Automotiv non-asbestos high strength braking friction disk, and its prodn. method

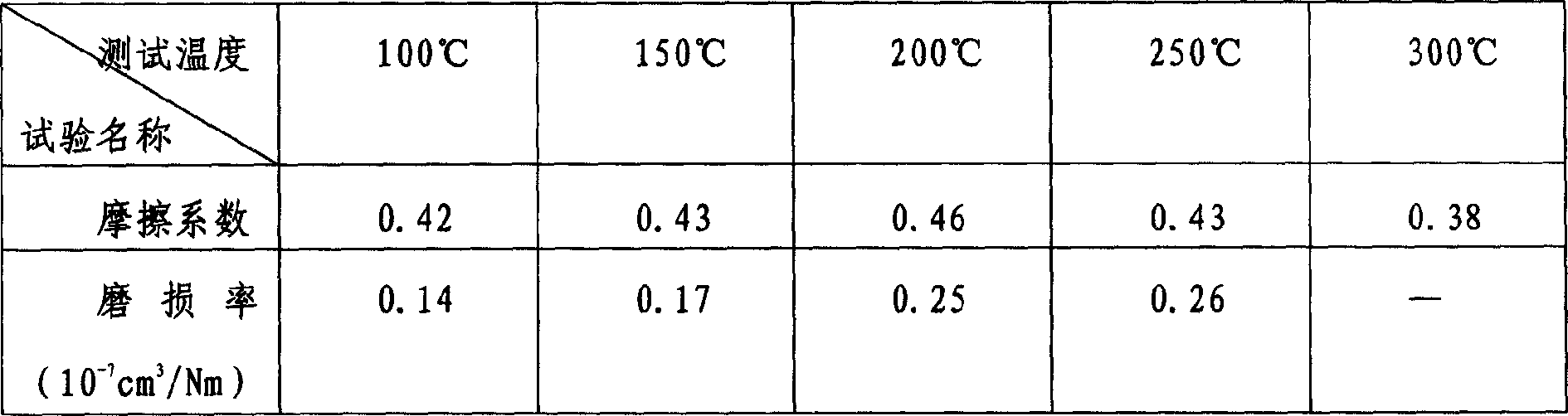

A non-asbestos, high-strength technology, applied in the field of brake friction materials, can solve the problems of lack of high temperature resistance, lack of promotion and application, high cost, low thermal weight loss, reduced test times, and good thermal decomposition temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] First carry out the production of double-modified phenolic resin, pulverize the phenolic resin into granules, then add 2% styrene-butadiene rubber by weight for hot rolling, add 3% hexamethylenetetramine at the same time, then continue hot rolling, and then Add 10% dimer amine terephthaloyl diacetate, and when the surface of the resin becomes discolored after mixing, roll it down immediately and cool it down rapidly to make a double-modified phenolic resin. Accurately weigh various raw materials according to the following weight proportions: 20 kg of double-modified phenolic resin, 20 kg of steel fiber, 5 kg of polyester fiber, 10 kg of sepiolite fiber, 10 kg of barium sulfate, 10 kg of graphite, and 1 kg of aluminum oxide. kg, a total of 24 kg of mixed rubber powder, pottery clay, and walnut shell powder are added to the plow-type high-speed mixer in turn, and the mixture is mixed for 5 minutes until the mixture is uniform. 400-ton single-layer hot press machine, heate...

Embodiment 2

[0083]First of all, double-modified phenolic resin is made, the phenolic resin is crushed into granules, and then 5% styrene-butadiene rubber is added for hot rolling, and 2% hexamethylenetetramine is added as a curing agent, and then the hot rolling is continued. Then add 15% dimer amine terephthaloyl diacetate, and when the surface of the resin becomes discolored after mixing, roll it down immediately and cool it down rapidly to make a double-modified phenolic resin. Accurately weigh various raw materials according to the following weight ratio: 10 kg of double-modified phenolic resin, 20 kg of copper fiber, 10 kg of aramid fiber, 15 kg of glass fiber, 10 kg of barium sulfate, 10 kg of graphite, 2 kg of aluminum oxide, A total of 23 kg of mixed rubber powder, pottery clay, and cashew nut shell powder are added to the plow-type high-speed mixer in turn, and the mixture is mixed for 8 minutes until the mixture is evenly mixed. A one-step molding method, that is, a hot-pressing ...

Embodiment 3

[0085] First of all, double-modified phenolic resin is made, the phenolic resin is crushed into granules, and then 8% by weight of styrene-butadiene rubber is added for hot rolling, and 4% curing agent (hexamethylenetetramine) is added at the same time, followed by continuous hot rolling , plus 18% terephthaloyl diacetic acid dimixed amine, after mixing the resin and cooling, you can make a double-modified phenolic resin. Accurately weigh various raw materials according to the following weight proportions, double modified phenolic resin 15 kg, copper fiber 5 kg, steel fiber 13 kg, cotton fiber 10 kg, barite fiber 15 kg, barium sulfate 10 kg, graphite 10 kg kg, 2 kg of alumina, 20 kg of mixed rubber powder, pottery clay, and coconut shell powder, which are added to the plow-type high-speed mixer in turn, and mixed for 8 minutes until the mixture is uniform, and the one-step molding method is implemented, that is, hot pressing For the chemical process, a 400-ton single-layer hot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com