Intelligent direct drive electromagnetic forging hammer

An electromagnetic and direct drive technology, applied in the direction of forging/pressing/hammer device, forging/pressing/hammering machinery, power hammer, etc., can solve the problems of high equipment maintenance requirements, low energy utilization rate, hard blow, etc., and achieve maintenance Low cost, small mechanical wear, and the effect of reducing mechanical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

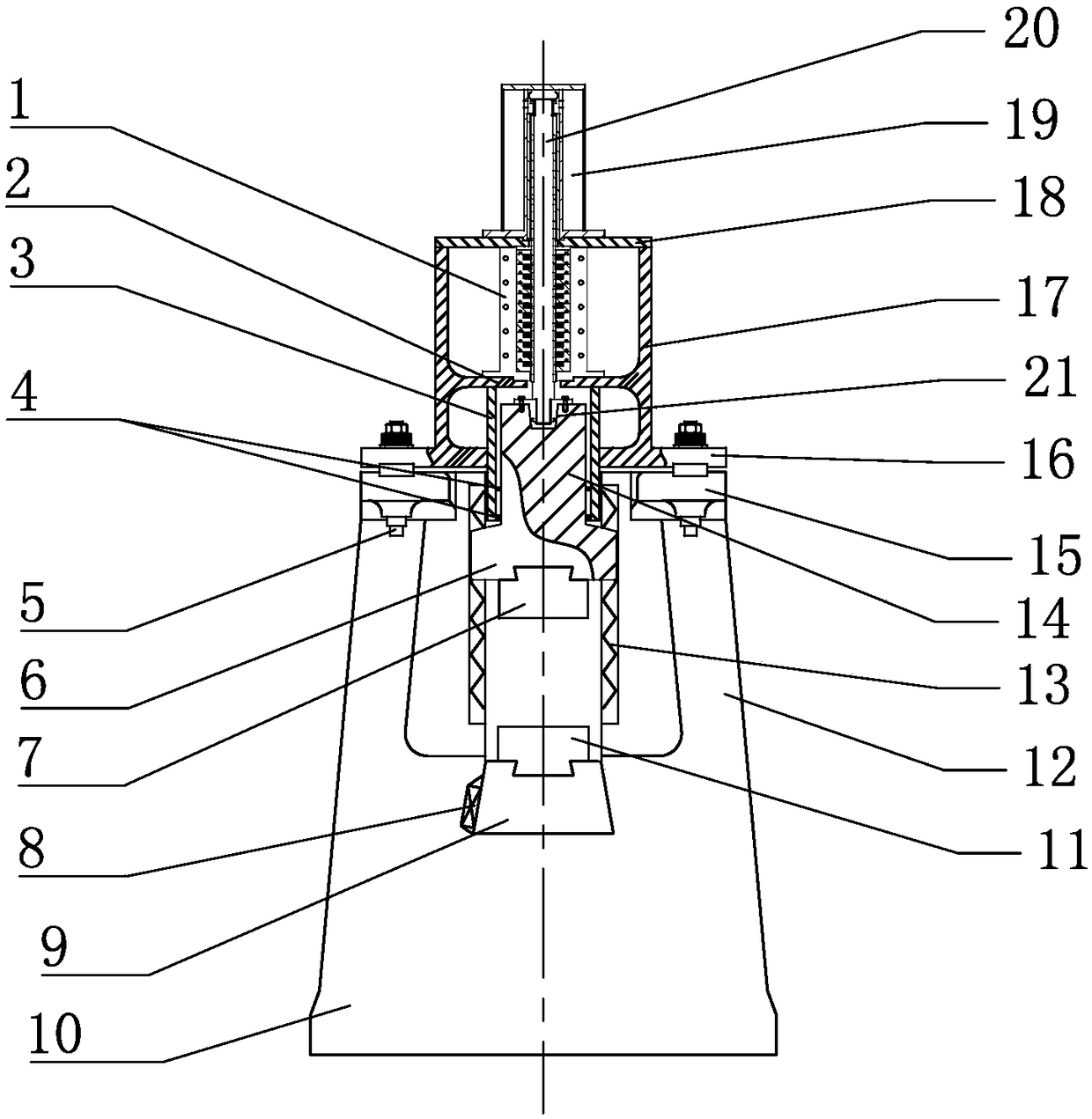

[0035] Such as Figure 1 to Figure 4 As shown, an intelligent direct-drive electromagnetic forging hammer includes a frame, the frame includes a base 10, the upper part of the base 10 is a column 12, the upper part of the column 12 is connected to a frame flange 15, and the frame is connected with a