NdCa4O(BO3)3 crystal zero frequency temperature coefficient cut and application

A technology with temperature coefficient and zero frequency, which is applied in the field of zero-frequency temperature coefficient cutting of piezoelectric crystal NdCa4O3 crystal, which can solve the problems of narrow crystal frequency stability range and low electric coupling coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

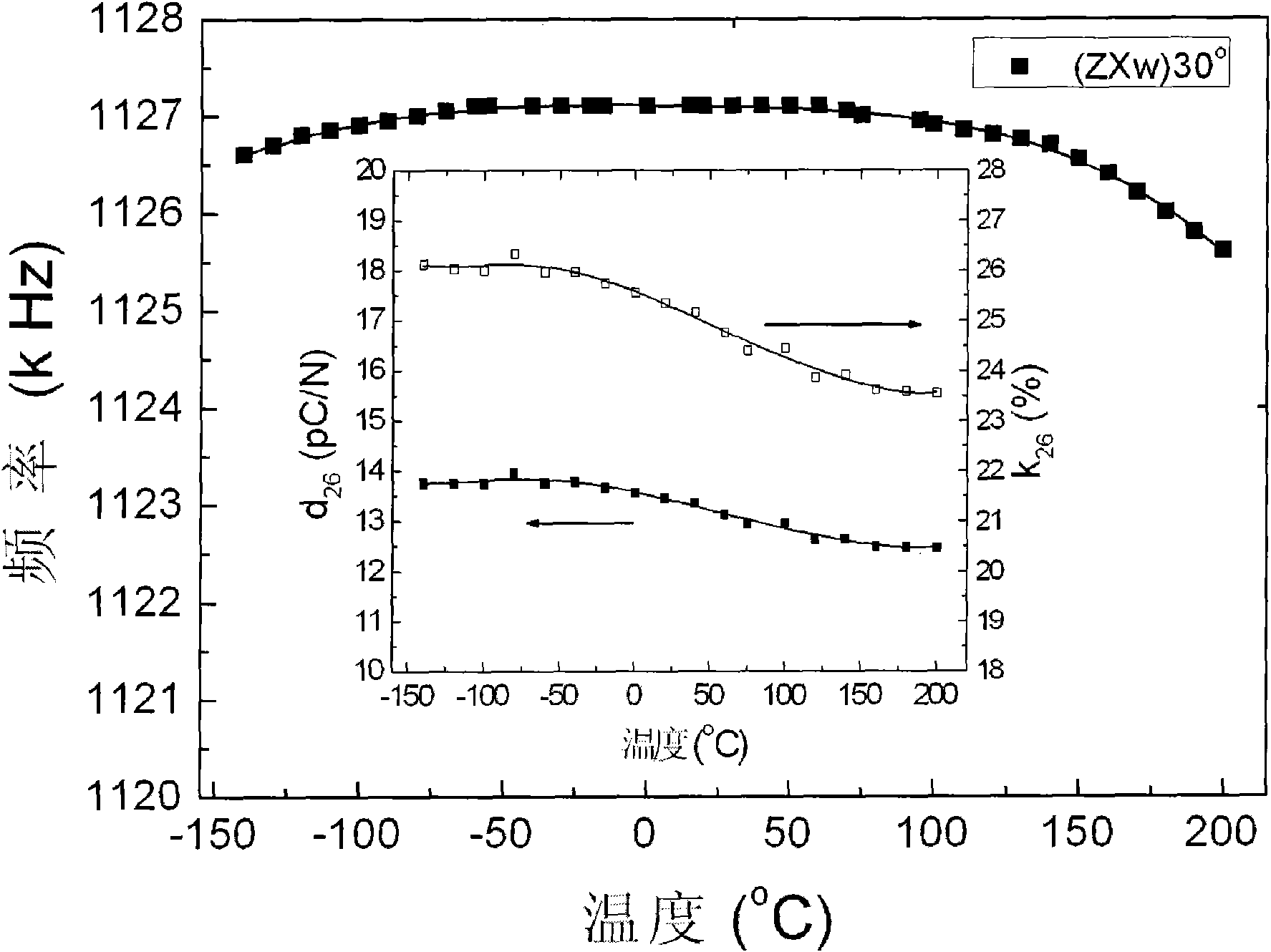

[0043] Example 1: NdCa 4 O(BO 3 ) 3 Crystal Zero Temperature Compensation Cut

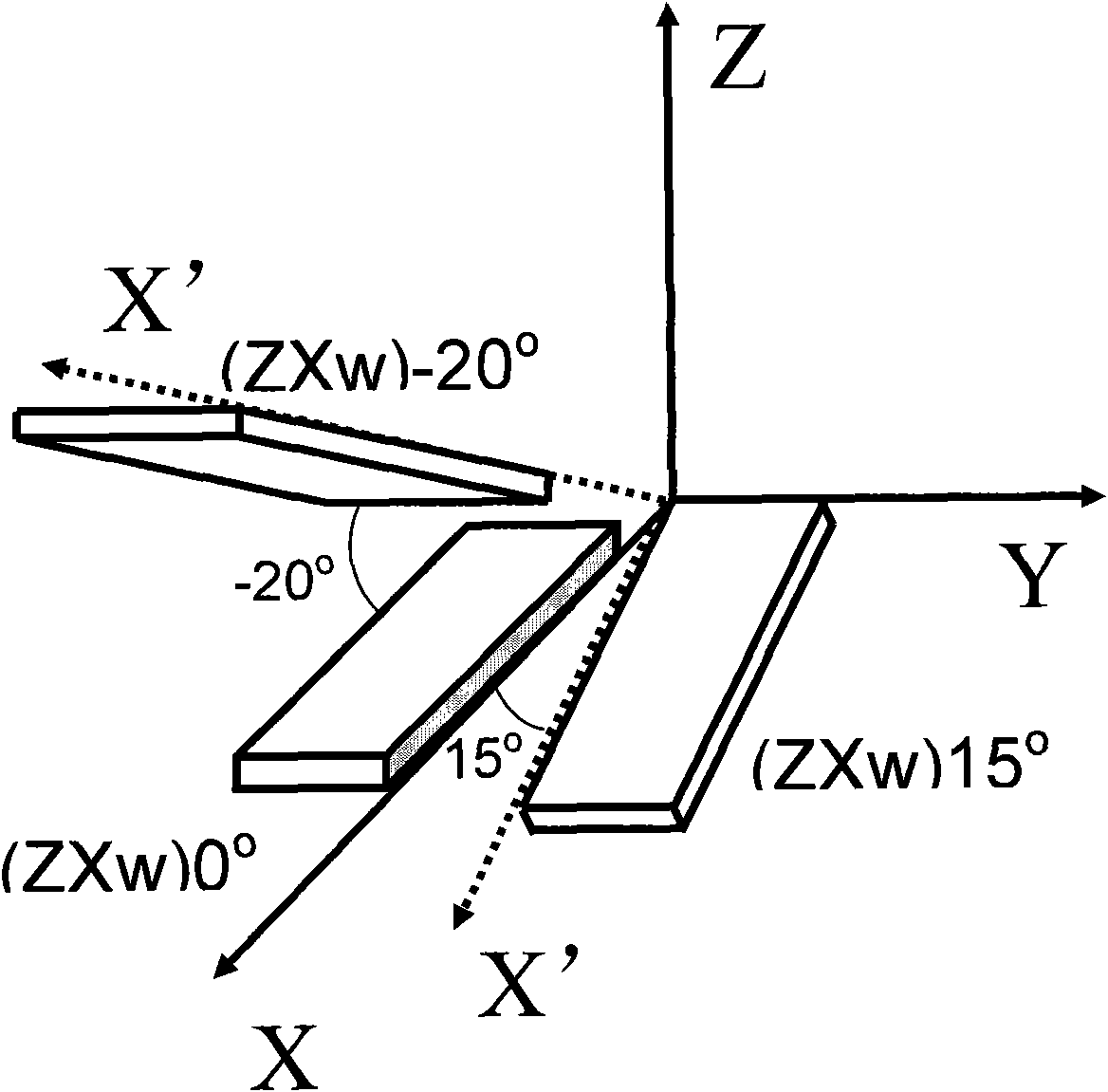

[0044] 1. If figure 1 Shown, NdCa 4 O(BO 3 ) 3 crystal positive d 22 The direction of is taken as the positive direction of Y, the Y and Z axes of the physical coordinate axis are parallel to the b and c axes of the crystal axis, the X axis of the physical coordinate axis is perpendicular to the Y and Z axes and follow the right-hand spiral rule. The thickness direction of the crystal is Z, the length direction is X, and the width direction is Y. Rotate in the Y direction according to the right-handed spiral rule at an angle of -20°, which is recorded as (ZXw)-20°. The sample cutting and processing angles are as follows: figure 1 Shown; processing cutting size ratio of thickness: width: length = 1:3:8.

[0045] 2. In NdCa 4 O(BO 3 ) 3 Platinum electrodes are plated on the width direction of the cut sample, and the electrode thickness is 200nm. Place the platinum-plated sample device in a...

