Sterilizing method for medical equipment and its cleaning sterilizer

A disinfection method, cleaning and disinfection technology, applied in disinfection, sanitary equipment for toilets, water supply equipment, etc., can solve the problems of limited number of endoscopes, easy contamination of the external environment by pathogenic microbes and harmful compounds, and difficulty in cutting in, etc. To achieve the effect of not harming the health, being conducive to popularization and use, and simple working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

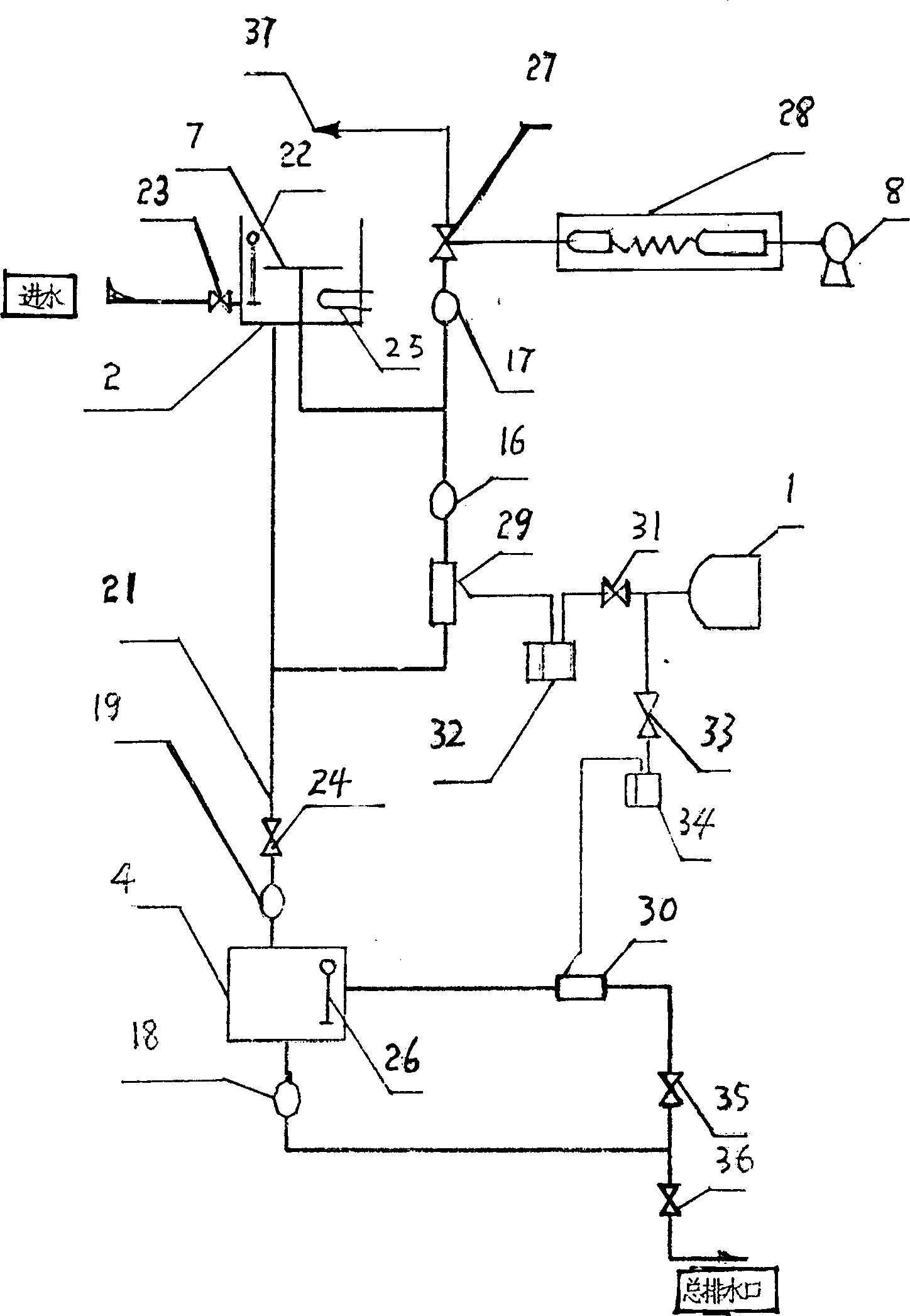

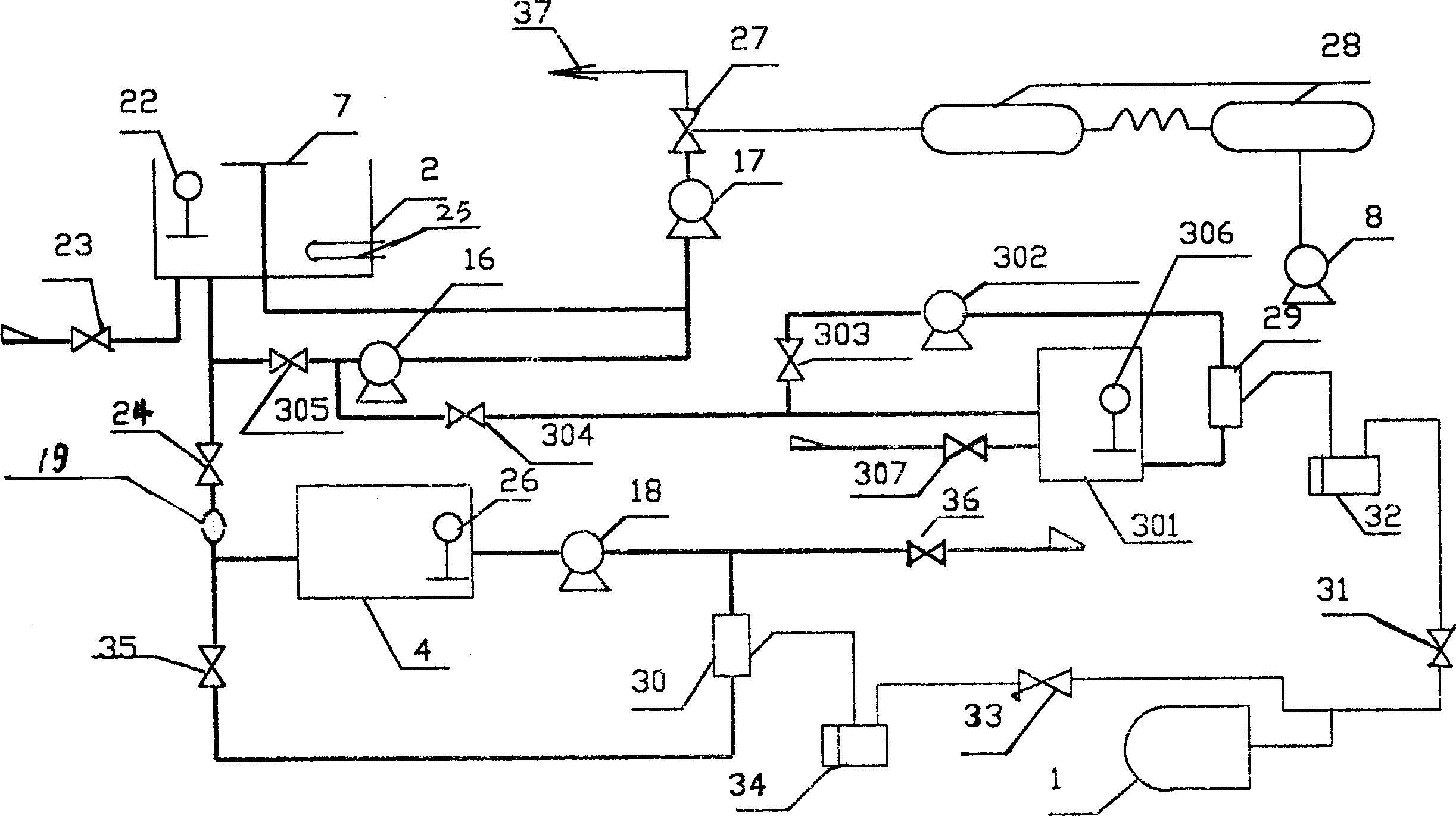

[0041] Example 1. Such as figure 1 , figure 2 As shown: it is provided with a closed spraying device, an ozone generating device, a drying device and a microcomputer control system 6 .

