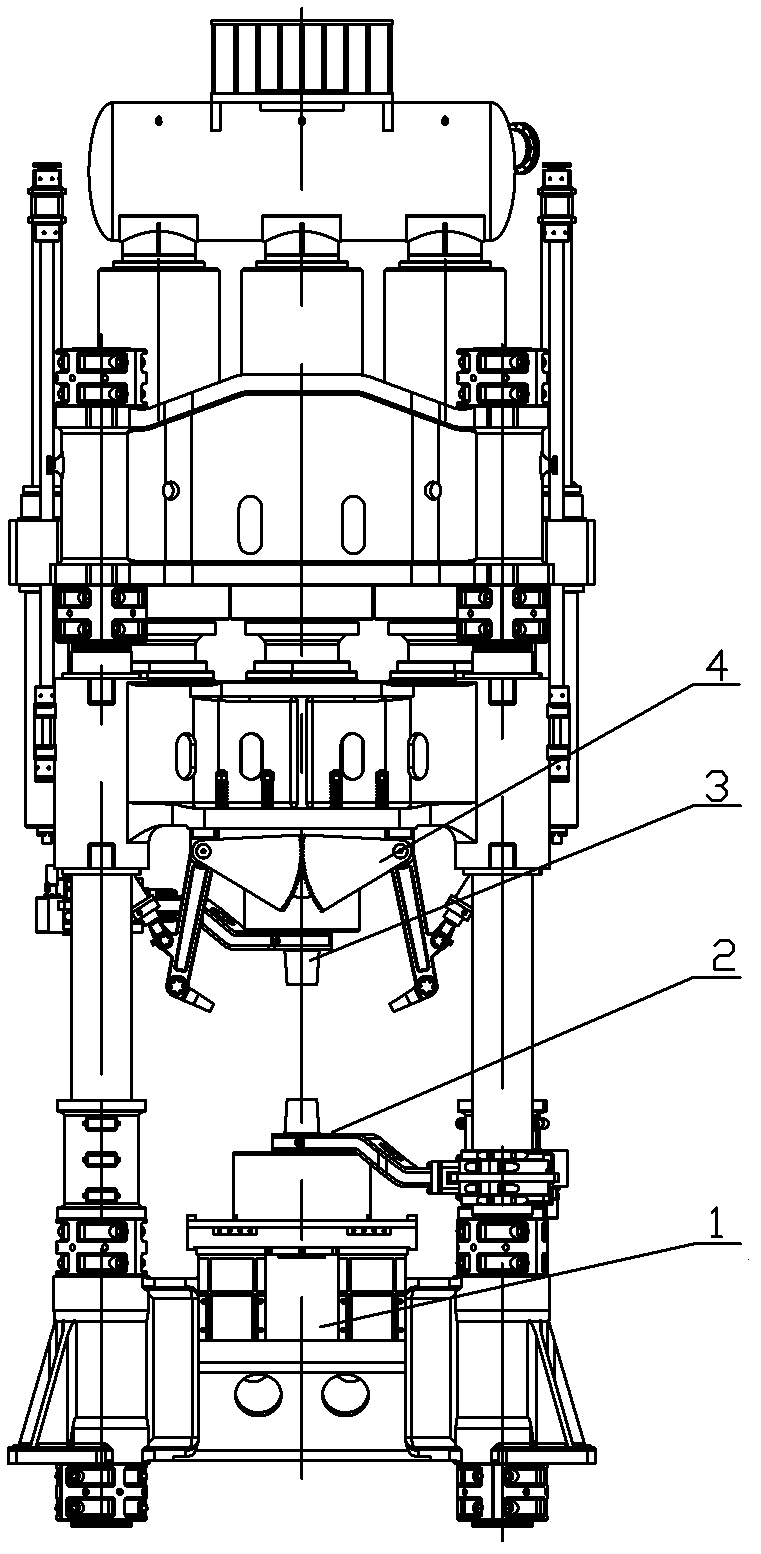

Multidirectional die-forging hydraulic press of novel structure

InactiveCN110586829AReduce weightHigh precisionPiercing pressesUpsetting pressesEngineeringHydraulic press

The invention provides a multidirectional die-forging hydraulic press of a novel structure. The multidirectional die-forging hydraulic press comprises a lower cross beam, an upper cross beam and standcolumns. The lower cross beam is transversely arranged, and the upper cross beam is located above the lower cross beam and is parallel to the lower cross beam. One pair of stand columns is arranged and located between the lower cross beam and the upper cross beam, and the stand columns are vertically arranged and are parallel. The top ends of the stand columns are fixedly connected with the uppercross beam, and the bottom ends of the stand columns are fixedly connected with the lower cross beam. A main rack is formed by the upper cross beam, the lower cross beam and the stand columns. A movable cross beam is further included and located between the upper cross beam and the lower cross beam, and is parallel to the upper cross beam and the lower cross beam. A die assembling cylinder is mounted between the upper cross beam and the movable cross beam, and drives the movable cross beam to ascend and descend. A workbench is further included and mounted on the lower cross beam through a guide rail, the guide rail extends from the rear side of the lower cross beam to the front side of the lower cross beam, and a movable workbench cylinder is mounted on the lower cross beam; and a pistonrod of the movable workbench cylinder is connected with the workbench, and the movable workbench cylinder drives the workbench to move front and back.