Embodiment 2

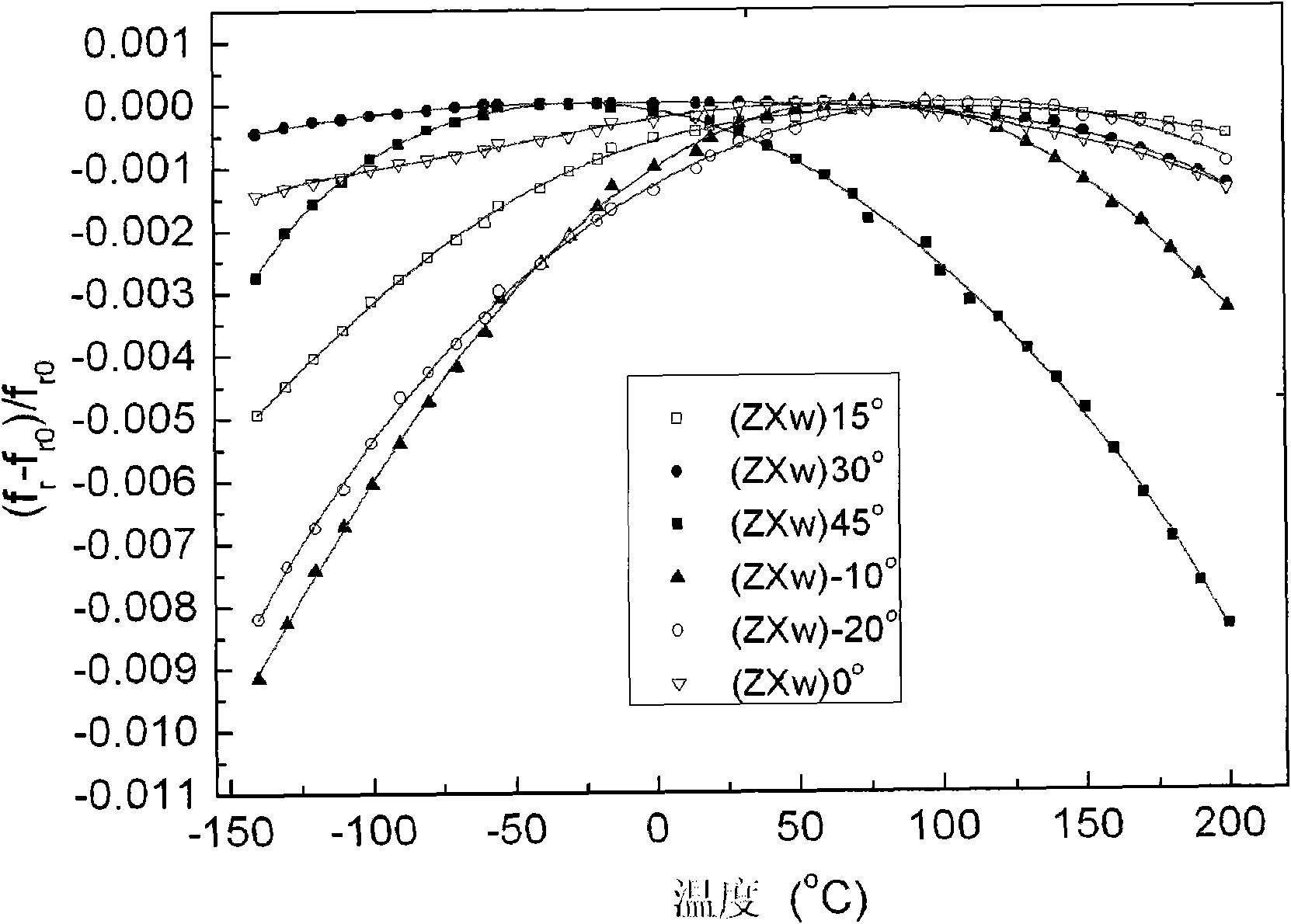

[0048] As in Example 1, the difference is that (ZXw)-10 ° cut type is also used, and the sample size ratio is thickness: width: length = 1:3:9 frequency device, and its frequency is measured in the range of -140-200 ° C With the change of temperature, the temperature stability of the obtained frequency device is within 25ppm / ℃, see figure 2 ((ZXw)-10° sample) shown.

Embodiment 3

[0050] As in Example 1, the difference is that (ZXw) 0 ° cut type is also used, and the sample size ratio is thickness: width: length = 1: 2.4: 7 frequency device, and its frequency is measured in the range of -140-200 ° C. The temperature change, the temperature stability of the frequency device is within 12ppm / ℃, see figure 2 ((ZXw)0° sample) shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com