High-precision forging die suitable for deep hole machining

A high-precision, mold-based technology, applied in the field of forging molds, can solve problems such as complex procedures, high cost, and unfavorable improvement of the overall strength and precision of the product, and achieve the effects of high overall strength, high forging precision, and good promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

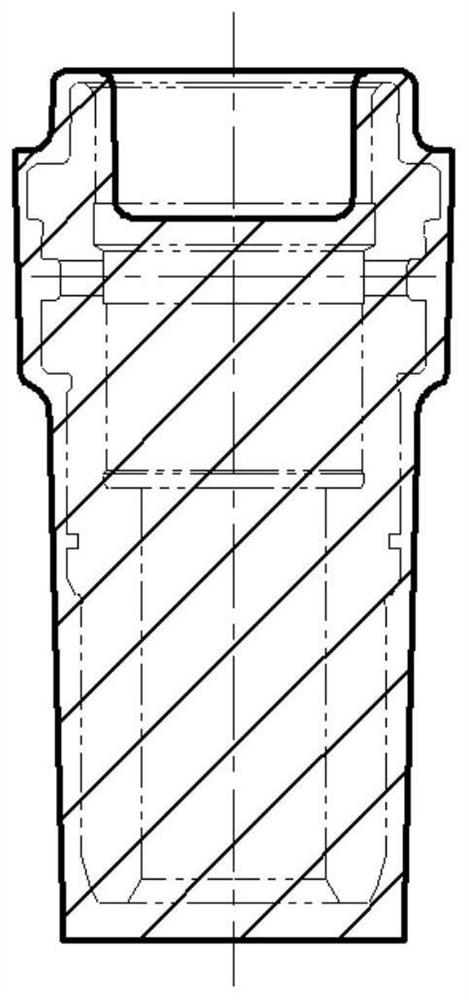

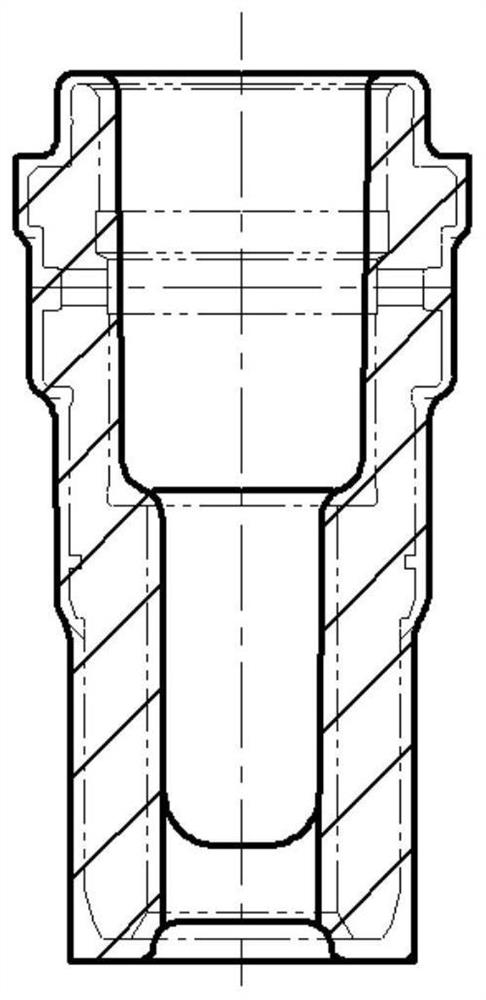

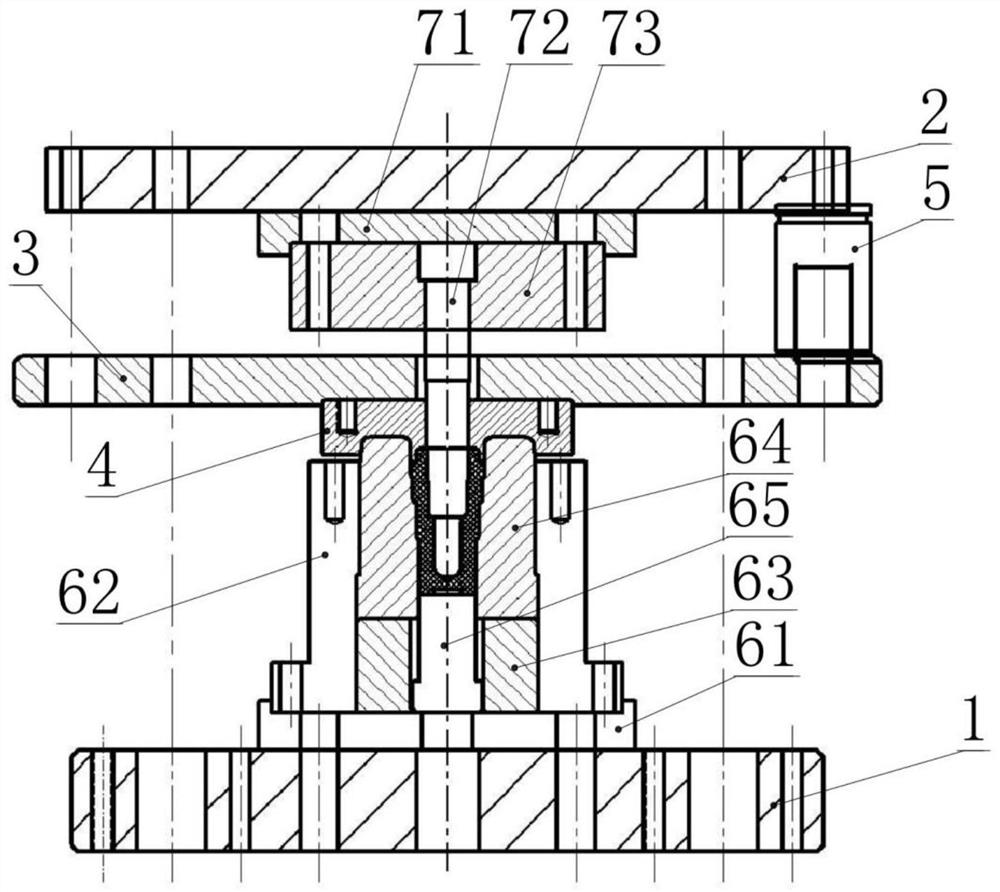

[0022] A high-precision forging die suitable for deep hole processing, such as image 3 shown. Using this forging die can forge such as figure 2 The shaft-like deep-hole parts shown are obviously better than those forged by existing conventional dies, such as figure 1 Artifacts shown. The forging die includes a lower base plate 1, an upper base plate 2, a discharge plate 3, an upper template 4, an elastic cylinder 5, a lower die assembly, and a punch assembly; the upper base plate 2 and the lower base plate 1 are slidably connected, and the discharge plate 3 is connected under the upper base plate 2 by a group of elastic cylinders 5; the upper formwork 4 is fixed on the lower end surface of the unloading plate 3; Combined with the lower mold assembly to form a closed mold cavity, a punch hole is left in the center of the upper template 4; the punch assembly includes an upper backing plate 71, a protective block 72, and a punch 73; the upper backing plate 71 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com