Owner:SHANGHAI DIANJI UNIV

Forming device and method for maritime work replacing looping forging

ActiveCN112371887AImprove molding efficiencyImprove production utilizationPiercing pressesForging/hammering/pressing machinesIndustrial engineeringSupport surface

The invention discloses a forming device and method for a maritime work replacing looping forging. The forming device comprises a supporting block, an upper flat anvil and an upper swage block; the supporting block comprises a first supporting surface and a second supporting surface; the first supporting surface and the second supporting surface are oppositely and obliquely arranged to form a 90-degree V-shaped groove; the V-shaped groove is used for supporting a part of a to-be-machined workpiece; the upper flat anvil comprises a horizontal working surface; the horizontal working surface is used for extruding the workpiece located on the supporting block along the center line of the V-shaped groove; the upper swage block comprises a forming surface matched with the outer contour surface of the maritime work replacing looping forging; and the forming surface is used for extruding the workpiece located on the supporting block along the center line of the V-shaped groove after the horizontal working surface is extruded. According to the forming device and method, the traditional upsetting and stripping forming mode of the maritime work replacing looping forging is changed, the problems that folding is produced easily with the upsetting and stripping forming mode and the profiling degree is low are solved, and the forming efficiency and the product utilization rate of the maritimework replacing looping forging are increased.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD

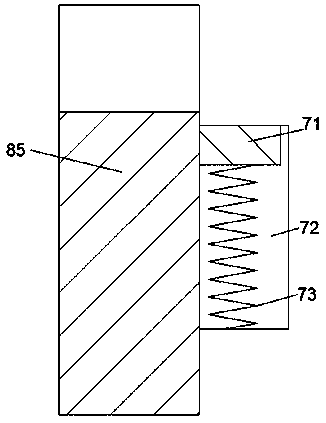

High-thickness blank through hole forging device

InactiveCN111069508AForging realizationGuaranteed deformationPiercing pressesForging/hammering/pressing machinesEngineeringMachine

The invention relates to the field of application of forging technologies, in particular to a high-thickness blank through hole forging device. The high-thickness blank through hole forging device includes a machine body and a forging cavity arranged in the machine body and provided with a leftward opening, a supporting plate is arranged in the forging cavity in an up-and-down sliding manner, three clamping blocks arranged in a sliding manner are annularly arranged on the top wall of the supporting plate, a clamping device arranged in the supporting plate drives the clamping blocks to get close to the center of the supporting plate simultaneously, and blank clamping is realized. By means of the high-thickness blank through hole forging device, high-thickness blank center through hole forging can be realized, blank fixing and blank centering can be achieved during forging of the device, meanwhile, gradual forging of blank center through holes can be realized through the device, and deformation caused by long-time contact and extrusion between a forging column and a high temperature blank is ensured.

Owner:NINGBO XICHE MECHANICAL TECH CO LTD

Method for performing metal forging by using metal forging device

The invention discloses a method for performing metal forging by using a metal forging device. The metal forging device comprises a forging box, wherein the forging box comprises a machining cavity, aclamping hand mechanism is arranged in the machining cavity, the clamping hand mechanism comprises a crank, the crank can rotate back and forth in the machining cavity, the front-back rotation of themachining cavity can control the radius change of parts needing to be machined, and the clamping hand mechanism further comprises rolling wheels. According to the metal forging device, the structureis simple, the operation is convenient, the functions of forging, punching and setting of metal subjected to hot working are realized, the device combines a forging device and a circular ring machining device on the market, and loss or casualties caused by falling off in the material transportation process can be avoided.

Owner:台州椒江佑沐智能科技有限公司

Radioactive substance container, manufacturing apparatus thereof and manufacturing method thereof

InactiveUS7176472B2Produced moreEasy to manufactureNuclear energy generationPiercing pressesRadioactive agentDiagonal

In the metal billet to be used for hot dilation forming, a forward side with respect to the pressing direction has a quadrate section and its diagonal length is not more than an inner diameter of a container. Moreover, a backward side with respect to the pressing direction has a circular section and its diameter is substantially same as the inner diameter of the container. The metal billet is heated to a temperature suitable for press working and is set into a container for press forming. While a center of a workpiece of the metal billet is being bored by a boring punch to be operated by a pressing machine, the metal billet is hot-dilated so that a bottomed container for a cask is formed.

