Special direct-current frequency converting control system for washing machine

A DC frequency conversion and control system technology, applied in the direction of a single motor speed/torque control, torque ripple control, etc., can solve the problems of washing machine noise, low light load power factor, complex structure, etc., to achieve average energy consumption and noise reduction , The communication protocol is simple and reliable, and the control precision is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

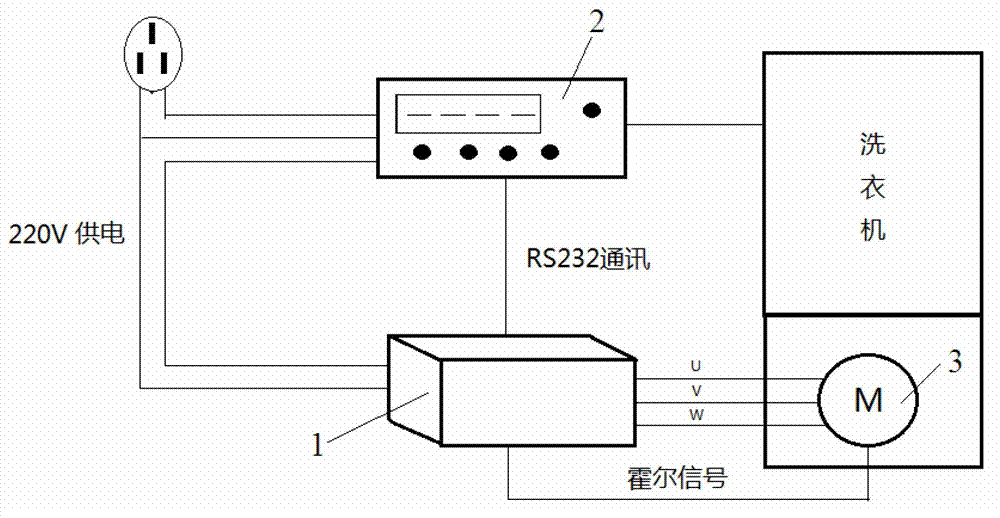

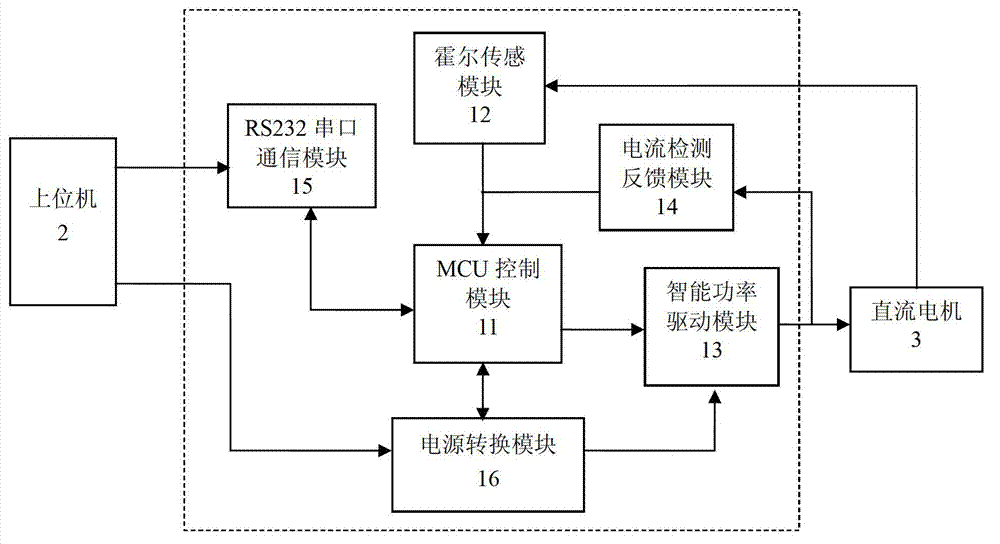

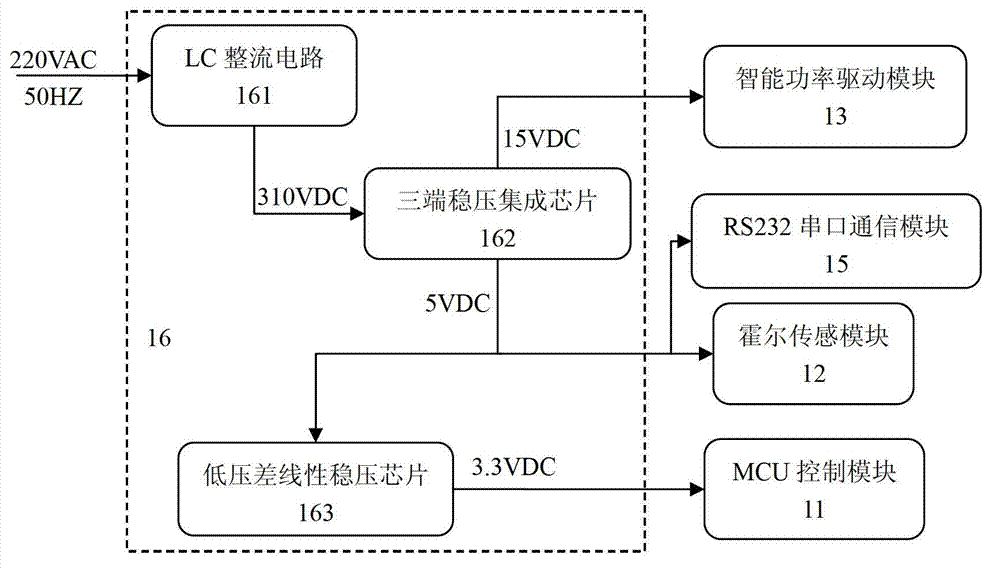

[0031] Such as Figure 1-Figure 2 As shown, a special DC frequency conversion control system for washing machines, the system is connected between the host computer 2 and the DC motor 3 of the washing machine, the system 1 includes a power conversion module 16, a Hall sensor module 12, an MCU control module 11 , intelligent power drive module 13, current detection feedback module 14 and RS232 serial port communication module 15, described power conversion module 16 is respectively connected Hall sensor module 12, MCU control module 11, intelligent power drive module 13 and RS232 serial port communication module 15. The MCU control module 11 is respectively connected to the Hall sensor module 12, the intelligent power drive module 13, the current detection feedback module 14 and the RS232 serial communication module 15, and the RS232 serial communication module 15 and the power conversion module 16 are both Connect with host computer 2, described Hall sensing module 12, intelli...

Embodiment 2

[0049] Such as Figure 1-Figure 6 As shown, in the special DC frequency conversion control system for washing machines in this embodiment, a level conversion circuit 17 is also provided between the Hall sensor module 12 and the MCU control module 11, and the level conversion circuit 17 outputs the Hall sensor module 12 The 5V voltage signal is converted into a 3.3V voltage signal that eliminates interference after being level-converted and transmitted to the MCU control module 11, thereby obtaining the current rotor position of the motor. The level conversion circuit 17 includes a 74HC07D chip, a pull-up resistor and a filter capacitor connected in sequence. The rest of this embodiment is the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com