Universal-joint sleeve blank cold-upsetting formation art, and equipment therefor

A universal joint shaft and forming process technology, which is applied in metal processing equipment, manufacturing tools, forging presses, etc., can solve the problems of low precision of universal joint shaft sleeves, long working hours, and high production costs, and achieve saving Effects of raw materials and resources, low defective rate, and labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

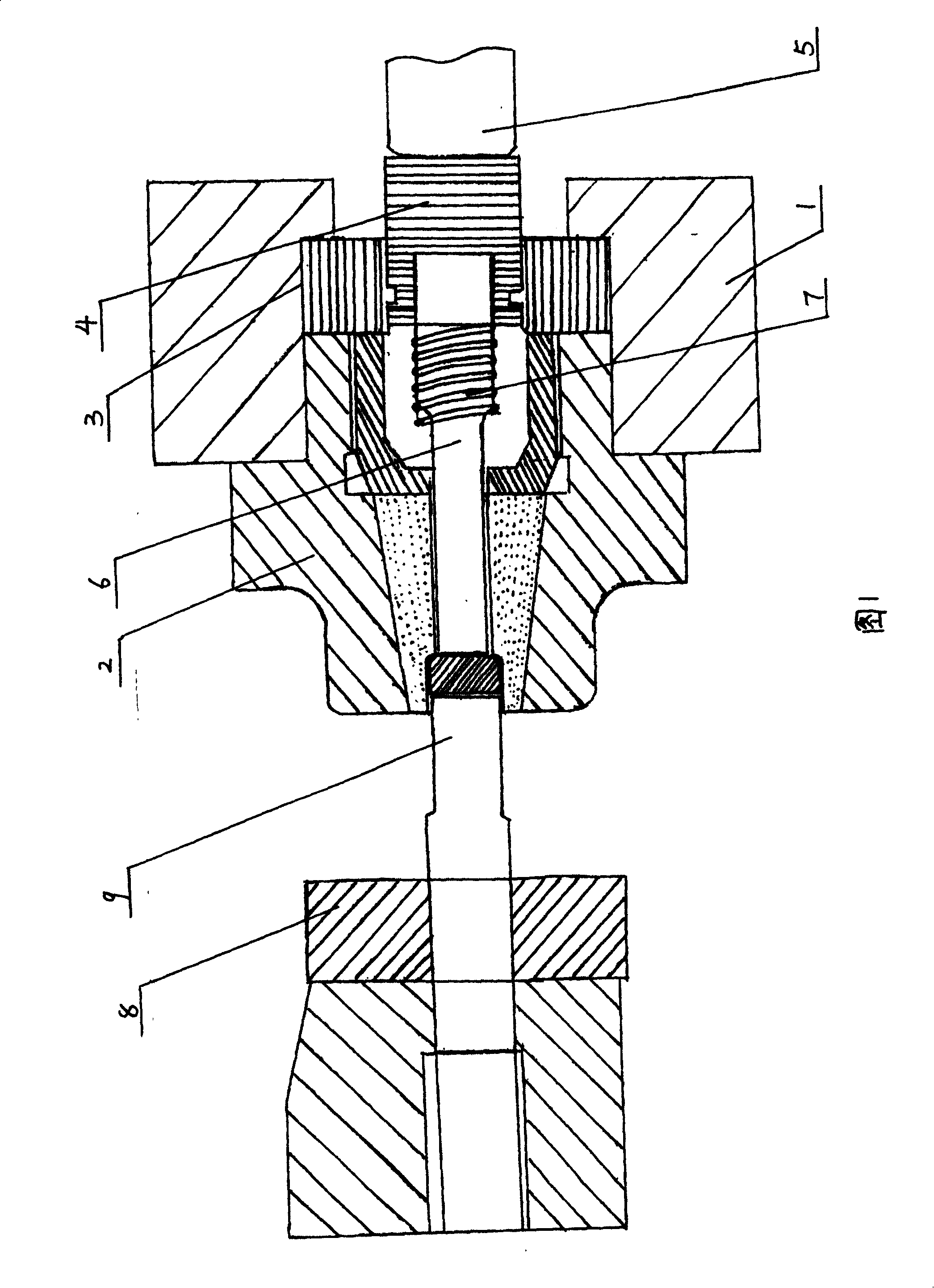

[0030] Embodiment 1: The blank of the universal joint bushing in this embodiment is manufactured by a multi-station cold heading forming machine, and its punching force is about 100-500 tons. As shown in Figure 1 and Figure 2, the modules include: mold box 1 and front punch chuck 8, one end of the mold box is provided with a tungsten steel mold shell 2, and the tungsten steel mold shell 2 has a round table type mold core 10, and the mold core 10 Has a cylindrical cavity. The mold box 1 is provided with a mold shell washer 3, and the mold shell washer 3 has a rear lock sleeve 4, and the rear lock sleeve front end is topped with a rear push rod 5, and the other end is locked with a rear punch rod 6. Positioning spring 7 is arranged on the rear punch rod. A front punch 9 is fixed in the front punch chuck 8 .