Owner:MITSUBISHI HEAVY IND LTD

Piercing apparatus, plug used for piercing apparatus, and method for producing seamless steel pipe

ActiveUS20140260494A1Occurrence of inner surface flaw in the hollow shell is suppressedPiercing pressesMandrelsBiomedical engineering

Owner:NIPPON STEEL CORP

Forming device and forming method for ring forging for offshore engineering

ActiveCN112371887BImprove molding efficiencyImprove production utilizationPiercing pressesForging/hammering/pressing machinesThermodynamicsEngineering

The present invention discloses a type of sea industry for molding device and molding method. This device includes: support blocks, support blocks include support surface one and support surface two, and support surface one and support surface two.Type slot, V -shaped grooves are used to support the part of the workpiece to be processed; the upper anvil, the upper anvil includes a horizontal working face, and the horizontal working surface is used to squeeze the workpiece on the support block of the center line of the V -shaped slot;The upper -type anvil, the upper -type anvil includes the formation surface that matches the outer contour surface of the coastal -to -ring forging. The molding surface is used for horizontal working surface to squeeze and then along the central line of the V -shaped slotextrusion.The present invention has changed the tradition of the tradition of the coastal tolerance to the tradition of the ring forging, avoiding the problem of folding and low imitation of the peeling molding method, and improving the molding efficiency and product utilization of the sea industry for the type of ring forging.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD

Punching device for hot forging

The invention discloses a punching device for hot forging. The punching device comprises a worktable. Supporting rods are fixedly connected with the worktable are symmetrically arranged on the lower side of the worktable. A lower die holder is arranged on the upper side of the worktable. Guide sleeves fixedly connected with the lower die holder are symmetrically arranged on the upper side of the lower die holder. Guide columns connected with the guide sleeves in a sliding manner are inserted into the upper ends of the guide sleeves. An upper die holder fixedly connected with the guide columnsis arranged at ends, far from the guide sleeves, of the guide columns. A female die is arranged in the lower side of the lower die holder. A male die is arranged on the lower side of the upper die holder. A die shank is arranged on the upper side of the upper die holder. Connecting rods connected with the worktable in a sliding manner are symmetrically arranged in the worktable. The punching device has the advantages that a burr removing device is additionally arranged on the punching device, so that after a forge piece is punched, the burr removing device moves to remove burrs generated in punching; and since the forge piece has a certain temperature, the deformation resistance of the forge piece is relatively small, burr removing is facilitated, the service life of a cutting tool is prolonged, and the burr removing efficiency is improved.

