Monolithically integrated bulk acoustic wave duplexer and manufacturing method thereof

A monolithic integrated, bulk acoustic wave technology, applied in impedance networks, electrical components, etc., can solve the problems of high cost, long time, and increase the difficulty of manufacturing duplexers, and achieve the effect of improving frequency and temperature stability and enhancing mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

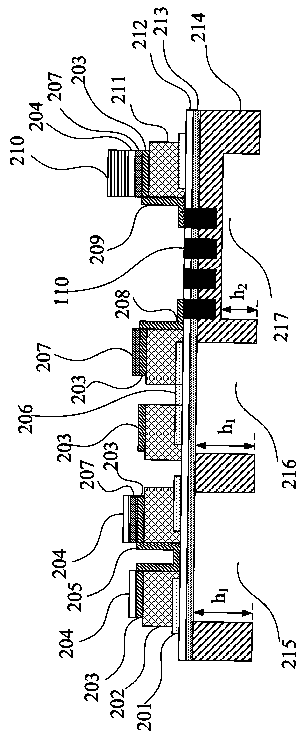

[0036] The present invention is described in detail below in conjunction with accompanying drawing:

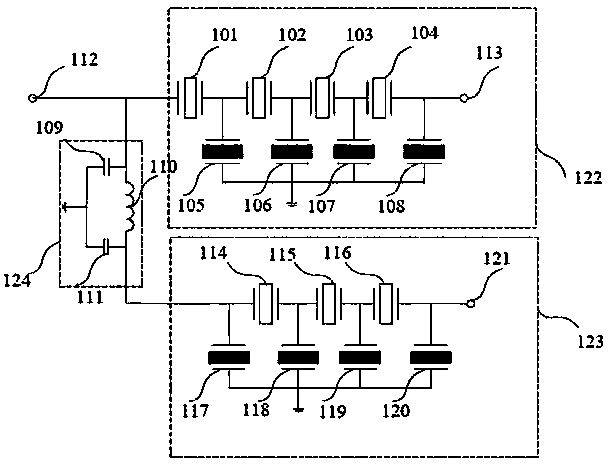

[0037] Taking the application of FDD-LTE band 7 as an example, figure 1 It is a circuit schematic diagram of a bulk acoustic wave duplexer integrated in a single chip in the present invention, the bulk acoustic wave duplexer includes: a transmitting bandpass filter 122, a receiving bandpass filter 123 and a phase shifter 124, and the port 112 is an antenna port , port 113 is the transmitting port, and port 121 is the receiving port.

[0038] The transmit bandpass filter includes four series-connected FBARs and four parallel-connected FBARs, the four series-connected FBARs have the same structure, and the parallel-connected four FBARs have the same structure. Looking from the antenna port 112 to the transmitting port 122, the connection relationship of the FBARs in the transmitting bandpass filter is: the first series FBAR 101, the first parallel FBAR 105, the second series FB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com