Transverse punching mechanism of gasifier for ignition and processing equipment of gasifier

A gasifier and horizontal technology, applied in the field of horizontal punching mechanism and its processing equipment, can solve the problems of time-consuming and labor-intensive, sidewall deformation damage, short punching distance, etc., to improve production efficiency and product quality, The effect of reducing production difficulty and punching clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

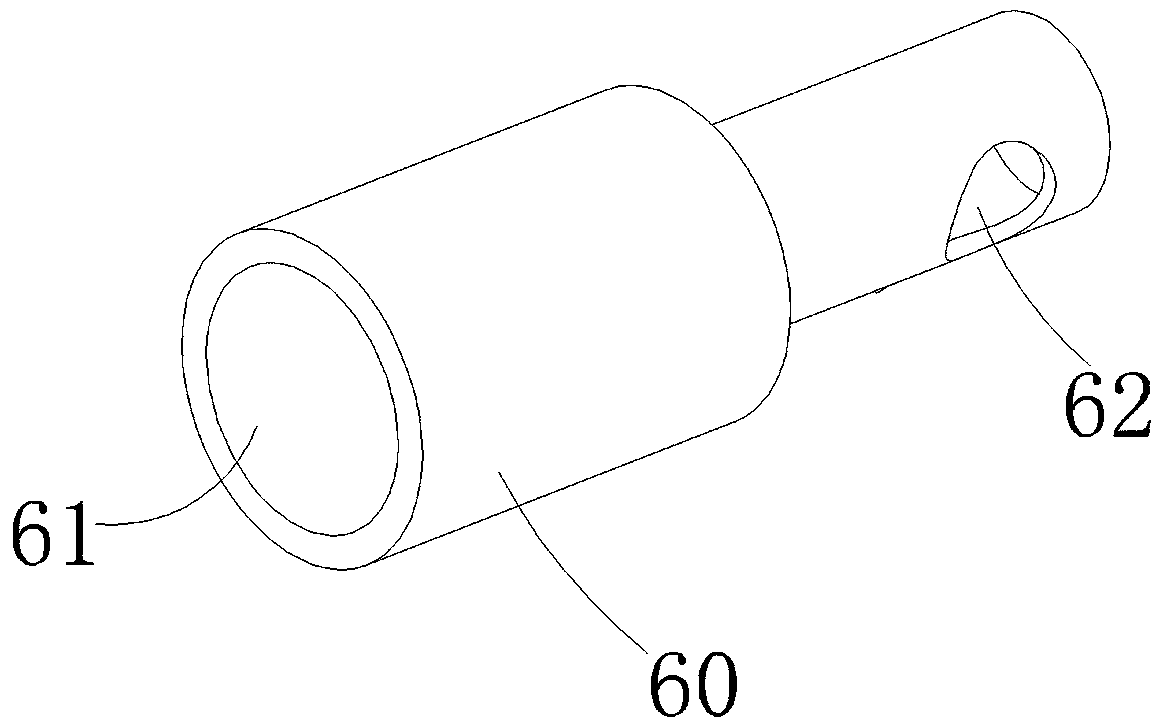

[0039] refer to Figure 1 to Figure 12, a horizontal punching mechanism for a gasification furnace for ignition, comprising an outer mold 2 having an accommodating cavity 1, an inner mold 3 movably arranged in the accommodating cavity 1, and an inner mold 3 that is suitable for the gasification furnace 60. The matching cavity 4, the outer wall of the inner mold 3 is provided with two transverse insertion holes 5 that are symmetrical to each other centering on the cavity 4, and the transverse insertion holes 5 are also communicated with the cavity 4, The inner wall of the housing chamber 1 is symmetrically provided with two guide chute 6, wherein one guide chute 6 is provided with a first bump 7, and the other guide chute 6 is provided with a second bump 8. A horizontal punching knife assembly 9 is provided in the horizontal jacking hole 5, and a first return spring 10 is sheathed on the horizontal punching knife assembly 9, and the outer end of the horizontal punching knife as...