Owner:成都正西液压设备制造有限公司

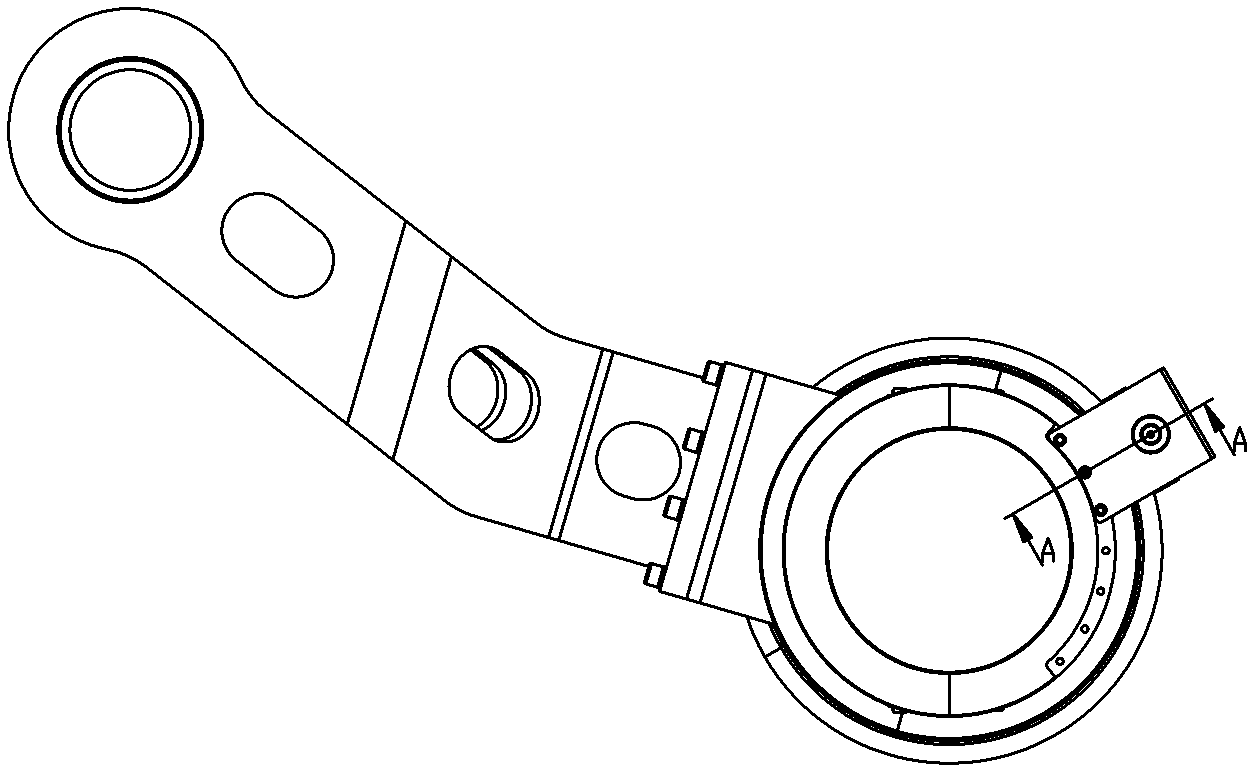

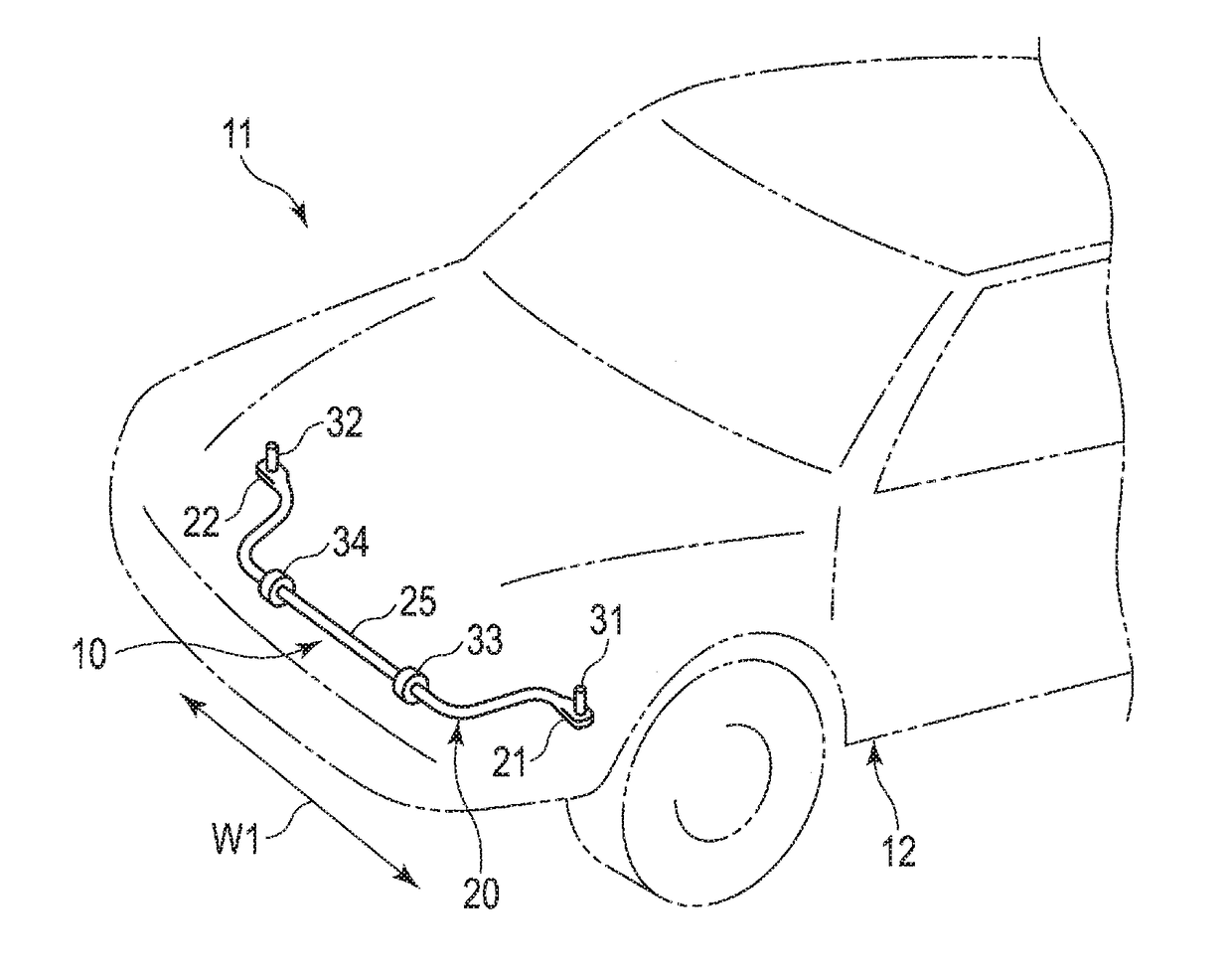

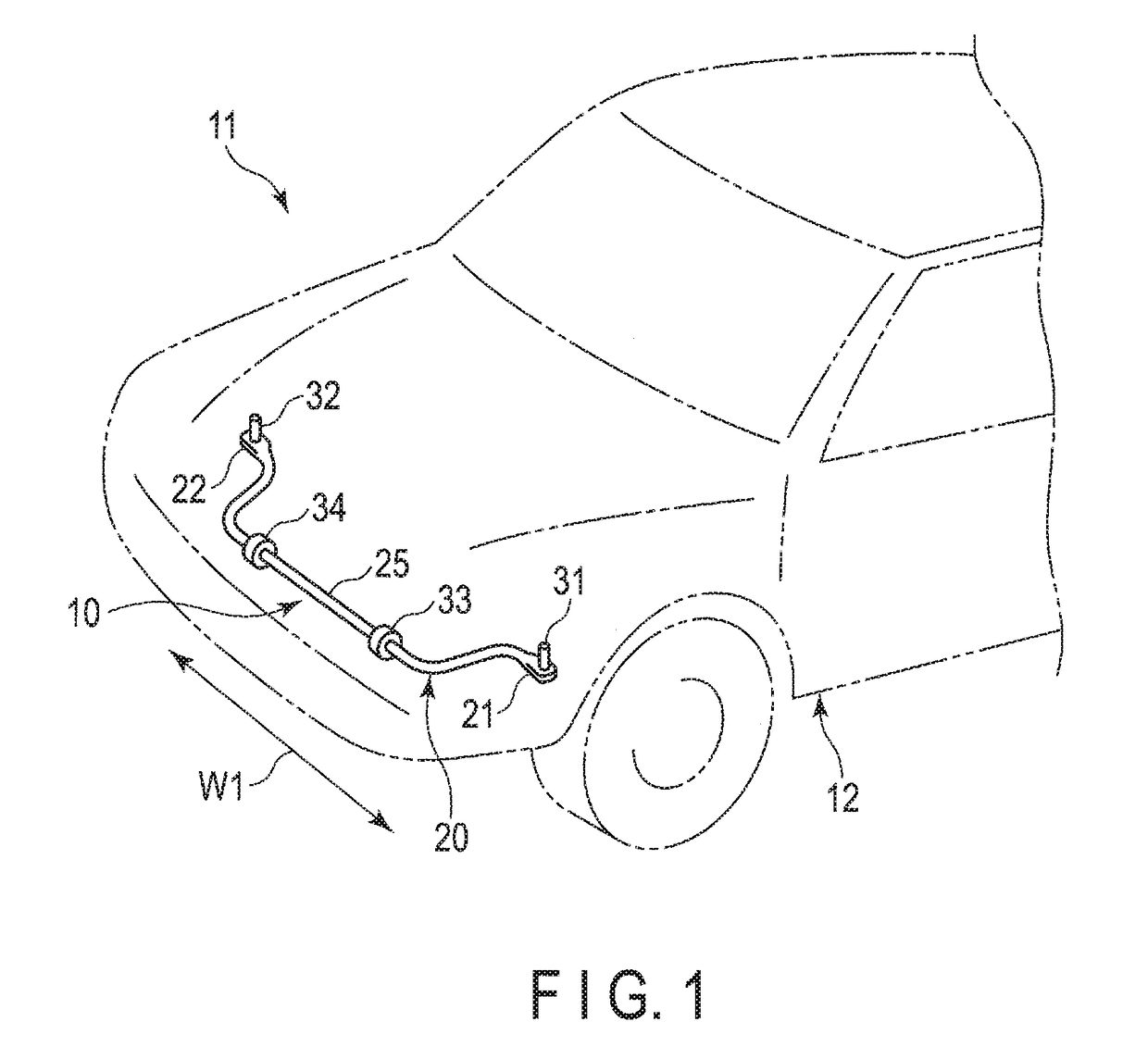

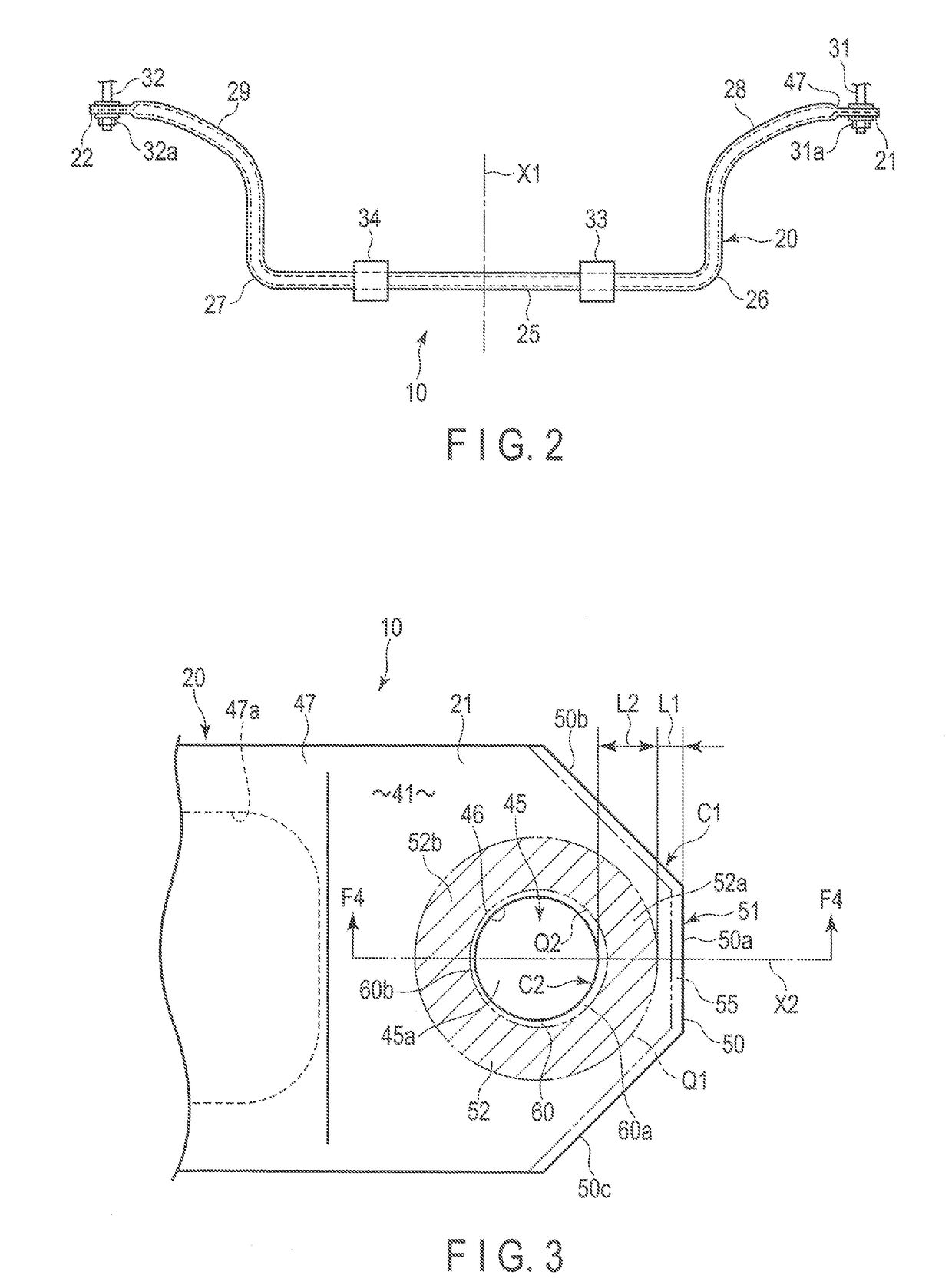

Vehicle stabilizer, processing device for eye portion of stabilizer, and processing method for eye portion

An annular reference surface is formed around a through-hole of an eye portion. A distal-end-side curved portion is formed at a first corner portion, on an outer side of the annular reference surface. The thickness of the distal-end-side curved portion is reduced in a range of a length from the first flat surface toward the distal end surface. A hole-side curved portion whose thickness is reduced toward an inner surface of the through-hole is formed at a second corner portion, on an inner side of the annular reference surface. The length of the hole-side curved portion is less than the length