[0031] The cold heading forming process of the universal joint bushing blank in this example is used to manufacture the universal joint bushing of model F110.

[0032] a...

Embodiment 2

[0039] Embodiment 2: The cold heading forming process of the blank of the universal joint bushing in this example is used to manufacture the universal joint bushing of model Changjiang 750.

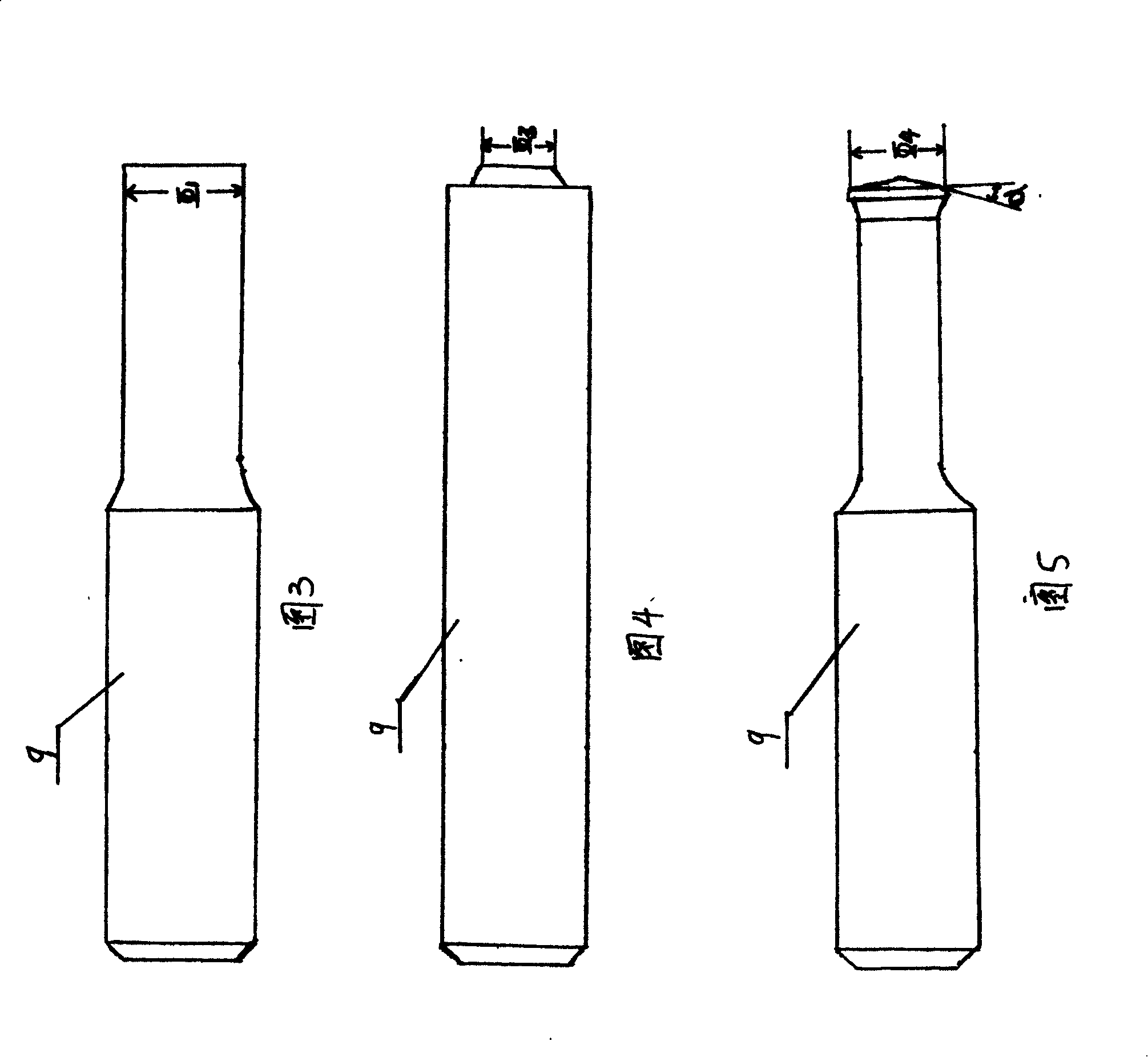

[0040] a. Send the wire-drawn circular material to the cutting mold from the feeding wheel of the cold heading forming machine for cutting. After cutting, the cutting knife plate sends the material to the first mold, as shown in Figure 7. The height h of the mold material 10 is 11.2mm, and the outer diameter D is 14.95mm;

