Method for Improving Temperature Accuracy of Crystal Oscillator, Oscillator and Packaging Method

A crystal oscillator and packaging method technology, applied in electrical components, output stability, impedance network and other directions, can solve problems such as unfavorable product generalization, affecting product thinning, increasing crystal oscillator thickness, etc., to achieve accurate compensation output, The effect of reducing thickness and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

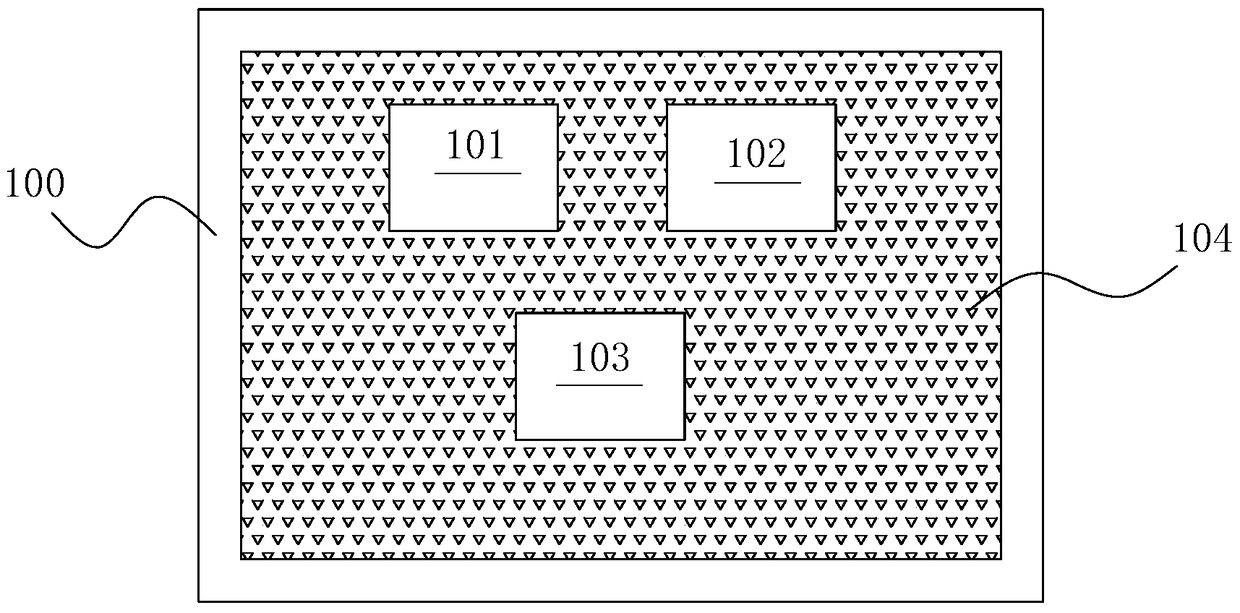

[0045] In this embodiment, a method for improving the temperature accuracy of a crystal oscillator according to the present invention includes a crystal 101, a temperature control module 102, and a temperature sensor 103 discretely arranged on a substrate 100, and a filling material 104 with good thermal conductivity is used for the crystal. 101. Fill the gap between the temperature control module 102 and the temperature sensor 103, so that the temperatures of the temperature control module 102 and the temperature sensor 103 tend to be consistent.

[0046] In this embodiment, the filling material 104 is a plastic sealant with good thermal conductivity.

[0047] Specifically, filling the gap between the crystal 101, the temperature control module 102, and the temperature sensor 103 is as follows: the substrate 100, the crystal 101, the temperature control module 102, and the temperature sensor 103 are potted together with a filling material 104, and the filling is solidified. M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com