of the distal-end-side curved portion. The hole-side curved portion is curved with a greater curvature than that of the distal-end-side curved portion.

Owner:NHK SPRING CO LTD

High-precision forging press

The invention discloses a high-precision forging press. The high-precision forging press comprises a forging and pressing device, a dropping bath and a correcting device, wherein the correcting deviceis fixedly connected with a return pipe on one side of the correcting device; the dropping bath and the correcting device are positioned on the same side of the forging and pressing device; the correcting device is positioned over the end, which is connected with the forging and pressing device, of the dropping bath; and an emulsified liquid drop irrigation device is arranged on one side of the dropping bath. The high-precision forging press is reasonable in structure, the correcting device is arranged on one side of the forging and pressing device, when deviation exists between a limiting hole in a machined piece and a limiting rod on the forging and pressing device, a punching machine of the forging and pressing device punches downwards, a beating assembly is driven to downwards press aclamping block, thus, an effect of clamping the machined piece is weakened when the clamping block rotates clockwise, meanwhile, the limiting hole shifts slightly, and is positioned under the limiting rod, a punch needle on the forging and pressing device can accurately punch the machined piece, and the punching accuracy is improved.

Owner:海宁市德亿金属制品股份有限公司

Piercing apparatus, plug used for piercing apparatus, and method for producing seamless steel pipe

ActiveUS9545658B2Occurrence of inner surface flaw in the hollow shell is suppressedPiercing pressesMandrelsBiomedical engineering