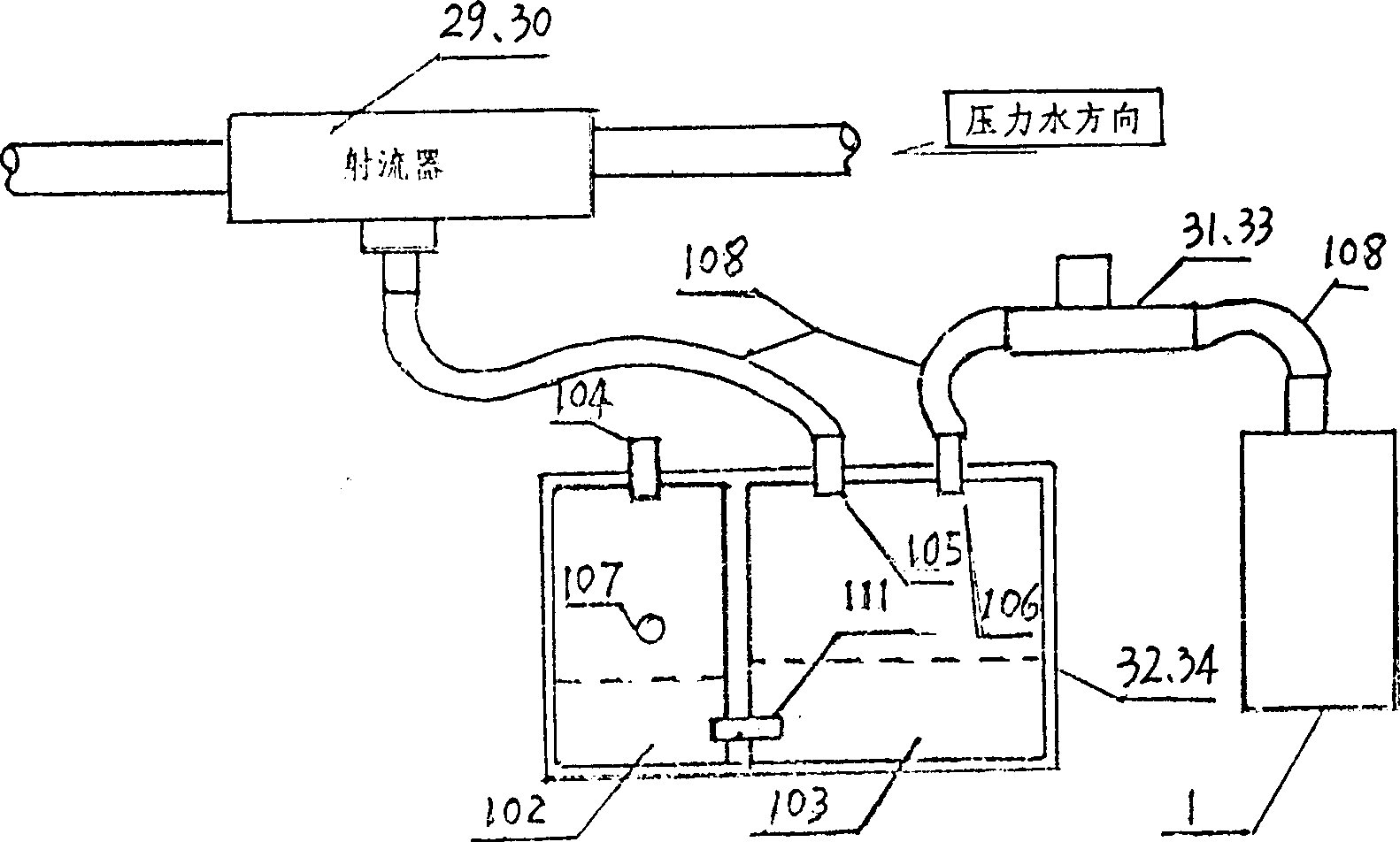

[0042]Closed spray device: there is a closed spray box 2, the box is equipped with a rotary sprayer 7, a closed spray box water level gauge 22, an enzyme solution heater 25, and the rotary sprayer 7 is continuously increased through the tee piece. The pressure pump 17, the lower connection flushing circulation pump 16, the booster pump is connected to the outlet of the hot air regulating heater 28 of the drying device by the clamp channel two-position three-way valve 27, and the flushing circulation pump is connected to the output of the ozone generator by the circulation jet 29. Air hole 105 (see image 3 ); be provided with water inlet solenoid valve 23, one end is connected with the inlet pipe of closed spray box 2, and the other end is connected with tap water outlet 11 (see Figure 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com