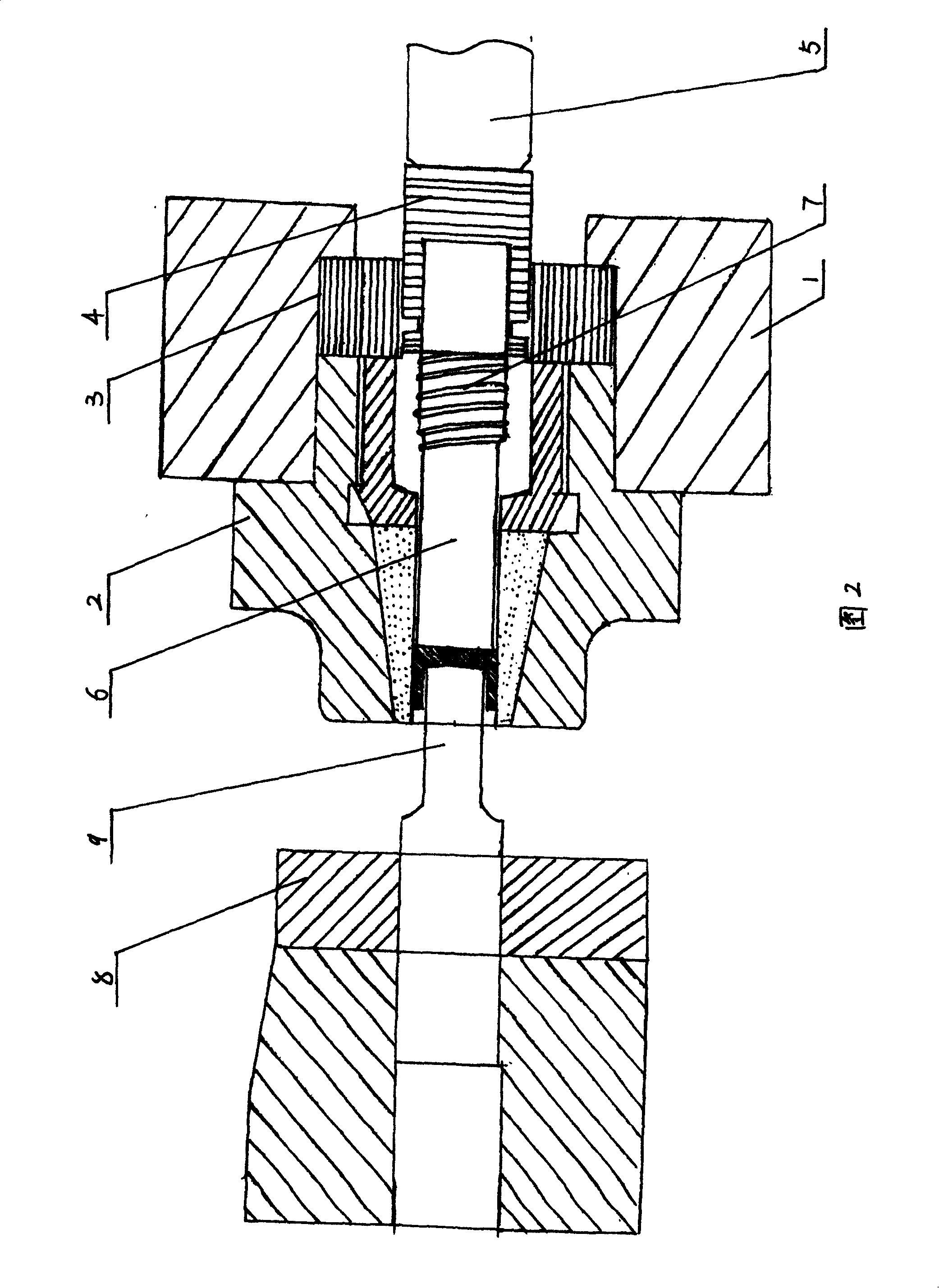

[0041] b. The first module performs cold heading extrusion on the cutting material, as shown in Figure 3, the end faces of the rear punch 6 and the front punch 9 are planes, and the diameter Φ1 of the front punch 9 of the first module is 15.3 mm, as shown in Figure 6 , the diameter Φ2 of the rear punch rod 6 is 12.5mm, the inner diameter of the mold cavity is 15.5mm, after extrusion, the outer diameter D of the cutting material is increased to 15.5mm, and the height is...

Embodiment 3

[0048] Embodiment 3: The cold heading forming process of the blank of the universal joint bushing in this example is used to manufacture the universal joint bushings of models Changhe 110 and WH110.

[0049] a. Send the wire-drawn circular material to the cutting mold from the feeding wheel of the cold heading forming machine for cutting. After cutting, the cutting knife plate sends the material to the first mold, as shown in Figure 7. The height h of the molding material 10 is 14mm, and the outer diameter D is 14.95mm;

[0050] b. The first module performs cold heading extrusion on the cutting material, as shown in Figure 3, the end faces of the rear punch 6 and the front punch 9 are planes, and the diameter Φ1 of the front punch 9 of the first module is 15.3 mm, as shown in Figure 6 , the diameter Φ2 of the rear punch rod 6 is 12.5mm, the inner diameter of the mold cavity is 15.5mm, after extrusion, the outer diameter D of the cutting material is increased to 15.5mm, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com