Owner:NIPPON STEEL CORP

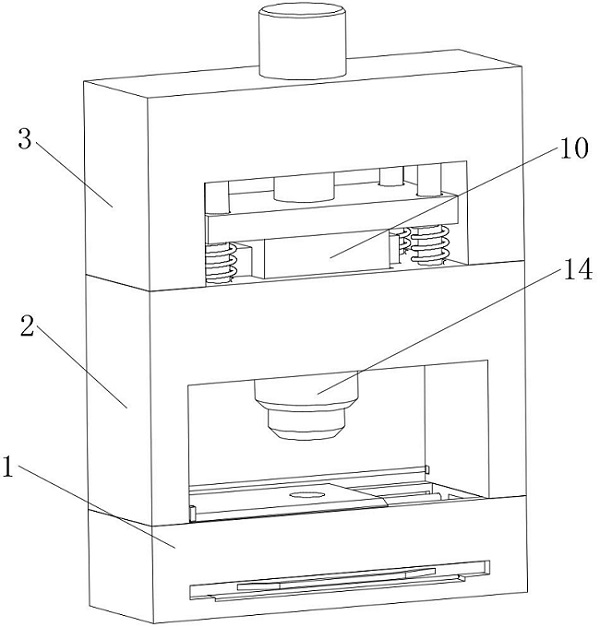

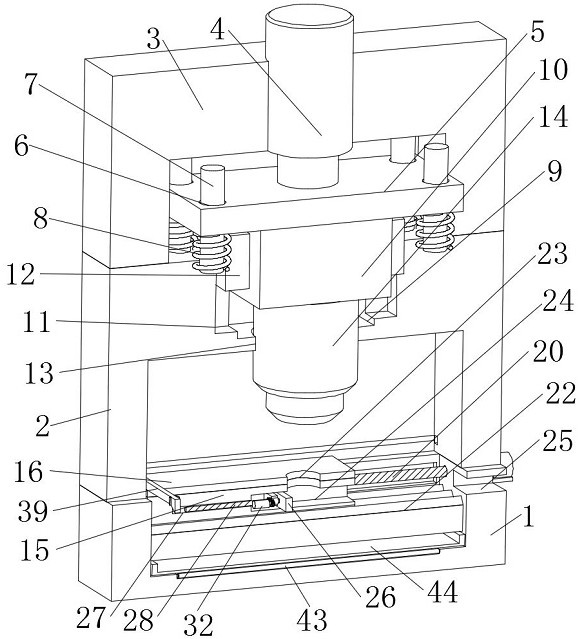

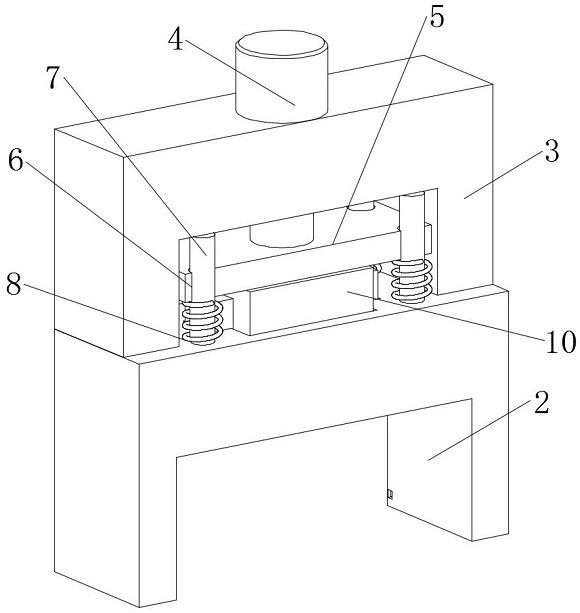

High-precision forging die suitable for deep hole machining

PendingCN112548017AImprove forging precisionHigh strengthPiercing pressesForging/hammering/pressing machinesEngineeringMachining

The invention belongs to the technical field of forging dies, and particularly relates to a high-precision forging die suitable for deep hole machining. The high-precision forging die comprises a lower bottom plate, an upper bottom plate, a discharging plate, an upper die plate, elastic air cylinders, a lower die assembly and a punch assembly, wherein the upper bottom plate and the lower bottom plate are slidably connected; the discharging plate is connected to the lower portion of the upper bottom plate through a set of elastic air cylinders; the upper die plate is fixed to the lower end faceof the discharging plate; and the lower die assembly is fixed to the lower bottom plate and corresponds to the upper die plate up and down, the upper die plate can cover the lower die assembly to form a closed die cavity, and a punch hole is reserved in the center of the upper die plate. The punch assembly comprises an upper base plate, a protective block and a punch, wherein the upper base plateis fixed to the lower end face of the upper bottom plate, and the punch vertically penetrates through the protective block downwards and is fixed to the lower end face of the upper base plate throughthe protective block. According to the high-precision forging die suitable for deep hole machining, deep hole forging can be conducted on a shaft workpiece, the forging precision is high, the overallstrength of a product is high, and the subsequent machining workload and machining cost are greatly reduced.