Embodiment 2

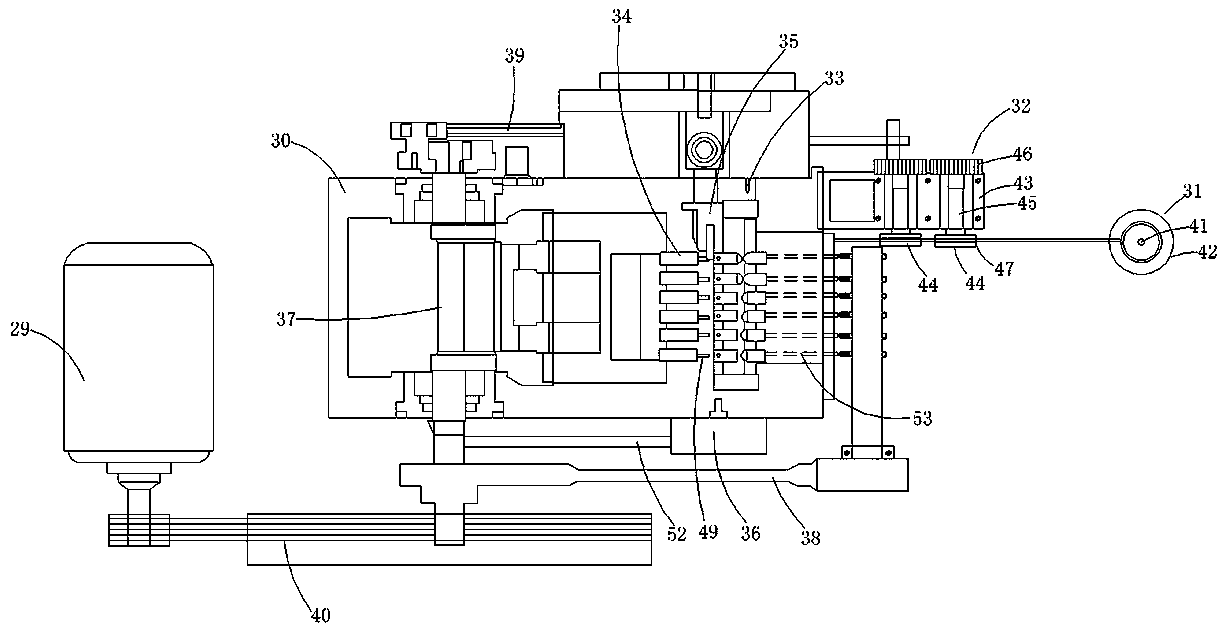

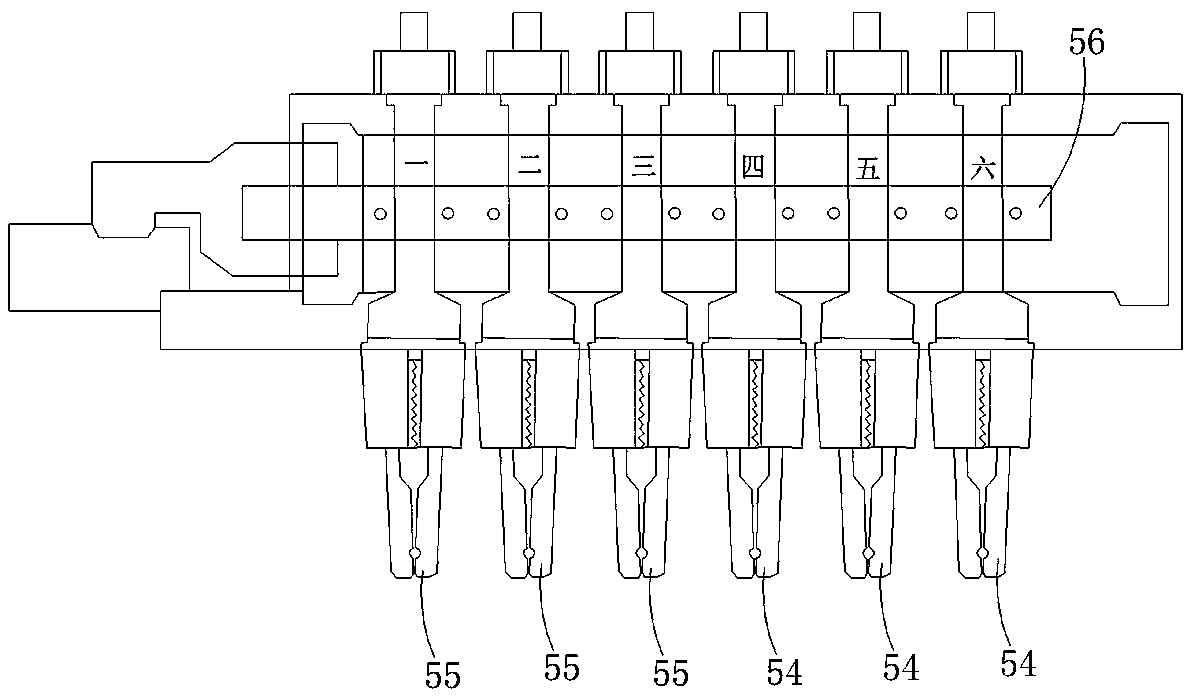

[0053] refer to Figure 13 ~ Figure 14 , the present invention also provides another horizontal punching mechanism 36 of the gasification furnace 60 for ignition, including a fixed block 15, a punch assembly 16 for realizing the horizontal punching of the gasification furnace 60, a push rod 17, and a The second return spring 18 of the punch assembly 16 and the push rod 17, and the guide block 19 driven by external power, the fixed block 15 is provided with a through hole 20, and the rear end of the punch assembly 16 is movable. In the through hole 20, the front end of the punch assembly 16 protrudes out of the through hole 20, and the front end of the push rod 17 protrudes into the through hole 20 and is in contact with the through hole 20. The punch assembly 16 is connected, the guide block 19 is provided with an undulating guide groove 21, the rear end of the push rod 17 is provided with a linkage part 22 that is compatible with the guide groove 21, and the linkage part 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com