frame flange 15 The upper cross beam 17 is connected to the mover breathing bearing chamber 19 at the upper part of the upper cross beam 17. An upper mold 7 and a lower mold 11 are respectively provided inside the frame, and a cylindrical linear motor 1 is provided in the inner cavity of the upper beam 17.

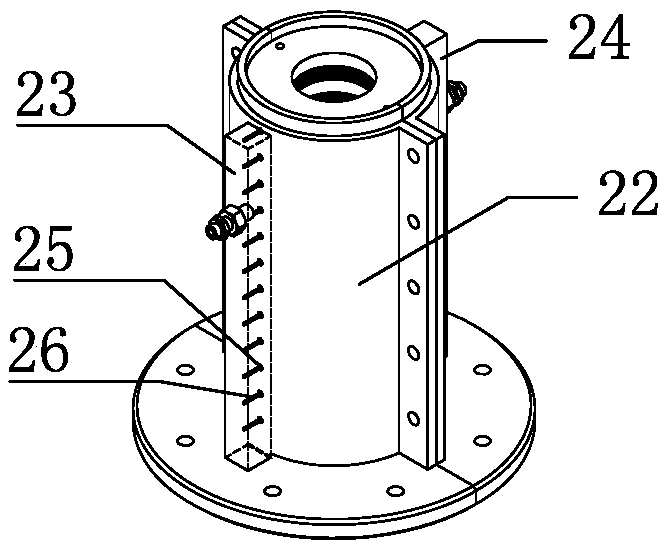

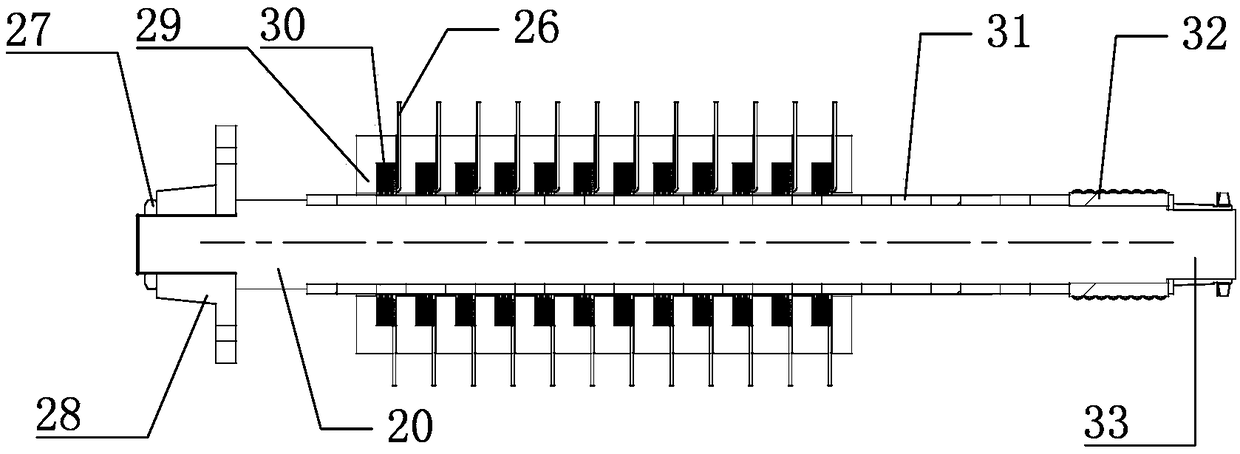

[0036] The upper beam 17 has an inner cavity structure, and the cylindrical linear motor 1 is fixedly installed on the motor mounting surface 2 of the inner cavity of the upper beam 17. The cylindrical linear motor 1 includes a motor housing 22, a cylindrical stator and a cylindrical mover. The stator is installed inside the motor housing 22, the mover is inserted into the stator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com