Owner:JIANGSU BAOJIE FORGING

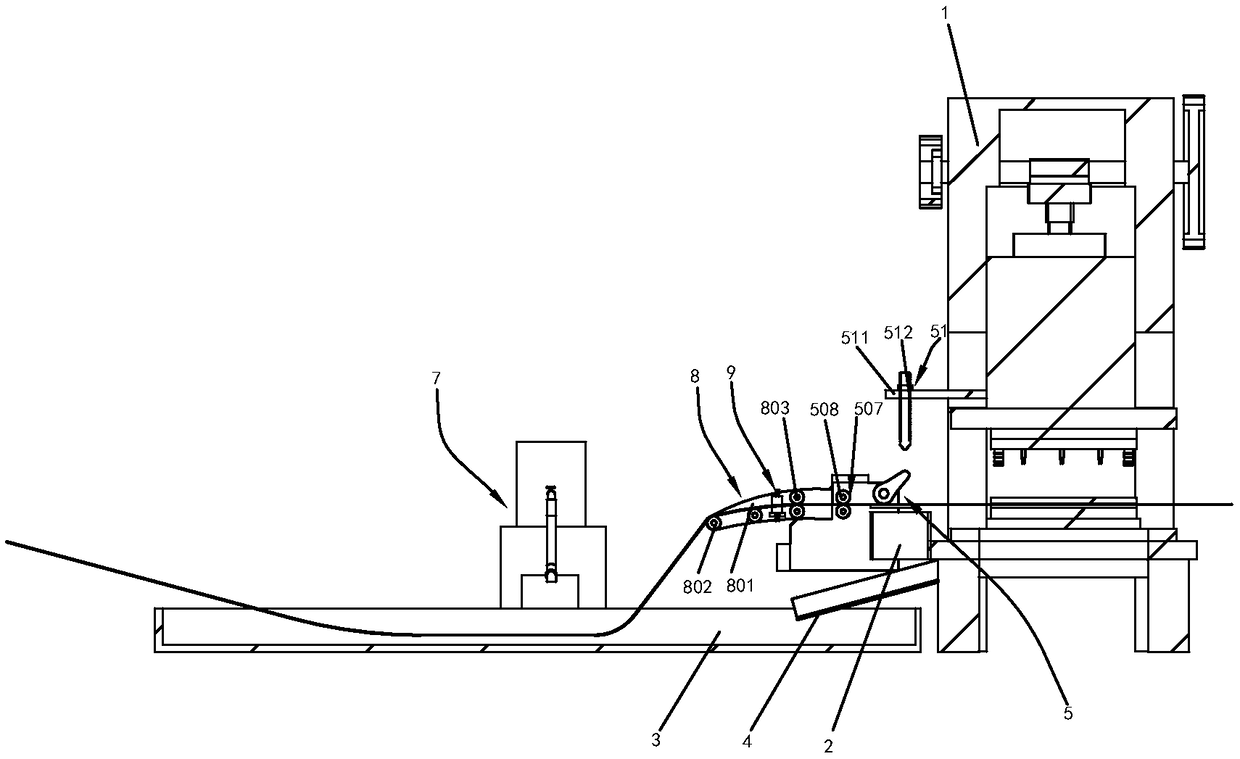

Transverse punching mechanism of gasifier for ignition and processing equipment of gasifier

PendingCN111215568ANo damageRealize automated productionPiercing pressesForging/hammering/pressing machinesPunchingProcess engineering

The invention discloses a transverse punching mechanism of a gasifier for ignition and processing equipment of the gasifier. The processing equipment includes a cold heading machine body with a motorand a transmission assembly, the cold heading machine body is sequentially provided with a material storage mechanism, a straightening feeding mechanism, a material cutting mechanism, a vertical punching mechanism, a translation mechanism and a discharging mechanism in the order of processing, the transverse punching mechanism is arranged between the vertical punching mechanism and the dischargingmechanism, and the transverse punching mechanism and the vertical punching mechanism are perpendicular to each other. The transverse punching mechanism is refitted onto an existing cold heading machine, so that the fully automated production of vertical punching and transverse punching on one device can be realized, the production difficulty is effectively reduced, and the production efficiency and product quality are improved; and meanwhile, two brand new transverse punching mechanism solutions are provided, and great improvements are made to an existing transverse punching structure, so that the processing equipment has the advantages of clean punching, smooth discharge and no damage to the gasifier.

Owner:王佳莉

Hydraulic cylinder body forging device

ActiveCN107891114AAvoid deformationGuaranteed accuracyPiercing pressesForging press drivesHydraulic cylinderControl engineering

The invention relates to the technical field of forging equipment and particularly discloses a hydraulic cylinder forging device. The hydraulic cylinder forging device comprises a base, a hydraulic telescopic mechanism is arranged at one end of the base, a guide rail is arranged at the other end of the base, and a clamping device is arranged in the middle of the base. The hydraulic telescopic mechanism comprises a hydraulic oil tank, an oil pump and a telescopic rod. The hydraulic oil tank, the oil pump, the telescopic rod and a supporting rod are sequentially arranged on the upper portion ofthe base, a crossbeam is arranged between the supporting rod and the guide rail, a supporting frame and a stepping motor are sequentially arranged on the crossbeam, and a rotating shaft of the stepping motor is sequentially provided with a supporting plate and a tool bit. The supporting plate is in threaded connection with the rotating shaft, guide rods are arranged between the supporting plate and the supporting frame, a seamless steel pipe is arranged between the supporting plate and the tool bit, the rotating shaft is sleeved with the seamless steel pipe, and the tool bit corresponds to theclamping device. The hydraulic cylinder forging device is mainly used for forging hydraulic cylinder bodies, and the problem that machining sizes are not accurate in the forging process is solved.

Owner:重庆博创知识产权运营有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com